Home › Forum › Ask A Member › 1922 Evinrude A Tiller

- This topic has 10 replies, 2 voices, and was last updated 7 years, 11 months ago by

slim60.

-

AuthorPosts

-

February 16, 2017 at 4:26 am #6359

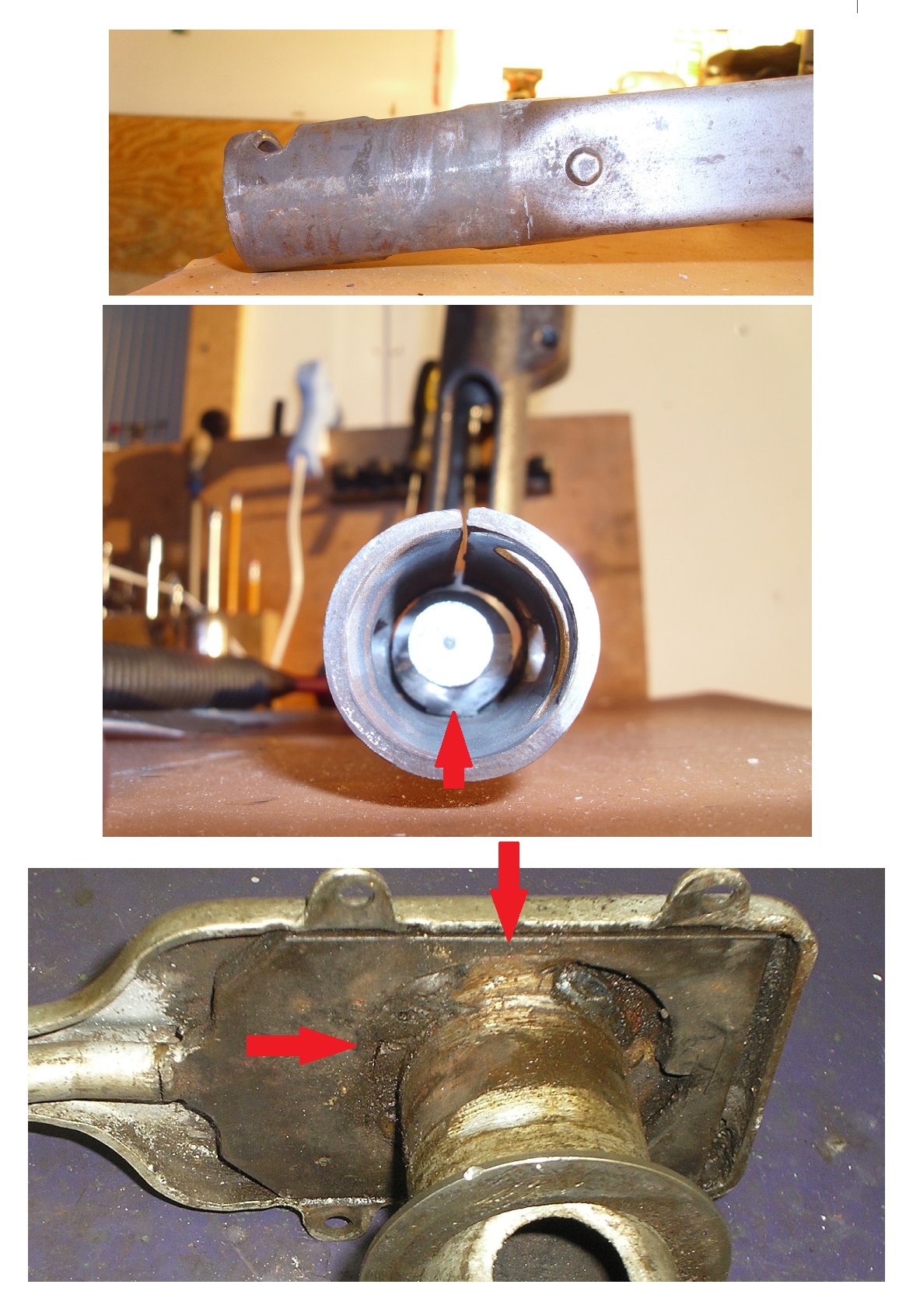

This is my tiller shift as it was when I got it. I cleaned it but it does not work. The through bolt and cap nut is probably wrong. There is a rectangular rod about an inch inside from the bolt and nut that does not move. Seems to me I’m missing a part. Motor ran last year in forward. Any help would be appreciated.

