Home › Forum › Ask A Member › 1936 Evinrude Fisherman

- This topic has 17 replies, 5 voices, and was last updated 7 years, 9 months ago by

roalco.

-

AuthorPosts

-

March 21, 2018 at 4:36 pm #9465

Hi all!

I’m very glad to find this forum, and have already spent hours reading and searching posts here.

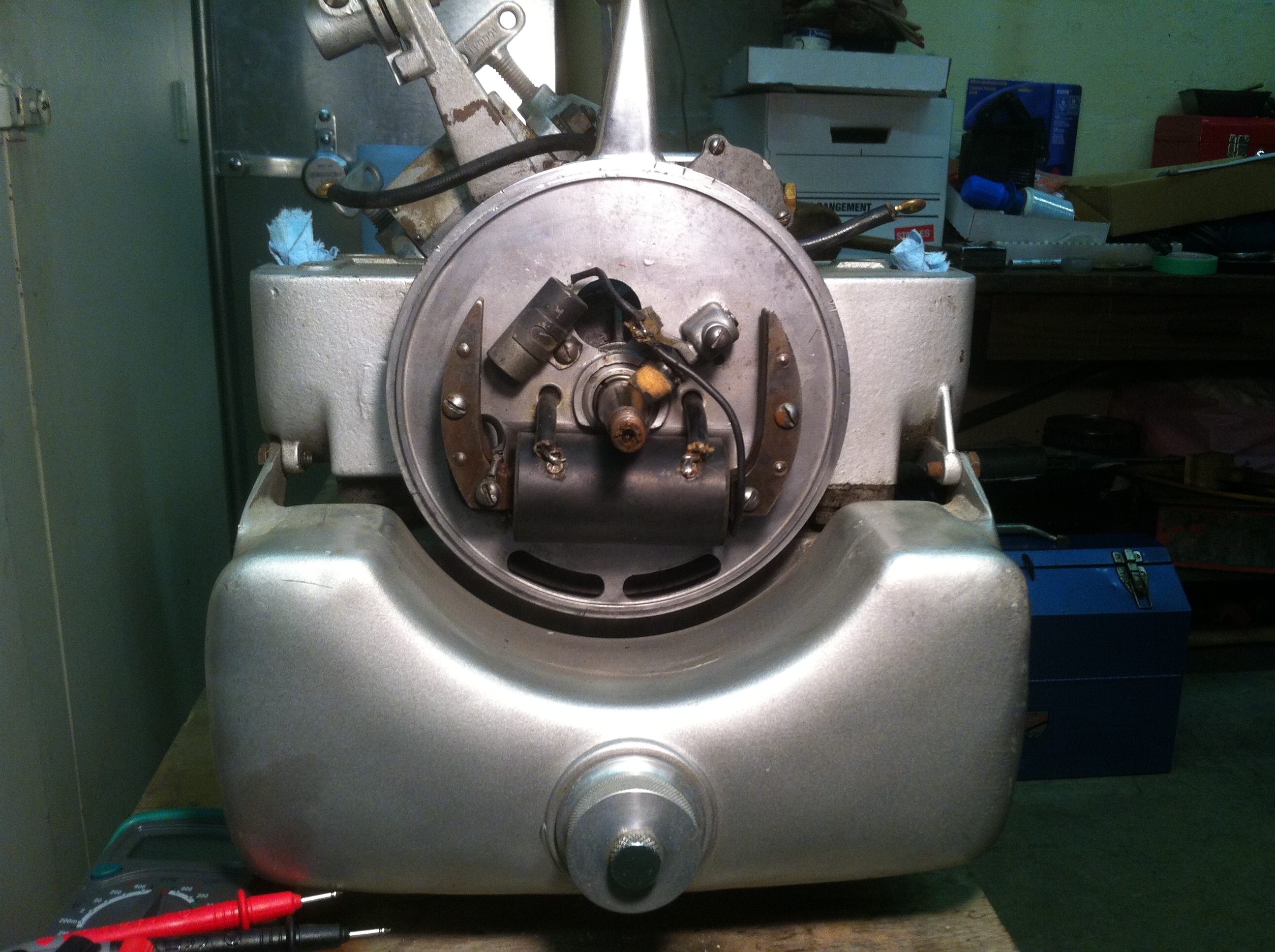

I was lucky enough to pick up this Evinrude fisherman a number of years ago, and now I’m retired, I’ve got it out and am learning about it, and was going to see if I can get it running. It looks in decent shape and would look nice on our 14′ whitehall.Evinrude Fisherman 2cyl

