Home › Forum › Ask A Member › 1948 Johnson HD25 Pull Start Rope

- This topic has 5 replies, 5 voices, and was last updated 8 years, 11 months ago by

garry-in-michigan.

garry-in-michigan.

-

AuthorPosts

-

May 11, 2015 at 1:20 am #1459

Anonymous

The pull start rope on my 1948 Johnson HD25 has lost its covering over the inner wire. Can anyone tell me where to get a new one or what to do to get a suitable replacement? Thanks in advance.

May 11, 2015 at 12:28 pm #15705Once the old cotton/wire cords begin to degrade it’s time to replace them. The wire will damage the starter housing.

I go to my local power equipment shop and match up the diameter of the old pull cord. A little bit smaller diameter is OK, but larger may not fit.

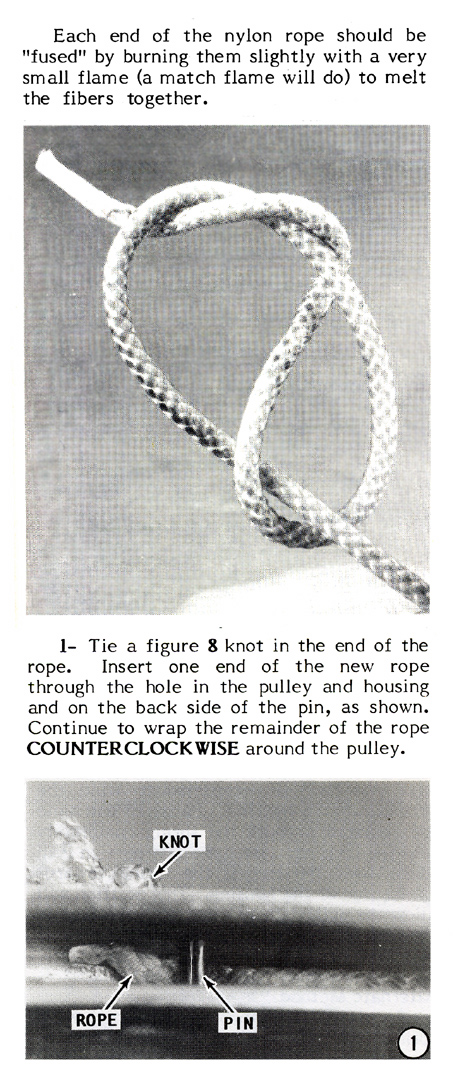

Use the old cord for reference, and make the new one a few inches longer as the knot will take up some length.

The modern pull cord is much more shock absorbent and will ‘give a little’ for smoother operation.

May 11, 2015 at 8:30 pm #15725Make sure the bronze cable core has NOT damaged the housing. Any rough edges will rapidly chew up a new cord. The cotton covered bronze cable is available, but I always replace them with quarter inch braided Nylon. It is more or less self lubricating, and just as strong if un-dammaged.

May 11, 2015 at 11:10 pm #15737quote Garry in Tampa:Make sure the bronze cable core has NOT damaged the housing. Any rough edges will rapidly chew up a new cord.

May 11, 2015 at 11:10 pm #15737quote Garry in Tampa:Make sure the bronze cable core has NOT damaged the housing. Any rough edges will rapidly chew up a new cord.This is extremely valuable advice – you want that rope guide bushing ID to be smooth and shiny. Some recoil assys. have a replaceable bushing, but with most, it’s part of the recoil case itself. Even a little burr in there will shred your new rope in short order.

Oh, and don’t remove the recoil spring, lol.. but do wear strong eye protection any time you’re working with a compressed spring, as in the case of recoil service.

May 12, 2015 at 1:02 am #15758I have the same problem and notice that the replies have kept away from how to install the new rope. My thought is that one needs to use the bronze end on the old rope that connects to the recoil. The new rope has to fit into that bronze end FIRST – then work the new rope in. Please correct me if I am wrong.

