Home › Forum › Ask A Member › 1947 Mercury KD4 gear case seals

- This topic has 14 replies, 6 voices, and was last updated 4 years, 3 months ago by

dave-bernard.

dave-bernard.

-

AuthorPosts

-

January 15, 2020 at 11:20 am #192115

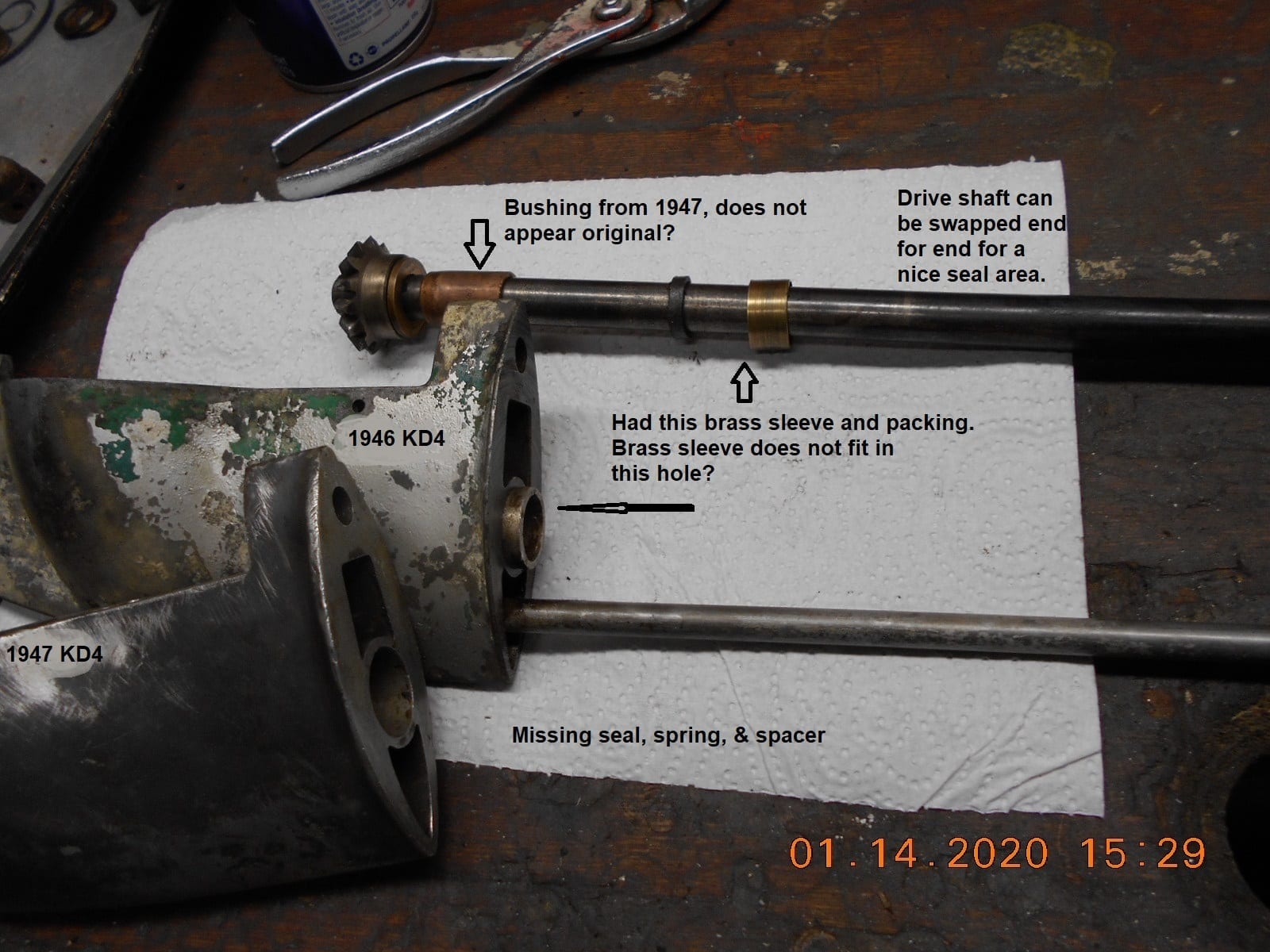

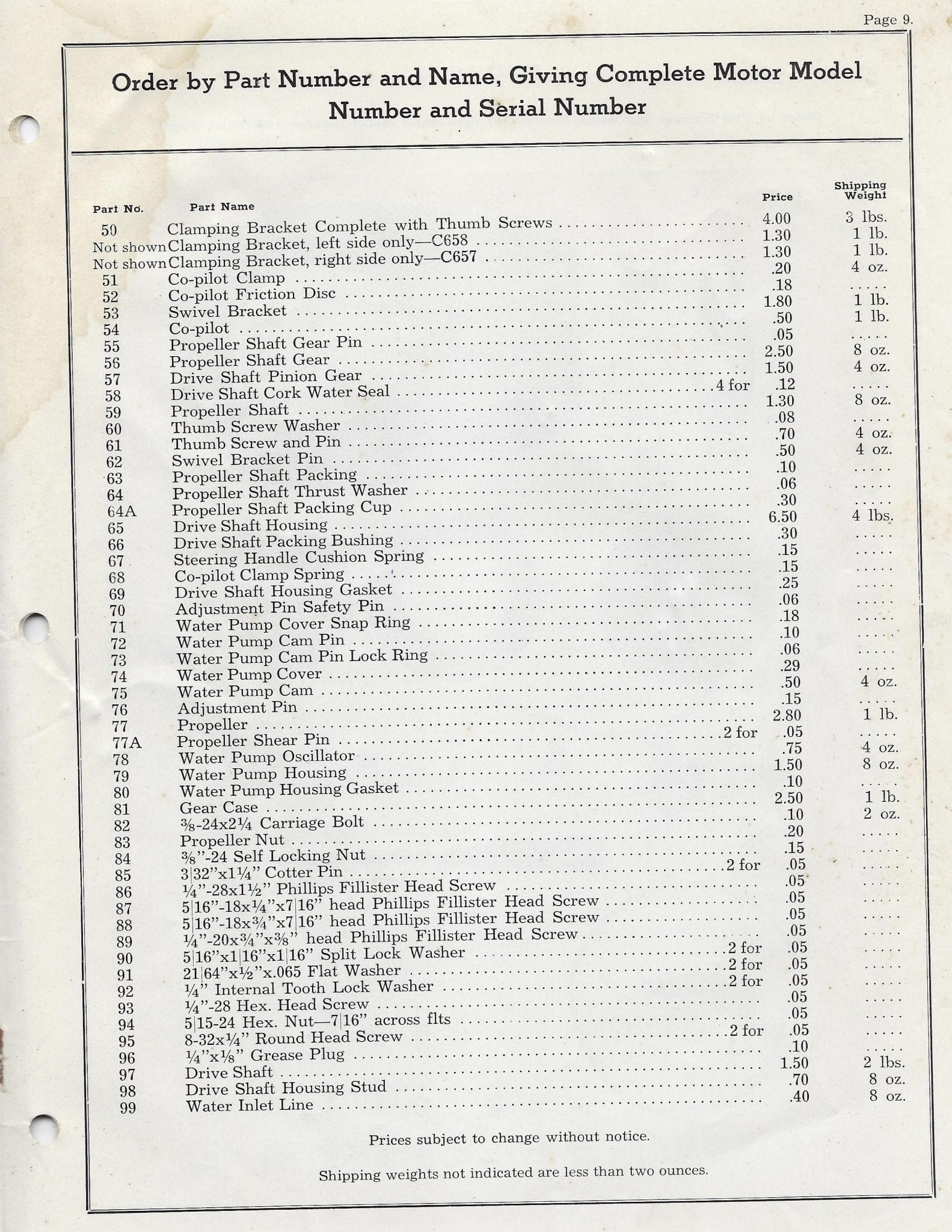

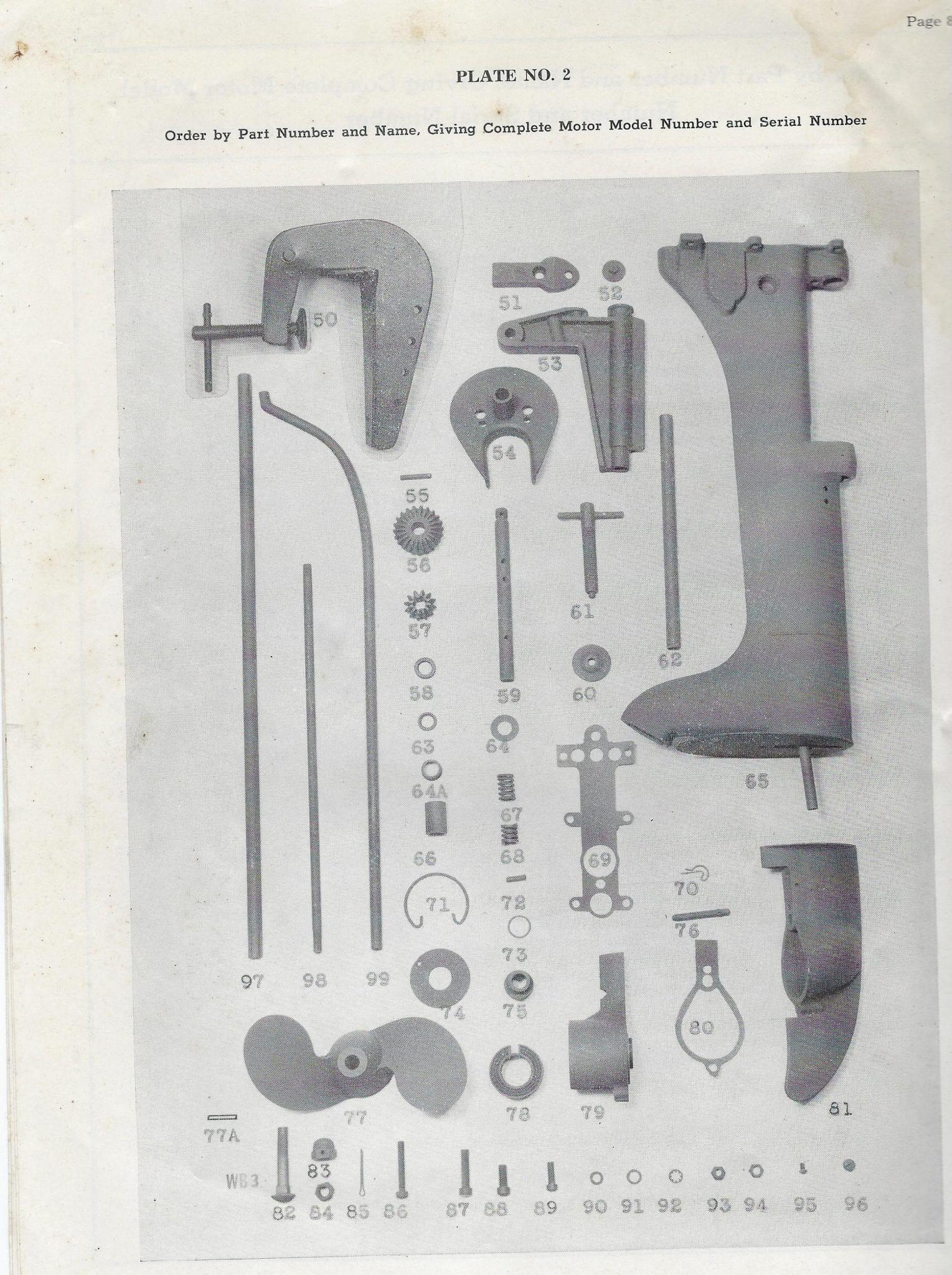

I’ve been examining gear case parts between the 1946 (runner) and 1947 (parts) Mercury KD4,

and seeing what and if I could switch around using some of the best parts.

It appears I can use the 1947 gear case with the vane type water pump impeller (as opposed

