Home › Forum › Ask A Member › 1931 Johnson OA-55 3hp.

- This topic has 26 replies, 11 voices, and was last updated 1 day, 10 hours ago by

Max Fowler.

-

AuthorPosts

-

January 22, 2025 at 10:36 am #293564

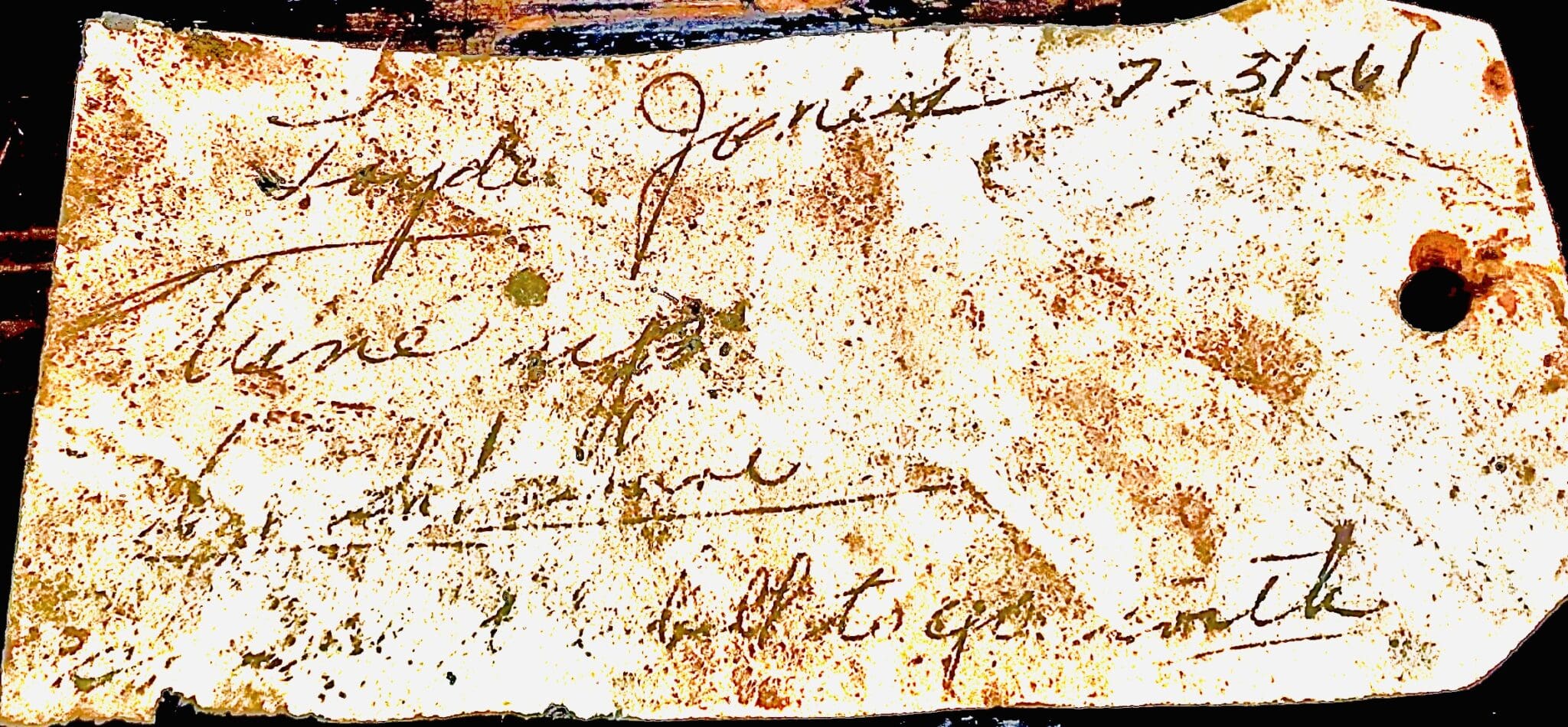

I got it in the fall. Unlike most motors, where you don’t know anything about its past, this tag reveals some of its history. I don’t know why I didn’t just through it away. After noticing what appeared to be some writing, I cleaning off the coating that covers this motor to see that, Lloyd Jones ( I believe somewhere is Nebraska) had it tuned up around July 31, 1961. Other than “to go with” I can’t make out anything else. Anyone able to make out some other part of it? Aside from the melted remains of what must have been sparkplug boots, the “new” plugs look to have never been fired. It would seem it hasn’t been run since then. Going by what covers this motor, it got put in an open building like a hay barn or machine shed where it was out of the rain, but little else. As the years went by, dust would collect on the motor. On those first warm spring days the motor would sweat, turning each new layer of dust into this hard crust. Its not on the gas tank, so maybe the tank was covered. Its not known just when it left that storage to get “thrown” on a trailer, with a bunch of other motors, for a trip to western Illinois. That’s where it came to me. The gas tank, muffler, and exhaust pipe, have dents in them. Some of the dents in the gas tank may be a result of its most recent trip. Everything that is suppose to move, choke/throttle lever, gas cap, petcock, transom clamp thumb screws, magneto, are all frozen. I can just barely turn the motor, but once it moved I stopped. This is going to be a real interesting motor for me as I have never had one. While it shares many parts similar to those on the early Johnson’s, the gear case is only found on this and one other model. Neither motor is very common. This thing is really a mess. I can’t wait any longer to get into it!!! Tubs

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

January 22, 2025 at 11:05 am #293570Interesting history… and you even have the often missing carb snorkel

Joe

January 22, 2025 at 3:04 pm #293573Cool motor! Work your magic and keep us posted on your techniques, etc.

January 22, 2025 at 8:25 pm #293587