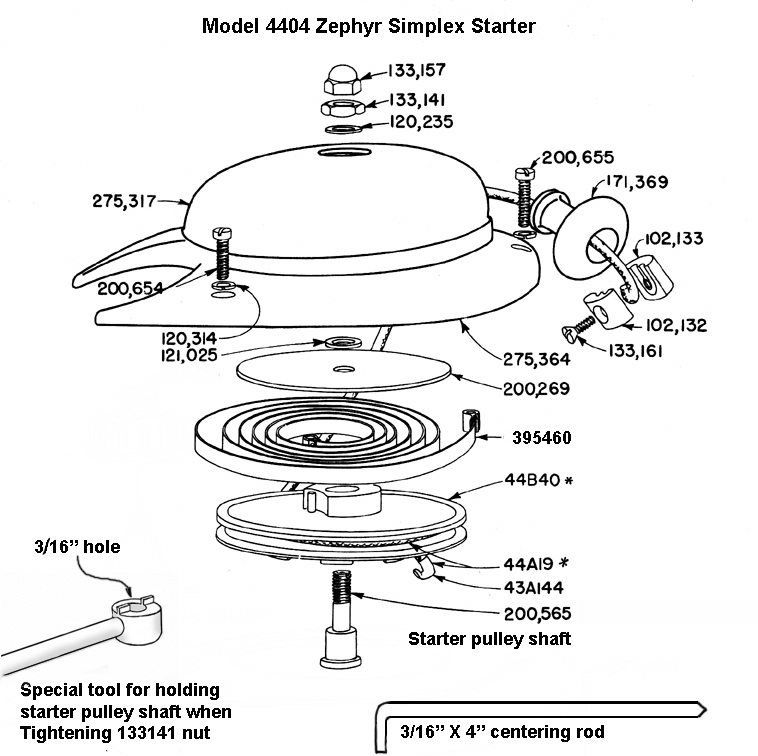

May 12, 2015 at 4:35 am #15764That starter was also used on Evinrudes. The big starter spring was used for over 50 years.

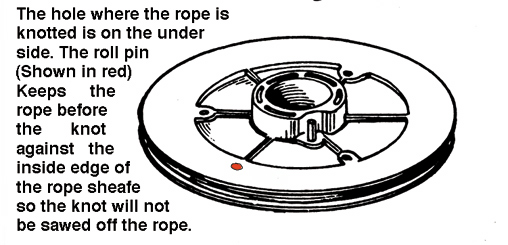

If the rope is unbroken and a replacement bronze cable replacement is found, Replacement is easy. The old rope is pulled all the way out and the rope sheave is locked in place. A nail with a squared off end can be put through a hole in the rope sheave to keep it from rewinding. I have had them slip with bad results, so I use a "C" clamp. The old rope is then cut off and the new threaded through the sheave and housing. After the handle is transferred, the spring is allowed to pull the rope into the housing.

