Home › Forum › Ask A Member › 1939 Johnson Seahorse

- This topic has 11 replies, 4 voices, and was last updated 2 years, 10 months ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

May 28, 2022 at 11:41 pm #260599

27E250 is just a casting number of little significance. Sounds like you have a model KA-39 which is stamped on top of the rope sheave.

May 29, 2022 at 7:39 am #260601Thank you!

May 29, 2022 at 5:04 pm #260621Harry, would it be possible for you to give me a short tutorial on how to start this motor? The earliest that I’ve gotten running is a 1963 3hp Johnson.

Thank you,

Dave Jenkins

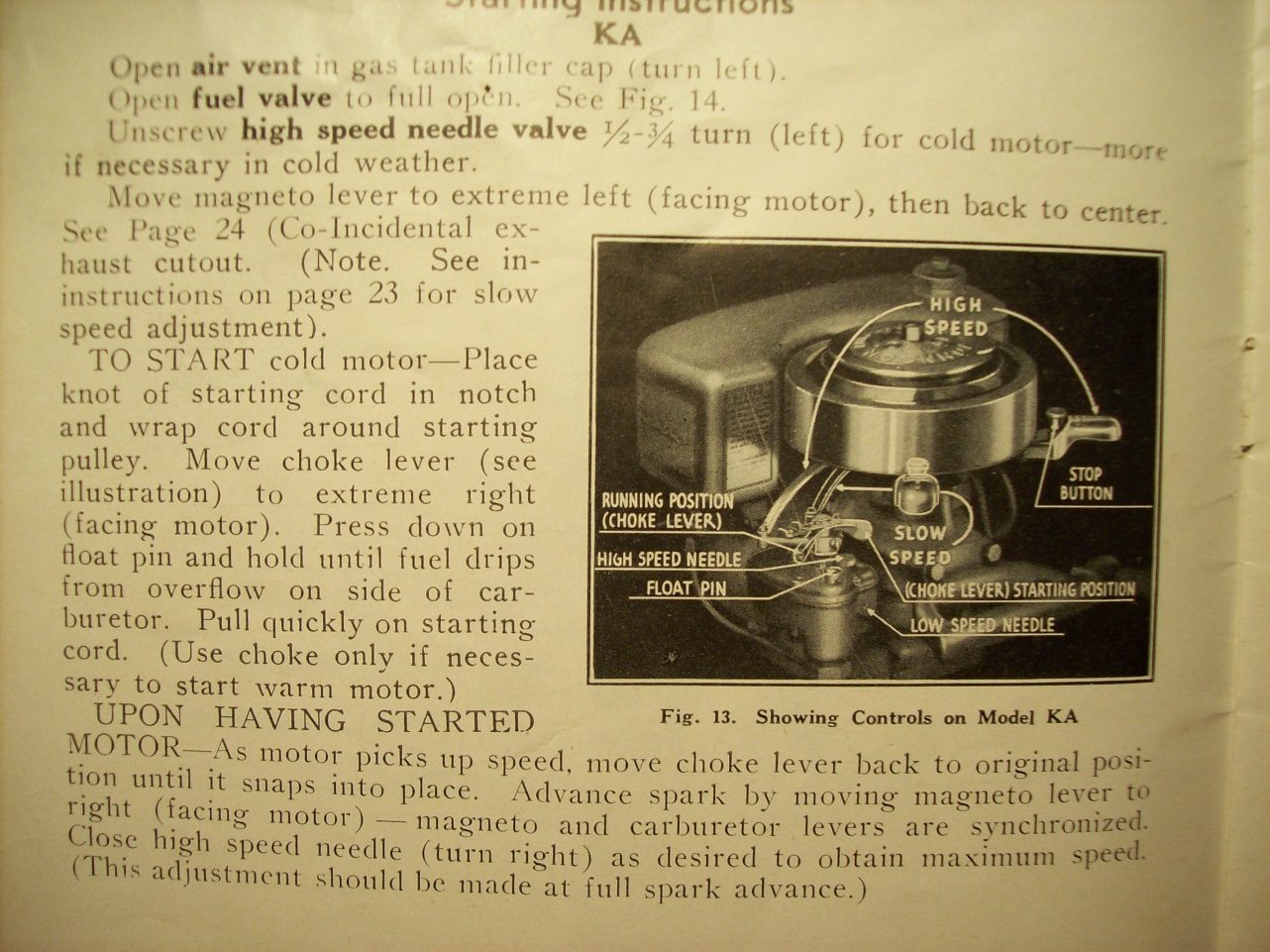

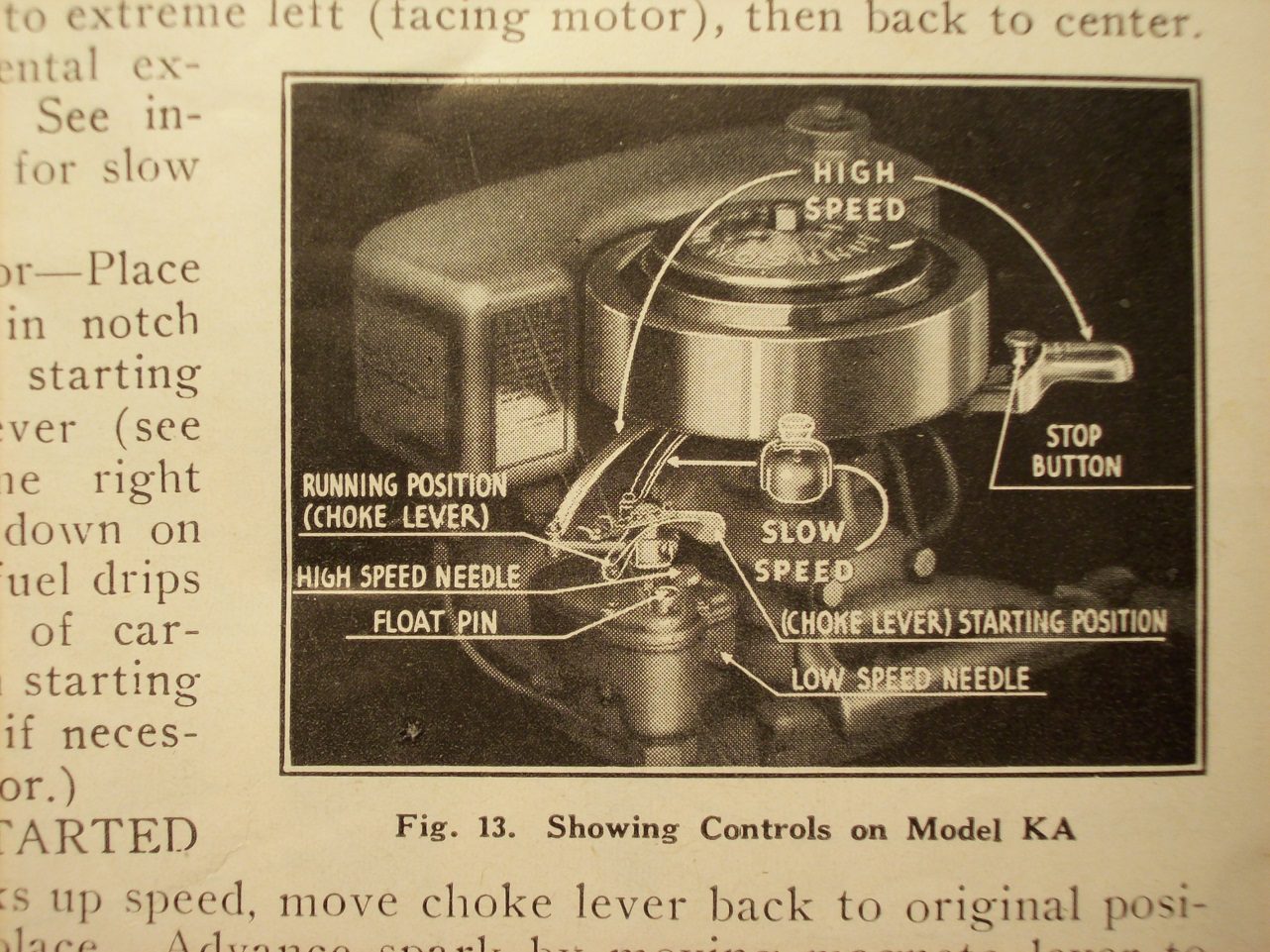

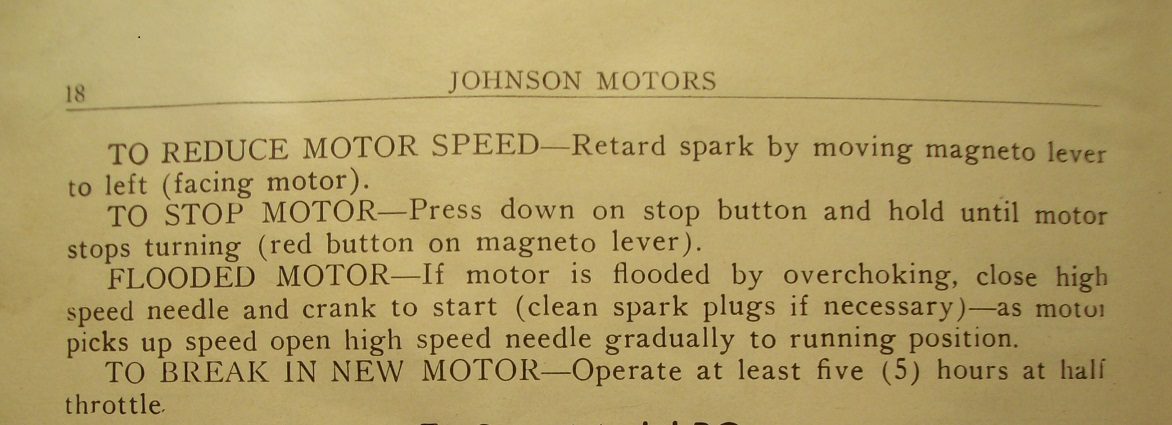

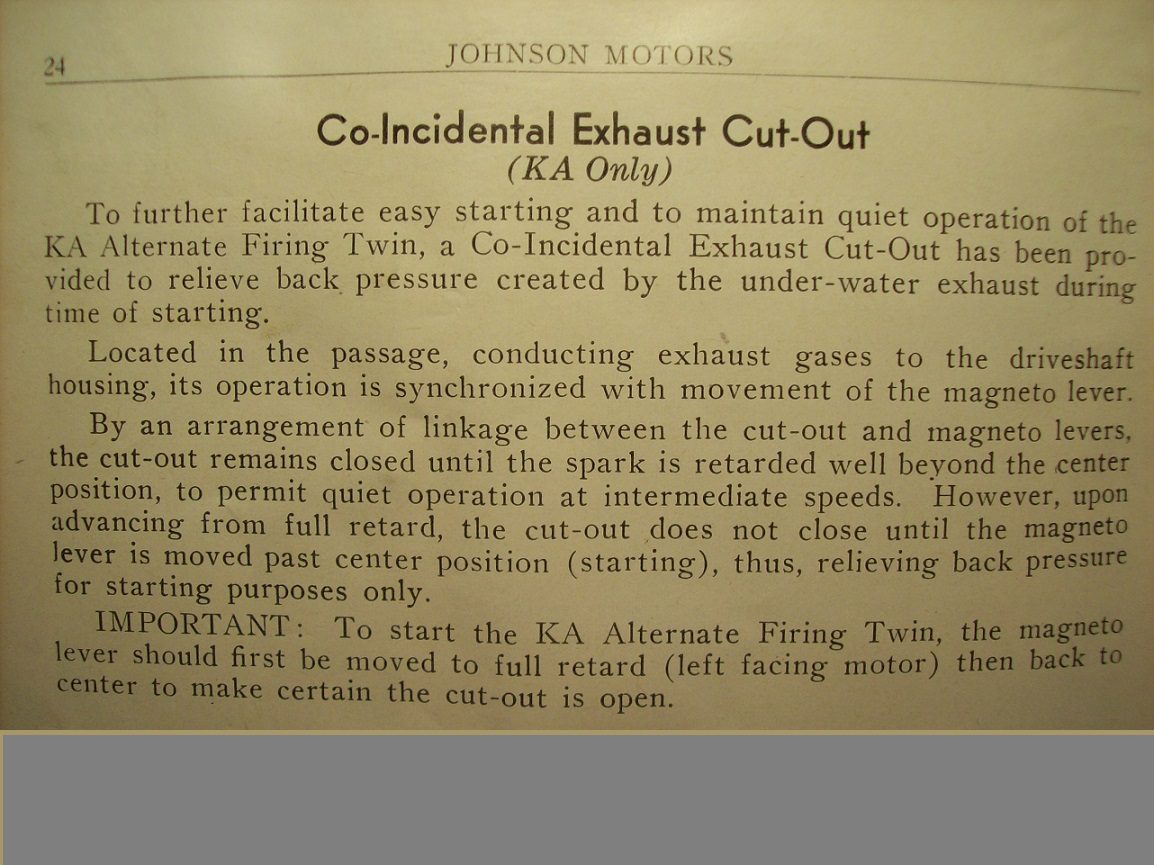

May 29, 2022 at 11:12 pm #260641May 29, 2022 at 11:35 pm #260647There are the starting instructions in the pics. Starting is easier done than written.