Interesting history… and you even have the often missing carb snorkel

Joe

It’s there but has the typical damage. I haven’t had very good results with my efforts to straighten them. I can do OK on the straight part. I haven found a solution for the turn. The ID of the tube is close to 51/64. A search for a steel ball that size revealed, to my surprise, that they aren’t that hard to get. I’m going to give that a try on this one.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

January 22, 2025 at 9:11 pm #293588Tubs,

That’s the type of motor that needs some skilled attention and in your hands it’s certainly in the right place! Keep us posted with regular updates.Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1957 Evinrude 3022

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."January 23, 2025 at 8:28 pm #293609Tubs great start.

What method are you thinking about in order to fix the tank dents? Open the tank, or go down the filler neck?

Hopefully Dixie Hammock will have a decal.

Bob DJanuary 23, 2025 at 10:49 pm #293614

I’m thinking I’m going to try my hot glue method but I don’t know if the glue will stick enough to pull steel. I don’t have to polish this tank so just getting it straight will do. Plan B would be remove one end and work it straight over a piece of exhaust pipe, like I do Row Boat Motor mufflers. (B H Repair) That would be the easiest and fastest. I’m flip flopping on how to remove one end though. And then I have to get it back on. Not the best at soldering. I can get by doing the flat Row Boat Motor tanks but this thing is round. Steel tanks I usually save for last. They only take days. I have some time to think about it.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

January 24, 2025 at 9:45 am #293617Tubs, suggest start with a slightly smaller steel ball .. 3/4″ is about o.o47 smaller than 51/64

Joe

January 24, 2025 at 4:05 pm #293633Tubs- The best that I can make out on the tag with playing around and using filters and adjustments on my iPad is-

Loyde Jones 7-31-61

Tune up

best shot we have (Taking a educated guess from what letters I can make out)

_____ ______ the belt to go with (belt could also be bolt)

this is my guess. Hopefully someone else could do better.

gary

January 24, 2025 at 4:44 pm #293635 -

AuthorPosts

- You must be logged in to reply to this topic.