Home › Forum › Ask A Member › 1954 15 hp Evinrude starter

- This topic has 13 replies, 8 voices, and was last updated 5 years, 4 months ago by

JOHN HOLBIK.

-

AuthorPosts

-

February 16, 2020 at 12:33 pm #195030

My evinrude is very hard to pull over with starter but easy with rope around flywheel. Compession 90 psi & 81 psi. Is it the starter or me I am 83. The starter pulls easy when removed from motor.

February 16, 2020 at 1:58 pm #195043That is old style starter. Has less mechanical advantage than later type.

I have a ‘53’ version. Great running but hard to pull over when cold.

David Bartlett

Pine Tree Boating Club Chapter"I don't fully understand everything I know!"

February 16, 2020 at 2:02 pm #195044It’s you. I’m 83 also and know what you mean. My little 3hp’s get harder to pull every day. And harder to lift too.

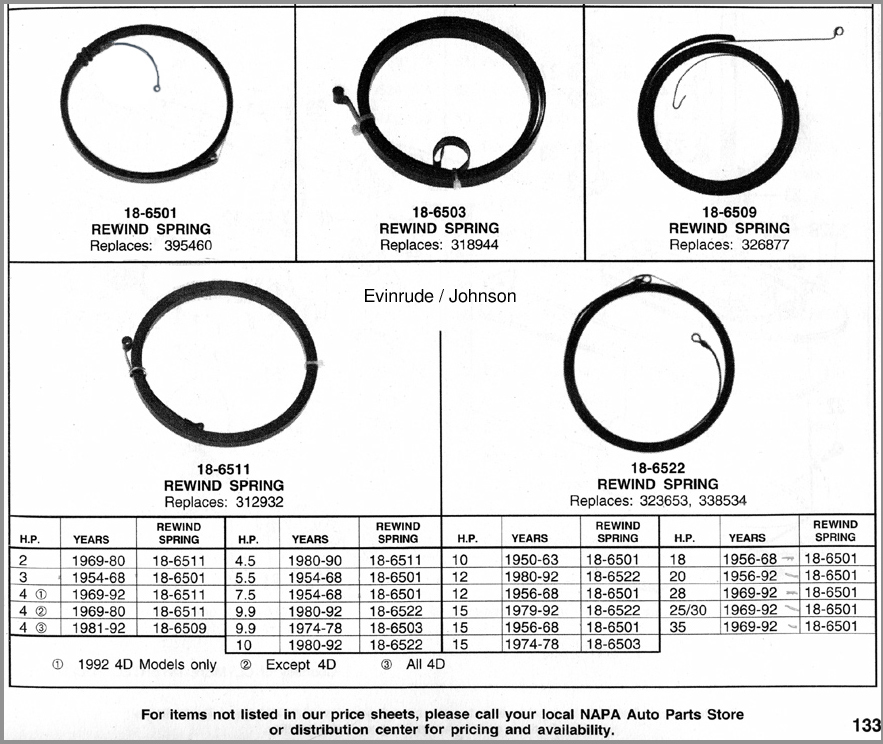

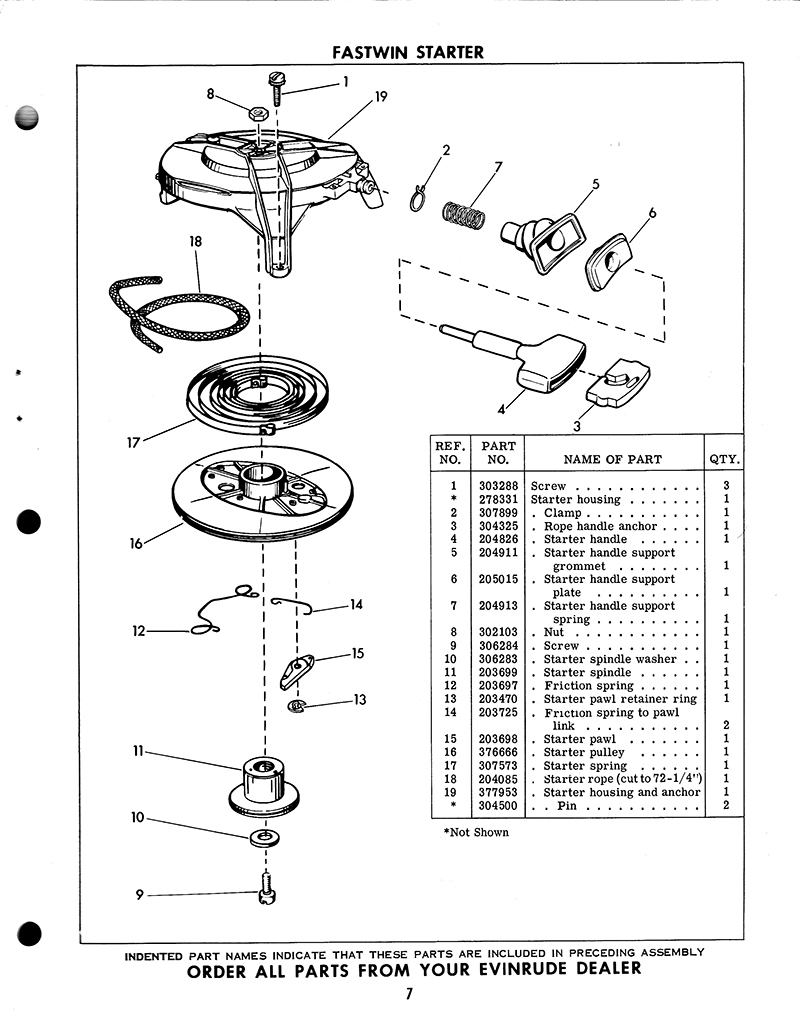

Yes, those early Simplex starters had small pulleys and were harder to pull. Could be extremely hard if it has the wrong spring installed There were two springs at the time, one was for the Big Twins and was much stronger. Due to supersedings over the years, I don’t know how the new ones compare, or what’s in yours.

