Home › Forum › Ask A Member › Recoil Spring Replacement

- This topic has 14 replies, 10 voices, and was last updated 9 years, 6 months ago by

wiscoboater.

-

AuthorPosts

-

May 25, 2015 at 4:48 pm #1601

Broke the recoil spring on my 5.5hp ’58 cd-15. Luckily, it started on the pull when it broke, so I was able to motor back to the dock.

I ordered a new spring and I hope it will be here before the weekend. I was surprised that they are still cheap, got it for $10.

So does anyone have any tips/tricks when reinstalling it? There’s not many pieces to worry about, just trying to line it up on the pins while under tension.

May 25, 2015 at 4:59 pm #16844

May 25, 2015 at 4:59 pm #16844Wear eye protection, preferably a full face shield. And don’t forget to lubricate the new spring..

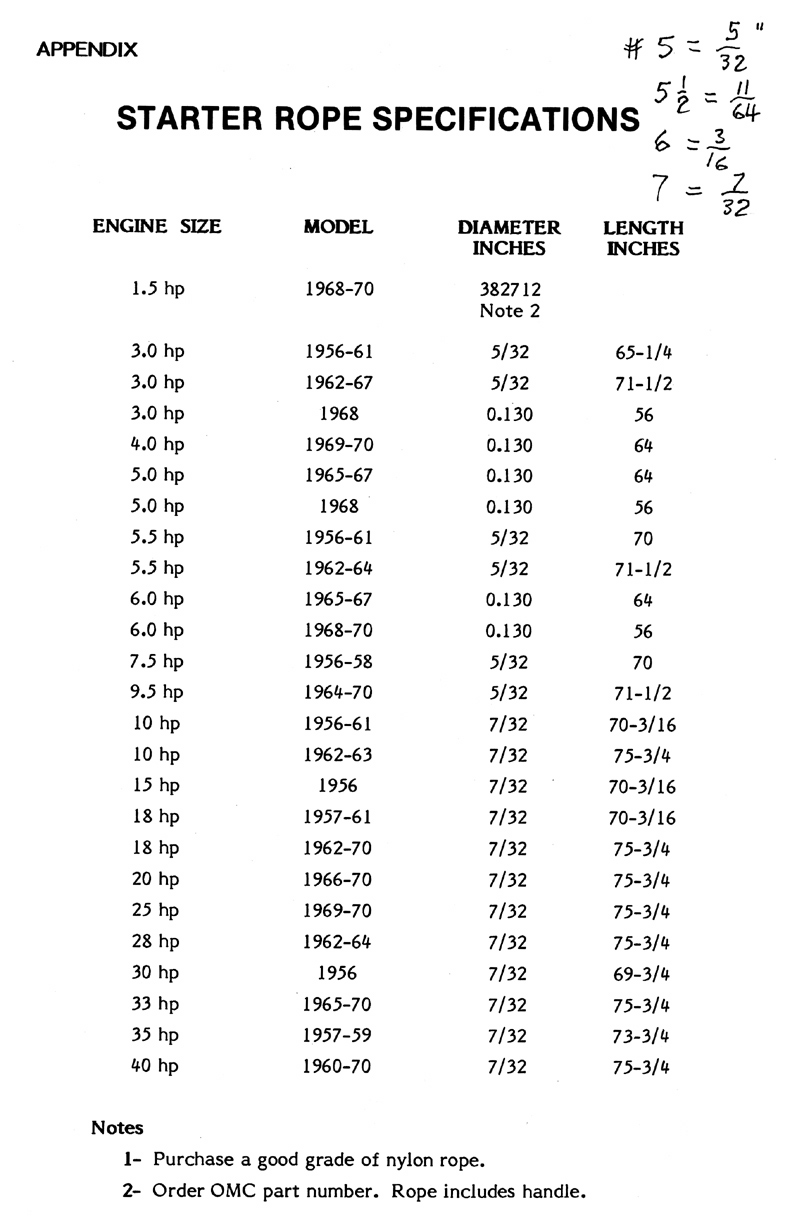

May 25, 2015 at 8:18 pm #16853This isn’t specific to the spring, but the ’58s have the elliptical rope sheave, so make sure that you have the arrow on the recoil housing aligned with the "J" on the sheave when you are getting things back together. This is achieved by using the proper rope length, which of course I can’t find the specs on at the moment. Correct alignment makes starting these motors much easier.

Hope that makes sense!

JPMay 25, 2015 at 8:29 pm #16854quote MarvK:So does anyone have any tips/tricks when reinstalling it?

If you have a clean flat area to work on such as a picnic table or a truck box and tailgate, it will make it easier to wind it in. A new spring will straighten out when you cut the clips so be ready for it.I like to lay the starter down on a towel or something so it can spin freely while working the spring in over the starter legs. Put a light coat of grease on it a little bit at a time, maybe two feet so it wont pick up any dirt and while holding the wound spring in with your thumbs, turn the starter housing while working the spring in. If it comes off the pin, you will have to start all over again. Just be carefull as there is a lot of energy stored in the wound spring and it can cause some serious damage if it gets loose.

If you’re going to be doing a lot of them, you might want to invest in one of these handy tools:

http://www.ebay.com/itm/E-Z-COIL-SPRING … 57&vxp=mtr

May 26, 2015 at 12:48 am #16887Yeah, getting the spring wound into the housing isn’t too tough, except if it decides to escape while winding it in! The tricky part is connecting the spring to the pulley without having the spring jump out at you. Don’t forget to replace the starter rope, cut it to its proper length also.

Good luck, please wear eye protection.May 26, 2015 at 1:04 am #16890No, I don’t plan on doing a lot of them, but it seems like I need to go into this with a lot of respect. It will come coiled up I’m assuming, can I set it in the recess and cut the bands holding it together?

JP, I will have to look at the housing more closely before I start to try and understand what you mean. Left it up at the lake, so if I get the new spring before this weekend I’ll attempt it then.

I tried to find a video of doing it, but I only found lawn mower recoil springs. Similar, but not quite the same. Anyone know of a good one that shows installing it?

May 26, 2015 at 1:38 am #16894Marv,

Keep this diagram for reference…see the "rope aligning marks" annotation.

JP

May 26, 2015 at 2:16 am #16897This is what I have –

May 26, 2015 at 9:11 am #16910

May 26, 2015 at 9:11 am #16910No you will have to straighten it out, then wind it in 1 coil at a time.

I do like Mumbles, spin the starter around on a towel, keeping one finger on the loop over the pin as I go, to keep it from jumping out.

the outer loop, I put a bit of a bend upwards on, so I can see it as I lower the pin down onto it.

May 26, 2015 at 6:07 pm #16943The 50s Elgin manuals say to keep one hand on each side of the starter as you wind. I found this works great. One hand is holding what is already wound while the other hand puts on the next half turn.

-

AuthorPosts

- You must be logged in to reply to this topic.