Home › Forum › Ask A Member › 1937 Thor ~ Sea King 2.4 hp

- This topic has 16 replies, 6 voices, and was last updated 7 years, 6 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

March 24, 2018 at 1:14 pm #9480

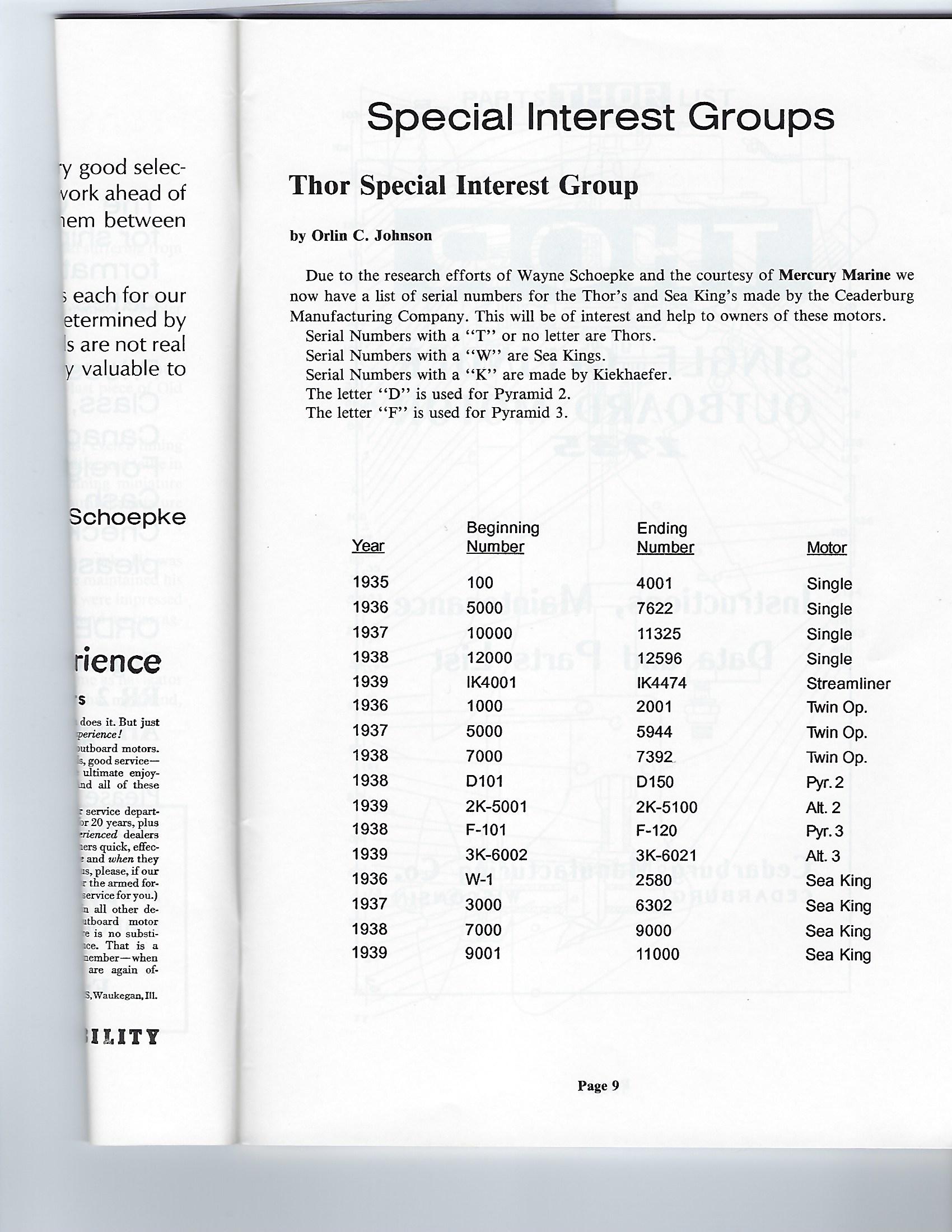

Initial research says I have a Thor built Sea King, as the

serial number starts with "WK", and that it’s 2.4 hp.

