Home › Forum › Ask A Member › 1956 Johnson QD-17 10 hp. No Spark / Crank Key

- This topic has 11 replies, 8 voices, and was last updated 5 months ago by

seakaye12.

seakaye12.

-

AuthorPosts

-

June 20, 2024 at 1:38 pm #288430

Appreciate all the help here. I have a couple of issues id like to ask about.

After installing new Mags , Condensers , Wires and cleaning up what look like good points i still have no spark.

Also drift key on crank looks like its installed angled , is this normal ?

One end out other end more inserted. Can i remove it with a sharp punch if this is incorrect ?

June 20, 2024 at 2:22 pm #288433The key looks fine. A couple of questions: Did you adjust the point opening to 0.020″ on the high point of the cam? Also, from the coils, one wire goes to ground, the other to the set of points that is counterclockwise from the coil when looking down on the mag plate. Maybe a photo of the mag plate might help.

T

1 user thanked author for this post.

June 20, 2024 at 4:04 pm #288442Thanks for the reply Tom , I got everything set and wired properly . But there’s a lot be to said for cleaning the points even if they look clean ! 🙁

Now on to fuel , This should be fun. I have to find preliminary carb settings and install a fuel pump conversion kit.

Any guideline would be appreciated , Thanks

June 20, 2024 at 11:14 pm #288473RK initial settings will be a turn and a quarter on the low speed. Around three quarters to one turn on the high speed. A little rich at startup usually helps starting.

dale

1 user thanked author for this post.

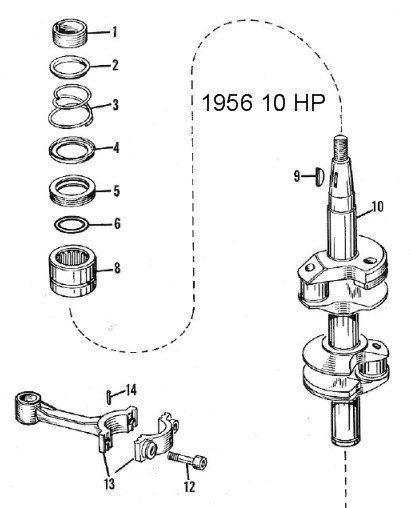

June 21, 2024 at 11:37 am #288482Well, that key definitely looks deformed. How does the keyway slot look in the flywheel? I would certainly replace that flywheel key.

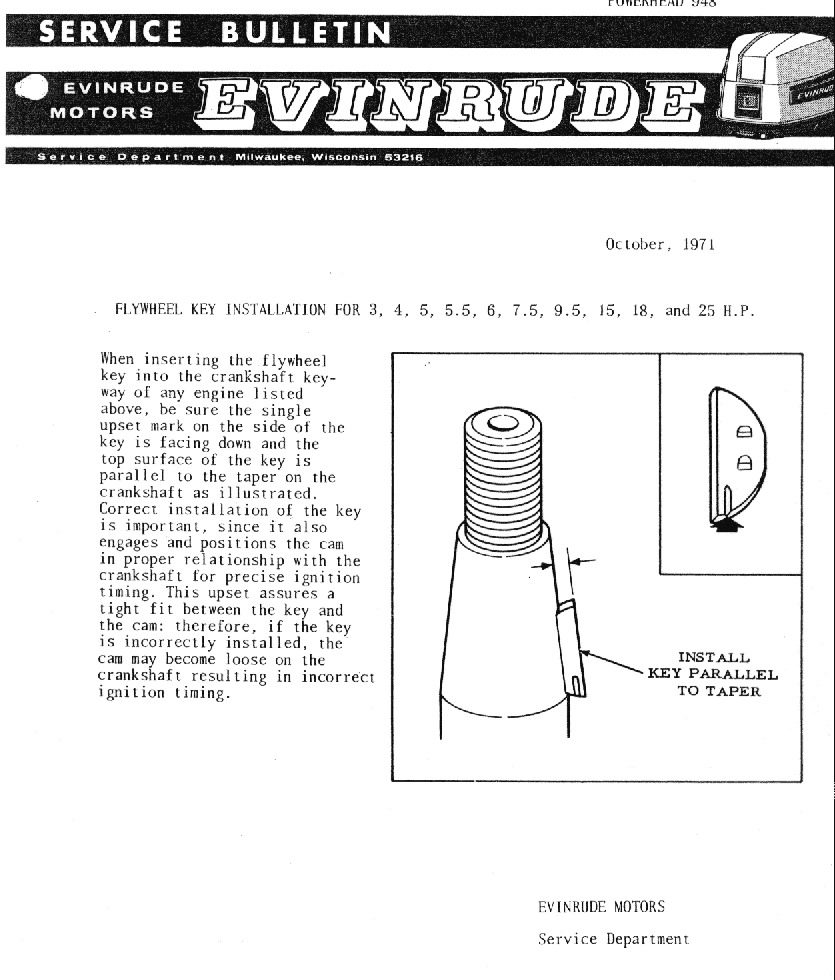

June 22, 2024 at 6:43 am #288499“Also drift key on crank looks like its installed angled , is this normal ?”

A service bulletin from ’71 says it should be parallel, but it doesn’t mention the 10 horse. Is that an oversight or is there some reason the 10 was excluded? Could it possibly have something to do with the spring arrangement below the cam and above the carbon seal? Because that’s the only thing I see different from the other motors listed. I don’t know, maybe others have insight into this.

1 user thanked author for this post.

June 22, 2024 at 8:33 am #288502That key looks like dog doodoo, is it chewed up?

http://www.richardsoutboardtools.com

classicomctools@gmail.com1 user thanked author for this post.

June 22, 2024 at 9:54 am #288505“Also drift key on crank looks like its installed angled , is this normal ?”

A service bulletin from ’71 says it should be parallel, but it doesn’t mention the 10 horse. Is that an oversight or is there some reason the 10 was excluded? Could it possibly have something to do with the spring arrangement below the cam and above the carbon seal? Because that’s the only thing I see different from the other motors listed. I don’t know, maybe others have insight into this.

This is a good question for sure. I have often wondered about the differing recommendations.

1 user thanked author for this post.

June 22, 2024 at 12:25 pm #288508“Also drift key on crank looks like its installed angled , is this normal ?”

A service bulletin from ’71 says it should be parallel, but it doesn’t mention the 10 horse. Is that an oversight or is there some reason the 10 was excluded? Could it possibly have something to do with the spring arrangement below the cam and above the carbon seal? Because that’s the only thing I see different from the other motors listed. I don’t know, maybe others have insight into this.

SteveD; interesting Service Bulletin. Do you have a collection of them? I search for them when I have time….never seem to come across very many. Do you have others?

1 user thanked author for this post.

June 22, 2024 at 1:07 pm #288509You can install the flywheel key as shown in the diagrams and that’s good. When installing the flywheel, however, there is nothing to prevent some rotation in the key. Many of the keys that I’ve seen have some noticeable rotation.

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.