Home › Forum › Ask A Member › Replacing non available condensers

- This topic has 2 replies, 3 voices, and was last updated 7 months, 3 weeks ago by

Finn Freeman.

Finn Freeman.

-

AuthorPosts

-

April 3, 2024 at 4:57 am #286476

I know this has been discussed many times in the past but at the time I didn’t need the info, so now I do. What is used to replace a mf.1 to mf.2 condenser and where do you buy them? They were a small electric little bugger. Thanks.

April 3, 2024 at 7:40 am #286477visit th Western region AOMCI site for excellent articles by m Mohat … articles part1-4

Magazine Articles | Western Reserve Chapter (wrcoutboards.org)

Joining AOMCI has priviledges 🙂

April 4, 2024 at 4:02 pm #286503Copied from two other posts:

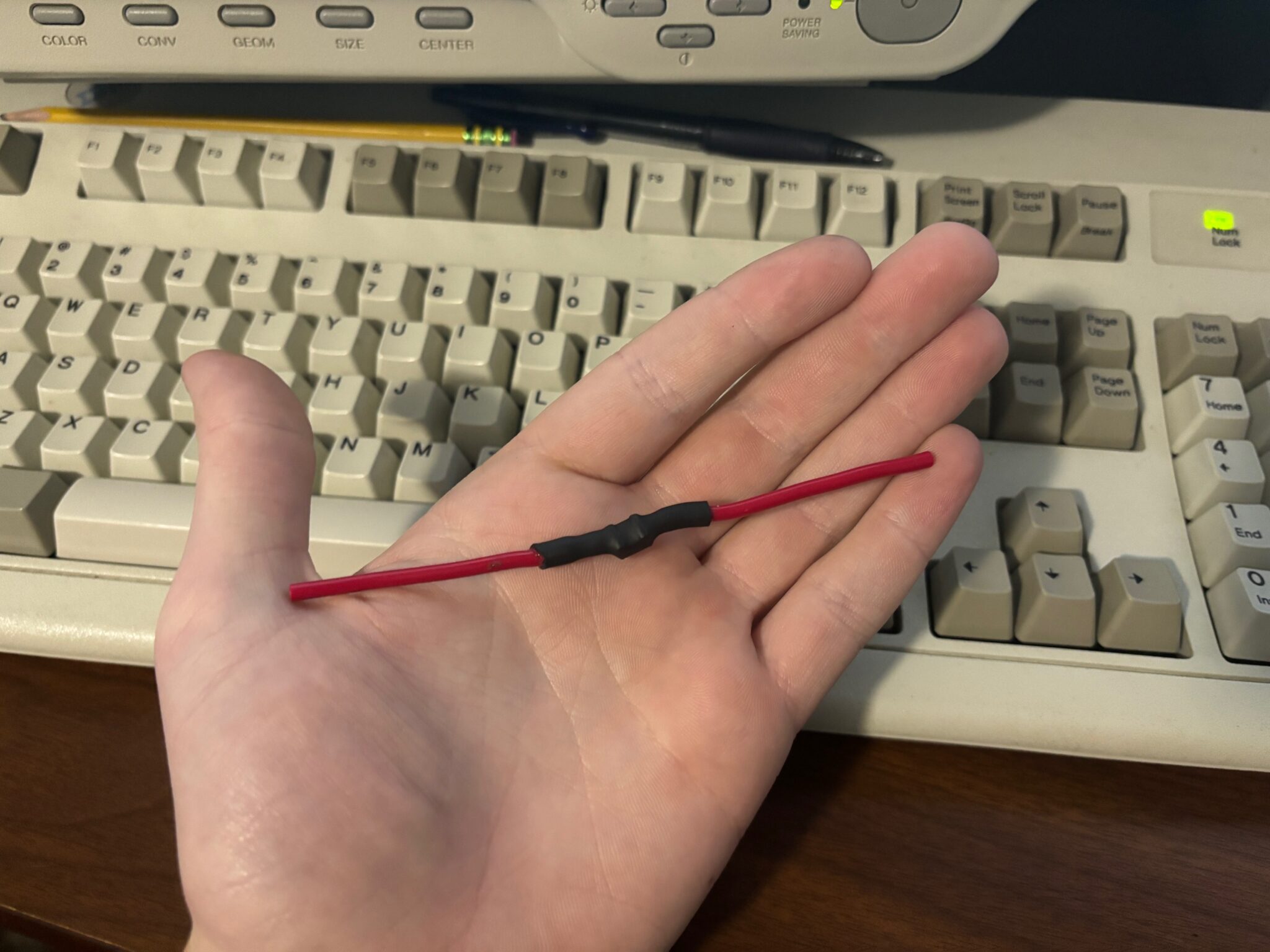

“I would like to put my word in for the Ceramic Capacitors. I got my first two at Constantine from Jay Miller, and since then have bought a few more. They run great in my ’62 Evinrude, and I plan to put them in everything else that needs condensers. It takes a little bit of soldering skill to get them together but well worth it.

https://www.digikey.com/en/products/detail/murata-electronics/krm55tr73a224mh01k/4905676

“

”I plan on making a detailed video on the process next time I order more, but here is the short version:

The soldering iron needs to be HOT. I ran mine at 350 degrees Celsius, but I probably should go hotter. Spend as little time as possible touching the iron to the capacitor. Use rosin core 60/40 solder. Do not use any flux. Tin both ends of the capacitor and tin the wire. I found that I needed a considerable amount of solder on the end of the wire for it to easily bond and hold to the capacitor. Hold the wire to the capacitor and just touch it with the iron till the solder melts. Polarity does not matter when installing the caps.

Some of this advice is what I was told by Jay Miller and some is what I learned by doing it myself.

I used 16 gauge wire and 5/16 in. double wall, adhesive-lined heat shrink with a 4:1 shrink ratio.”

Also, my statement about making a video still stands. I’ll be ordering some more later today

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.