Home › Forum › Ask A Member › 1940 Elto Handitwin 4357

- This topic has 7 replies, 4 voices, and was last updated 6 years, 7 months ago by

Damn342.

-

AuthorPosts

-

May 2, 2019 at 12:58 pm #174686

Just acquired this unit and am looking for some info

1 I have no spark and am looking for a procedure to test the secondary in the coil.. The primary tests ok but I am not sure I am testing the secondary correctly.. I am also exploring coil replacement options any suggestions are welcome..

2 what is period correct for spark plugs push on style or screw on ring terminals?

3 Fuel leaking from float pin in carb. any thoughts I assume a new float and reseat the float pin as well ….

May 2, 2019 at 1:16 pm #174691I believe the originals were Champion 8COM plugs which are NLA. I am using D16’s and I bought brass screw on terminals to make it look a little better.

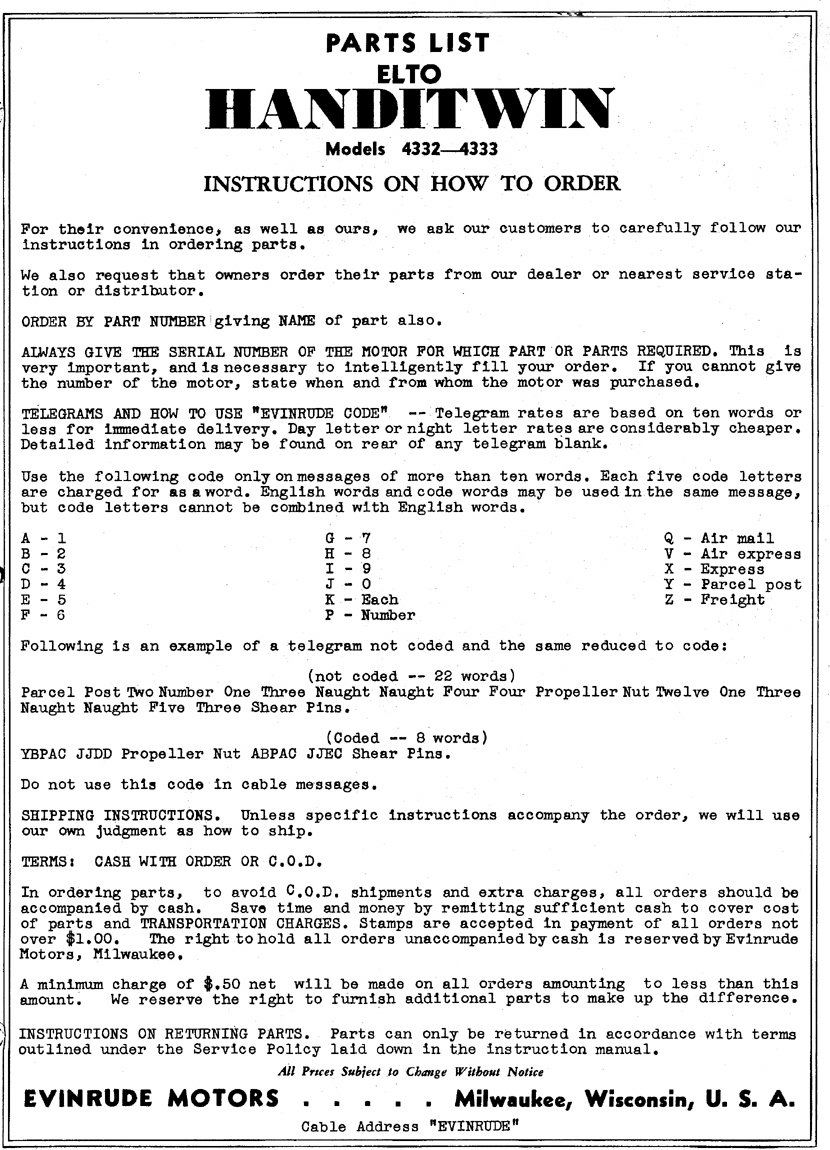

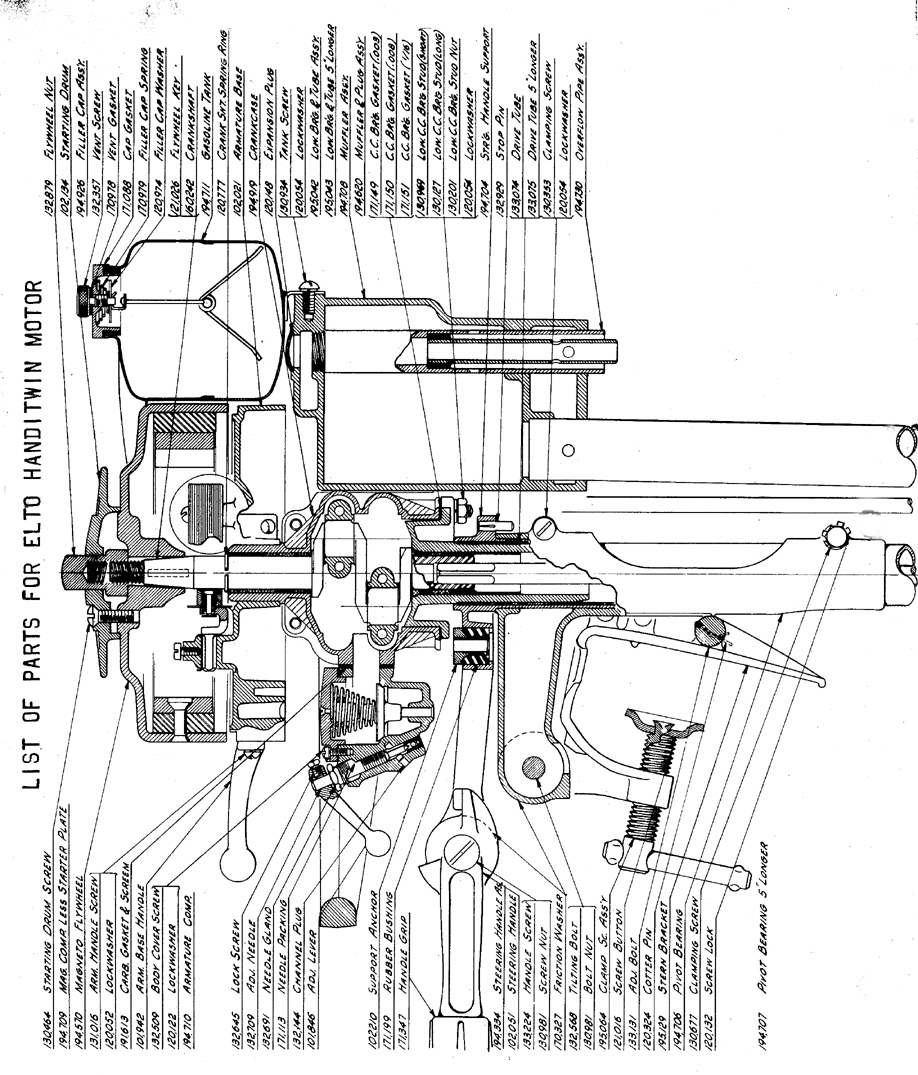

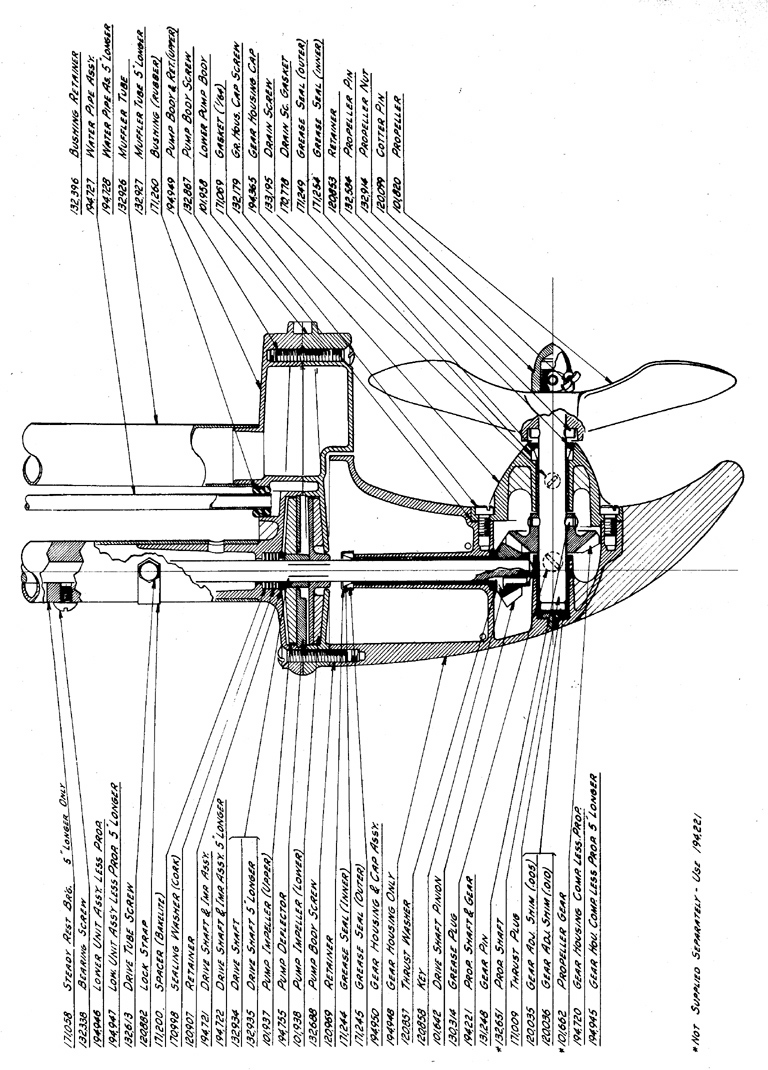

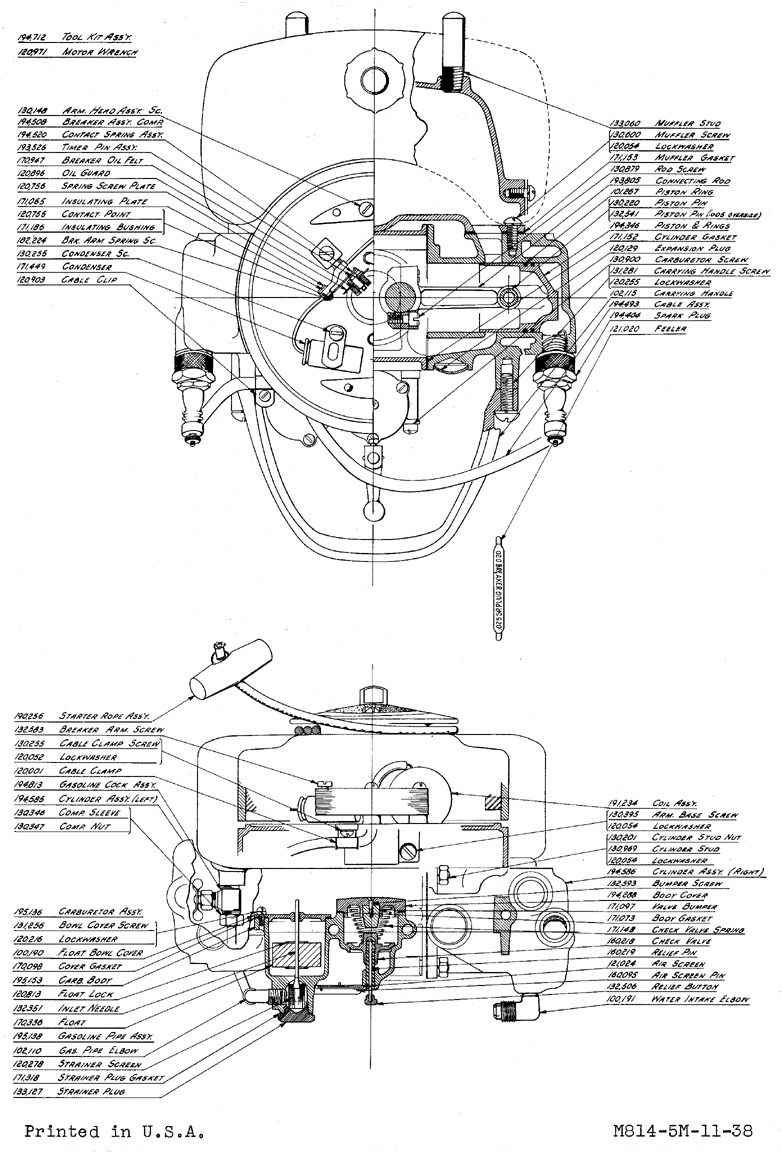

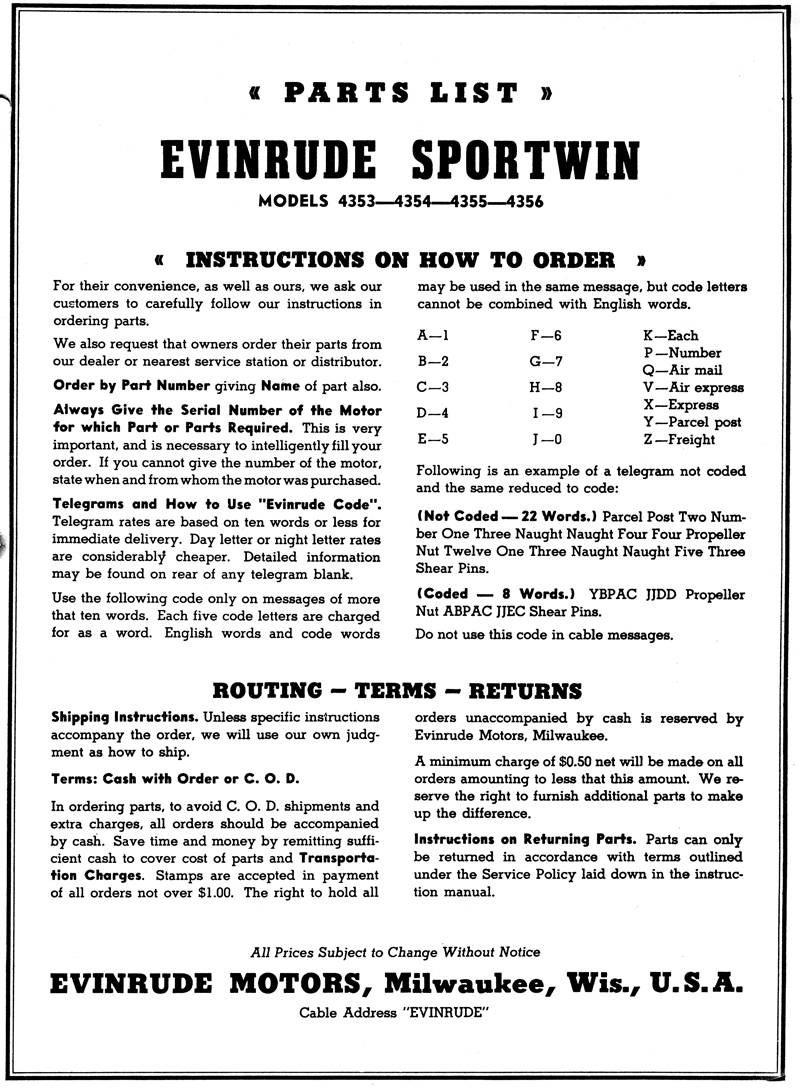

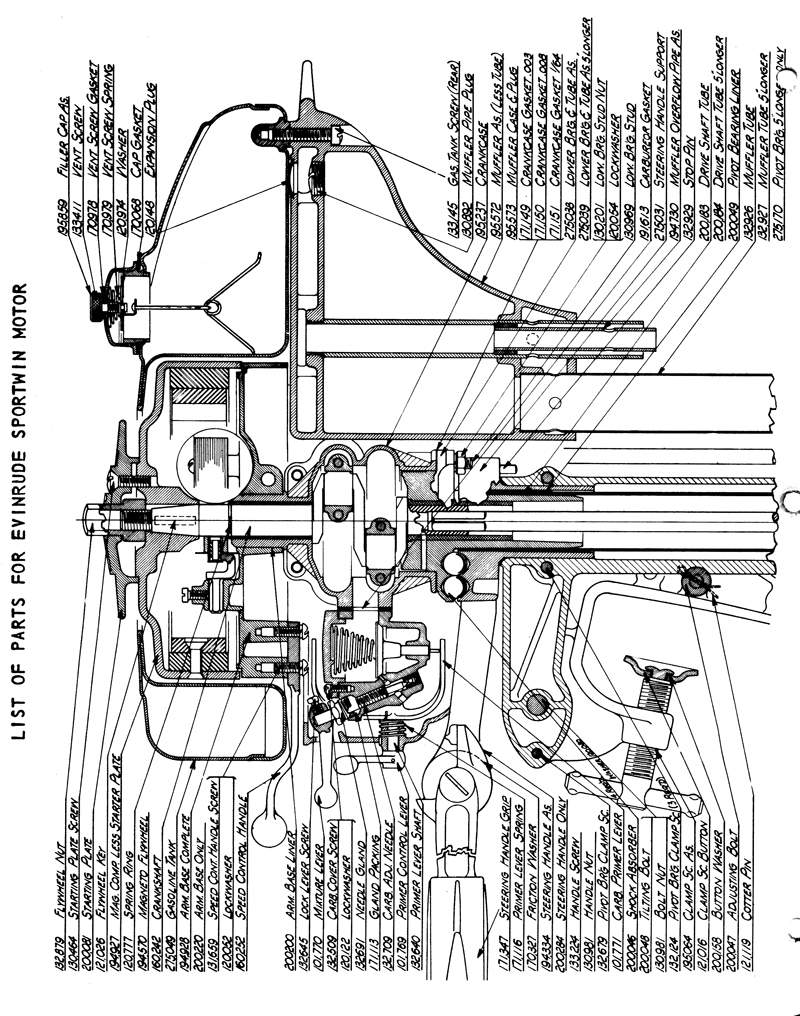

