Home › Forum › Ask A Member › Question about 7.5hp evinrude throttle gear

- This topic has 9 replies, 5 voices, and was last updated 8 years ago by

shoestringmariner.

-

AuthorPosts

-

April 13, 2016 at 1:40 am #4033

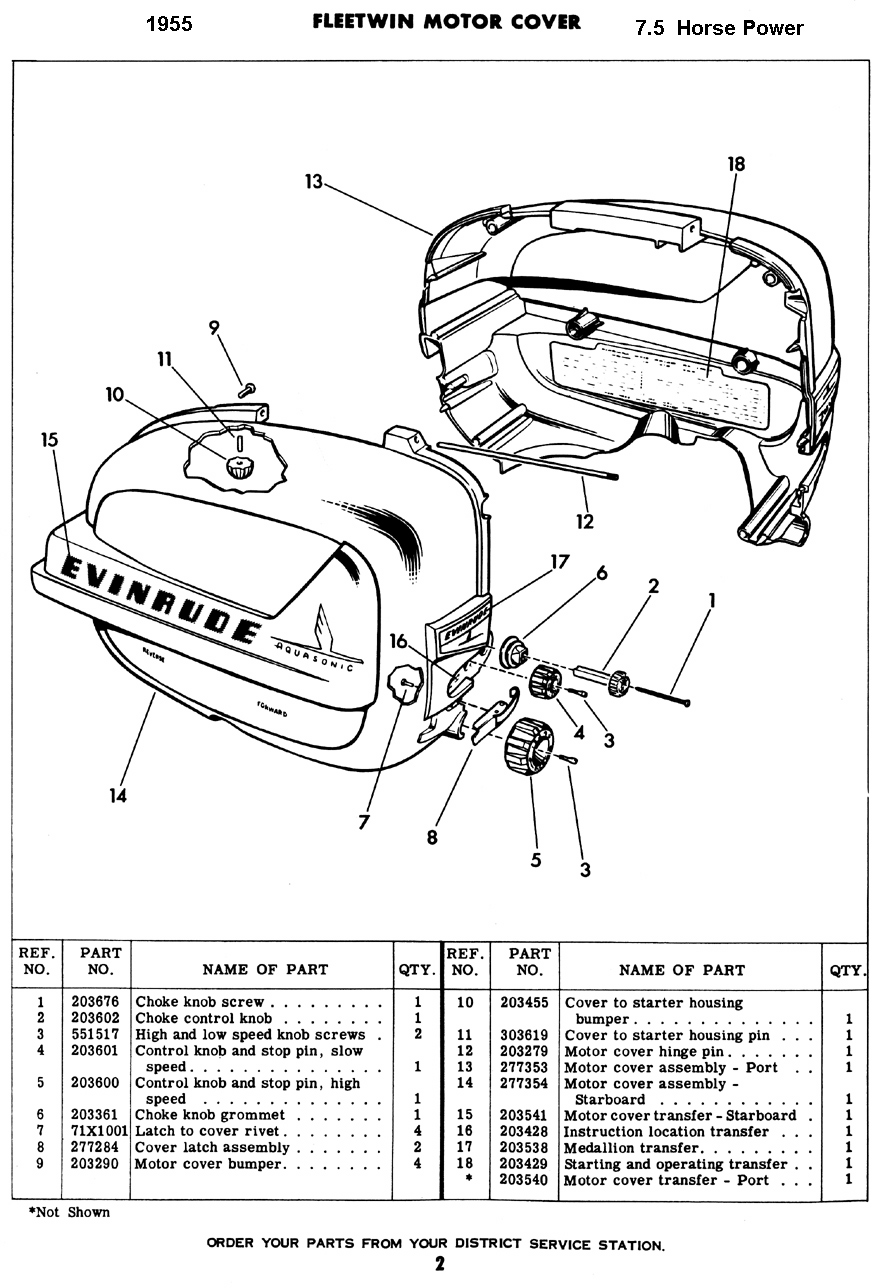

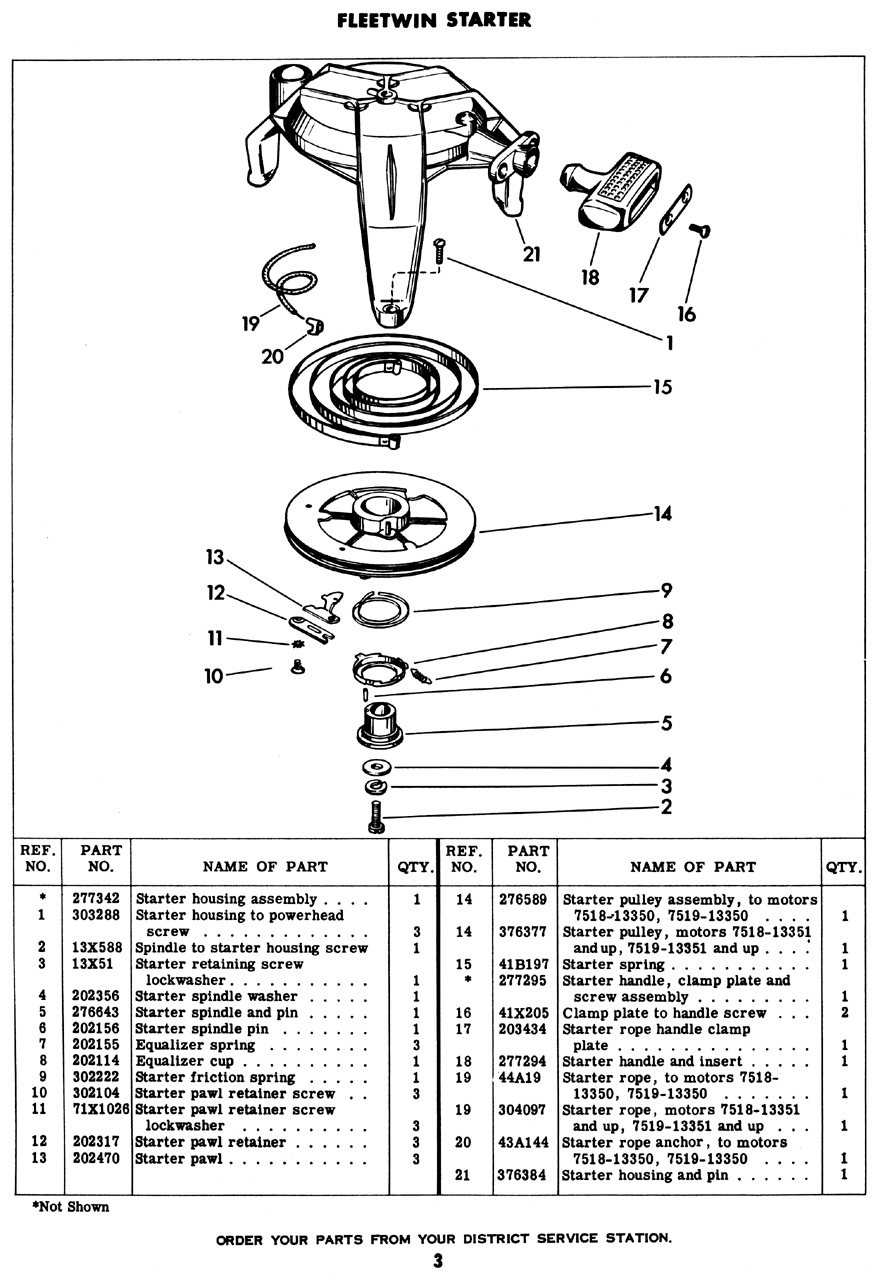

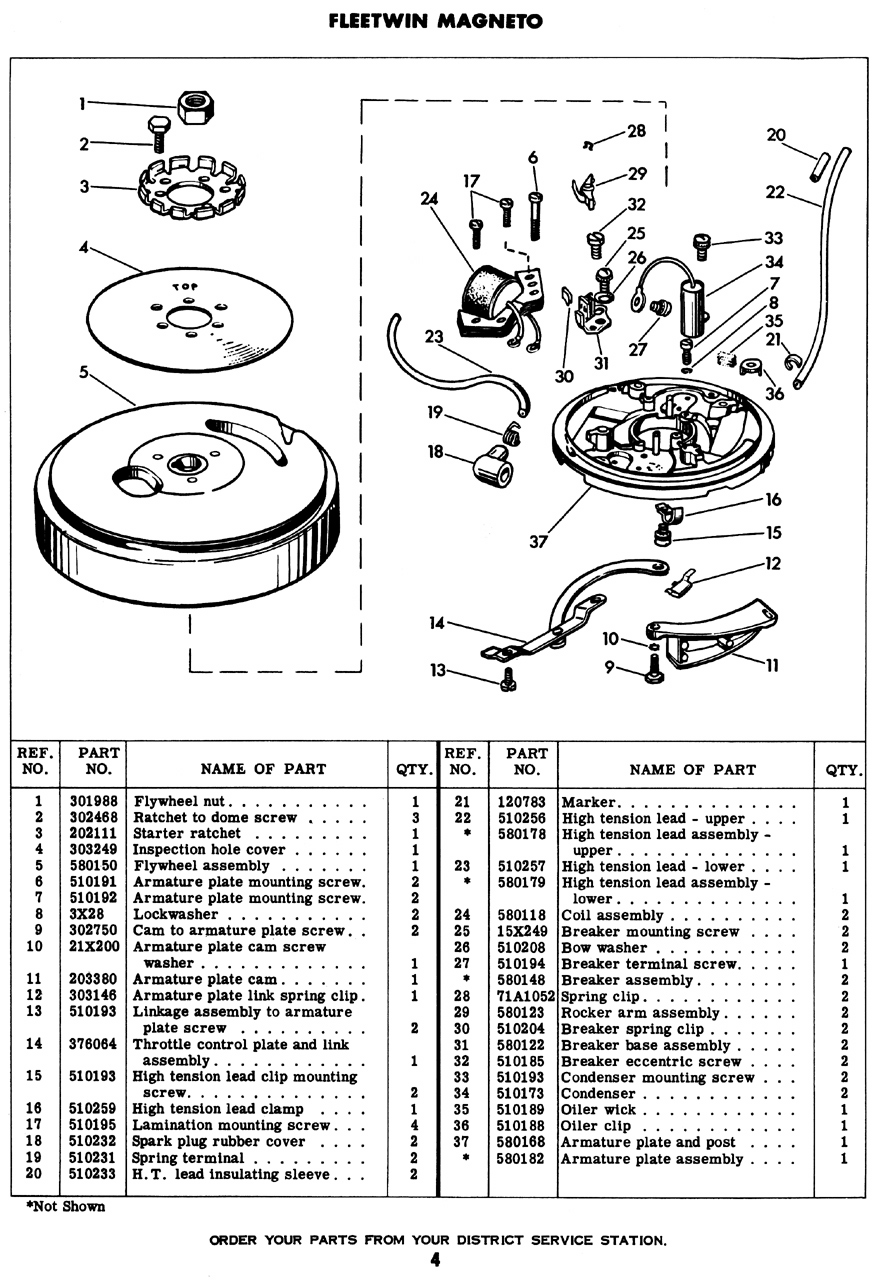

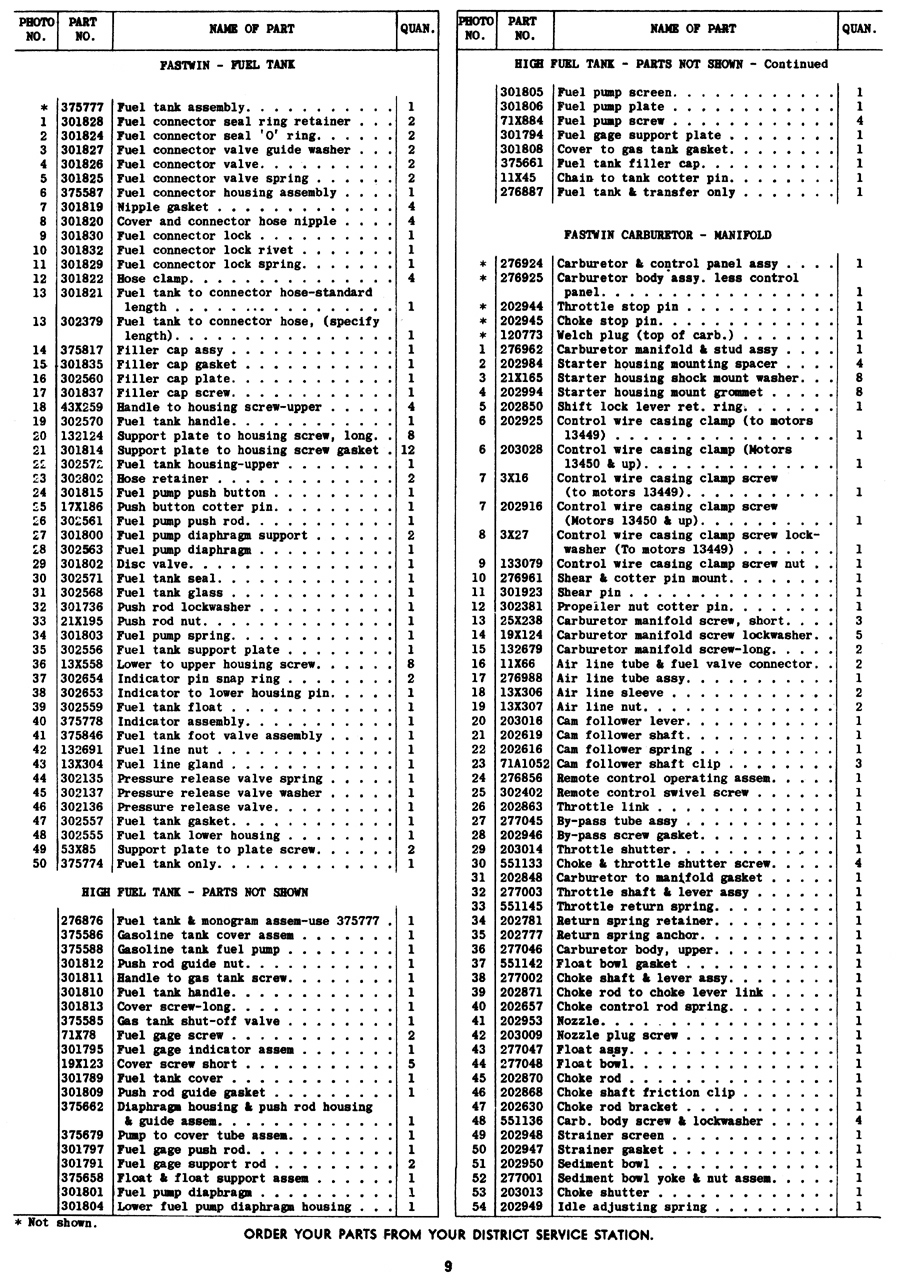

So I picked up a really nice, unrestored 1955 Evinrude 7.5 hp motor that I was quite pleased to acquire. Its had quite a bit freshened up on it but one thing I’d like to do is to take some of the play out of the the gear that the tiller handle throttle controls. (the 90 degree gear that twists the rod that operates the rotation of the ignition plate) I haven’t run the motor yet because I don’t have the right tank, but I am assuming this play translates into throttle response?

Were these motors designed like this, or do these gears wear out? If the latter is correct, can the gears or bore be restored or made to work tighter?

April 13, 2016 at 2:18 am #34756Lets just say they were far from precision. We all know how to live with the slop, and you will too, after 5 minutes of running. While on the subject, the wording on the twist grip dial plate is far from accurate. You will learn to live with that too.

One thing that wears badly (or shears off) is the pin that goes through the bottom end of the vertical shaft. Come to think of it, I’m not sure the ’55 even had a replaceable pin—another reason for slop.