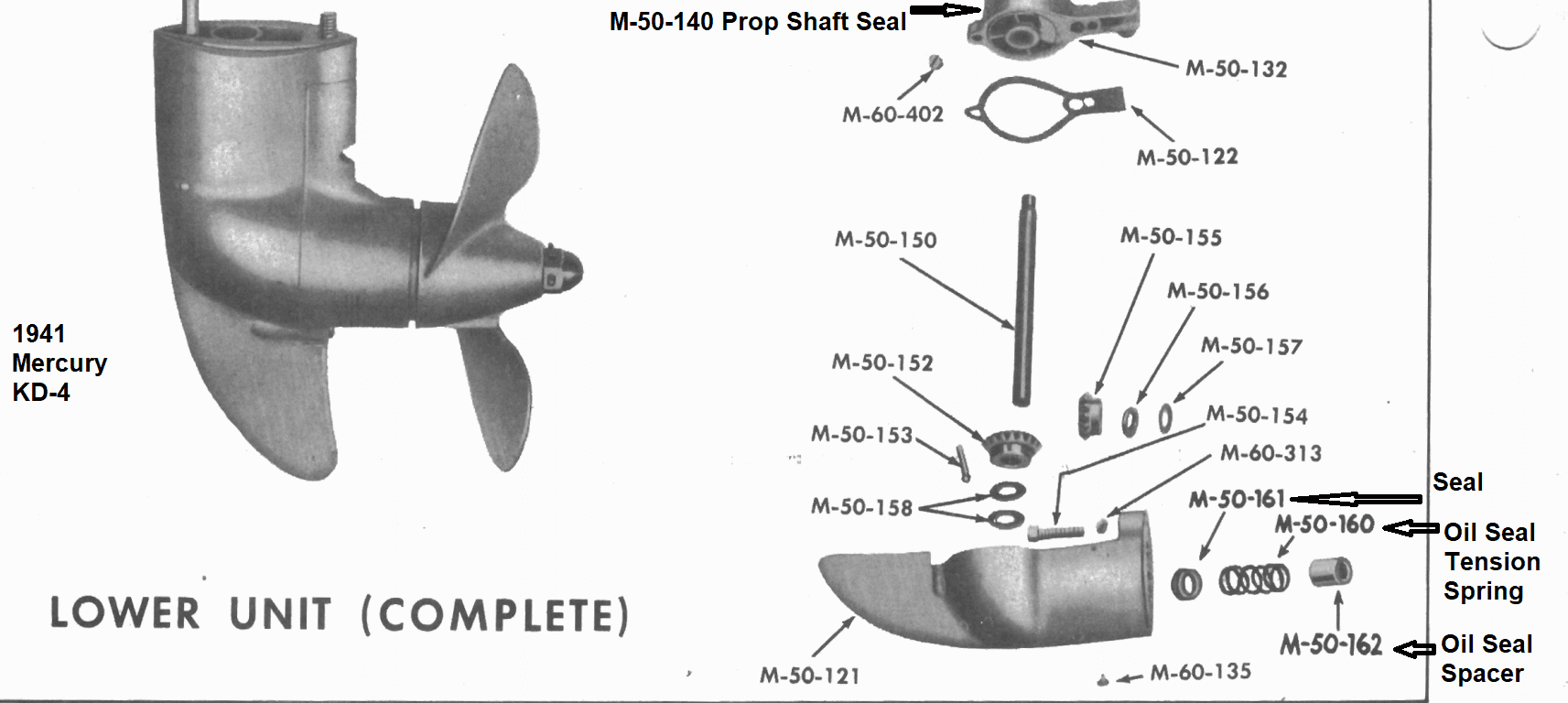

to the wobbler style pump in the 1946) and the good gears from the 1946.The 1947 has a prop shaft seal of sorts in the gear case cap. It looks to be a solid rubber affair

about 1/4″ thick. The prop shaft is .500, and the seal OD appears to be 3/4″.

What have any of you used for a modern / better replacement for this prop shaft seal?Per the parts manual, the drive shaft seal, tension spring, and spacer are all missing

on the 1947. The 1946 has a brass sleeve with some packing in it, but the brass sleeve

doesn’t fit in the sleeve in the top of the gear case, so I don’t see how it even worked.

I don’t have a parts manual for this earlier gear case to see what suppose to actually

be there.

What have any of you used for the drive shaft seal for a modern / better replacement?

The drive shaft needs a new bushing. The worn one that I took out doesn’t

even look original. It appears someone drilled out the worn original bushing

and placed another bushing inside of it. The original bushing has a flange

(that the drive gear thrust washer rides on) that’s bigger than the bore.

There’s not enough room to drive the bushing out of the bore, into the

gear case, and with a flange on the bushing, it can’t be pulled out the

top side of the bore. How can this be?

The bushing is not shown on the parts list, so guessing it’s not meant

to be replaced.

I was thinking about machining another bushing to go on top

of the drive shaft bushing, and putting a modern seal on top of that….. if I

can find something of the correct OD.The drive shaft on these appear to be reversible, so I could flip the drive shaft

end for end and have a virgin seal area.Thoughts or tips on any of this appreciated. Thanks!

Prepare to be boarded!

January 16, 2020 at 6:25 pm #192250The drive shaft seal on all models K1 thru KE3 and WA2 thru WG4

as well as the two Sea King singles is a piece of leather or raw hide.

Replacement can be using gasket punch. I can not recall ever finding

an old seal that was not rotted or missing entirely.Drive shaft is ground on gear case end and is slightly smaller in diameter. If the larger end fits thru the bushing in gear case , the bushing is worn out. Both bushings in the gear are cast into the gear

case and can not be driven out. Boring out busing and pressing

in inserts and reaming would require a holding fixture so

the two bushings are in precise alignment.,,a lot of work for just one

gear case, Easy solution is good usable gear case from any og

the many models that shared gear case.There were 3 different water pump designs, each will work with any of

the Early K Models and their Wizard and Sea King singles made by

Kiekhaefer. The propeller shaft, water pump cover and the retaining

spring will work with all, The rotating impeller design (3 slit water pump) are preferred as the oscillators are hard to come by. The

16 square hole and 7 slit water pumps are more complex and often

are missing small items.The single cylinder models have a 12 tooth pinion on drive shaft and a 22 tooth gear on prop shaft. No shims or spacers.