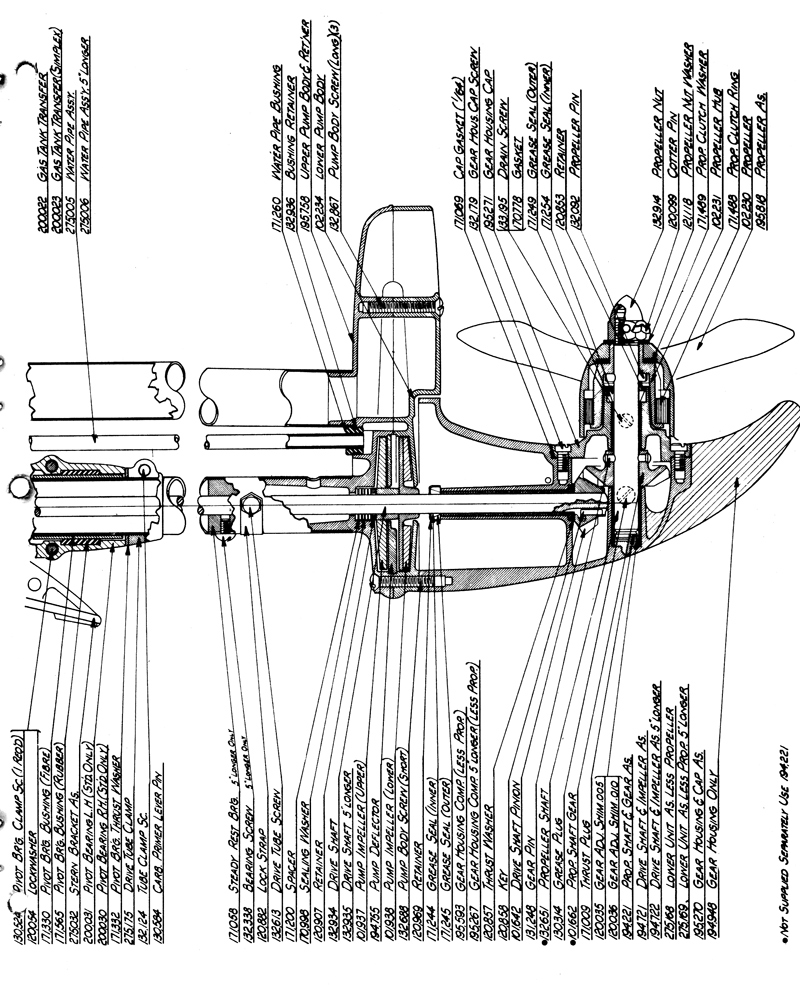

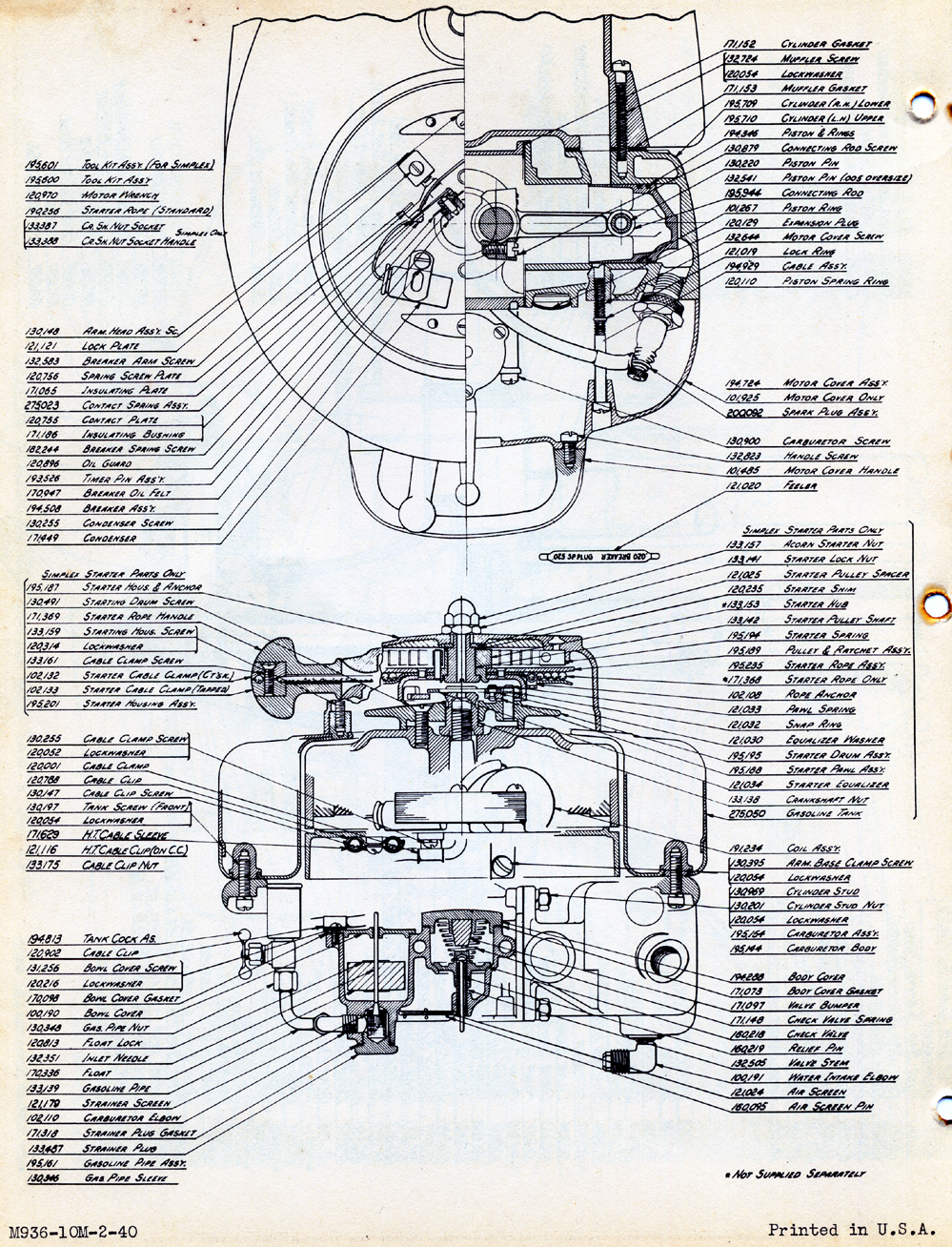

May 2, 2019 at 3:15 pm #174695This is what I have on the Elto handitwin – – –

And the Evinrude equivalent – Sportwin.

