Home › Forum › Ask A Member › 1936 Evinrude 4.4 hp Fisherman model 4148 motor

- This topic has 39 replies, 6 voices, and was last updated 2 years, 1 month ago by

Ed Voll.

Ed Voll.

-

AuthorPosts

-

June 2, 2023 at 10:12 pm #276720

New member, newly acquired motor. would like to get it running if possible and clean up. This motor has laid in a basement for ~ 60 years. The tank has dried fuel like shellac. Where can I get a manual, service manual for this motor? Also, what solvent can I use to soak the tank interior with and also to flush through the fuel line and spray in the carb. It is pretty gummed up and I want to preserve the labeling , instructions on the body as much as possible.

Finally parts like seals and gaskets, maybe magneto and accessories would potentially be needed. Thank you much.

Ed Voll

June 3, 2023 at 9:33 am #276723It will be best to remove the carb, disassemble, and soak the

metal parts in carb cleaner.The gas tank should be removed as well.

Remove the fuel fitting from the bottom of the gas tank.

Some models have a fuel filter screen attached to this fitting

which will often need replaced, or cleaned at the least.I often use a pint of mineral spirits and throw a bunch of

sharp wood screws inside of the gas tank, and shake the

tank a couple of times a day over a few days. Soapy

water and lots of rinsing will remove the loose residue.Good luck on your project! Hope to see some photos

some time!Prepare to be boarded!

1 user thanked author for this post.

June 3, 2023 at 10:16 am #276724

There isn’t a service manual just for that motor.

Some info may be found in this general service manual. Try copying and pasting this link to see if that will work.

file:///F:/11Outboards/11My%20Outboard%20Motors%20Help/Manuals/Manual%20Evinrude/EvinrudeSM1912-1945.pdf

For cleaning out dried up fuel I like Berrymans B12 using the same process as the Buccaneer

describes. It will affect your decal though so be careful with it. I use Gumout for cleaning other

fuel system parts. I don’t believe there are any seals in that motor. Use lubriplate 105 or corn

head grease in the gear case as a substitute for the original grease’s that are no longer available.

This person is reproducing gaskets for earlier outboards on eBay. He may be interested in

making you what you need. I, like many others, just make my own.

https://www.ebay.com/sch/i.html?item=265683099819&rt=nc&_trksid=p2047675.m3561.l2562&_ssn=johnfolke

Later coils can sometimes be adapted if necessary. Points should only need a cleaning.

A later condenser can be used if necessary.

Here is a video on how to remove the flywheel if there are no holes for a puller. I have welded 2 nuts together but if you just jam them together on the bolt it will work.

https://youtu.be/RWgE9XiIBnk

I hope this helps you some.

Tubs.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

1 user thanked author for this post.

June 3, 2023 at 9:39 pm #276746I use Supe Clean the purple jug to clean my tanks with

nuts, bolts, & BB’s from pellet gun.

Art Dekalb has a great check list for getting them running.

Art’s Five Point Plan | PrecisionServOutboard

1 user thanked author for this post.

June 13, 2023 at 10:02 pm #277022I never understand why people use a bunch of small items to clean the inside of the tank. I prefer to use a small length of chain. That way only one item in tank and no fear of not getting the last small item out.

June 21, 2023 at 10:45 pm #277219some pictures of 1936 Evinrude Fisherman 4.4 HP . Cleaned out the fuel tank , valve, and line and now looks good. But the ignition is the issue; spark wires broke at magneto plate, testing shows condenser is open and coil also looks bad. Finally the magnets only lightly hold a screwdriver tip to them, they seem weak. If anybody has specs on a replacement condenser, and a coil I would just replace them. Also I will inquire from Art if he can remagnetize my flywheel head to full strength.

Ed Voll

June 22, 2023 at 8:32 am #277236

I have had a magnet charger for over 40 years. I have learned that although the magnets

do loose strength over time they still retain enough so the motor will start and run fine.

If you can find someone to recharge your flywheel great, but don’t bail on this motor

If you can’t.

Without knowing the exact value of your condenser a value of .25 mf in most cases

should be close.

You should test the coil windings. If they are not open its worth giving the coil a try

even without knowing the secondary value.

Need to see a picture of the mag to let you know of other possible coil options if necessary.

