Home › Forum › Ask A Member › 1948 evinrude 3.3 sportwin specs/help

- This topic has 16 replies, 7 voices, and was last updated 8 years, 6 months ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

April 21, 2015 at 1:17 am #1280

Hi gentleman..picked up a evinrude 3.3 sportwin last week #4423-03978.Did a compression test on it and got a 84 top and 88 bottom reading.No spark on one cylinder. Pulled the flywheel and took out the points and cleaned them and reset them at .020.Coils looked fine.Put flywheel back at 40 lbs.torgue.(don’t know if that is correct).Cleaned plugs(j8c)and gapped at .030.Strong spark now.Used 16 to 1 gas mix using synthetic 2 stroke oil.Put in barrel and took about ten pulls after priming it 4 times.(gas leaking slightly from front primer seal).would only stay running at higher speeds with a revving slightly up and down.Water was misting out of vent holes on leg and streaming further down the leg.To stay running the rich needle has to be set on its richest setting.Started to run hot so I shut it down.Both plugs were hot so they seemed to be firing ok.After it cooled down for some time I took out the plugs and they were dry.Before I take off the carb for cleaning,is there anything I should be doing?Also,are my specs right for fly wheel torque,plug gap et.?What kind of water pump impeller does it use?Also,does the lower gearcase take grease?I am not an avid collector or have the skills many of you guys have.i am just someone who likes to work on 3 or 4 old outboards a year and get them running well again if possible.Any help would be appreciated.Thanks for reading.

April 21, 2015 at 1:04 pm #14431Bob, I sent you a PM.

Prepare to be boarded!