The twins have 14 tooth pinion on drive shaft and an 19 tooth gear

on propeller shaft. PLUS two 0,010 steel shims on propeller shaft

ahead of the gear AND a 0.100″ bronze spacer above pinion gear

and a 0,010″ steel shim between spacer and bushing,

The steel shims are often rusted or missing along with the bronze

spacer. These parts are essential for proper gear spacing and smooth

operation. The gears will self destruct without the spacer and shims

properly installed.

Also note the 12/22 and 14/19 are gear sets…they are NOT be mixed.

Sometimes you find a twin with a single gear set or a single with

a twin gear set due to prior work. May overheat overcool due to water

pump being driven too slow or too fast.Drive shafts often have worn splines or are pitted in area of seal and

bushing…drive shaft lengths vary so best to compare old and potential

replacement before purchase or assembly.The seal in 3 slit rotax rotating impeller type water pump have a difficult

to remove seal that is usually well past its Best By Date. Replacement

is a standard inexpensive item, but, first you have to get the old seal

out which may involve removing it a piece at a time.The early K Model Kiekhaefer outboards are well though out designs

but, they can have wear, corrosion and lost parts issues. Fortunately there are a wide range of years and models sharing the same or will fit

parts. Unfortunately cowls and spark plug covers are usually gone and

the available supply is thin, Complete and original examples are worth

a premium just to avoid a parts chase. Even a bare bones parts can be

made into runners that may someday find the rest of its partsl

Louis

Twin Gear Sets are 14/19 I stand corrected.-

This reply was modified 5 years, 5 months ago by

green-thumbs.

January 16, 2020 at 7:22 pm #192252Thanks for your detailed reply Louis!

I comment within your reply.The drive shaft seal on all models K1 thru KE3 and WA2 thru WG4

as well as the two Sea King singles is a piece of leather or raw hide.

Replacement can be using gasket punch. I can not recall ever finding

an old seal that was not rotted or missing entirely.Whatever the rings of packing were made of, they crumbled into 100

pieces when I probed them. You have me curious as to what “raw hide”

actual is? Uncured hide perhaps?….. or a Western?Drive shaft is ground on gear case end and is slightly smaller in diameter. If the larger end fits thru the bushing in gear case , the bushing is worn out. Both bushings in the gear are cast into the gear

