Home › Forum › Ask A Member › 1936 Evinrude 4.4 hp Fisherman model 4148 motor

- This topic has 39 replies, 6 voices, and was last updated 1 year, 2 months ago by

Ed Voll.

Ed Voll.

-

AuthorPosts

-

July 17, 2023 at 10:01 pm #278193

other pictures:

Ed Voll

July 17, 2023 at 10:05 pm #278194other pictures:

Ed Voll

July 17, 2023 at 11:24 pm #278195Now take apart the pump again and remove all traces of grease/lube from the piston and checkballs. Grease/oil attracts sand/grit causing pump failure.

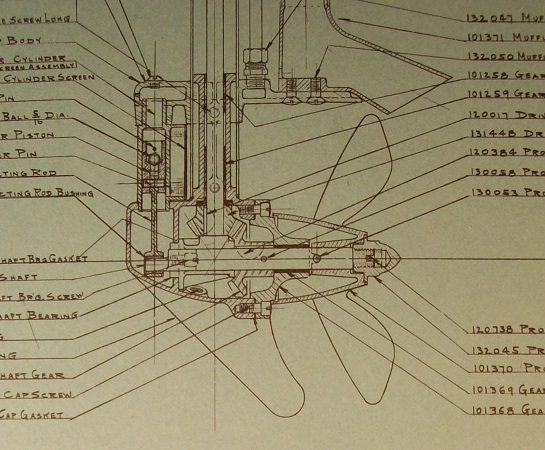

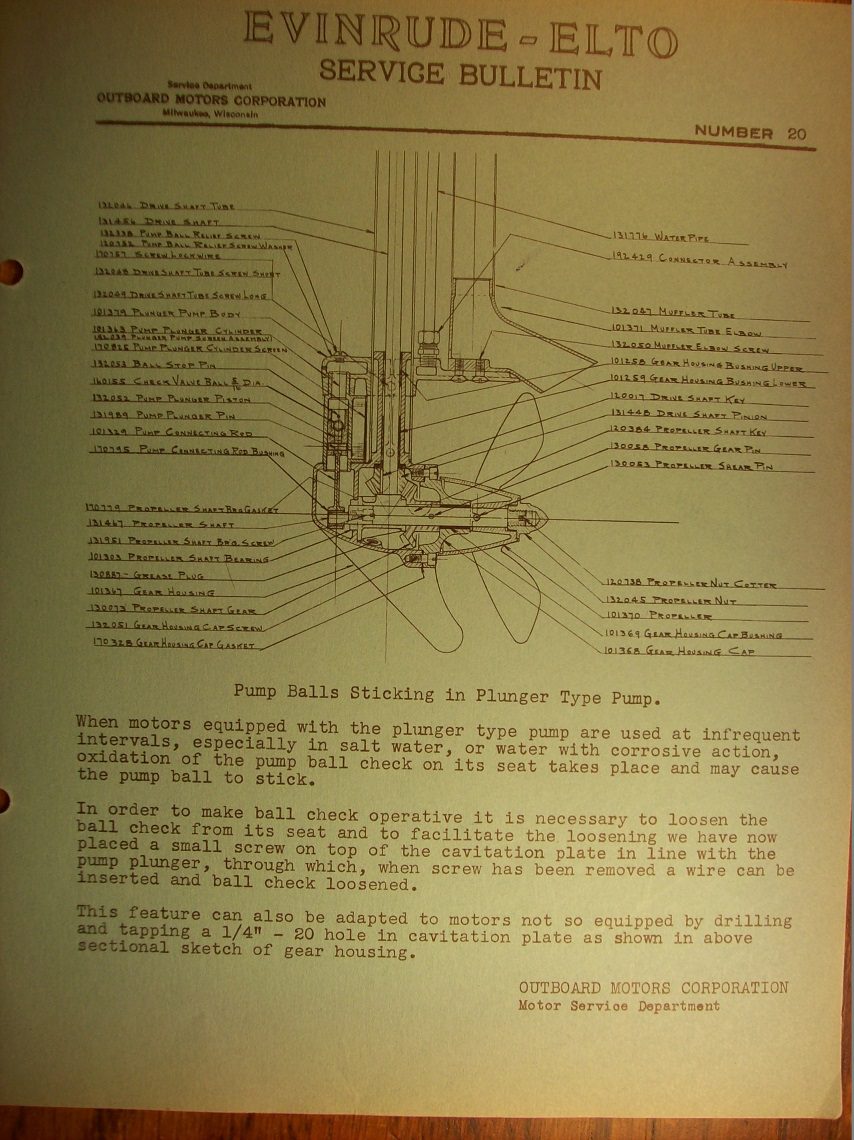

July 18, 2023 at 12:30 am #278196Here are 2 Evinrude Service Bulletins from 1934-35. The ’34 Fisherman had one check ball, the 1935 began using 2 check ball valves. So the ’36 probably has 2 check valves. Only one ball is shown here in the picture and the other one should be at the bottom of the water line inlet.

1 user thanked author for this post.

July 18, 2023 at 9:21 am #278203Did you try blowing compressed air in the water line,

where it connects to the check valve, to see if any air

blows out the exhaust manifold blow hole, or else where?Did you have the exhaust manifold off to check the cooling

passages?Prepare to be boarded!

July 19, 2023 at 8:51 pm #278283Now take apart the pump again and remove all traces of grease/lube from the piston and checkballs. Grease/oil attracts sand/grit causing pump failure.

QUOTE

Harry, do you by chance have a schematic of the carburetor on this Evinrude, similar to the diagrams for the lower unit that you attached? Thanks.

Ed Voll

July 19, 2023 at 10:35 pm #278284No carb schematic but it is a simple carb. There may be a defective fuel screen someplace such as in the tank outlet or carb. Plugged or disintegrated. Maybe dirt in the float bowl. Never use compressed air in a carb if a brass float is in place.

1 user thanked author for this post.