February 16, 2017 at 4:11 pm #53120Yours is from an earlier motor.

A 22 would look like tiller pictured here.

https://aomci.org/forum/viewtopic.php?f=3&t=10728

There should just be a straight pin going through there

not a bolt. Your bolt would have be loose so it can move.

If that doesn’t work it could be welded so it can’t move.

Have you had it apart?These are all the parts for yours except for these two screws. (Red Arrow)

A 1922 gear case should look like this.

If yours looks like the 1920 one yours is earlier.A "Boat House Repair" is one that done without having tools or the skills to do it properly.

February 16, 2017 at 9:04 pm #53131Thanks Tubs; I can’t take photos today so I’ll just try to explain. My lower looks like a ’22. There is a P1B on the pump bracket. Model and serial numbers were cut off the tag on the fuel tank. The flywheel has patent numbers for the mag of 1915, 1916. On your tiller photo the tube at top has a slot in it and two holes with bolts. Mine does not. The rod below that with the spring and pin, mine looks like it’s broke and it is rivited to the tube. One more thing. I have an open circuit between the points until I close them. When I connected the condenser wire I got a closed circuit. I spun the flywheel with the spark plug grounded and got a good blue spark. I also got shocked from the bolt in the start knob. Compression is very good. I have to hold on to the fuel tank and wear gloves to spin it through.

February 17, 2017 at 2:35 am #53143We (me anyway) would like to see pictures of the

issues with your reversing mechanism rather than

speculate what you may have there. Someone here

should be able to make some sense of it.I would suspect and be looking for a failure in

one of the insulator’s going to the spark plug

wire, starting here (arrow), with the insulation

on this wire looking for a place where the spark

could be jumping to the mag plate.A "Boat House Repair" is one that done without having tools or the skills to do it properly.

February 18, 2017 at 4:32 am #53200February 18, 2017 at 1:33 pm #53206That rivet holds a collar to guide the shaft

and should be there. Not everyone was a

fan of this reversing mechanism and there

was a verity of ways to lock them in the

forward position. That was the purpose

of the 2 brass screws in the unit I posted

earlier however welding is more common.

Has someone welded your shaft to the

collar to accomplish this and that’s what

making you think it has been broken?A "Boat House Repair" is one that done without having tools or the skills to do it properly.

February 18, 2017 at 6:14 pm #53220I don’t see any welds. The shift rod inside is definately shearded off and will not move. At this point I would like to run her in the test tank since it will be in the 60’s all week here. I can live with forward only for now. If parts are available I’ll finish the resto later. What is the spark plug gap? Thanks Tubs.

February 19, 2017 at 2:35 am #53238I gap the plug at .025 but that may not be

the factory speck. I don’t know what it is.A "Boat House Repair" is one that done without having tools or the skills to do it properly.

February 19, 2017 at 5:27 pm #53279ThanksTubs; She started on the third spin and ran for a minute. Made some adjustments and ran for five minutes and stalled. Then seven minutes and stalled again. After that she would not start again. Was running cool. I won’t be messin’ with her for awhile do to family commitments. My dad recently passed away. He was ninety five.

February 20, 2017 at 2:40 am #53310Too bad about your dad.

My mom made it to 95 also.

Any talk of leaving the family home was met with

" When I leave here it will be feet first" and that’s

the way it was. 7 years ago this month. You cant

speak to them any more but they will always be

with us.

The guys that are really into these usually don’t

have much trouble getting them to start and run.

For armatures like you and me what you have

experienced is typical. Especially when there

people around watching.A "Boat House Repair" is one that done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.