Home › Forum › Ask A Member › Why is it so hard to test a Condenser? (Was: Condensers for Johnson / OMC)

- This topic has 26 replies, 11 voices, and was last updated 9 years, 6 months ago by

rzelmer.

-

AuthorPosts

-

May 15, 2015 at 1:23 am #1494

(Edit 15-May-2015 – Topic shift in progress, didn’t see any reason to create a new thread..)

Quick question – what’s the part number (NAPA, etc) for the generic ignition condensers used in the older Johnson / OMC magnetos? And does NAPA still stock these items?

I’m fairly sure the specs are the typical 0.22uF @ 400/600V.. as found in any old battery-coil ignition, as you’d find in numerous older vehicles from the 1930’s up through the early-mid 70s, when the auto mfrs. went to those amazing never-fail solid-state HEI systems.. 😉

Always got a kick out of that.. "Solid state ignition – they either work, or they don’t – no in-between guesswork!".. 😆

May 15, 2015 at 5:44 am #16016580321 is the OMC/BRP P/N for the most commonly used cap in the universal magnetos but 581419 was also used in FD, some RD and early 9.9 and 15 horse motors. You’ll have to find a Sierra catalogue on line to get the after market equivalents.

May 15, 2015 at 7:03 am #16018Thank you very kindly, Mumbles.

If anyone else knows the ‘generic’ part number, I’d still be quite keen to know!

May 15, 2015 at 10:52 am #16023Just go to marineengine.com they often have the Sierra part listed as an option, if not go to NAPA and see if they will give you last years Sierra catalog.

http://www.omc-boats.org

http://www.aerocraft-boats.orgMay 15, 2015 at 8:04 pm #1604818-5199 is the Sierra part number.

May 16, 2015 at 2:20 am #16081As ever, thanks to everyone.. Phil, ChrisP, Mumbles, for the info.

But all of these part numbers describe the vertical through-hole mount type, which passes through a hole in the stator plate. My particular motor uses the flat, horizontal type.. the main difference being the orientation of the mounting tab.

AFAIK, the type I need is the same style as found in most all automotive and motorcycle ignitions, throughout the 1960s-70s.

May 16, 2015 at 2:30 am #16083Since we’re talking condensers, why is it so dang difficult to test them – and what is actually required to spot a bad or failing part?

I have at my disposal several different test instruments. Among them, is a Heathkit IT-28, a "Capacitor Wizard", a generic general-purpose microcontroller-based component tester (which measures value, ESR and Q) and a couple of basic DVMs with capacitor functions.

While any of these instruments can detect an open, shorted or leaky condenser, I’ve yet to find any instrument that can positively identify +all+ or even +most+ flaky parts.

Too many times, all instruments have ‘passed’ parts that turn out to be faulty in actual service.. so now why would that be? You might say it’s a lack of actual operating voltages, but the IT-28 will test caps for leakage up to 600V – plenty high enough for a magneto-ignition condenser. All are capable of reading value and short / open conditions, but again, this just isn’t enough.

So why is that? And ultimately, how would one engineer a test that can reliably detect faulty ignition condensers? Does it require a full HV circuit test – where the condenser is used in a mock-up ignition circuit, and the spark voltage / current / quality is quantified based on maximum gap, etc?

In all my years, I’ve never come across an adequate answer to this.. so why not try asking again.

May 16, 2015 at 2:57 am #16084best unit to use is the Merc-o-tronic 98.

May 16, 2015 at 3:23 am #16085quote legendre:My particular motor uses the flat, horizontal type.

.Can you be more specific as to what year and model you are working on? Pictures always help.

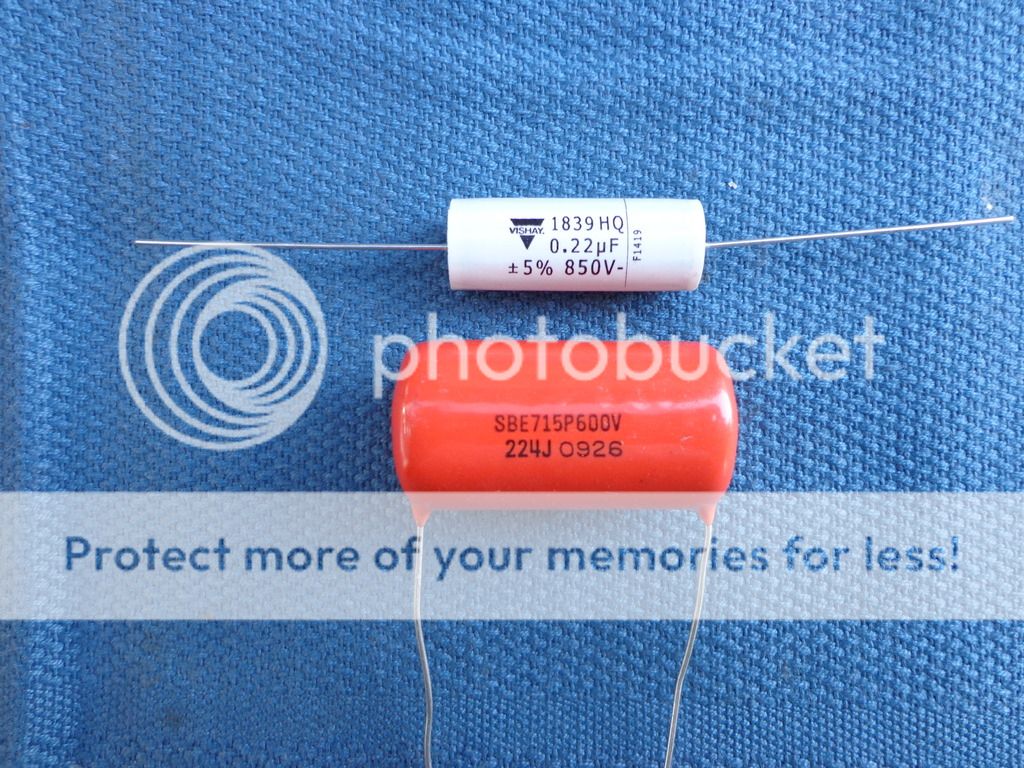

Vishay and Orange Drops are two capacitors which will substitute for the original tin can caps if you can’t find them.

May 16, 2015 at 3:31 am #16086quote Dave Bernard:best unit to use is the Merc-o-tronic 98.

May 16, 2015 at 3:31 am #16086quote Dave Bernard:best unit to use is the Merc-o-tronic 98.Now what in the HECK is THAT thing? LoL.. (Did a quick google..)

Edit: Ok, yep.. it’s one of those proprietary Swiss-knife instruments, looks like it’s capable (…) of testing all manner of flywheel magneto-based ignition components. Neat item, I’ll have to keep my eyes open for one – could be useful.

But in the meantime, there has to be a more straightforward way to test an ignition condenser.. some test setup that can provide meaningful, quantitative data which can be used to characterize the performance of the condenser unit under test.

-

AuthorPosts

- You must be logged in to reply to this topic.