Home › Forum › Ask A Member › 1951 4443 Evinrude Fleetwin 7.5

- This topic has 4 replies, 2 voices, and was last updated 3 years, 8 months ago by

Bc1972.

-

AuthorPosts

-

August 2, 2020 at 7:01 pm #210687

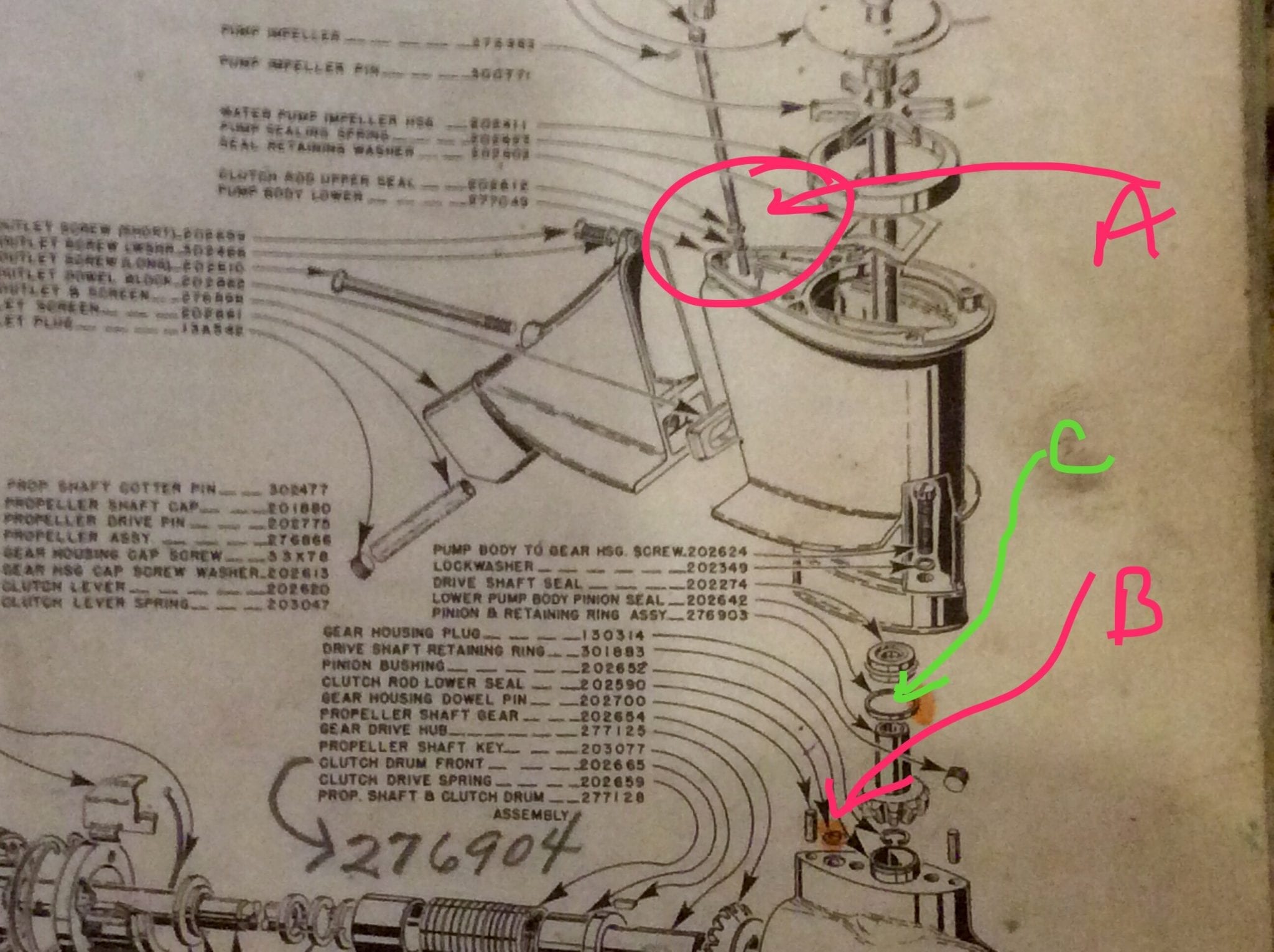

Have questions based on the picture provided

A). Shows the lower clutch rod

I was able to order a replacement clutch rod upper seal (2022612)

I do not have a seal retaining washer (202902) and don’t remember seeing one when I broke the unit down. The big question is — I can’t figure even how this o-ring will be held firm to the lower pump body even with the retaining washer. As the clutch rod moves up when pulled up, both the retaining washer and o-ring will ride with it upward??? When this happens it will allow water to flow down the rod shaft. What am I missing in this analysis?B). Clutch rod lower seal (202590) – I wasn’t able to order one of these but should be able to find one at NAPA – I hope!

C). Lower pump body pinion seal (202642) – I wasn’t able to order this one either- it is not your typical o-ring – has straight wall instead of your typical rounded o-ring. The old one is in reasonable shape but would prefer to replace.-

This topic was modified 3 years, 8 months ago by

Mumbles.

Mumbles.

August 3, 2020 at 5:45 pm #210795From what I remember I put a dab of epoxy on top of the o-ring and slid it up the shaft. I couldn’t figure what else to do either.

I don’t see it holding after prolong use. Maybe the other seals will keep the water out of your gear box?

On the clutch rod lower seal I think I used a tad bit oversized o-ring and epoxied it down to ensure it held while putting it back together.

Mine is a runner but I haven’t run it since I prettied it all up.

GlenAugust 4, 2020 at 4:44 pm #210873Well after much deliberation, I came up with a plan that hopefully was better than original….. made a plate to hold the o ring in place.

-

This reply was modified 3 years, 8 months ago by

Mumbles.

Mumbles.

August 5, 2020 at 7:18 am #210901Hard to tell..is the o-ring on top of the plate inside the exhaust housing? How did you secure it? I noticed on line they make high temperature O-rings. May have to redo mine someday.

GlenAugust 5, 2020 at 12:43 pm #210912I used 1/8 aluminum stock to fabricate a plate that fits tight against both side walls and back of housing. Took a couple tries. Wanted angle of whole for clutch rod in plate to be same as shaft. Whole needs to just be slightly larger than rod so the oring stays firmly in place in housing base. I carefully selected the #6 self taping screw noted in picture. I was able to predrill close to the clutch rod end of plate so it does not interfere with exhaust housing bolt. Your typical self taping screws have a drill bit tip so you lose threads. I used several screws, start one, throw it away when driver slipped on the head, start another one etc. last thing you want to do is strip or break off! I used some gasket sealer around the oring and under the plate. Seems to work well. Put some triple guard grease on the rod to slide through plate and oring.

Couldn’t get the picture of box of screws to post for some reason. Make by Teks, 1/2 inch #6, self drilling screws metal to metal.

-

This topic was modified 3 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.