July 20, 2023 at 7:14 pm #278309No carb schematic but it is a simple carb. There may be a defective fuel screen someplace such as in the tank outlet or carb. Plugged or disintegrated. Maybe dirt in the float bowl. Never use compressed air in a carb if a brass float is in place.

you are correct, it is a simple carb. I will get into it next week. early on I checked the brass cylindrical screen at the entrance to the carb. it was immaculate but since I’ve been running it a bit some dirt may have come downstream to plug. will see about the float, etc. next week. Thanks, again.

Ed Voll

July 27, 2023 at 7:52 pm #278556So after cleaning the water pump system, the carb (which was really in good shape), and the brass fuel filter screen which was totally blocked with junk still coming out the tank, I felt we were set to go. Instead of pulling my arm out with rope, I tried my cordless drill with a Gator grip adjustable 3/8 in socket. this really may turning the flywheel easy and the gator grip mechanism allows an easy off capability once the motor takes off. here is the video below:

I am set for now, YESSS. I don’t own a boat and don’t have a lot of garage space to get into this but this has been fun, I must say.

Thanks to Buccaneer, Tubs, and Harry for helpful advice to a rookie. and yes, the cooling water does exit the blowhole of the exhaust manifold as seen in the video.

I must say, for an 87 year old motor sitting around for probably 60 years, this baby really cranked up ! You’re right Buck, I need a bigger test drum, haha!

Ed Voll

July 27, 2023 at 8:39 pm #278560

Watched your video several times. You done good Ed.

Hope you can find someone that will let you run it on their

boat one day. Don’t leave it just leaning up against a wall

so it can fall over an damage what I suspect is near perfect

gas tank and a nearly complete original decal.

Rare to find on a motor of that age.

Tubs

TubsA "Boat House Repair" is one that done without having tools or the skills to do it properly.

1 user thanked author for this post.

-

AuthorPosts

- You must be logged in to reply to this topic.