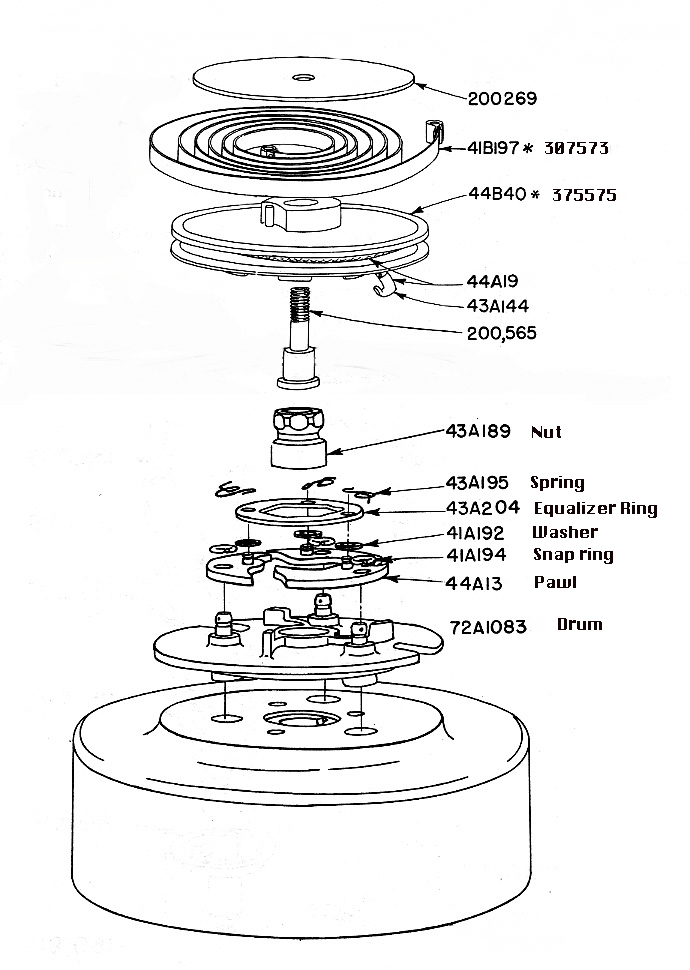

If you replace it with the woven nylon rope, then a hole will have to be drilled for the pin that holds the rope. That would include removing the rope Sheave to clean out the metal chips and re-lubracating the clock spring. This would be done by undoing the handle and allowing the pulley to SLOWLY rewind until all the tension is out of the spring. Note that there is still a LOT of energy in the spring So extreme caution should be used in removing the pulley. I usually put the housing on the floor with a foot holding it down while I remove the nut holding the center bolt. Sometimes the bolt needs a bit of encouragement , but you will know when the pulley and spring drop free of the housing.

After everything is cleaned and lubricated (105 Lubriplate) The spring is carefully wound back into the housing. The tail end should be close to the center hole. If not it may be bent so it lines up with the pin in the rope sheave. Wrap all the rope around the pulley and drop it in place so the pin goes into the eye on the end of the spring, Put the center bolt in to hold it in place. Put two turns or the pulley to tension the spring, then feed the rope through the housing and install the handle. Pull out the rope and let it retract when you place the housing. This should retract the starter pawls to let the housing drop in place. The center bolt is hollow and a pointed metal rod is run through it to insure it is centered over the crankshaft when the bolts are tightened.

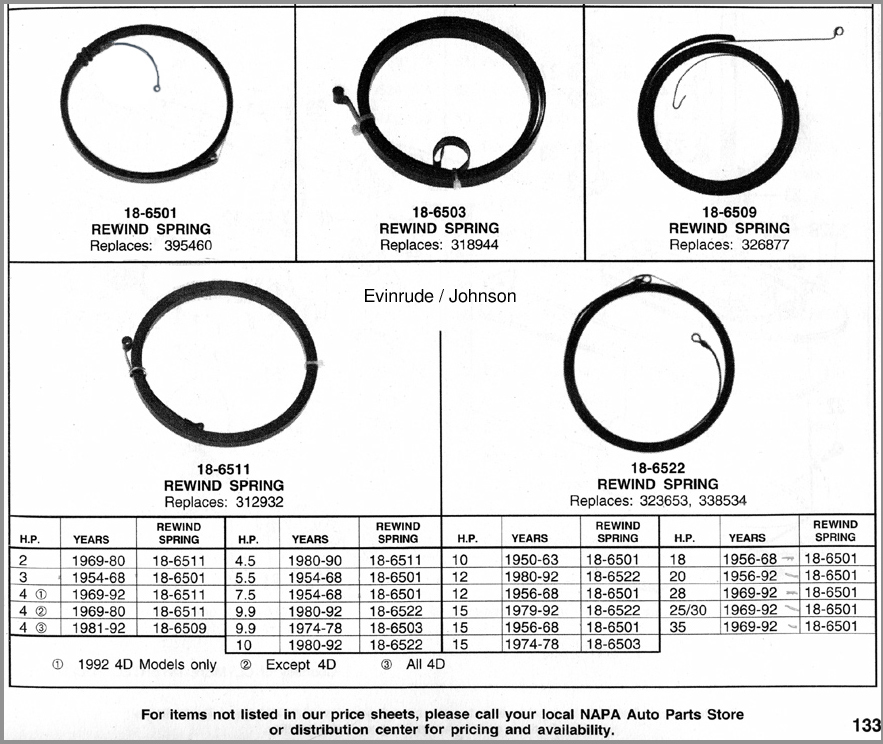

A lot of part numbers changed when OMC went to computer inventory control in the mid to late ’50s. The final number of the spring is 395460.

-

AuthorPosts

- You must be logged in to reply to this topic.