Home › Forum › Ask A Member › TD20 In-Tank fuel filter (w/screen) pt# 375663???

- This topic has 17 replies, 8 voices, and was last updated 7 months, 4 weeks ago by

John Gragg.

-

AuthorPosts

-

November 27, 2023 at 8:56 pm #282842

With all the fuss about cleaning my tank I find I screwed up the filter screen. It separated along the seam…

So I order what I assume to be a legitimate replacement from ebay because even tho’ it looks different (porous stone filter) several sellers are selling the same part under the correct part #375663.

I got it today. Won’t work, it has a 5/8″ thread instead of a 1/2″.

Did OMC make an adapter so the updated/newer 5/8″ filter could be used in the 1/2″ tank opening?

Any ideas on repairing my old one?

Comparison pic attached.

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A

49 Sea King 5hp GG9014A

48 Johnson TD20

49 Johnson TD20

54 Johnson QD15

55 Johnson CD12November 27, 2023 at 10:44 pm #282845If you can find some 100 to 150 mesh brass screen, they’re not

that hard to make new ones.Prepare to be boarded!

November 28, 2023 at 8:00 am #282847from wiscoboater in 2017 … The filter in the tank is a very fine mesh little brass sock that sits at end of the copper fuel line. I have the same motor that I restored a few years ago. My filter sock was beyond hope and I could not find a replacement. I put 2 small brass barbed nipple fittings at both the tank and carb end. I then used regular rubber fuel line with a small inline filter from a lawn mower. Had no more issues with filter clogs after that.

maybe that could work for your td20

Joining AOMCI has priviledges 🙂

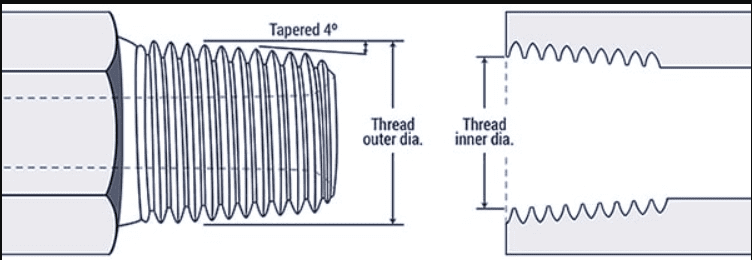

November 28, 2023 at 8:45 am #282848In the first place, those are not 5/8 and 1/2 inch threads. They are tapered pipe threads. Pipe sizes harken back to the days of iron pipes and are sized according to the INSIDE diameter of the pipe. Even that is not totally true, as iron pipes were made with over-size ID to allow for full flow in spite of clogging with rust buildup inside. Since you think it is 1/2″, I assume it is really 1/4″ NPT (National Pipe Thread). Next size down, 1/8″ NPT is often mistaken for 3/8 at first glance (not).

I don’t see the problem with the screen. Are you concerned with the seam that runs the length of it? It would be simple to just re-solder it. It may not even be necessary, if the seam lies reasonably tight together.

November 28, 2023 at 1:18 pm #282852In the first place, those are not 5/8 and 1/2 inch threads. They are tapered pipe threads. Pipe sizes harken back to the days of iron pipes and are sized according to the INSIDE diameter of the pipe. Even that is not totally true, as iron pipes were made with over-size ID to allow for full flow in spite of clogging with rust buildup inside. Since you think it is 1/2″, I assume it is really 1/4″ NPT (National Pipe Thread). Next size down, 1/8″ NPT is often mistaken for 3/8 at first glance (not).

I don’t see the problem with the screen. Are you concerned with the seam that runs the length of it? It would be simple to just re-solder it. It may not even be necessary, if the seam lies reasonably tight together.

Pipe threads have always confused me a bit, but I thought I was ‘safe’ when I measured the tank hole by testing a 1/2 x 20 tap so I could get a proper plug at the hardware store. How is it that the tap matches the threads, but you are calling it something entirely different?

I called the threads 1/2″, is that incorrect? If it is, what size threaded plug would I go to Ace and look for? 🤔 please edumacate me?

I tried resoldering the seam. Even pre-heated the mesh. Solder would not stick, as clean as I got the mesh. I even tried using flux paste to clean the mesh, no dice. Ended up making more of a mess.

thx

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A

49 Sea King 5hp GG9014A

48 Johnson TD20

49 Johnson TD20

54 Johnson QD15

55 Johnson CD12November 28, 2023 at 2:57 pm #282854try some SS or galv fly screen … cut a 1″x 2″ rectangle just roll it up like a carpet…. pinch the top and stuff it inside the threaded section. dab the edge with JB steel weld to hold the screen in place . you can get SS screen from a cheap spagetti screener at the dollar store ,,, cut it up… roll it up

done.

or get brass mesh cloth from Mcmaster $$$$

Joining AOMCI has priviledges 🙂

1 user thanked author for this post.

November 28, 2023 at 4:02 pm #282857November 28, 2023 at 6:51 pm #282868try some SS or galv fly screen … cut a 1″x 2″ rectangle just roll it up like a carpet…. pinch the top and stuff it inside the threaded section. dab the edge with JB steel weld to hold the screen in place . you can get SS screen from a cheap spagetti screener at the dollar store ,,, cut it up… roll it up

done.

or get brass mesh cloth from Mcmaster $$$$

Dang. Of course! JB to the rescue…

That will work splendidly!

Thanks

Best Regards

John Gragg

RIverside, CAJust starting in the hobby, please be patient.

48 Sea King 5hp GG9014A

49 Sea King 5hp GG9014A

48 Johnson TD20

49 Johnson TD20

54 Johnson QD15

55 Johnson CD12November 29, 2023 at 5:12 am #282872When cleaning out Johnson “T” series tanks, I’ve been using a 1/2″ brass plug to temporarily replace the filter screen fitting for years now. This is done to save the delicate filter screen from damage when shaking the tank with fasteners inside. This plug has worked very well, and that is why it’s a bit confusing.

The brass plug was purchased from a local plumbing supply. Have I unwittingly been using a tapered thread plug all of this time?

Sometimes you don’t know what you don’t know…

November 29, 2023 at 10:23 am #282882When cleaning out Johnson “T” series tanks, I’ve been using a 1/2″ brass plug to temporarily replace the filter screen fitting for years now. This is done to save the delicate filter screen from damage when shaking the tank with fasteners inside. This plug has worked very well, and that is why it’s a bit confusing.

The brass plug was purchased from a local plumbing supply. Have I unwittingly been using a tapered thread plug all of this time?

Sometimes you don’t know what you don’t know…

You may not have known the technical what-fors and why-fors, but you must have known there was something different about that thread, which led you to a plumber for a plug. Experience is a great teacher.

-

AuthorPosts

- You must be logged in to reply to this topic.