Home › Forum › Ask A Member › 1.5 Sea King water pumping

- This topic has 9 replies, 3 voices, and was last updated 8 years, 4 months ago by

melugin.

-

AuthorPosts

-

April 27, 2017 at 12:21 pm #6859

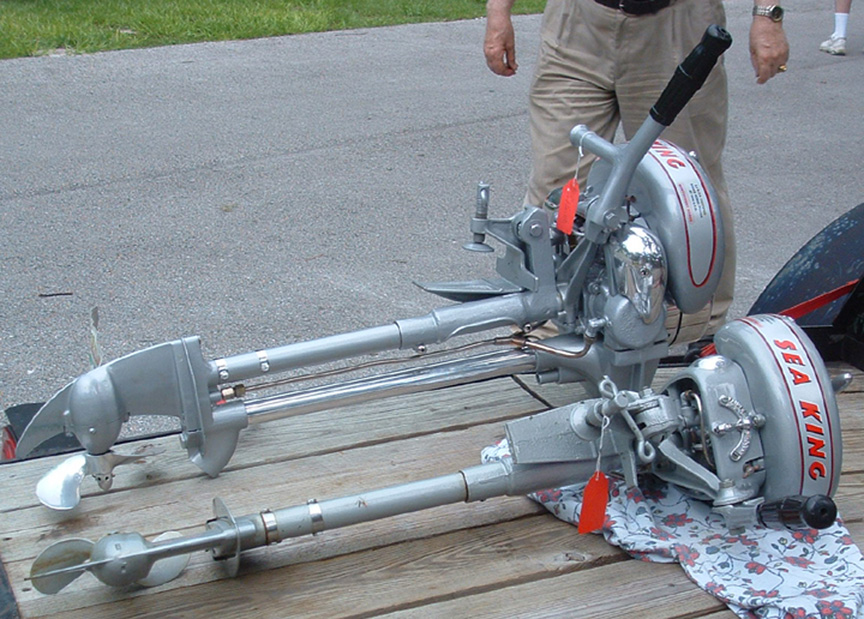

I have four 1.5hp Sea King post war motors which are in running shape, to some extent. They have NOS impellers and some will pump water, however they are getting too hot. I am running them in a test tank and also one on a boat. Water comes out the mid-section, indicating pumping, but they still overheat to the point of stopping. The cylinder gets very hot.

What am I missing here and what should I do next? I’d rather not pull the cylinder if I don’t have to.April 27, 2017 at 2:15 pm #56717I think those were the last motors Evinrude built with a piston pump driven by a brass eccentric on the drive shaft. They can ware badly when run through sand. If the bottom of the piston wares through a copper penny way be soldered to the bottom to seal the hole. A worn eccentric would have to be replaced by fashening a new one. They are also susceptible to pollution clogging the water jacket. . .

April 27, 2017 at 2:50 pm #56720

April 27, 2017 at 2:50 pm #56720I just reread your post – I was obviously thinking PRE war Sea King. The POST war horse and a half used a rubber rotor driven by an eccentric on the propeller shaft. Unfortunately the Oilite prop shaft bearing allowed some oil the seep into the pump housing causing the rubber rotor to swell. This increases it’s diameter and reduces the amount of water pumped. On the other hand, the water jacket on those motors consists of a loop of copper tubing wrapped around the grey iron sleeve as it is put into the die casting machine in Waukegan Illinois. Then some are sent to Milwaukee for Evinrude Sportsmen and some to Galesburg for various brands. They are resistant to corrosion but not from clogging. They can be cleared by reverse flushing. This illustration of a Johnson pump by Frank Robb shows what to look for in your Sea King. . . 😉

April 27, 2017 at 5:56 pm #56725

April 27, 2017 at 5:56 pm #56725If used in salt water, corrosion somehow managed to get around that copper tube and collapse it. If that happens, too bad, so sad.

April 27, 2017 at 6:40 pm #56727These are all fresh water motors. We don’t even say the word out loud, S-A-L-T. I may pull off another cylinder and have a look. The rotors are new and fit well.

If the tube is plugged, would the water still exit the mid-section?April 27, 2017 at 6:49 pm #56728quote melugin:These are all fresh water motors. We don’t even say the word out loud, S-A-L-T. I may pull off another cylinder and have a look. The rotors are new and fit well.

If the tube is plugged, would the water still exit the mid-section?I suppose that would depend on the degree of plugging. Do your motors have aluminum or cast iron jugs?

April 28, 2017 at 1:37 am #56748These are the aluminum castings. Three of my five motors have gotten very hot after a minute or so of running. I’ve stopped them or they quit at that time. Another one is apart and the last is a slick original I don’t want to risk hurting. Two of the runners do exhibit flaking paint on the cylinder from heat or the lack of primer. That paint isn’t discolored. They don’t look to have been stored outside or abused any more than normal wear and tear.

One interesting point, the best one has a tab standing off from the bock to stabilize the fuel line. A 1/2" by 2" piece of aluminum sheet the fuel line runs through to keep it from shaking. Painted the same color as the motor.April 28, 2017 at 7:14 am #56755So of course I got curious and looked. Sure enough, the GG9003B (1W10) does have a gas line support. GG9003A (1W5)

does not show one.Sorry, I just don’t have an answer for your overheating problem. Seems a bit odd that you would have more than one doing it, especially in a fresh water motor. The collapsed copper tube idea still bugs me though.

April 28, 2017 at 5:21 pm #56769Looks as if the rotor pumps to a small oval opening which goes up toward the powerhead. Possibly lower unit grease or dirt is caking here restricting water flow. The 3hp models have a ‘water flush’ plug at this point. I will pursue this.

April 28, 2017 at 6:56 pm #56774Copper water tube is cast into the tower housing to transmit water upwards and exposed on all but its’ ends. I’ll check to see if one may be worn thru by rubbing the drive shaft.

-

AuthorPosts

- You must be logged in to reply to this topic.