KA-39 is 9.8HP at 4000rpm, weighs 64 pounds, has no moving water pump parts – it uses the pressure from the prop blades to push water up to the cylinders and also sucks to exit water from the water passages, prop is 3 blade with 9 1/2″ dia & 9″ pitch, fuel ratio is 1 pint of 40 weight oil to each gallon of regular (no-lead) gas, steering tension is adjustable with a nut, the gearcase should be drained of water by removing both “VENT” and “GREASE” plugs and filled with lubriplate 105 or John Deere Corn Head grease, do not remove the “DRAIN” plug which is for draining the water system only, spark plugs were Champion 5M or AC5 (Champion D9J nowadays) gapped at .025″, contact points in magneto need to be clean and gapped at .020″, flywheel & crankshaft tapers should never be lubed – they need to be clean & dry always, check or tighten flywheel nut each time, after starting the motor go fast to remove air from the system- then you can safely go slow, there is no visible water outlet – the system must be airtight, there are 2 fuel screens which are dirty – one is in a tubular shape soldered into the top of the gas shutoff valve inside the tank end and the other is washer shaped on the end of the fuel line at the carb attachment, carb is probably also dirty- just clean it (never blow air into a carb which can collapse the brass float).

May 30, 2022 at 12:02 pm #2606868:1 fuel mix, not 16 or 24:1. The large rotary valve on the crank is probably the reason for the extra oil needed.

May 30, 2022 at 4:12 pm #260703Thank you so much!

June 1, 2022 at 7:12 pm #260823Another question. The fuel tank is pretty banged up. Does anybody have a nice tank? Or, who can educate me on who can repair this tank? Or, can I tackle it myself. I’ve heard that it’s labor intensive, and, therefore, expensive, but I would like to know what my options are.

Thanks!

June 1, 2022 at 10:34 pm #260830A 1942 Johnson book states that the same tank fits models K-80, KA-37, KA-38, KA-39, KA-10, KS-15, KD-15. They may or may not be identical (needs comparing) but they will fit and function. Many Of these model motors are around so a tank should be most easily available. Doing it yourself can be an interesting learning experience applicable to other tanks which are not common. I did a K-65 tank once which came out very nice, good enough to polish. I cut out a section on the inside face behind the flywheel big enough to access the dents and TIG welded it back together. It takes lots of time and care though.

A KA-39 tank may be a painted tank, which would be easier since bondo and sanding can be used.

-

This reply was modified 2 years, 10 months ago by

HARRY D. NICHOLSON.

-

This reply was modified 2 years, 10 months ago by

HARRY D. NICHOLSON.

June 4, 2022 at 9:15 am #260954Another question. The fuel tank is pretty banged up. Does anybody have a nice tank? Or, who can educate me on who can repair this tank? Or, can I tackle it myself. I’ve heard that it’s labor intensive, and, therefore, expensive, but I would like to know what my options are.

Thanks!

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

-

This reply was modified 2 years, 10 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.