February 16, 2020 at 2:49 pm #195050

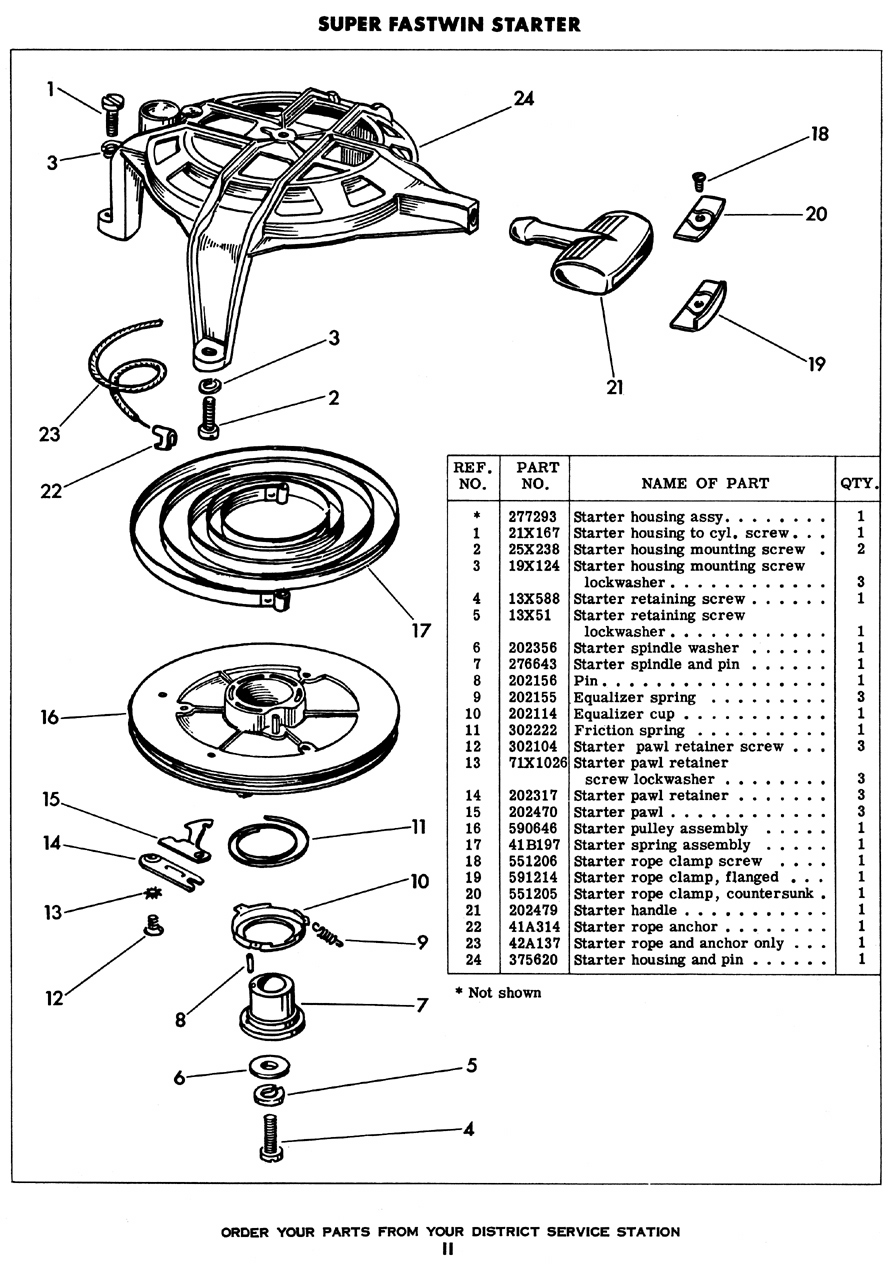

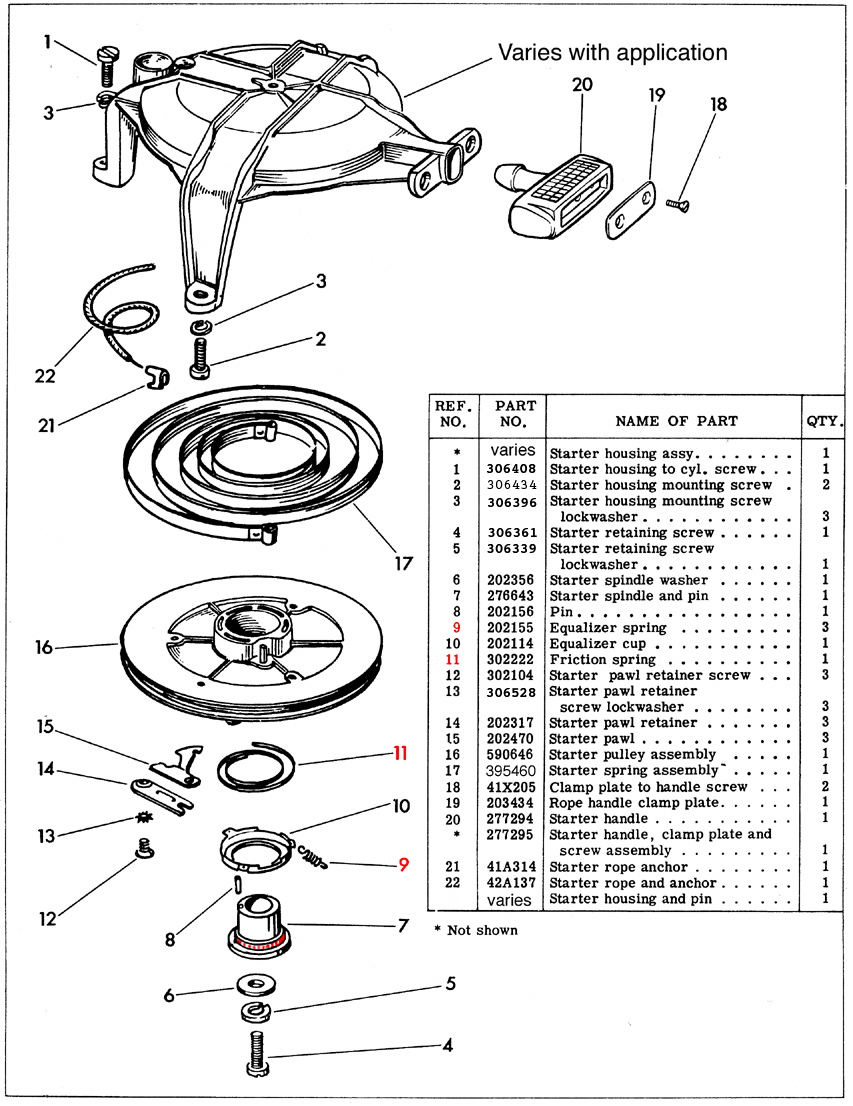

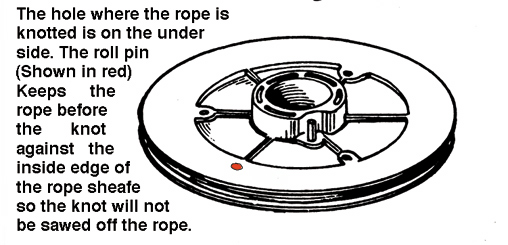

In cases where the starter rope has come loose from the handle or broken, the rope sheave will rewind so fast that the spring will fold back on itself. The spring should then be replaced. If an attempt is made to straighten the spring The kinks will cause friction and require greater tension to rewind. Also the lithium bases (white) grease used to reduce friction stiffens with age. Note the starter uses a friction spring 302222 to extend the starter pawls. This spring MUST be seated an the indicated step on the starter spindle.

The original starter rope and anchor had a bronze cable at it’s core. If exposed, thin can cut into the aluminum housing. A nylon woven rope is now used. Be SURE there are NO rough edges in the housing that will damage the nylon. Heat is used to fuze the end of the nylon rope to keep it from fraying and stiffen it to keep the knot from slipping.

The starter spring used is number 18-6501

-

This reply was modified 5 years, 5 months ago by

garry-in-michigan.

garry-in-michigan.

February 16, 2020 at 3:04 pm #195053Back in “the Day”, the small Simplex starters used 41-197 (307573) spring, while the Big Twins used a 375836 spring (stronger). Note that the Sierra chart above lists their number 18-6501 as a fit’s-all spring.

February 16, 2020 at 3:45 pm #195055The 18 horse starter has an elliptical rope sheave and requires less effort. It needs a different flywheel and I don’t know if any parts are interchangeable . . .

-

This reply was modified 5 years, 5 months ago by

garry-in-michigan.

garry-in-michigan.

February 16, 2020 at 5:43 pm #195088Well I think I will sell it to a 30 year old, thanks

February 17, 2020 at 10:22 am #195137

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

February 17, 2020 at 1:14 pm #195157I had to remove one plug to start it, after I ran it a while it would start on 2 plugs. I ran the motor 1/2 speed about 10 minuets and it got a little easier but still hard to pull. I tried my 1956 Johnson 15 hp and it was a lot easier it has the 18 hp type starter.

February 17, 2020 at 1:26 pm #195158That’s now true history when Frank & Garry reply. Reminds me of a few programs ago with the club. I too find things heavy now. ;>)

-

This reply was modified 5 years, 5 months ago by

jeff-register.

-

This reply was modified 5 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.