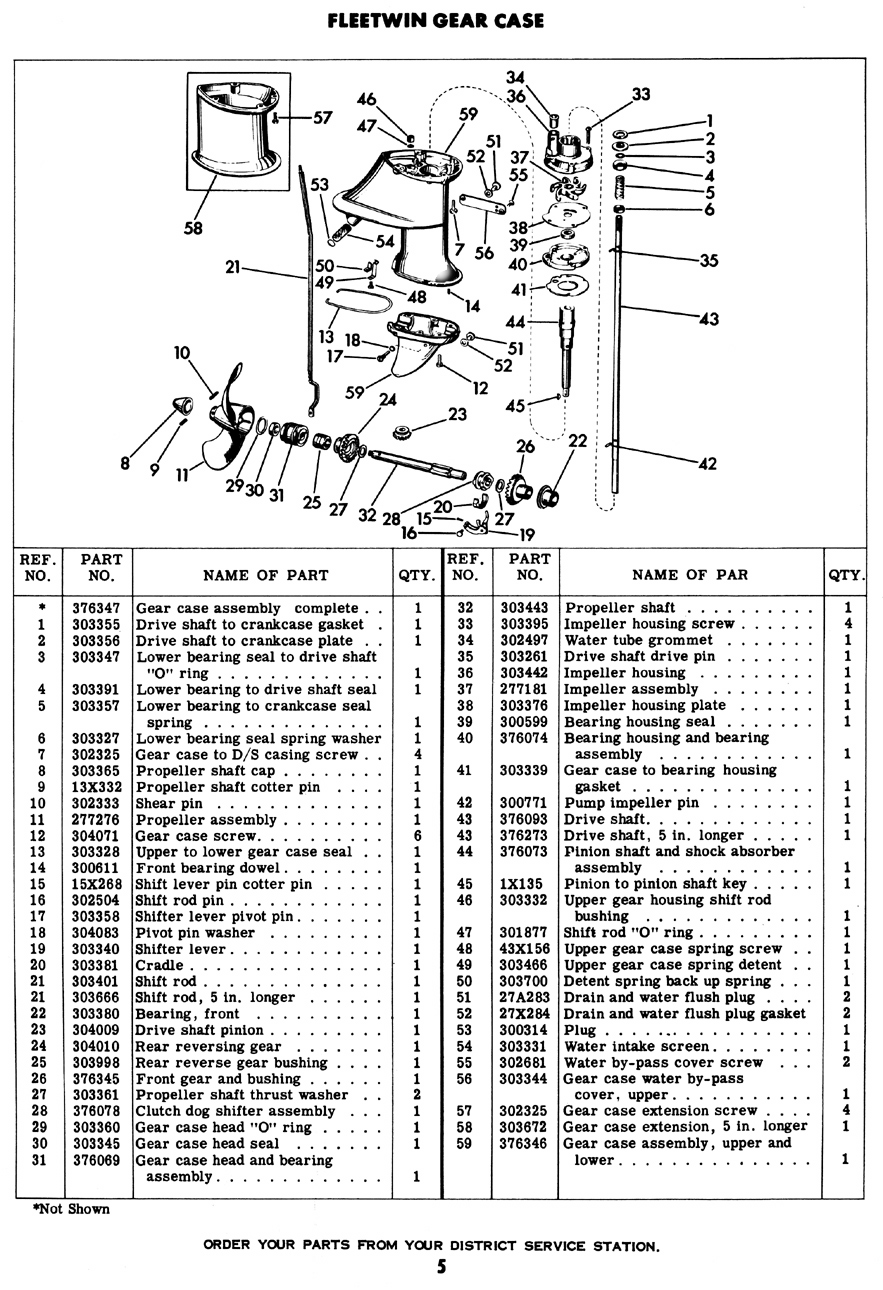

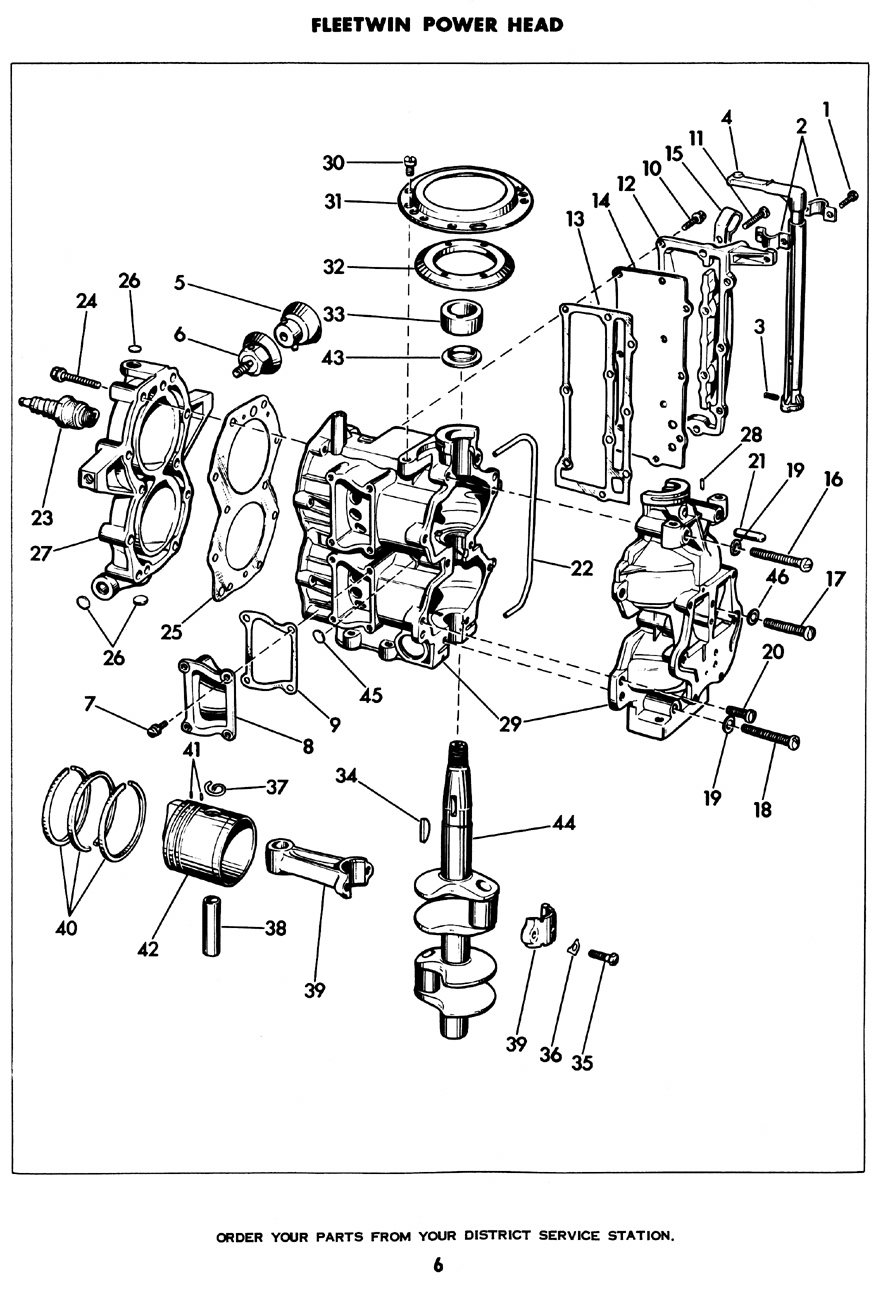

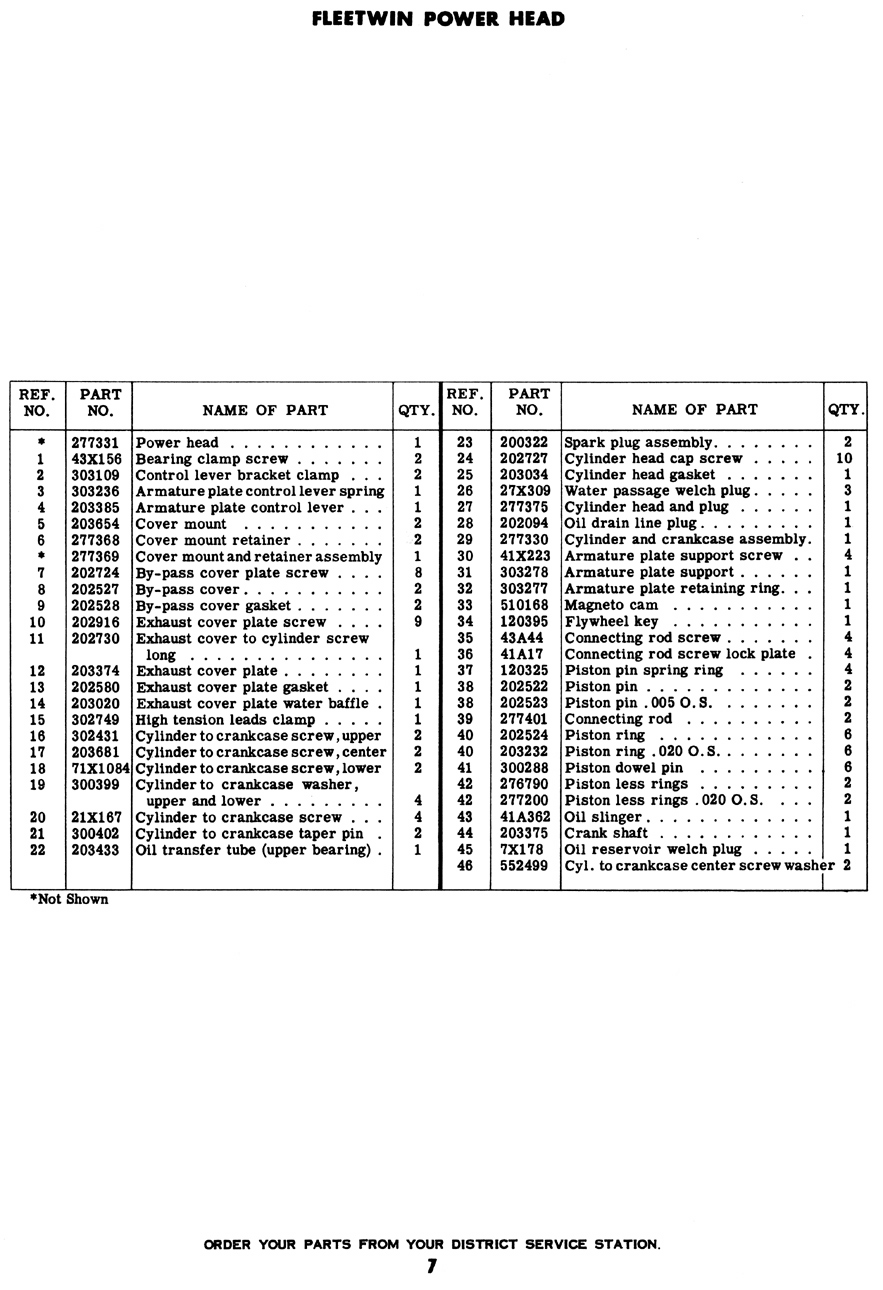

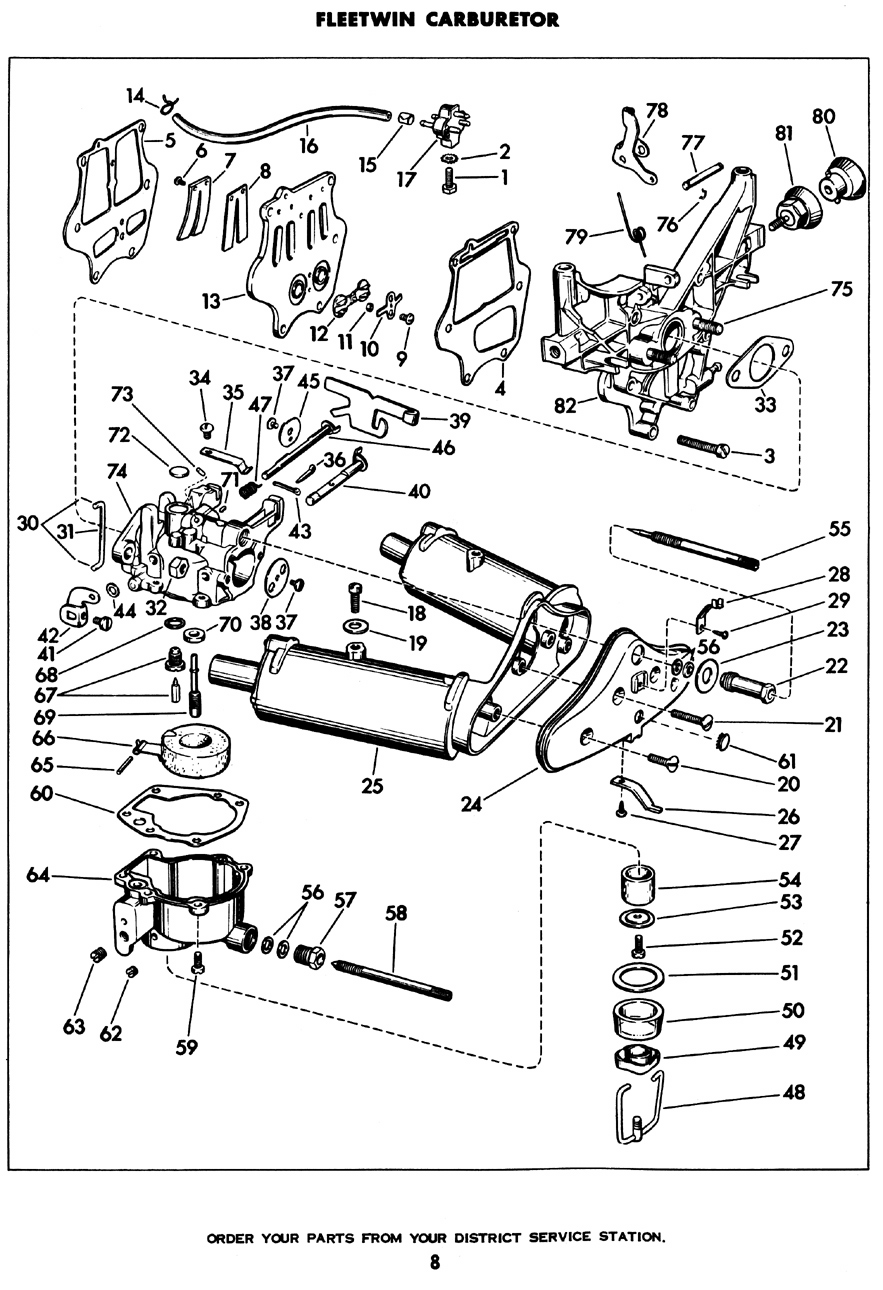

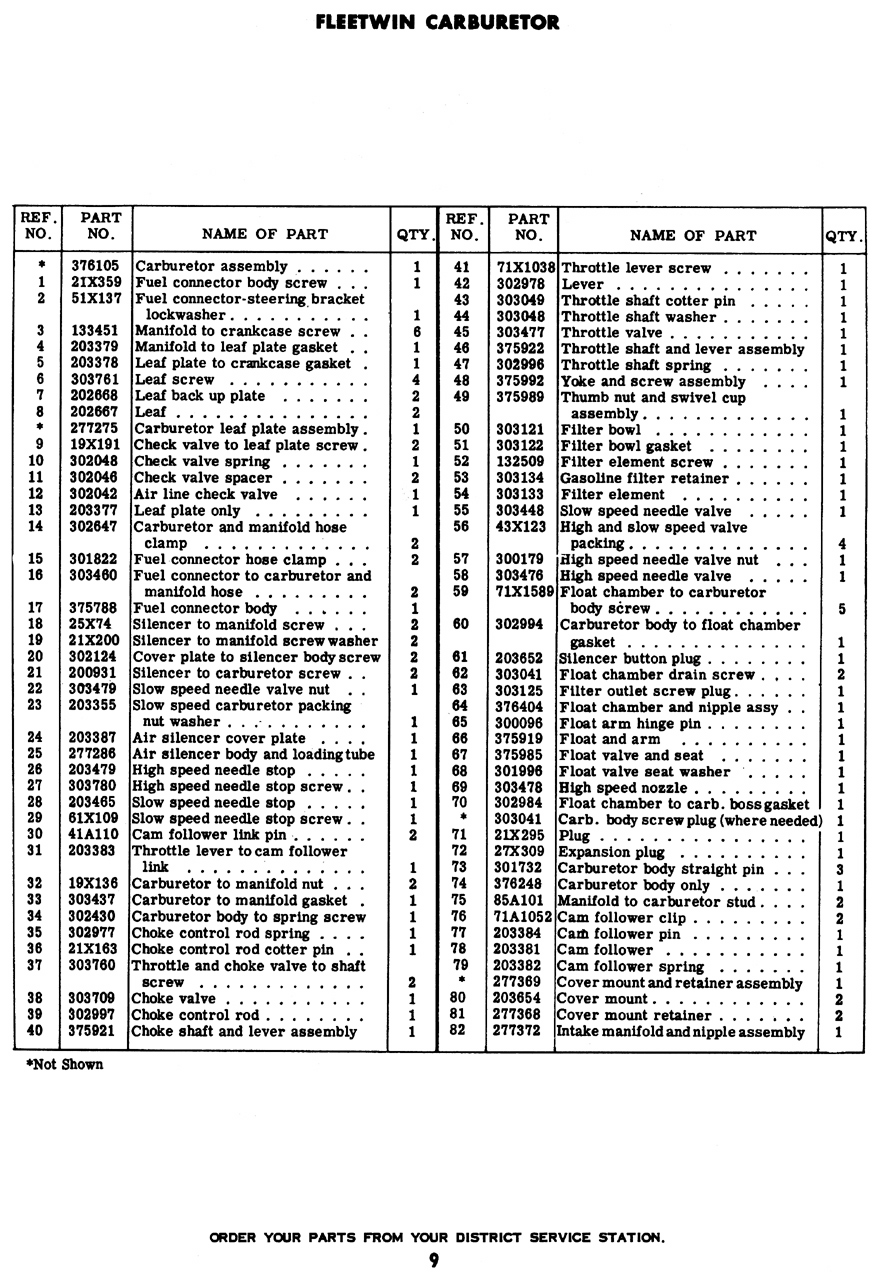

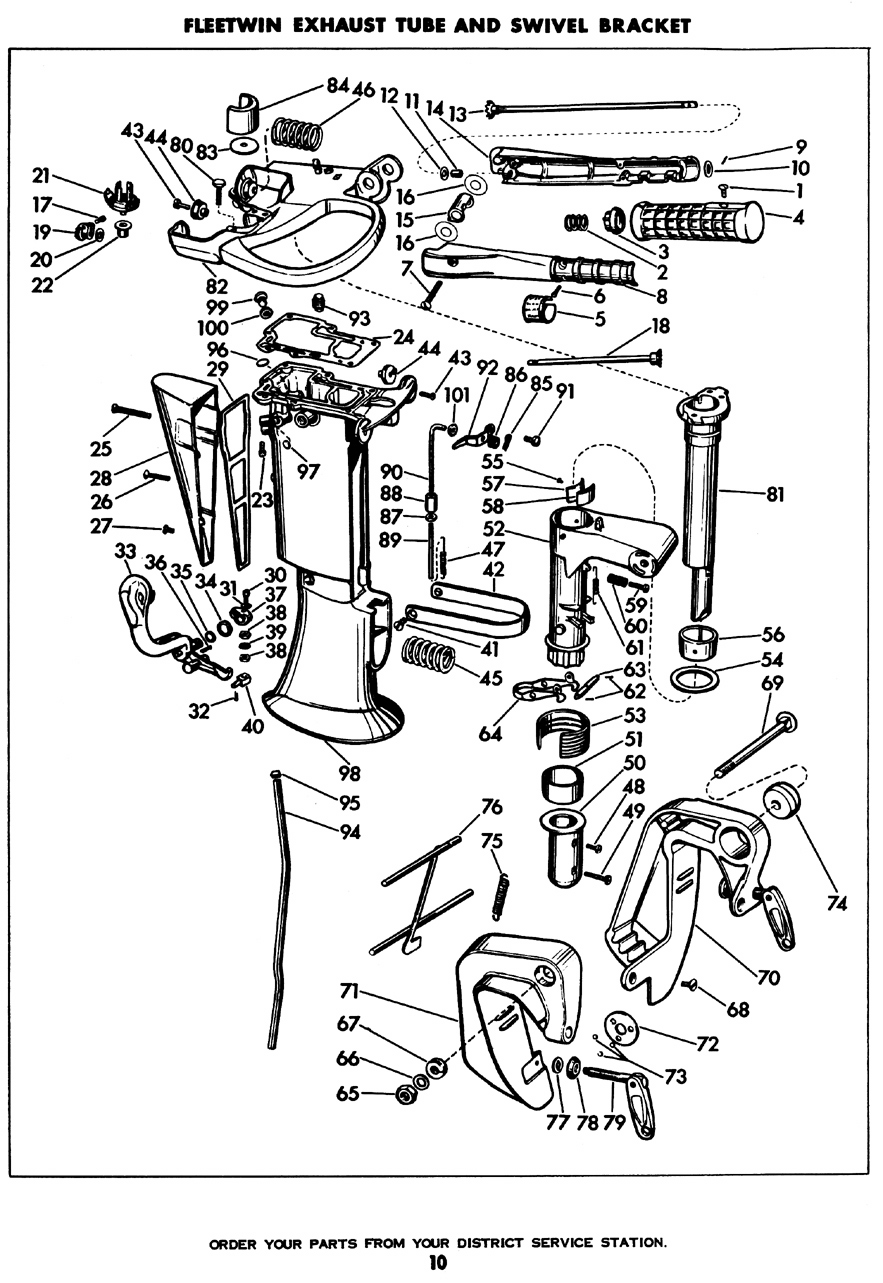

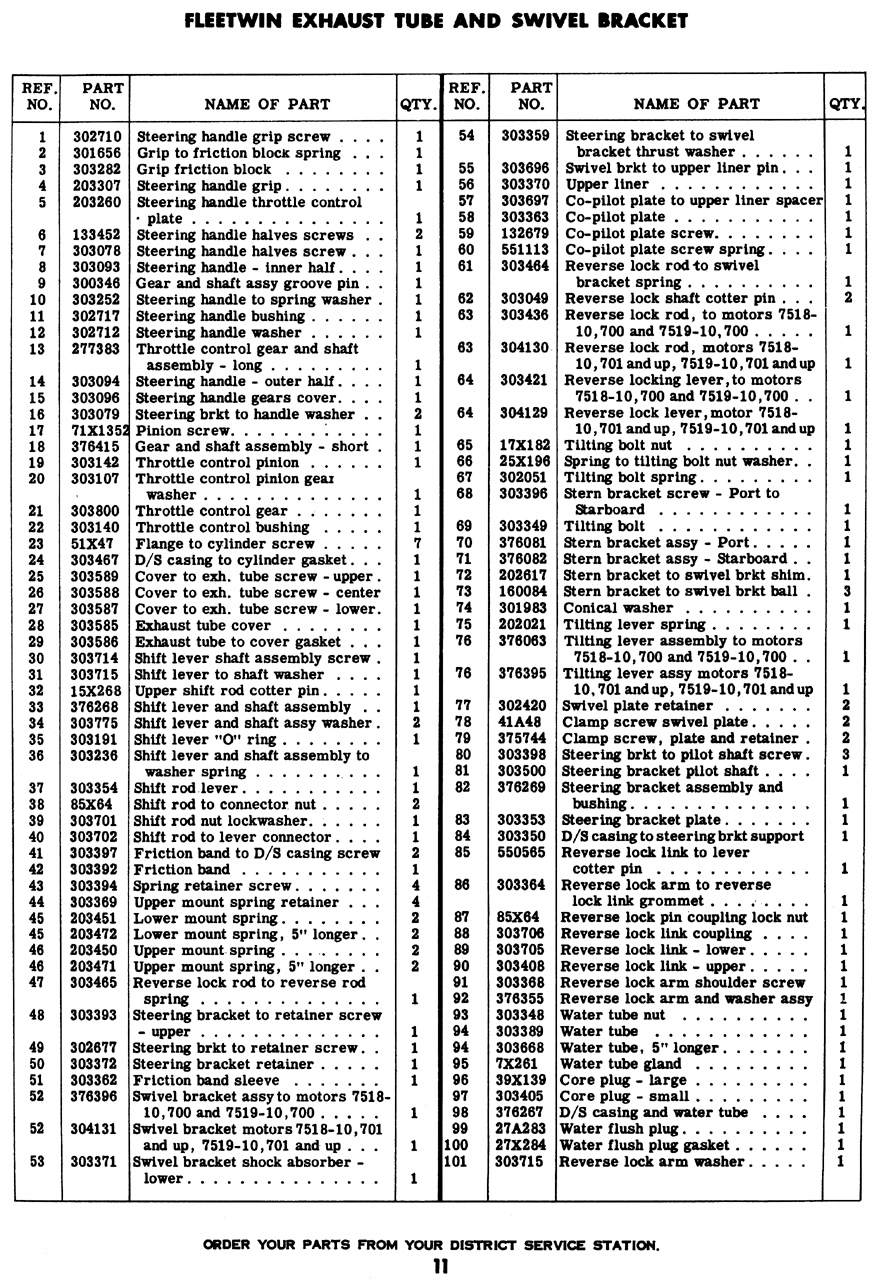

April 13, 2016 at 8:26 pm #34777Would this help? It shows the pin as 303236 . . . . . . . . 😀

April 13, 2016 at 9:30 pm #34778

