Home › Forum › Ask A Member › 1931 Johnson OA-55 – Phase 2

- This topic has 26 replies, 9 voices, and was last updated 10 months, 1 week ago by

Tubs.

Tubs.

-

AuthorPosts

-

February 12, 2025 at 10:18 am #294060

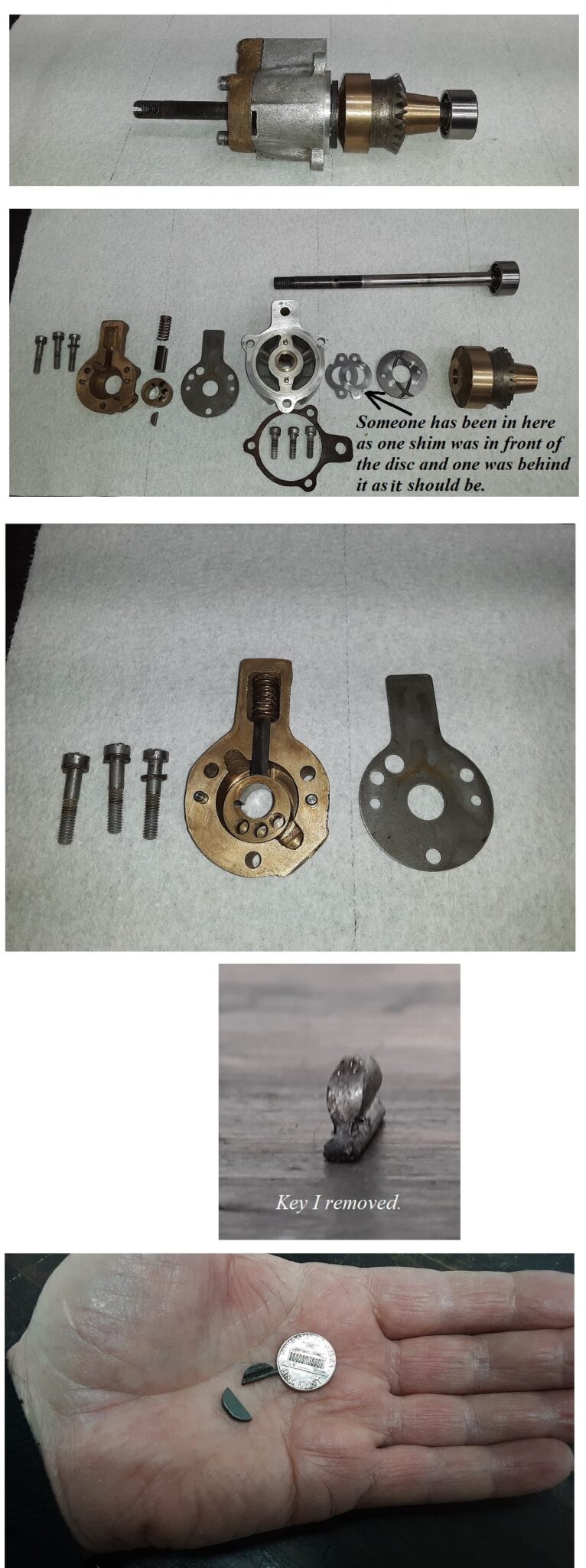

Everything is cleaned up. Starting with the gear case as it’s new to me. Full of grease — along with a little 60+ year old water. Someone has been in here before me as one shim was in front of the disc and one was behind it. The pump eccentric is keyed to, and driven by, the prop shaft. Everything looks good except for —– the key for the pump eccentric. It’s a #2. There is only one size smaller. Looks to be the weak link in this system. A water pump failure seems likely if they had kept using it. The rest appears to be in really good condition.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

February 12, 2025 at 3:14 pm #294066I am always amazed at how well that old black grease protects the gearcase parts. I have take apart many with very little damage.

Great pics, Tubs!

David Bartlett

Pine Tree Boating Club Chapter"I don't fully understand everything I know!"

February 12, 2025 at 8:45 pm #294074Nice project Tubs. Keep posting progress pics!

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1957 Evinrude 3022

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."February 14, 2025 at 9:10 am #294104February 14, 2025 at 9:17 am #294106

Looks like you needed to replace the spring as well.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

February 14, 2025 at 11:05 am #294119

Hammered the muffler can over a pipe to get the dents out. The smaller one was pretty deep. It came out better than I expected. Used some sockets for the dent in the pipe.

The fuel line has become separated from the sediment bowl. Trailer Ride? Sediment bowl nut has evidence of contact from player jaws. Contents in the sediment bowl may explain why. Smoothed out the nut as best I could.

Cleaned up the magneto. Points are OK. The coil tested good. When testing a condenser, if its leaking, the needle could be anywhere in the green. Shorted, somewhere in the red. I’ve never had a condenser do this before. Video Link – https://youtu.be/XvNYrsN1ZSE?si=YyOeJTUCJzkdCQhp

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

February 15, 2025 at 9:17 am #294145

I’ve fix the video link above.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

February 15, 2025 at 9:36 am #294146

I’ve fix the video link above.

Yup it works now! I never seen a condenser do that either. Puzzling for sure.

dale

February 18, 2025 at 9:39 am #294195

I could just get the motor to turn when I got it but now it was stuck. Took a 50/50 mix of gas and oil and put about 8 oz. in the crankcase and some in the cylinders. Sloshed it around once a day and after a few days it would move again. One half of this exhaust port was almost totally blocked with carbon. After cleaning it out, I positioned the piston so I could check the rings. Both were stuck hard. I was hoping not to have disassemble the power head but with all the carbon in this motor it seemed to be necessary. Turned out it’s a good thing I did. The wavy thing, I’ve been told, is a back fire suppressor. They can break up, like this one has, and go into the crankcase. As you can imagine, that is not a good thing. Even if you find them to be in good condition you should remove them. The rings freed up pretty easily except for the top ring. It was only stuck in the area of the exhaust port. It took forever to get it free without breaking it. Piston and cyl. both look good.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

February 18, 2025 at 4:28 pm #294216Looks like it will be ready to run way before test barrel

is ready…….. probably 2-1/2 months here!Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.