It has virtually no compression, and is missing the tiller

handle. If anyone has photos of a complete unit

with the tiller handle, I’d be curious to see how it

engages in the socket in the front of the power head.

Also, is there any digital literature or manuals "out there"

for this one?

Thanks!Prepare to be boarded!

March 24, 2018 at 3:32 pm #72957March 24, 2018 at 4:20 pm #72960Mumbles, thanks for the pics. Neat to see all of those Thors!

I’m guessing your tiller is incorrect, in at least in the sense that

it’s sticking in the wrong side. Note on mine that the starboard

side hole in the tiller socket has a piece of spring still rivited

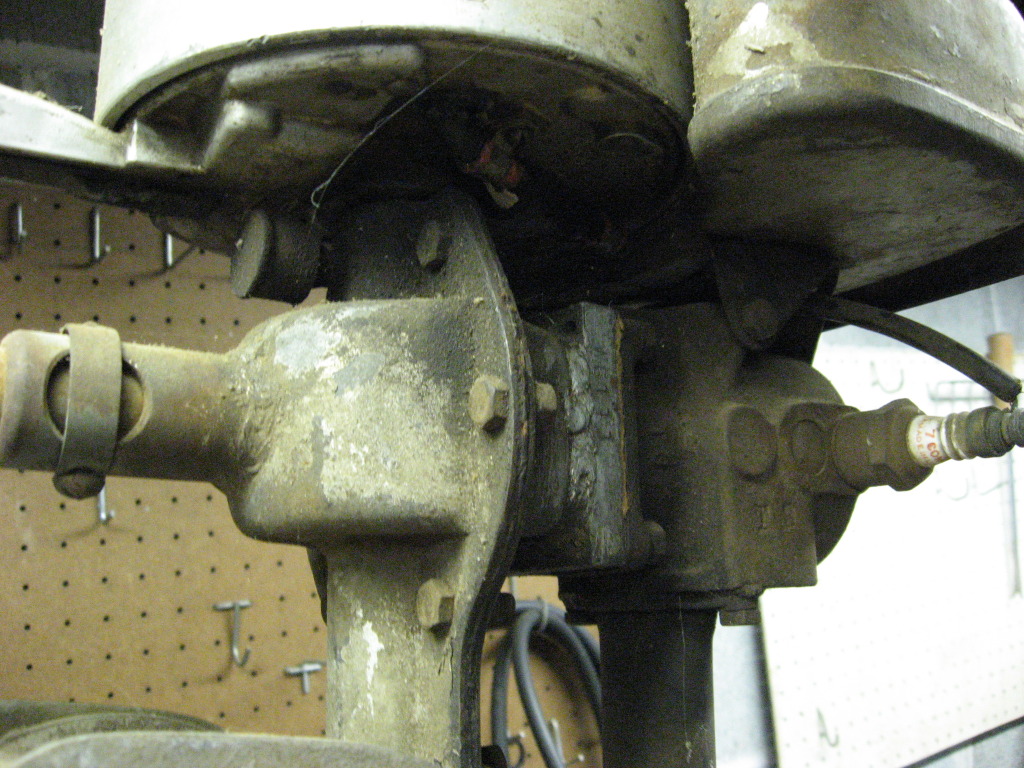

over it. That’s why I’m curious how the set-up is suppose to work.As I’m tearing a few things apart on it this morning, I’m wondering

if the flywheel, rope pulley, and the spacer between them are

original. Doesn’t look right to me. Took some pictures, but

the camera is out in the garage.

Will be curious as to why it has no compression, so heading back

to the garage now!

Thanks!Prepare to be boarded!

March 24, 2018 at 7:19 pm #72961March 24, 2018 at 8:39 pm #72962Fifty2One, Thanks for the photos and data.

I can’t tell from your photo how that clip

is holding the handle in place. Perhaps you

can describe?