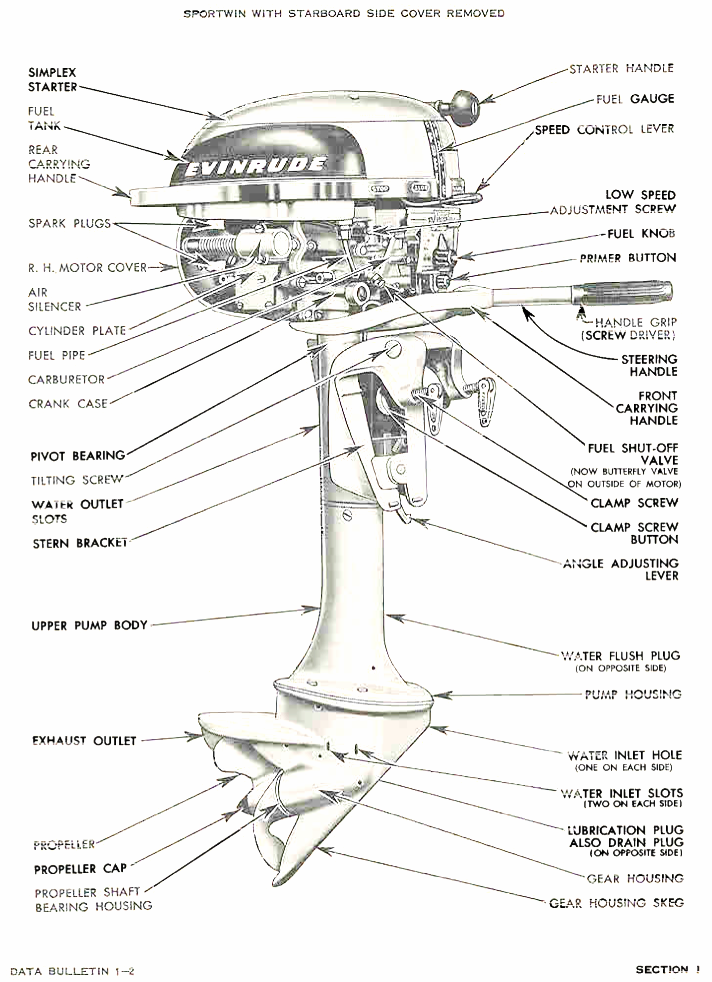

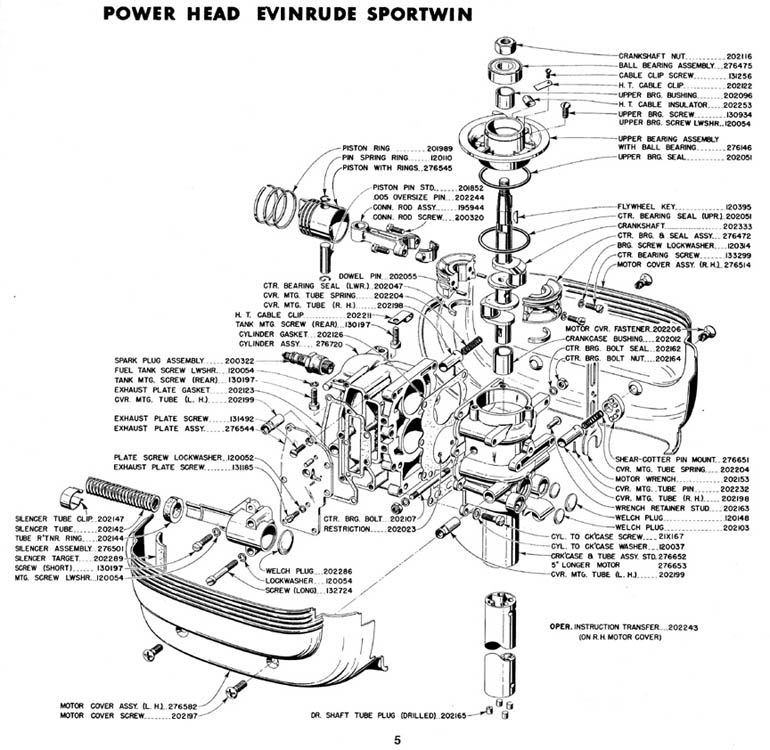

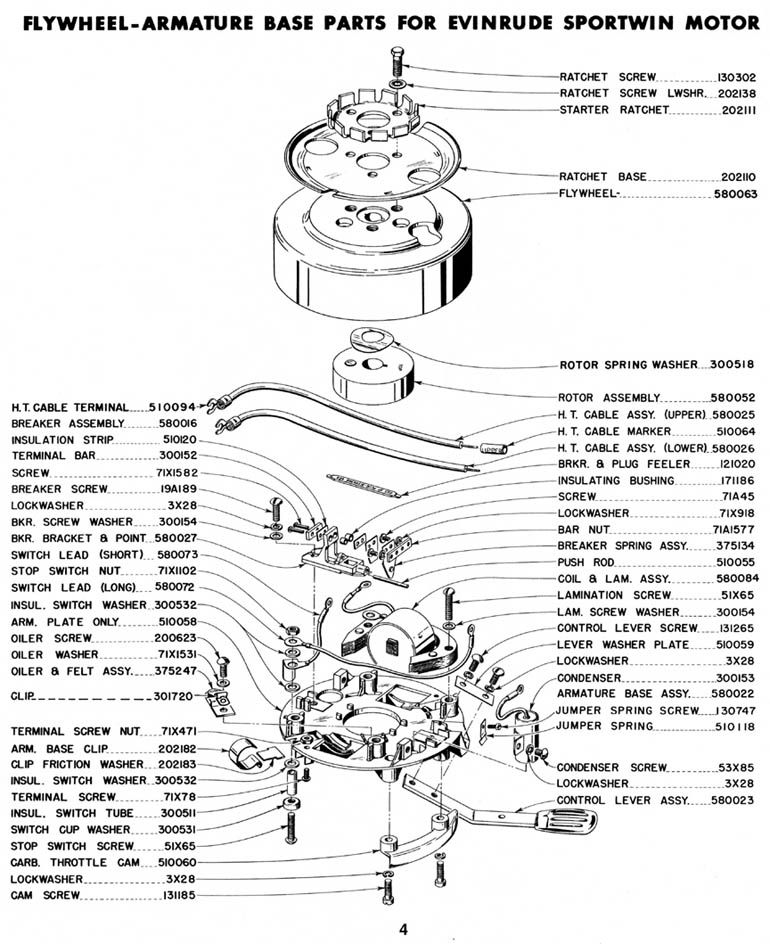

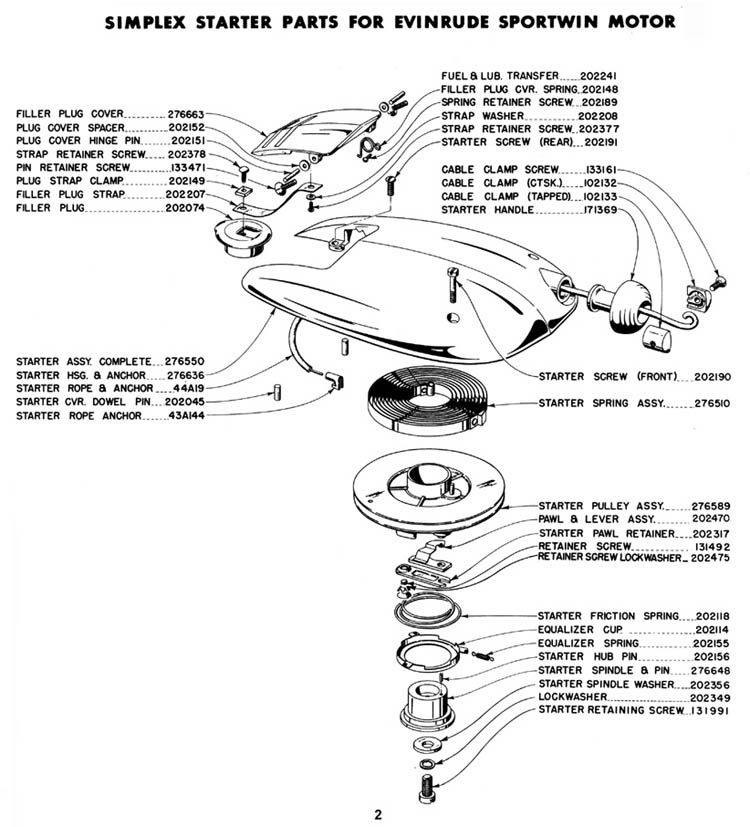

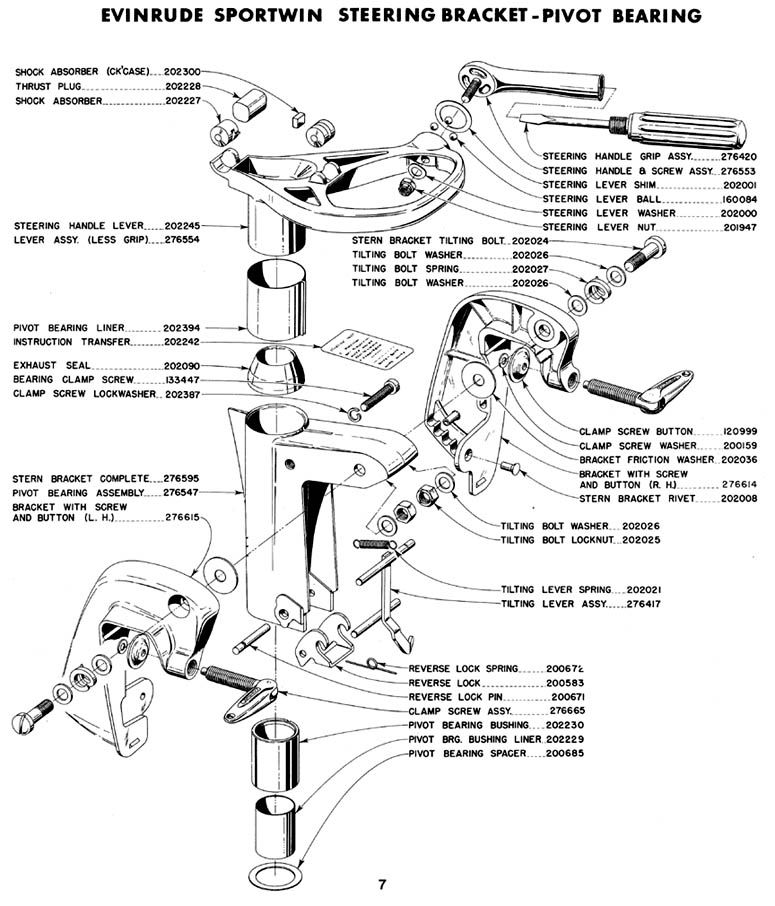

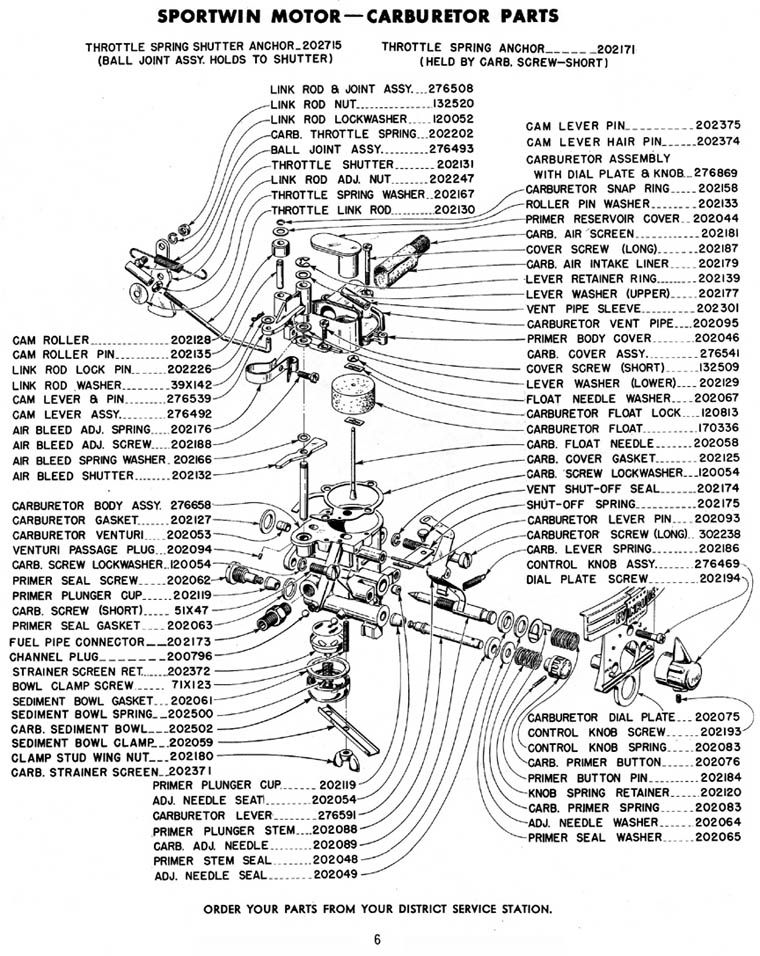

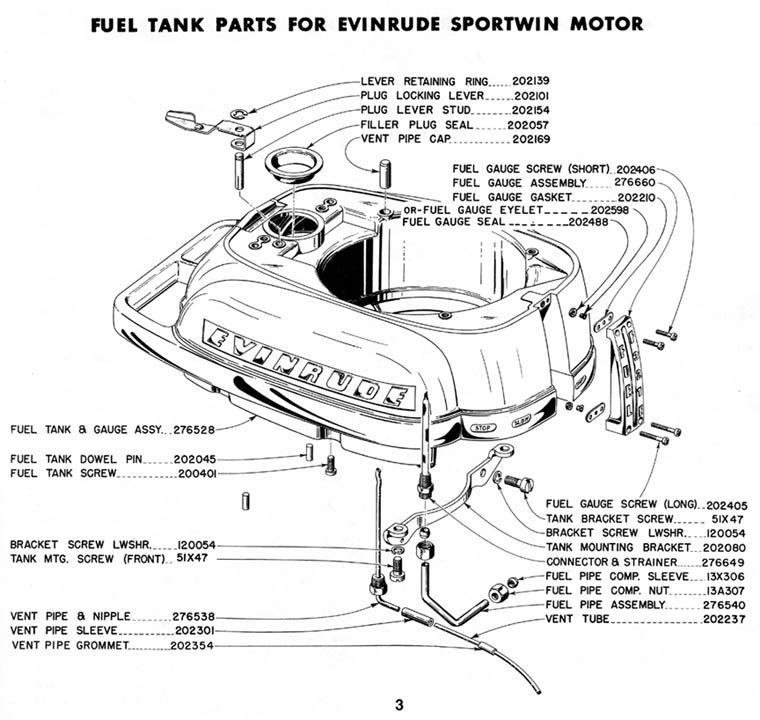

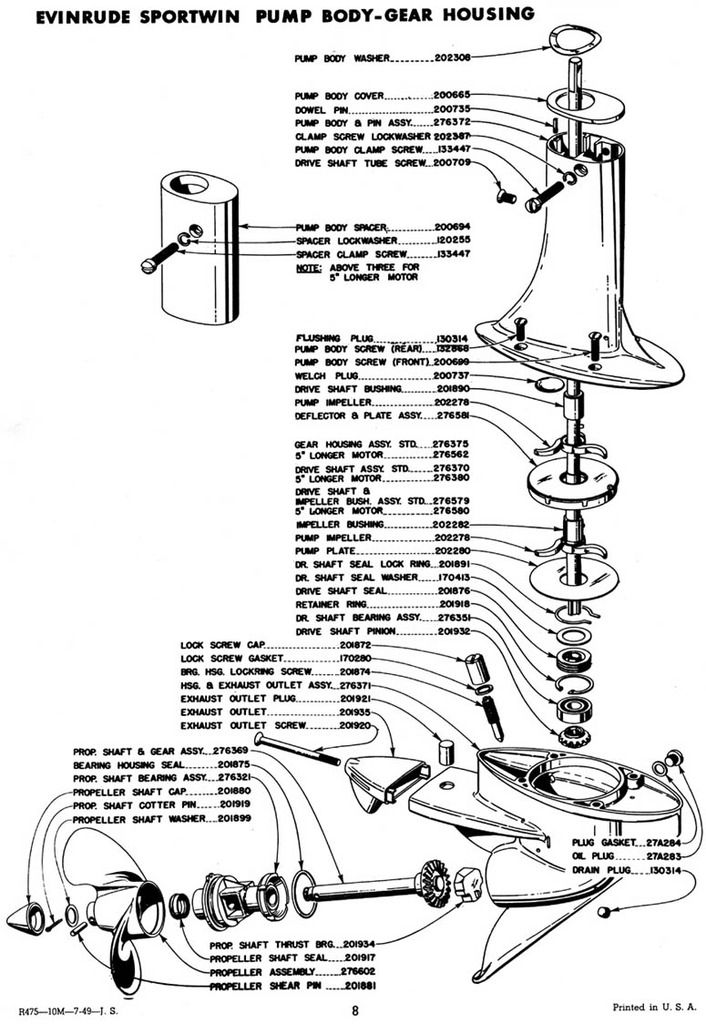

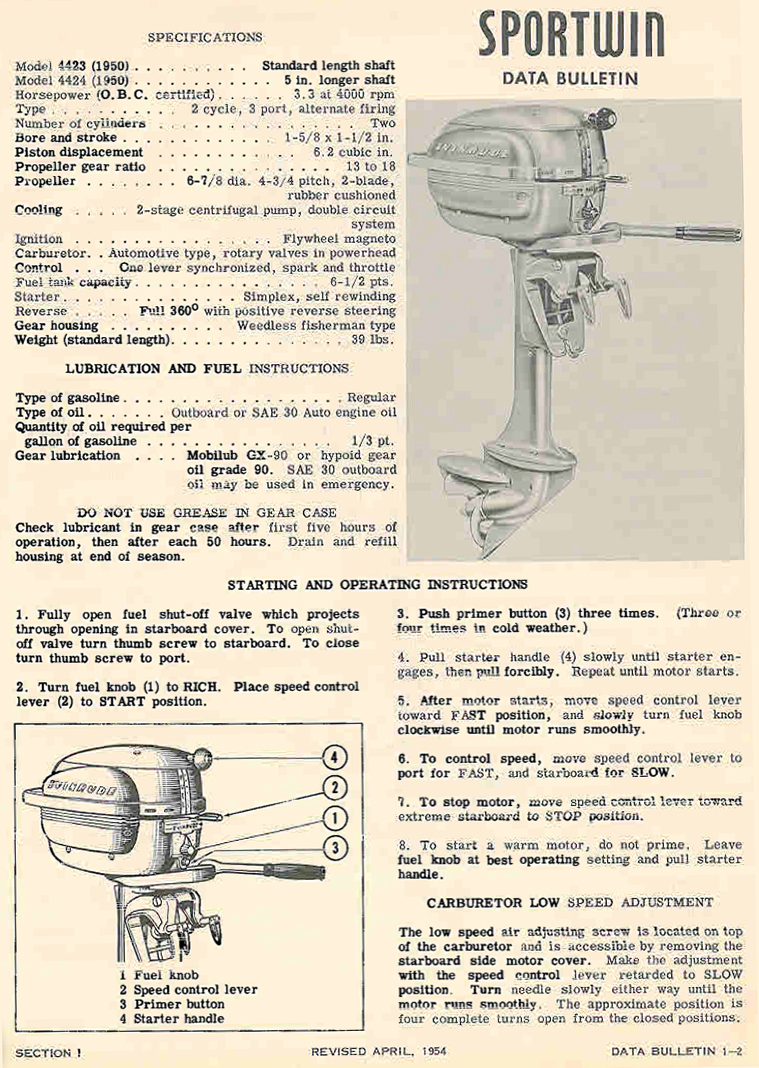

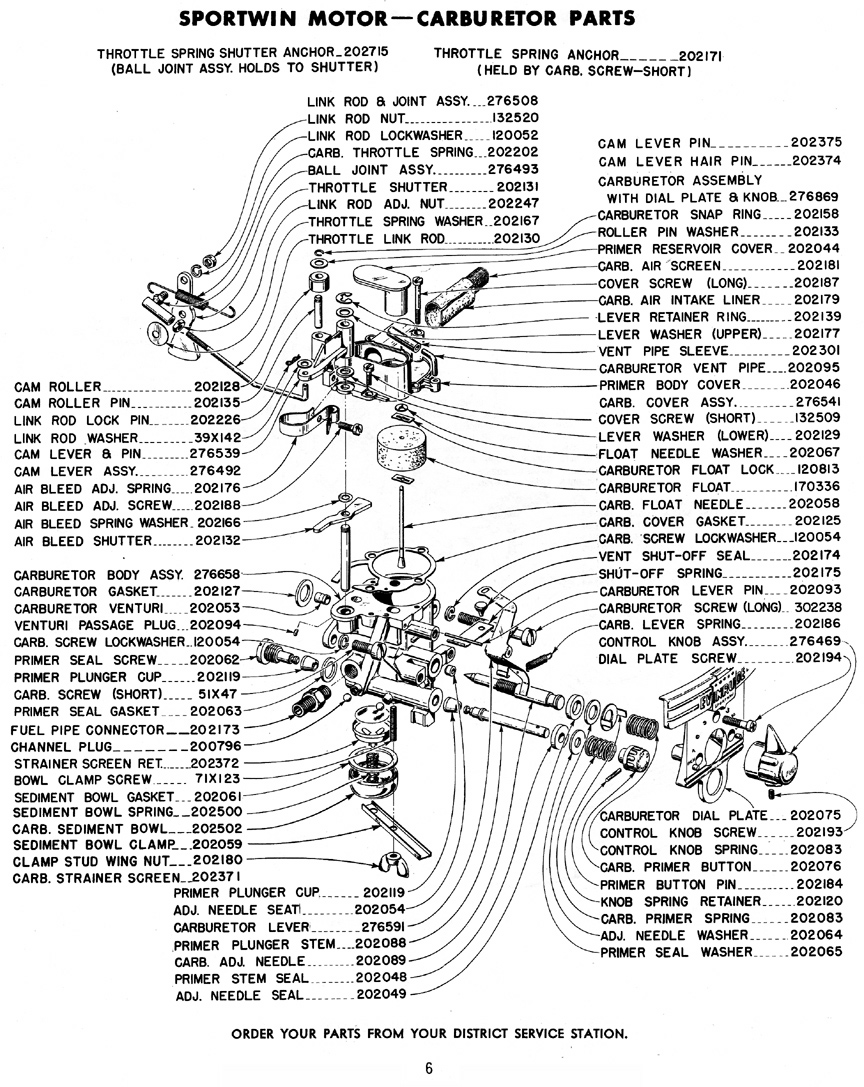