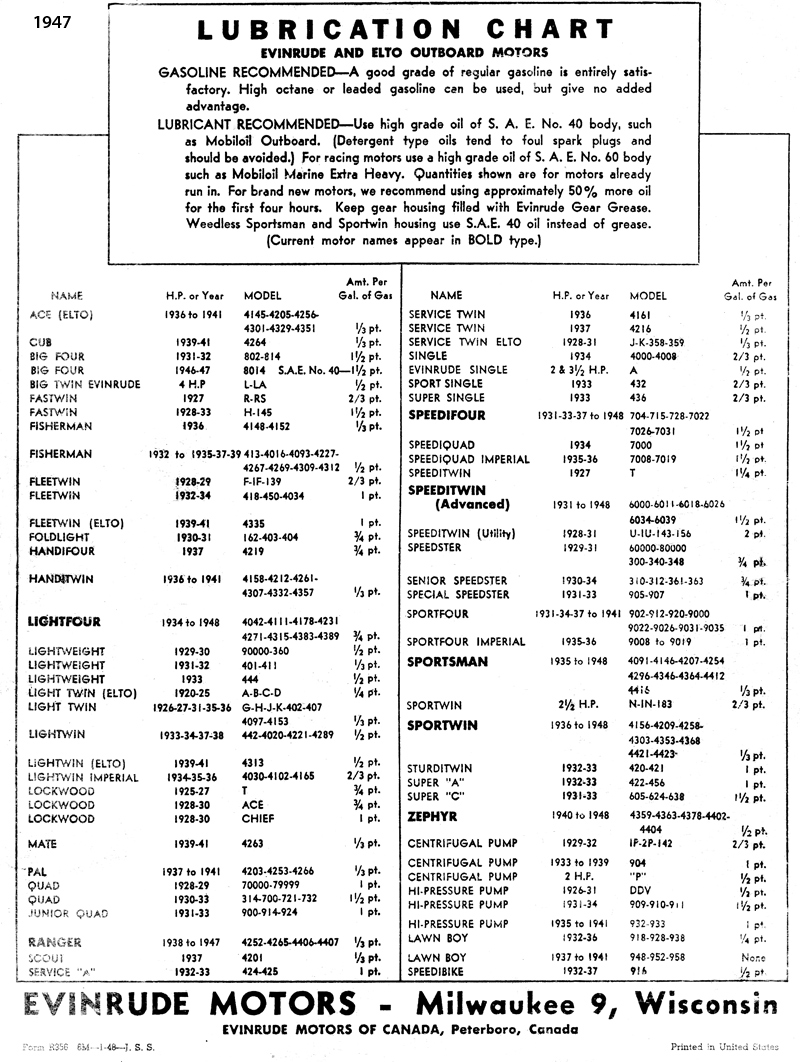

Lubrication –

The recommended Champion CJ-7 spark plug was replaced by the D-16 which is now Champion 526.

The spark plug gap is 0.025″ and the breaker points should be set at 0.020″ The primary coil windings should be under 5 ohms – secondary resistance in read through the high voltage wires and should be in the neighborhood of 5,000 ohms. Much lower resistance indicates some windings may have shorted, lowering the output voltage.THe soft iron magnets can loose there charge if handled carelessly. An iron “Keeper” should be placed across the magnets whenever the flywheel is off the outboard. BE SURE TO REMAVE IT WHEN THE FLYWHEEL IS REPLACED. Flywheel nut torque is 25 foot pounds.