April 13, 2016 at 9:30 pm #34778Nope, that is a spring. The diagram posted shows the vertical shaft #4 as the one without a pin. It just has nubs on the bottom of #4.

April 14, 2016 at 12:05 am #34783🙁 better save those pics…. marineengine.com is starting to loose the 50`s on us

Joining AOMCI has priviledges 🙂

April 14, 2016 at 1:54 am #34790Oh, very cool. Thanks for the diagrams!

I dont mind the slop. If that’s the norm, I wont mess with it. I’m just trying to make it 101%Got a gas tank tonight.

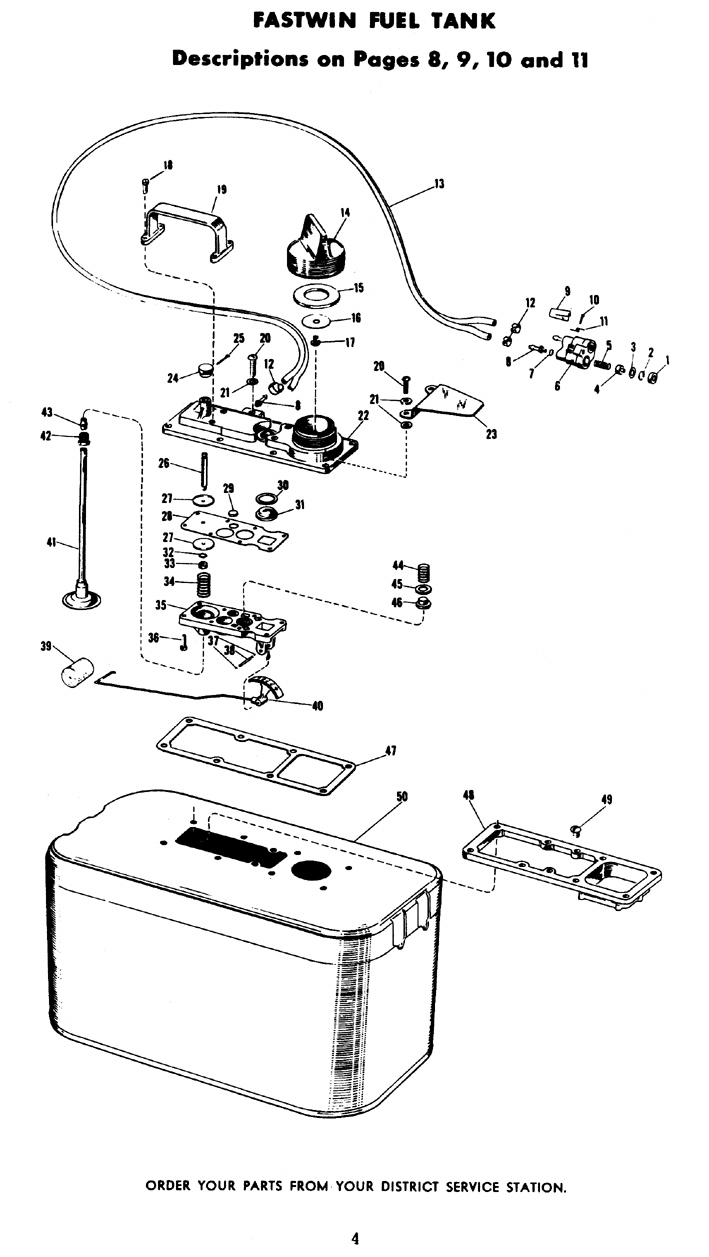

Rolled the dice…..will it hold pressure, or do I need to order a kit???

Its super clean inside and out. No dents or rust. Almost all paint and decals intact. One of the hose wrap "ears" is broken. I hope to find a replacement part at one of the upcoming swap meets

April 14, 2016 at 2:45 am #34793And of course it does not hold pressure…

Next…

April 14, 2016 at 3:11 pm #34802Shoestring,

Repair kits for the tanks are available, but don’t spend money if you don’t have too. Check the basics first like cover gasket integrity, and check the check valves which can fail due to crud stuck in there. You have nothing to lose.

April 15, 2016 at 12:47 am #34824When the cast in "Ears" break off, File the casting flat and use these replacements –

Part number 0302802 . . . . . . 😀

April 16, 2016 at 3:44 am #34864

April 16, 2016 at 3:44 am #34864Terrific, thanks guys

Garry, that’s a great idea. I can make those up in a pinch.Update: Chris P got me straightened out on how these tanks actually work. I misunderstood the concept and have discovered the primer actually works.

Tomorrow I’ll see if the tank builds pressure 🙂 -

AuthorPosts

- You must be logged in to reply to this topic.