April 21, 2015 at 2:43 pm #14433Hi Bob. The manual calls for 1/3 pint of oil to the gallon, 24/1, but I’d leave it at 16/1 for the sake of the motor. These motor have bushings and will last much longer with the extra oil. The water pump has two hard to find rubber impellers separated by a plate. There’s two NOS ones right now on Ebay. The flywheel gets torqued to 25 foot pounds. This was the first year for these motors to use modern seals and oil in the gearcase as they have a ball bearing on top of the pinion gear. If the NLA seals are worn, they can be replaced with new SKF seals. I’ve done this on a Sportsman and Sportwin with no signs of leakage yet. Here’s some diagrams of your motor:

April 21, 2015 at 3:33 pm #14437

April 21, 2015 at 3:33 pm #14437GENTLEMEN,THANK YOU VERY MUCH FOR YOUR REPLIES.THESE DIAGRAMS ARE VERY VALUABLE,AND SO IS THE OTHER INFO.OBVIOUSLY,I HAVE OVER TORQUED THE FLYWHEEL NUT.COULD BE THE REASON THE MOTOR RAN HOT AND UNEVENLY AND NOT BEING ABLE TO RUN AT SLOWER SPEEDS.HOPE I DIDN’T MAKE A MAJOR MISTAKE AND RUIN ANYTHING UNDER THE FLYWHEEL OR DRIVE SHAFT.ARGHHH! I DIDN’T KNOW IT HAD A DOUBLE WATER IMPELLER EITHER.I HAVE ONLY WORKED ON ONE 40’S MOTOR BEFORE(TD-20),SO THIS IS NEW TO ME.I GUESS I WILL HAVE TO BE AN OLD DOG WHO LEARNS NEW TRICKS.THANKS AGAIN…GEEZER BOB

April 21, 2015 at 4:43 pm #14440I would think the reason will not run a slower speed could be the low speed jet is plugged up and not letting fuel through. My guess would be cleaning the carb will fix that problem then will need impellers to fix the running hot issue.

Doug

how is it motors multiply when the garage lights get

turned off?April 21, 2015 at 5:31 pm #14443.YES,I THINK YOU ARE RIGHT.I WILL PULL THE FLYWHEEL OFF FIRST AND SEE IF I DID ANY DAMAGE TO THE COILS.IF NOT,THE CARB WILL BE NEXT WITH THE FIX ALSO ON THE PRIMER SEAL.IT DID SEEM TO PUMP WATER WELL OUT OF BOTH VENT AND OUTLET,THOUGH.SOMETHING MAYBE BE SLIGHTLY CLOGGED IN THE WATER PASSAGES,OR MAYBE UPPER IMPELLER ISN’T PUMPING WATER WELL ENOUGH.THANKS FOR YOUR ADVICE