The one photo appears to show a grease cup

under the magneto. Mine does not have that.I found out why mine has no compression.

The piston rings are AWOL. 😮

To compound the problem, the piston is .020

oversize. I have not researched replacements yet.

The piston is for a 2.020 bore, and the ring width

needs to be 1/8".The crank bushings are a tad loose, but

they have bronze bushing inserts, 3/4" ID

x .875 OD x 1-1/2" long, so I probably

could replace them.The crankshaft was fitted with some shim stock

to tighten the flywheel on the taper.

Any "fix" for this, other than a different flywheel?Is that spacer between the flywheel and rope pulley

original?Prepare to be boarded!

March 25, 2018 at 1:34 am #72972The crankcase bushings on those Thors were known to wear out real quick if the oil concentration in the fuel wasn’t heavy enough.

Good news is they are easy to replace, since they are just an insert held in between the two steel stampings. Bad news is you have to machine them and make sure the concentricity of the ID to the OD is bang on. Use SAE 660 bearing bronze if you do make new ones. Don’t try to get by with an Oilite bushing insert.

There was an aluminum plate in between the rope sheave and flywheel as I recall on my former Thor.

Shim stock on the flywheel taper isn’t usually a good sign. It indicates that the likelyhood is very high that a previous mechanic has overtightened the flywheel nut, causing the tapered section of the flywheel hub to open up as it got forced too far downward on the taper. If you take the shim stock out and put the flywheel back on the crank with the magneto plate installed, you will probably find that the flywheel sits down too low, and makes contact with the coil heels or some other part on the mag plate. If this is the case, you are correct that one sure fix is a replacement flywheel. But you can probably re-use the shim stock and get away with it.

Hope this helps.

Best,

PM T2He's livin' in his own private Idaho..... I hope to go out quietly in my sleep, like my grand-dad did..... and not screaming, like the passengers in his car...

March 25, 2018 at 1:39 am #72973Further on the crank bushings – measure things to eliminate the guess-work. You want to turn "a tad loose" into knowing exactly what your clearances are. Those bearings should not have any more than about 0.003" clearance, otherwise it will be difficult to start due to sucking in too much air around the crank journals. If thee clearance is great er than 0.003", you can get by with applying grease to the journals when you assemble it, but the effect the grease has on startability won’t last forever.

Best,

PM T2He's livin' in his own private Idaho..... I hope to go out quietly in my sleep, like my grand-dad did..... and not screaming, like the passengers in his car...

March 25, 2018 at 2:04 am #72974PM T2, thanks for the tips on the bronze bushings. Will have

to look up 660 bronze. Perhaps I could get by without

line reaming the two bearings together (don’t have the

correct reamer anyway) as the bearings cases are sandwiched

between the two crank halves in rubber, and should somewhat

self align.

If I can’t find .020 oversize rings for the piston, the bearings won’t

matter much!Prepare to be boarded!

March 25, 2018 at 5:38 am #72981If rings are all you need, you’re way ahead of the game!

That ’37 Sea King of mine seems like a motor from hell as it needed lots of work and still does. The mixture needle was rusted off so I had to guestimate what it should look like. After making a knurled one, I found out I got it wrong. Apparently the original is a just a bent piece of 1/4" rod material. The waterpump cam was totally worn out and so was the driveshaft so I made a new shaft and cam and sleeved the pump housing and used a pump plunger from a donor Johnson motor. New bushings were made for the gearcase and the powerhead and oil seals were adapted to the propshaft and upper crankshaft. The crankshaft seems soft and bends easily and it was a bear to keep it spinning freely while tightening up the crankcase halves. I ended up cutting gaskets for the cases and using The Right Stuff by Permatex to try and keep the alignment good and the cases sealed. After all that I found out my tank is rusted thru all over the place. On the bright side, it has rings and I think the coil is good!

March 25, 2018 at 11:33 am #72984I have lots of respect to you guys that can take engines in such poor condition and bring them back to life!!

-

AuthorPosts

- You must be logged in to reply to this topic.