Home › Forum › Ask A Member › Top shaft seal leaking of 1967 18hp Evinrude

- This topic has 26 replies, 10 voices, and was last updated 3 years, 1 month ago by

jeff-register.

-

AuthorPosts

-

October 21, 2022 at 9:43 pm #268021

Hello,

I seek advice what to do with top crankshaft seal of 1967 18 hp Evinrude. It shows the bubbles leaking as shown in the picture. It doos not leak at the shaft and rubber seal interface but it leaks at the outer bearing and the block interface. I bought the seal but if I change the seal, I don’t think it addresses this leak. Should I have to disassemble the block?

October 22, 2022 at 4:19 am #268026To save taking the motor apart, why not apply some sealer to the outside of the new seal before pressing it in?

October 22, 2022 at 5:52 am #268027If what you say is, in fact, true, then yeah, you would have to take the block apart. I would be surprised though, because unlike some earlier engines, that one should have an o-ring seal between the block and the bearing. However, anything is possible, especially if the power head has been apart before. I suppose you could always just replace the seal and see where that gets you. If you have to take the block apart after that, at least your seal replacement is already done. I might as well bring this up now, while we are talking about leaks in this area: I have seen more than one 18 crank shaft with pits in the seal area, making it incapable of being able to hold a seal….

Long live American manufacturing!

October 22, 2022 at 9:15 am #268033I got the motor a month ago. Everything looks original and the power head looks never opened. It is idling nice but base on my reading, 18 hp has common problem with the top shaft seal so I decided to check it out and want to change the seal (not expensive part). Then I found this leakage. I know for sure that is the leak of where the recess on aluminum casting (picture). I have never done anything on it yet it got 100 psi /95 psi of compression test. So if it is a O-ring leak, I may open it up and change the top seal as well as the O-ring.

October 23, 2022 at 11:28 am #268094OK, well I’m a little confused, but this is a common topic for sure. It looks like the 67 models did not use the oring, but perhpaps I am not looking at the breakdown accurately. From your picture, it looks like this engine uses the “recirc style” system with the vacuum port above the seal. But, I am confused, a very big leak should have been detected there when you did your test. OMC did make a tool to remove that seal without pulling the powerhead apart, I don’t have the part number for the tool handy though.

So, I will back up a bit, and start with a simple question…. Was the mag plate a mess with excess oil splattered on it and the points? If not, I would not mess with the seal. Sounds like you just tried to test the seal only because of what you have read about this issue. So, if it was mine, and the mag plate was relatively clean, I would not mess with the upper seal…

October 23, 2022 at 11:32 am #268095very wise suggestion 🙂

Joining AOMCI has priviledges 🙂

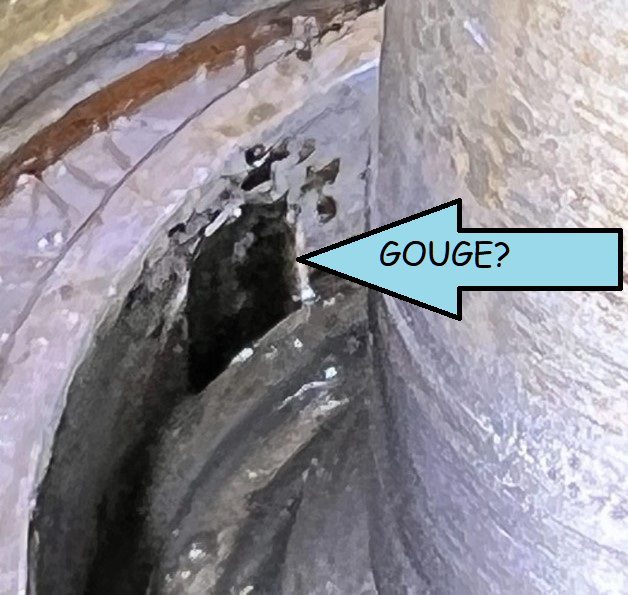

October 23, 2022 at 11:44 am #268100In the photos it looks like a gouge in the side of the seals bore. Possibly caused by a previous attempt at removal?

Best to repair this as any leaking here will allow air into the motor causing the top cylinder to run lean and no amount of carb adjusting will get it to run right.

October 23, 2022 at 12:07 pm #268102In the photos it looks like a gouge in the side of the seals bore. Possibly caused by a previous attempt at removal?

Best to repair this as any leaking here will allow air into the motor causing the top cylinder to run lean and no amount of carb adjusting will get it to run right.

Perhaps I am not looking at the same picture as you, not sure. But, what looks like a “gouge” in the crankcase casting is actually the “port” where the low pressure is applied from the intake manifold.

Again, might not be looking at what you are describing…

October 23, 2022 at 1:01 pm #268104The seal is in place but this doesn’t look right.

1 user thanked author for this post.

October 23, 2022 at 6:14 pm #268133Well, there are some little pick marks there, but the big void is meant to be there. The low pressure air passage is down inside that void to pull excess oil down to the intake manifold.

-

AuthorPosts

- You must be logged in to reply to this topic.