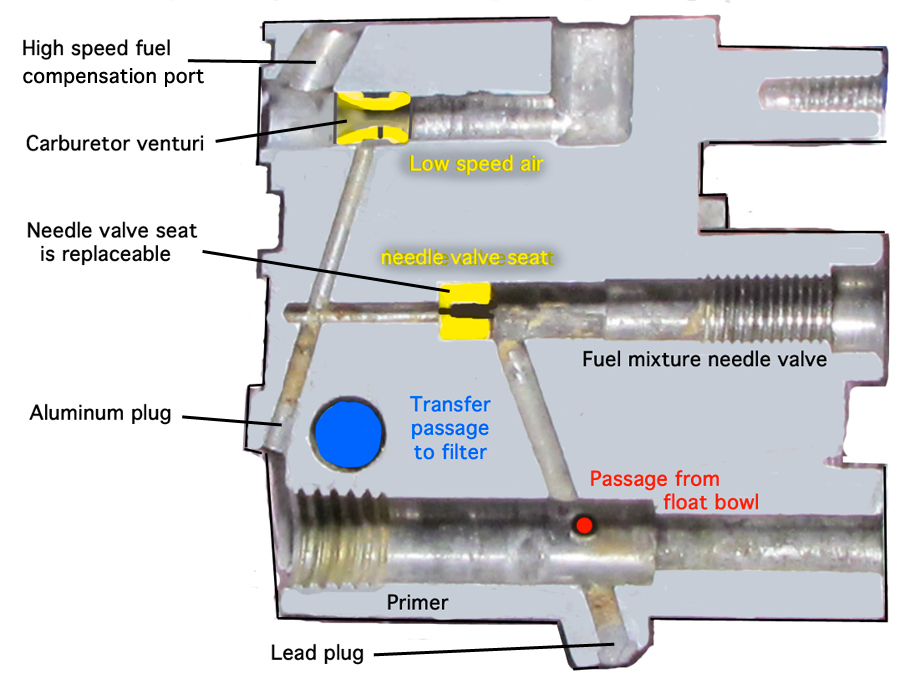

April 21, 2015 at 6:48 pm #14446That computer designed carburetor has only one jet. Irgie’s grand plan was to simplify it’s operation by making it more complicated. He was also the master mind behind the carburetors on the Evinrude Lightfour, Zephyr and the Johnson SD. Incidentally, they all work beautifully when properly maintained. That it only runs with the mixture control all the way out indicates a fuel restriction. The idle mix is adjusted by the air bleed screw 202188, top right, looking at the front of the carburetor. They were easier to work on when you could still get the seals, gaskets, primer cups, needle seats and particularly the 202053 venturi.

. . . . . . 😀

April 21, 2015 at 8:01 pm #14450

April 21, 2015 at 8:01 pm #14450THANKS GARRY.DID NOT KNOW ABOUT THE AIR BLEED SCREW TO ADJUST IDLE SPEED.YOUR SEVICE BULLETIN LETS ME KNOW ABOUT THE LOWER UNIT LUBRICATION ALSO.I DID THINK THE PARTS WOULD BE DIFFICULT TO FIND,AND YOUR REPLY VERIFIES THAT.THIS WILL BE A PROJECT AND A LEARNING EXPERIENCE.THANKS TO THE DIAGRAMS I HAVE AT LEAST A STARTING POINT AND WHAT TO LOOK FOR.GREAT KNOWLEDGE ON THIS FORUM.THANKS AGAIN

April 21, 2015 at 10:44 pm #14456Bob, I added to Garry’s carb cut away when I was trying to figure out how mine worked.

http://grayhitandmiss.com/Outboards/442 … taway2.jpgThis service bulleting mentions the shutter adjustment. Strange affair.

http://grayhitandmiss.com/Outboards/442 … lletin.jpgPrepare to be boarded!

April 21, 2015 at 11:37 pm #14462THANKS BUCCANEER…WOULD HAVE NEVER KNOWN HOW MANY TURNOUTS FOR LOW SPEED ADJUSTMENT NOR FLOAT ADJUSTMENT.ALL OF THESE DIAGRAMS ARE EXTREMELY USEFUL.WILL BE WORKING ON IT THIS WEEKEND.HOPE YOUR 3.3 PROJECT GOES WELL

…GEEZER BOB -

AuthorPosts

- You must be logged in to reply to this topic.