Home › Forum › Ask A Member › Armature plate support grease

- This topic has 14 replies, 7 voices, and was last updated 2 years, 2 months ago by

billw.

-

AuthorPosts

-

October 15, 2022 at 4:33 pm #267689October 15, 2022 at 5:19 pm #267692

I seem to remember the recipe for moly grease was one drop of oil to a small amount of moly grease, just enough to thin it out a bit. Whatever it was, I never use moly anymore and just use a light coating of a thin light grease. My daily driver now is the green Lucas Xtra Heavy Duty Wheel Bearing Grease which is thin and has no fibres in it to get hard when the weather is cold. It seems to work OK.

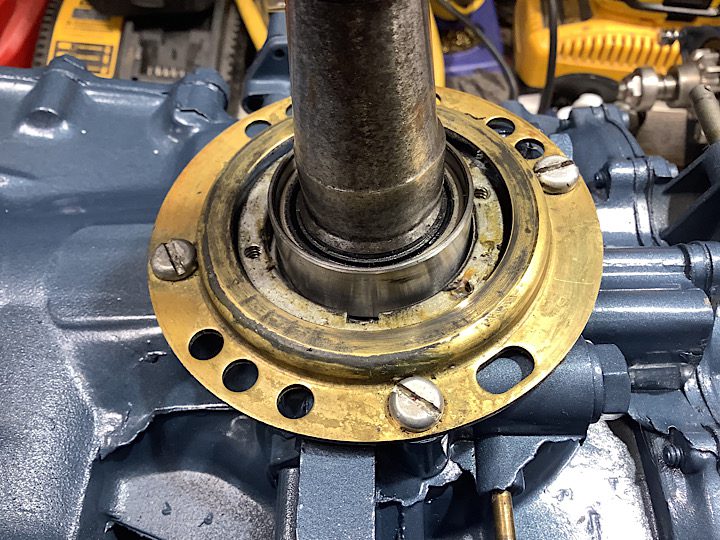

You have to remember that these bearing surfaces are in the ground path for the spark plugs so cleaning any tarnish off with fine grit paper first will help the electrons flow. What you don’t want to use is a dielectric (non conducting) grease of any kind as it will act as an insulator.

1 user thanked author for this post.

October 15, 2022 at 6:13 pm #267702Biggest mistake people do is slather on too much grease. It just splatters out and fouls the points. Just a thin smear is all it takes.

1 user thanked author for this post.

October 15, 2022 at 8:01 pm #267704Yep, it is a delicate balance for sure. The “recipe” you heard about the moly lube and the TCW3 oil is for the engines that use the mag plate/timer base that has the plastic bushing around the outer diameter. Use the moly lube on the pilot bushing, and a thin coating of TCW3 on the plastic bushing.

I use a very thin coat of the moly lube on the standard mag bushings as well.

1 user thanked author for this post.

October 16, 2022 at 6:33 am #267715I have been using Mercury 2-4-C with Teflon. It’s a fairly thinnish, yellow/brown grease that kind of reminds me of the old OMC type A. I just use it because I thought it “looked” period correct, and I have plenty of it. I haven’t had any problems.

Long live American manufacturing!

October 16, 2022 at 1:41 pm #267734Thanks everyone for the tips.

Bill I have some of the Mercury 2-4-C that I use on my Merc inline six, so I’ll use a thin coat of that.

Dug through an old 33HP OMC (white cover) service manual, and they said to use OMC Type A, so as Bill said, should be close enough.

Never knew what Jim said about those parts being an electrical conductor for the plugs!

I got paranoid, and scrubbed all of the old hard grease off them, and even popped them into the ultrasonic cleaner.

That should give me a good clean starting point.Bob D

October 16, 2022 at 2:15 pm #267737if you are really worried ……..run a flexing braid wire between the armature plate and the engine body for 100%….continuity 0 ohms

grease or not you will have a full circuit to the plugs

Joining AOMCI has priviledges 🙂

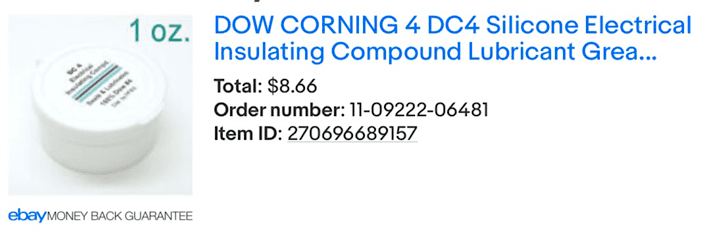

October 16, 2022 at 3:48 pm #267740Crosbyman, don’t think I’ll go that far……but in order for a good spark connection I did pick up some Dow Corning 4 DC4 silicone insulating compound for the connection between the coil, and spark plug wire. It was mentioned in the Johnson big red book, and I’m a sucker for stuff in tubes/ tubs.

Bob D

October 16, 2022 at 5:00 pm #267745If you ever install a ground wire, try and get a length of scrap elevator cable. It’s composed of many insulated mutistrand wires and is meant to flex as it coils up in the pit as the elevator goes up and down. The stuff I have is about 16G and it works great for a ground wire on a magneto plate which is costantly going back and forth.

October 16, 2022 at 5:17 pm #267749While it is true that the mount is the ground return, it’s nothing to get paranoid about. The high spark voltage has no problem jumping across any resistance.

-

AuthorPosts

- You must be logged in to reply to this topic.