case and can not be driven out. Boring out busing and pressing

in inserts and reaming would require a holding fixture so

the two bushings are in precise alignment.,,a lot of work for just one

gear case, Easy solution is good usable gear case from any og

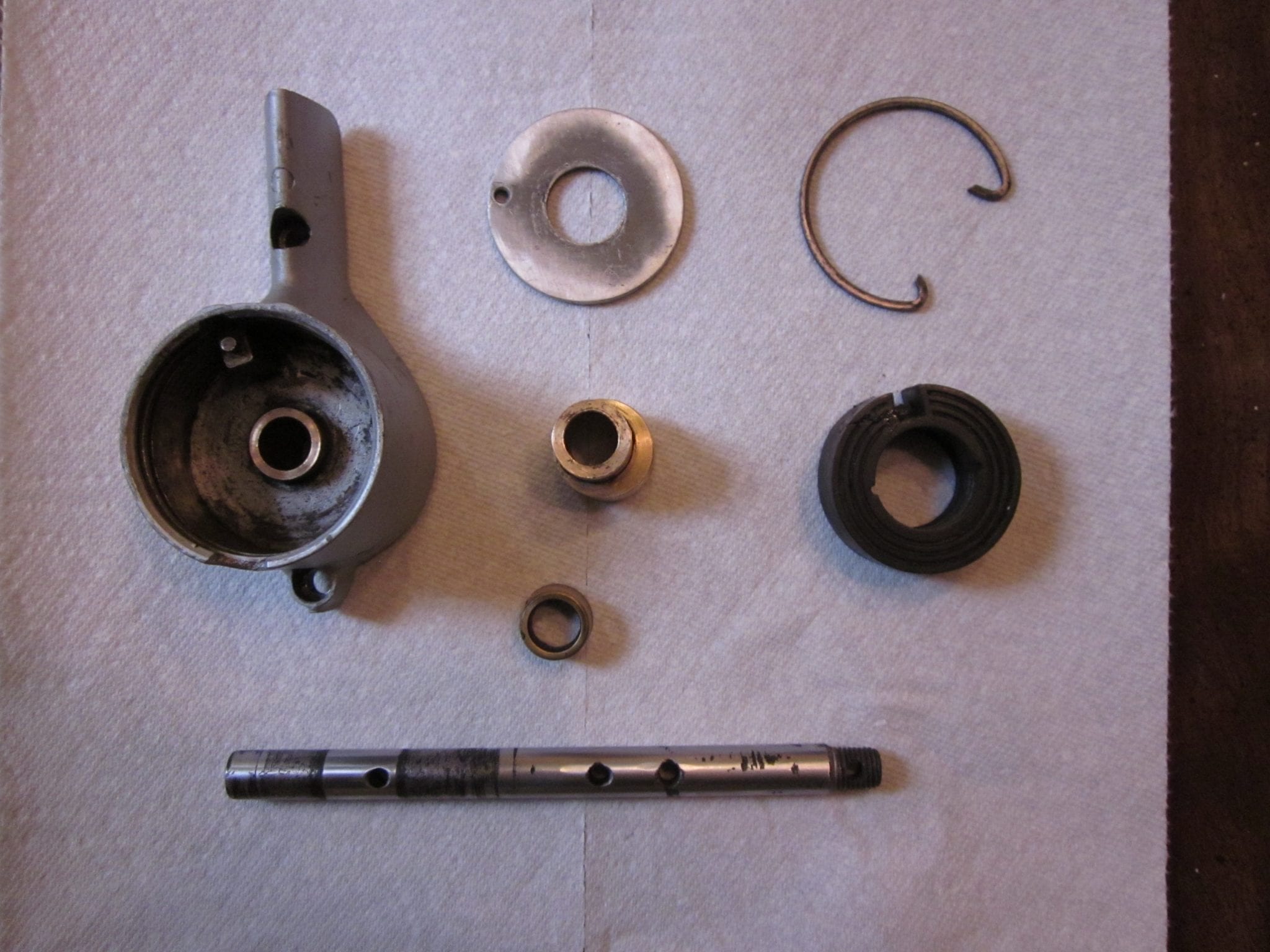

the many models that shared gear case.I ended up drilling the old worn out and out of round, 1-1/2″ long drive shaft bushing to 5/8″ dia.,

and made a bushing 2-1/2″ long, the bottom end of the bushing fits into the old bushing, and

the top 1″ of the new bushing is 3/4″ to fit the housing bore. On top of that I put a 1/2″ x 3/4″

seal, and custom made an alignment dowel to go atop of the seal, to align the gear case

with the mid section. “Line boring” was not an option, but I temporarily put it all together

and it seems to turn okay.There were 3 different water pump designs, each will work with any of

the Early K Models and their Wizard and Sea King singles made by

Kiekhaefer. The propeller shaft, water pump cover and the retaining

spring will work with all, The rotating impeller design (3 slit water pump) are preferred as the oscillators are hard to come by. The

16 square hole and 7 slit water pumps are more complex and often

are missing small items.This 1946 motor was originally the “wobbler” style water pump. It did seem to pump okay last Fall in the test

barrel…… not sure how, as the gear case was in sad shape.

I’m using 1947 rotary vane style pump housing, it’s prop shaft, but the gears from the 1946,

that were in much better shape. Both sets of gears for the prop shaft were the same 19 tooth count. I did

not count the teeth on the drive shaft gears.The single cylinder models have a 12 tooth pinion on drive shaft and a 22 tooth gear on prop shaft. No shims or spacers.

The twins have 14 tooth pinion on drive shaft and an 18 tooth gear

on propeller shaft. PLUS two 0,010 steel shims on propeller shaft

ahead of the gear AND a 0.100″ bronze spacer above pinion gear

and a 0,010″ steel shim between spacer and bushing,

The steel shims are often rusted or missing along with the bronze

spacer. These parts are essential for proper gear spacing and smooth

operation. The gears will self destruct without the spacer and shims

properly installed.

Also note the 12/22 and 14/18 are gear sets…they are NOT be mixed.

