Home › Forum › Ask A Member › 1930 Lockwood Chief Revival

- This topic has 37 replies, 11 voices, and was last updated 7 years, 2 months ago by

lyks2tinkr.

-

AuthorPosts

-

April 22, 2018 at 6:42 pm #9716

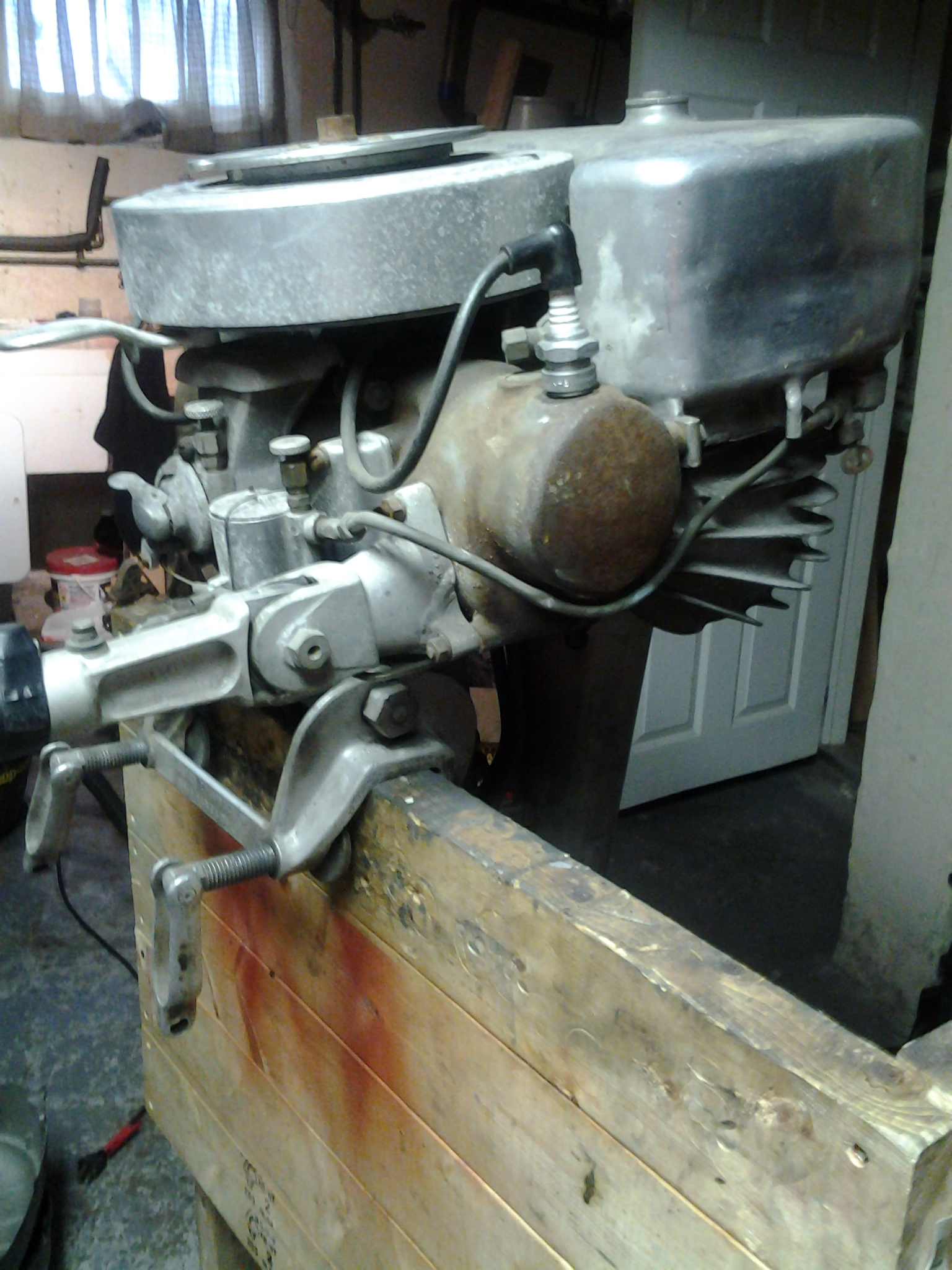

Im about to put a Lockwood Chief up on the stand to go through.

First time working on a Lockwood. Any details I should know before I begin? Im just going to get it running for now, then restore later once I can confirm its a good runner.

April 22, 2018 at 6:50 pm #74507April 22, 2018 at 6:51 pm #74508April 22, 2018 at 8:39 pm #74514Just off the top of my head, the drip tray is very fragile. And it looks like your tiller handle has been welded. If you don’t know how well that job was done, you might want to think about re-doing it, or replacing it. As far as the internals, I’d defer to Chris Scratch’s experience.