Spark plug wires look original. Good sign. Motor could be low hours.

Tubs.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

1 user thanked author for this post.

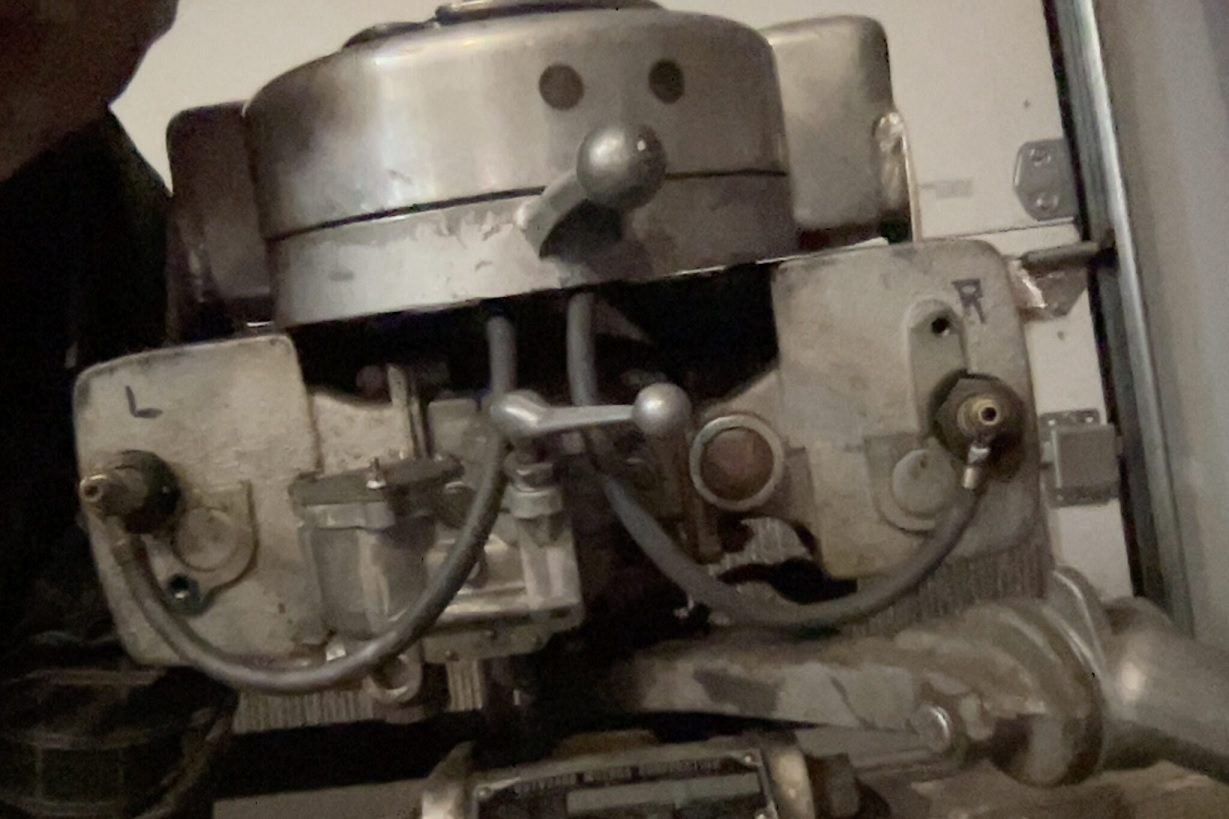

July 12, 2023 at 12:11 am #277991ksjfhlakhfajfh/Users/edwinvoll/Desktop/Photo on 7-11-23 at 10.33 PM #2 6.jpg

Ed Voll

July 12, 2023 at 12:20 am #277993So the picture above shows the needle valve lever in the center of the picture. how should I adjust that lever; it can rotate several times ;do I turn till I feel resistance, then back off a half turn? they position it is in now doesn’t really fit in the slot opening in the motor hood, cowling . I know most don’t run with the hood on but the lever should move freely when that motor hood is on. Thanks for any help,

Ed Voll

July 12, 2023 at 6:46 am #277994

Once you find the best running position set

the lever so it will be in the center of its movement

when the cover is on.

Only slight adjustments are necessary. Normally

slightly richer for cold starting.

Tubs.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.