Home › Forum › Ask A Member › 1937 Johnson #210 magnetos salvageable?

- This topic has 8 replies, 6 voices, and was last updated 5 years, 5 months ago by

jeff-register.

-

AuthorPosts

-

January 20, 2020 at 8:03 pm #192682

Took the cover off and found some damage to the aluminum wheel where the coil and magnetos are located.

Need help in seeing if the coil, magnetos are salvageable? If not where I could replacements.

January 21, 2020 at 7:57 am #192704Early Johnson coils are rarely bad.You can easily check it with a multi-meter.The condenser will probably need to be replaced,easily found at auto parts store.Clean the points,put on new wires and ends.The plate itself is remarkably thin and easily broken where the handle attaches.There were a lot of those motors made so you should be able to find replacement by placing want ad in classifieds.

January 21, 2020 at 10:52 am #192719January 25, 2020 at 10:34 pm #193088I may have a stator plate to replace that broken one.

January 25, 2020 at 11:26 pm #193090If you decide to replace your mag plate, the same 72-790 plate was used on several different models.

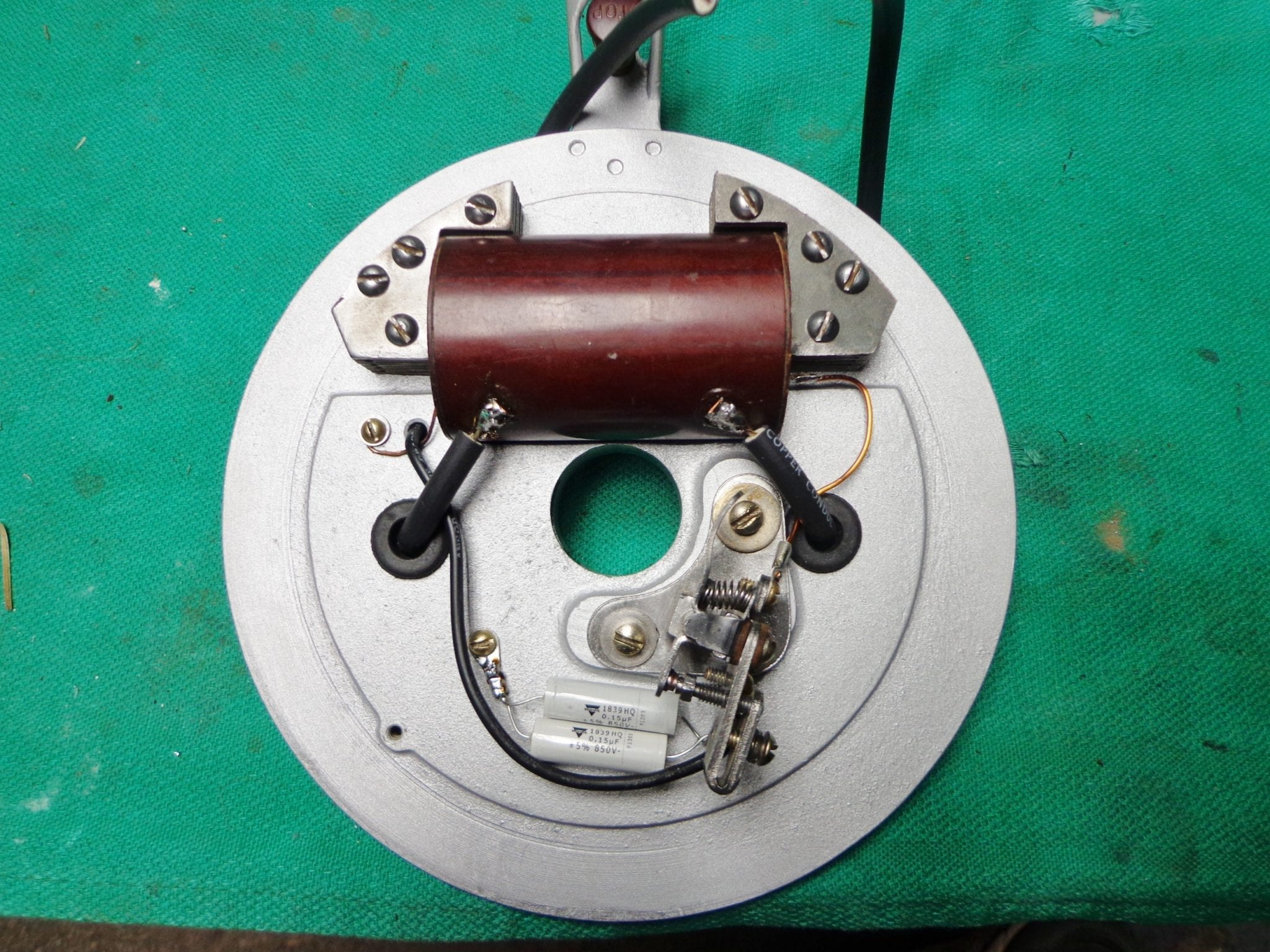

With a little bit of determination, you should be able to get that mag looking and sparking like new again. The original capacitor (condenser) for these mags was rated at .27 – .33 microfarads but in the photo I’ve used two axial caps rated at .15 mfd hooked up in parallel to get the same .30 rating.

January 28, 2020 at 12:19 pm #193335Thank you all for your help! Really appreciate the feed back!!

January 28, 2020 at 12:27 pm #193339

If you decide to replace your mag plate, the same 72-790 plate was used on several different models.

With a little bit of determination, you should be able to get that mag looking and sparking like new again. The original capacitor (condenser) for these mags was rated at .27 – .33 microfarads but in the photo I’ve used two axial caps rated at .15 mfd hooked up in parallel to get the same .30 rating.

Mumbles

Mag plate looks good! Did you sand blast? What product did you use?January 28, 2020 at 1:54 pm #193354No bead blasting on this one. Just a really thorough cleaning followed by a coat of PlastiKote 282 Cast Aluminum and a NOS coil.

I like to paint all my mag plates and carbs after rebuilding so I can tell at a glance if they have been worked on or not. Since I’m not very good in the record keeping department, this cosmetic painting comes in real handy. Especially when a motor is put away and forgotten about for a few years.

January 30, 2020 at 2:07 pm #193558I agree with the soldering. When repairing Tin or solder the spark plug wire before trying to solder. Then hold the wire on the coil hi volt terminal & apply heat to the wire. When you see the solder melt & shiny get the heat off fast. Try to not overheat the coil as the winds are very thin. For added protection get super corona dope and coat the coils. It’s a high voltage coating insulator, MG chemicals.com.

-

AuthorPosts

- You must be logged in to reply to this topic.