Sometimes you find a twin with a single gear set or a single with

a twin gear set due to prior work. May overheat overcool due to water

pump being driven too slow or too fast.I ended up with 3 thin steel shims below the prop shaft gear, and

a thicker bronze shim above the gear. This gave me good gear to

gear mesh with a hair of backlash, and a tiny bit of axial play on

the prop shaft. I think I luck out with the thickness of my new gear case

gasket.Drive shafts often have worn splines or are pitted in area of seal and

bushing…drive shaft lengths vary so best to compare old and potential

replacement before purchase or assembly.I’ll have to recheck the driveshaft out, to make sure it’s not too loose in

the power head, now that I plan to flip it end for end for a nice gear case

seal area.The seal in 3 slit rotax rotating impeller type water pump have a difficult

to remove seal that is usually well past its Best By Date. Replacement

is a standard inexpensive item, but, first you have to get the old seal

out which may involve removing it a piece at a time.The seal in the gear case cap I’m using appears to be a solid rubber

piece about 1/4″ thick, and in decent shape for reasons unknown.

The only 1/2″ x 3/4″ seal I’m finding over the counter is only 1/8″ thick,

but I have two coming, so suppose I could “double them up”The early K Model Kiekhaefer outboards are well though out designs

but, they can have wear, corrosion and lost parts issues. Fortunately there are a wide range of years and models sharing the same or will fit

parts. Unfortunately cowls and spark plug covers are usually gone and

the available supply is thin, Complete and original examples are worth

a premium just to avoid a parts chase. Even a bare bones parts can be

made into runners that may someday find the rest of its partsl

LouisMine came with the front cowl, and spark plug covers, so I don’t feel

bad about paying $65 for a running Mercury, even if the gear case needed much

attention! Thanks!Prepare to be boarded!