April 22, 2018 at 8:51 pm #74515Thanks Bill.

I was hoping to find a site glass as well if possible.

April 22, 2018 at 9:13 pm #74517Junk motor, I would take it off your hands so you are not subjected to the horrors of one of those things

😆http://www.richardsoutboardtools.com

classicomctools@gmail.comApril 22, 2018 at 9:32 pm #74519quote Chris_P:Thanks Bill.I was hoping to find a site glass as well if possible.

I have a dim memory of an old Outboarder article about renewing one of those with a gasoline resistant clear acrylic tube – maybe an article by Art Doling? You’d have to source the elbows, if you don’t already have them.

Another interesting/quirky feature of that motor is the spring-loaded checkball plumbed into the cooling line on the port side. The cooling system is a closed system, much like the Johnsons of the same period. Lockwood gave you a method of checking to see that cooling water was flowing. Looks like you have the correct prop – it is, effectively, the water pump. There’s a hole in the leading edge of each blade, right?

April 22, 2018 at 10:44 pm #74529Drip trays are every bit as fragile as Bill suggested. Take car of the one you have, there aren’t many unbroken replacements available.

Blow compressed air through the cooling system in both directions. You will want to make sure there are no obstructions. The Chief cooling normally is pretty effective as long as the passageways area all clear and there isn’t a bunch of scale or rust flakes clogging up the water jackets. I’d recommend dropping the lower unit and disconnecting the water pipes at all of the various junctions, including the "spider".

The check ball Bill mentioned on the plumbing fitting is actually not for checking water flow, but is a bleeder. It can bleed air out of the cooling system, but its real purpose is to let air in for drainage purposes when storing the motor away for long periods of time. If you don’t relieve the vacuum in the system, it will retain water in the cylinder cooling passages and two things can happen, neither one of them good;

1) The water helps create rust buildup in the water passages, and/or

2) IT will freeze in cold weather, causing possible fractures of the outer or inner wallsSo, after running, you crack the nut open where the ball is, let air go in so the water will all drain out, then you’re good to retighten the compression nut.

Powerhead – verify that the rod clearance isn’t excessive. If you have a pronounced loud clanking or knocking when rocking the flywheel back and forth, you may want to tighten the rod clearance up some…. or at least measure to see what it actually is.

Make sure the flywheel nut is tight. Too many Chiefs have suffered crankshaft keyway damage due to the flywheel nut coming loose and not being noticed.

Be careful with the drain plug at the left-rear corner of the tank. Those aluminum threads usually perish just by looking at them the wrong way. I’ve had to make several replacement plugs that are about 0.005" oversize in order for the plug to tighten in the port properly. I make them out of brass instead of aluminum.

Your motor has two fuel shut-off valves… one at the tank, and the other at the carburetor. I know the needle at the carb inlet looks like a mixture screw….. but it isn’t.

Don’t worry about a fuel sight glass tube until you have the right end pieces to mount it with. George Emmanuel knows how to make a sight glass out of modern materials (something acrylic, I think) but if you don’t have the end caps……

Carb – just verify that the jet passage is clean. Don’t coat the float. If its good, use it as is. If its rotted or crumbling, replace it.

Ignition – if your coil fails the resistance test… pretend you didn’t test it and just run the thing. I haven’t had a Chief pass a resistance test yet, but they always run. What a miraculous motor she is eh. Clean and dress the points, set gap to 0.020".

Starting – these old gals like it rich to start with, then you have to lean her out to get her to purr. 2 3/4 turn out to start isn’t unusual, but then once she fires, you have to reduce it to about 3/4 of a turn out to get her to wind out. 4000 RPM is about right for these at WOT. and they don’t like a lot of advance either, anything CCW past the 5 o’clock position is a waste of time. Fuel mix 8:1.

Lower unit – check for presence of water, refill with grease as necessary.

Hope this helps.

Best,

PM T2He's livin' in his own private Idaho..... I hope to go out quietly in my sleep, like my grand-dad did..... and not screaming, like the passengers in his car...

April 22, 2018 at 10:53 pm #74531Great write up Chris. Appreciate it!

Going to check all of this out. Would like to run this motor at the next meet.

Cheers.

April 22, 2018 at 10:59 pm #74532Are you taking it to Belwood? I’m planning on being there

PM T2

He's livin' in his own private Idaho..... I hope to go out quietly in my sleep, like my grand-dad did..... and not screaming, like the passengers in his car...

-

AuthorPosts

- You must be logged in to reply to this topic.