Home › Forum › Ask A Member › Martin 75 Synco Twist Plug Wires Binding

- This topic has 3 replies, 2 voices, and was last updated 7 years, 3 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

January 17, 2017 at 10:43 pm #6129

I put new coils on this Martin last year. It ran but had some issues, so I just put

new crankcase seals and poppet valve o-rings in it, etc.

I wasn’t happy with the spark plug wire routing last year,

and even less happy this year when trying to put it back together.

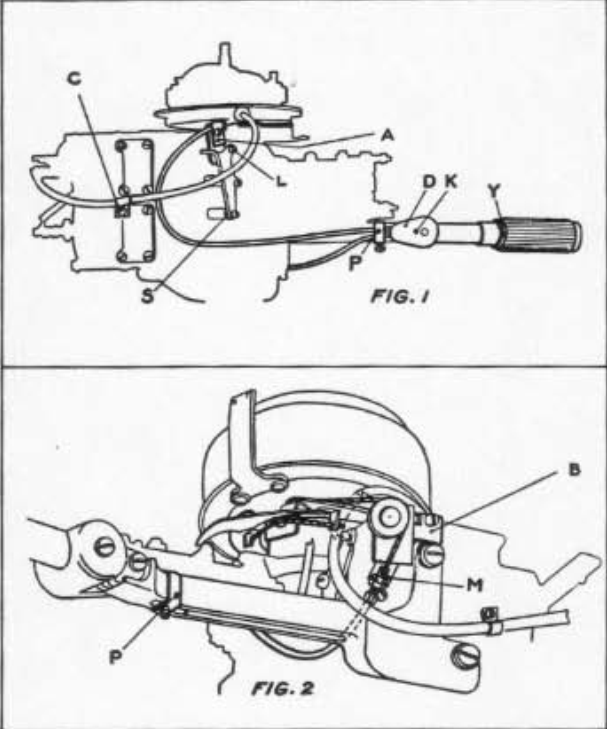

The magneto is advanced and retarded via cables on each side

of the power head that also attach to the twist grip.

The spark plug wires bind up when the magneto is moved, as the wires

have to drag over a cable pulley on one side, and a cable bracket

on the other side. I can get it to work so-so with the gas tank off,

but the plug wires have even more to bind on with the tank on.

Even though the old wico coils were replaced with OMC, the plug wires

still exit the mag plate thru the original locations, so that should not

be an issue. The original plug wires were chaffed from rubbing on

said points, so I’m beginning to think it’s a design issue.

(They later came out with the "Twist Shift" model, so perhaps this

issue went away?)

One page in the manual shows the plug wire routing, but that hasn’t

cured the problem.

Anyway, has anyone had the same problem with this model, and if

so, did you find a cure?

Thanks!Prepare to be boarded!

January 18, 2017 at 1:09 am #51227You might consider getting in contact with Russ Larson for an answer to your problem. It doesn’t look like there are any other options, as far as re routing the wires. One thing I’ve noticed about the modern copper core plug wire, is that the insulation isn’t near as abrasion resistant as the original stuff from the 50’s. Lately, I’ve been reusing most of the original plug wires on the motors I work on, just because it has/will hold up better. I’d love to have a big roll of the 50’s spark plug wire, just to have when I need it.

January 18, 2017 at 2:14 am #51237Jerry, thanks for your response. I purchased the seals, etc., from Russ,

so I guess it wouldn’t hurt to see if I can direct him to this thread.

Thanks!Prepare to be boarded!

January 18, 2017 at 11:18 pm #51290Jerry, Russ concurred with you regarding the modern spark plug wire not being

as abrasion resistant as in the past. Also he suggested shielding the plug

wire with aluminum.

I didn’t do that, but messed around for an hour with wire routing and "hold downs"

before I was satisfied.

I added a hold-down to each plug wire on the front of the power head, forcing

the plug wire to make a "loop" that more or less goes over the cable pulley

on one side, and cable bracket on the other.

I remember on my 1948 Evinrude Sportwin 3.3 hp project that the original plug

wire had some special routing, and it was a lot more "limber" than modern

wire. Installing modern plug wire on this unit didn’t work out well.

Anyone selling "limber" plug wire?

Anyway, the Martin is all back together…… just have to wait until April

or so until I can fill up the test barrel to try it out again 🙁Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.