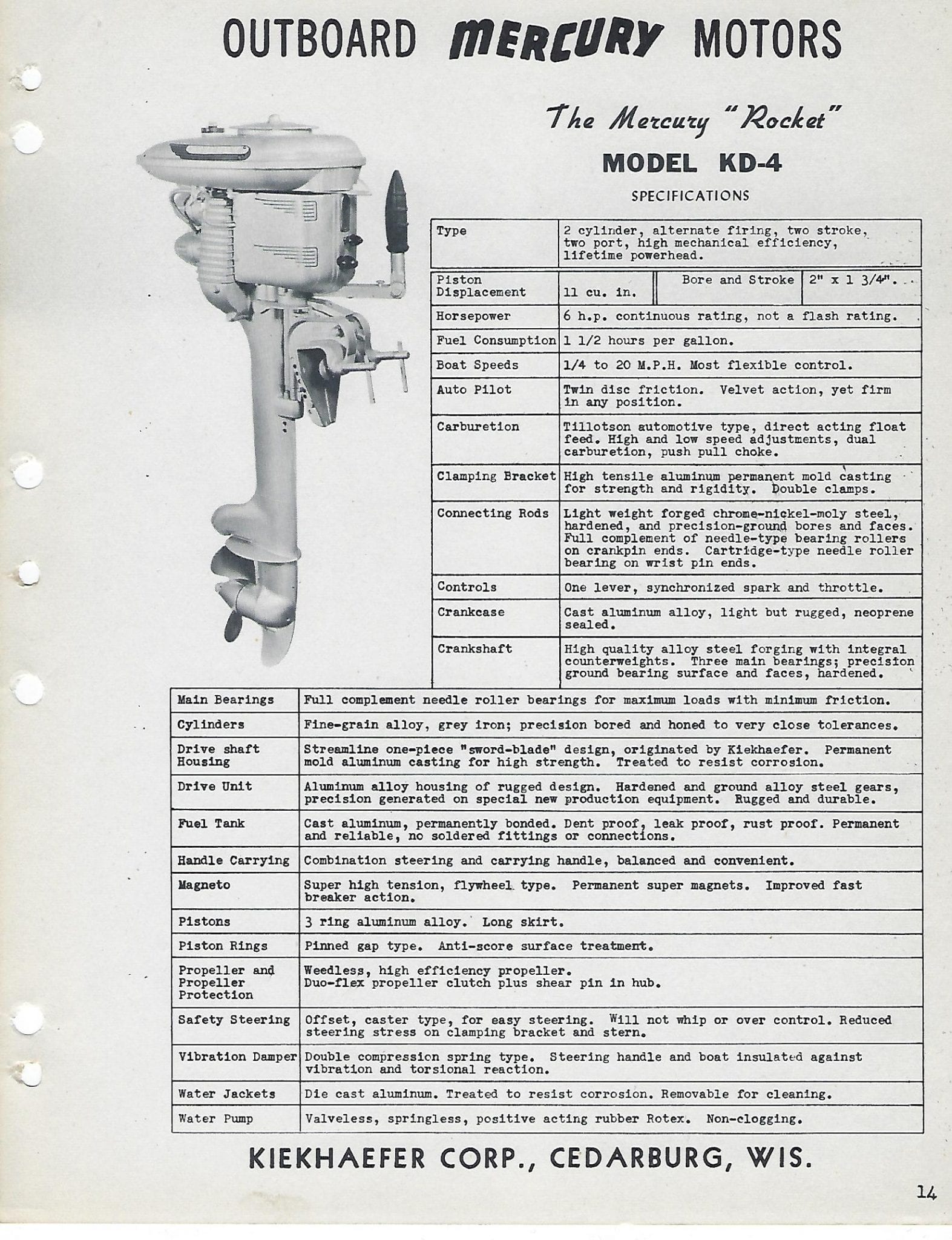

January 17, 2020 at 5:24 pm #192324Per Factory Specs MERCURY KD-4 should have left factory with a 3 Slit pump intake and a rubber vane type (ROTEX) impellor.

Why some one would swap out parts to older less reliable Oscillator (Hockey Puck) style water pump is a mystery?

I usually have the opposite problem? 1940’s K motors with newer 3 slit pump intake and rotex impellor, when the motor

Left the factory with 16 square hole intake, and oscillator style pump. Rumor has it that the 7 slot intakes were done by hand

Using a hack saw blade at factory?I’ll post some pics of Lou, “Green Thumbs” making seals from leather.

January 17, 2020 at 5:37 pm #192331January 17, 2020 at 5:42 pm #192337January 17, 2020 at 8:05 pm #192348Thanks for the photo and information. I assumed the wobber in my 1946 was

the first style pumps the KD-4’s had. Sounds like it was from something

prior.I received my Sierra rotary impeller today, and will see tomorrow if

I can make it fit.The prop shaft seal on the rotary style pump housing looks to be solid

rubber with no lip. Not sure if I’ll replace that or not. Anyone know

of a good / modern replacement?Prepare to be boarded!

January 18, 2020 at 1:33 am #192364Drive shaft lengths vary both because Kiekhaefer did some strange things and because Wizards generally had a distinctive tower that was

taller than Mercury models. I bough a really nice drive shaft at

Suter Meet figuring I could use it on a Mercury I had under repair,

About an inch too long, It eventually was reunited with a Wizard.

I have several drive shafts that vary in length by less than an inch

and I know not why…Mr Kiekhaefer did things his way,

I took a couple night school classes in machining so I gave some thought to renewing the bushings in gear case that drive shaft and prop shaft ride in. It appeared to me that for the gears to mesh

properly their respective shafts would have to be in close alignment

which meant the bushings wold have to be in correct alignment

to each other. The only way I could see all that happening required

a device to hold the gear case while it was bored preferably on

a Bridgeport mill. You seem to have found a work around.

My solution to this sort of issue has been to use parts off parts motors

I have measured drive shafts, the ground end is something like

0.495″ while the unground end is about 0.500″ If both ends will

fit thru gear case bushing I look for another gear case. Not many

outboards got enough use to wear out so parts motors usually

have good usable parts. In Michigan not much boating activity

from Labor day to Memorial day,

Louis-

This reply was modified 5 years, 5 months ago by

green-thumbs. Reason: add photos

January 18, 2020 at 12:38 pm #192385Louis, I don’t have a “work around” for line boring. I’m just hoping I get lucky.

Most of my outboards are lucky to get on the lake once or twice and

get put on the rack. Just hoping I have once nice ride with it!Prepare to be boarded!

January 18, 2020 at 4:43 pm #192445The long and short of Mercury and Wizard towers and drive shafts

Typical Wizar.

y postwar tower (dull aluminum) note exhaut

outlet is blended into cavitation plate

Mercury tower (gold) note the exhaust outlet is separated

from the cavitation plate. The silver Wizard tower is long

then the gold Mercury tower thus long and short drive shafts

I have no ideas about the fraction of an inch difference in the other

drive shafts. Prewar Kiekhaefer seem to be Mercury pattern

the Wizard pattern seems to be a postwar motors only.

Apparently Wizards and Mercurys left factory with towers usually

found with the other brand. There is also a Wizard manual on

the Wizard site showing a Wizard WD4 S with the typical Mercury

tower. It seems fair to assume that a lot was going on at Kiekhaefer

for reasons that can only be speculated about.

Louis -

This reply was modified 5 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.