(Model 4148, 4.4hp, 1936)

Transom clamp ID plate missing but a Brass disc fwd side of port cyl has following markings;

OMC

4148 (model)

0198 (s/n?)Spark plugs installed AC 84-M

I have three questions initially;

1) the water intake on the lower unit looks like there was a brass debris screen soldered on at one time, but has been removed. Would it be a good idea to replace it?

2) The how much grease should be in the lower unit? I’m assuming JD corn head grease would be good.

3) And finally, the big one, the engine has no spark… The primary coil (I’m assuming that both plugs fire together) seems to be fine, but the secondary seems to open (no continuity). Any thoughts on repair/replacements?

Many thanks,

RossMarch 21, 2018 at 7:07 pm #72826Question #1 Yes there is to be a screen there, and yes you can replace it…

Question #2 Fill her up sort of, if that makes sense, I have heard that if you get too much grease in there it somehow migrates up to block that water inlet…I have one of these but but as nice as yours.Question #3 These older coils were really good, so might I suggest making good and sure the points are clean as a whistle, also check your condenser, I would suspect that once the points are spotless and rope it over good you "should" see spark.

I had the same issue with my latest a Johnson PL40, no spark, cleaned the points meticulously, clean around the circumference of the point faces as well, as I have seen points that the face was fine but had crud around the perimeter of the points that prevented it from sparking. Once cleaned properly she sparked.

Good luck and great motor

Richard

http://www.richardsoutboardtools.com

classicomctools@gmail.comMarch 22, 2018 at 12:38 pm #72855March 22, 2018 at 1:07 pm #72858"3) And finally, the big one, the engine has no spark… The primary coil (I’m assuming that both plugs fire together) seems to be fine, but the secondary seems to open (no continuity)."

Are you measuring across the two high tension leads? Or are you measuring from each lead to ground or a primary wire?

Tom

March 22, 2018 at 3:06 pm #72862Thanks very much for the replies, and info!

Tom, I was measuring from either end of both HT leads (coil joint and also plug ring) to ground.

I will double check all the pointers that Richard kindly offered, but I fear that replacement is in order.

I’m glad to see Tubs mentioning refitting newer coils, the photo gives me much hope!

RossMarch 22, 2018 at 4:34 pm #72864Well that’s GOOD NEWS!

Don’t measure from HT lead to ground. Measure across the two of them. The secondary winding is independent of the primary on this coil.

Let us know the results.

T

March 22, 2018 at 5:55 pm #72866Thanks Tom! I will be able to get down to the shop later today, or tomorrow and will take a reading and let you know.

I sure do appreciate the guidance, it really helps!

RossMarch 23, 2018 at 7:06 pm #72915Ok, the resistance reading across the primary windings of the coil is 0.7 ohm, and across the secondary (the two spark leads) is 7.8K ohm. So possibly not a coil issue?

I have removed the ignition plate to adequately clean everything, including the points, check the condenser, etc.

I notice that the FW magnets are pretty weak, they may need to be remagnetized.

Thoughts?

Thanks,

RMarch 23, 2018 at 7:20 pm #72918Coil is likely good with those readings. Clean up all connections and contacts and see what you have. Both plugs must be grounded to the block to get spark in them, so hook up the wires and rest them on top of the cylinders to test for spark.

T

March 23, 2018 at 10:13 pm #72926Tom, That’s what I did, a good clean up of the whole ignition deck and components,( capacitor measures 250nF (.25uF)) and we have spark! Both sides! Good advice, thanks!

A bit of release-all in each cylinder for a soak, and pulled the lower unit (felt a bit rough). Very little grease in there, and consistency of beeswax…. A scrape and wash out, and a temporary testing repack with chassis grease (just until I can run up the valley and get some corn head grease) and she now spins over quite nicely. Might just try to fire her up this weekend….

😉

R -

AuthorPosts

- You must be logged in to reply to this topic.