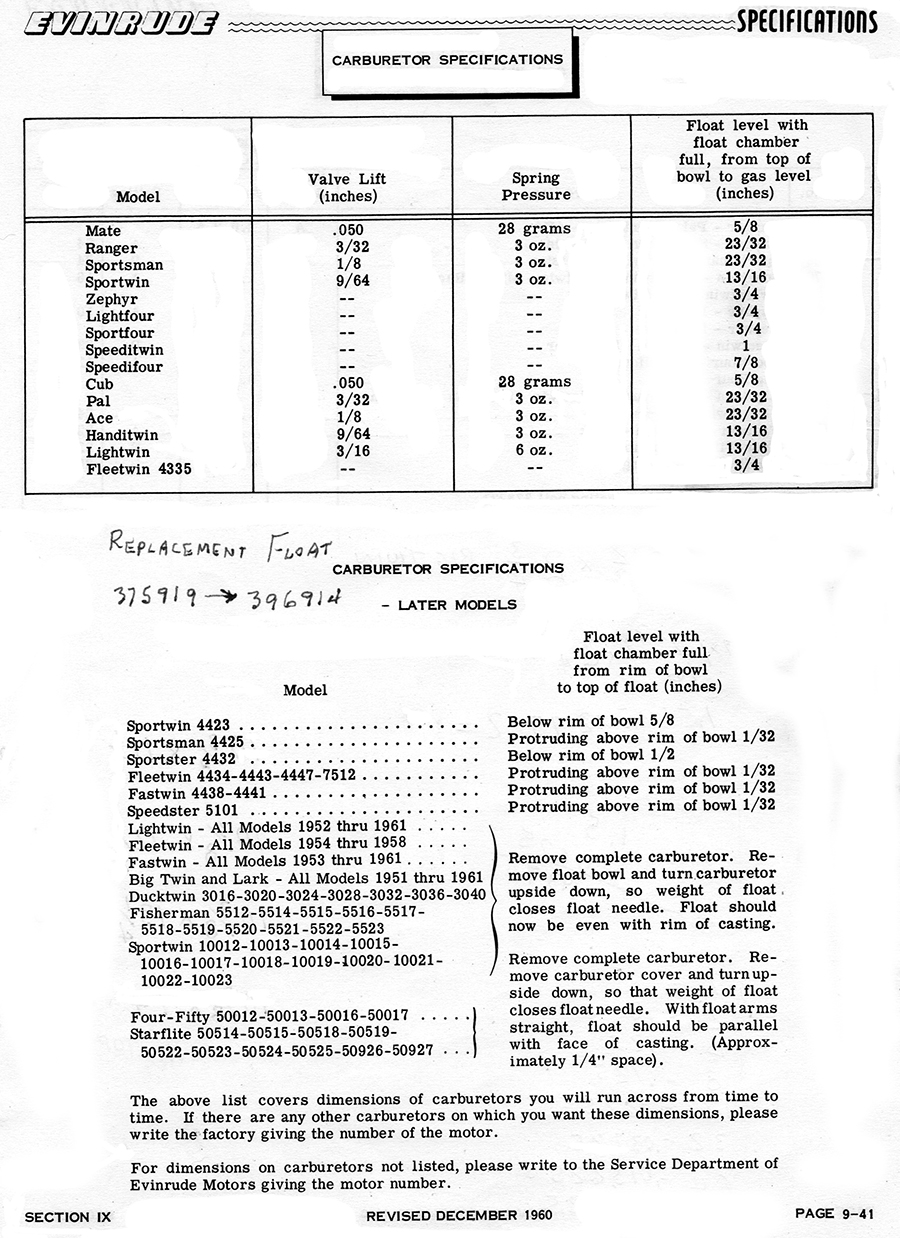

The factory cork seals in the lower unit (Gear case) are not that great – grease is used and I like John Deere Corn Head Grease available at Tractor Supply . . . SAE 40 wt. non-detergent oil mixed with unleaded fuel at a 24 to one ratio. (1/3 of a pint to the gallon) These are the carburetor specs – – –

-

This reply was modified 6 years, 7 months ago by

garry-in-michigan.

garry-in-michigan.

May 2, 2019 at 3:58 pm #174698Thanks for the info…dumb question tho when I test the coil secondary do I test one spark plug wire to ground one at a time or resistance from spark plug wire to spark plug wire? the double coil is confusing me…..

thanks

May 2, 2019 at 4:47 pm #174700The secondary is one winding, from one plug wire to the other. So measure kilohms by attaching a test lead to each spark plug wire. You should see something in the 2-6 kohm range.

When testing spark, make sure you ground one plug wire, and hook up a spark plug (or whatever you use) to the other one.

T

May 2, 2019 at 9:32 pm #174724Thanks guys much appreciated. Have a bad coil then I get on open loop if I measure across the two spark plug wires, but there is no continuity either….so it’s not shorted either …..

One question tho. The keeper mentioned earlier, what is that exactally ? Just some iron between the two magnets on opposite sides of the flywheel ?Thanks again

May 2, 2019 at 11:35 pm #174733Yes – a wrench or other piece of iron. The coil does this when the flywheel is on the motor. Dropping the flywheel, or just throwing it on the workbench without this continuity protection will weaken the magnet. In the old days most outboard repare shops had a magnet recharger. Many members have one today and can (When requested) bring them to meets to recharge flywheels for those who need the surface. The high voltage minding is just a single coil with a plug wire on each end It depends on both plug wires attached to plugs screwed into the motor to complete the circuit. It takes hundreds of turns of wire the boost the 6 volts at the points to the 60.000 volts going to the plugs. That means that wire is very thin and delicate. When everything is right the spark should jump o half inch gap between the ends of the spark plug wires.

-

This reply was modified 6 years, 7 months ago by

garry-in-michigan.

garry-in-michigan.

May 3, 2019 at 10:25 am #174756Thanks guys appreciate the info and getting me pointed the rite direction…

-

This reply was modified 6 years, 7 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.