Home › Forum › Ask A Member › 1954 evinrude 15hp armature plate

- This topic has 13 replies, 6 voices, and was last updated 7 months, 1 week ago by

fleetwin.

-

AuthorPosts

-

August 1, 2024 at 9:01 am #289576

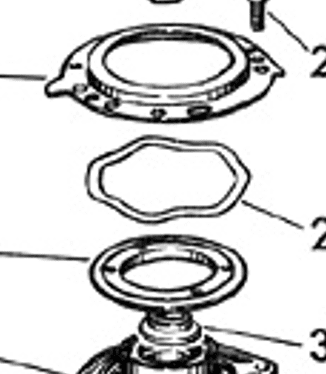

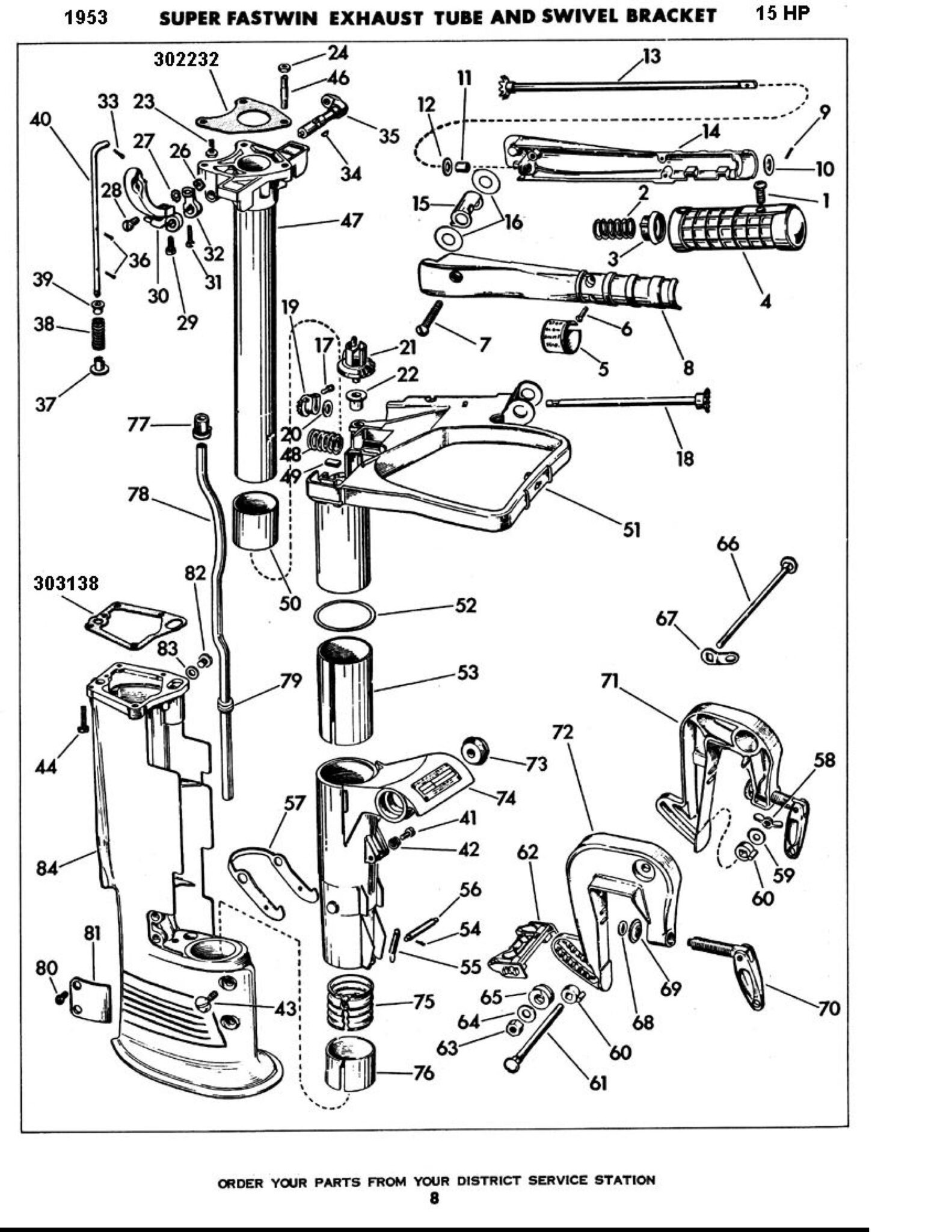

Well actually, it is not shown upside down. What they did was save money by reusing an older drawing where the “flat side” was stepped down to make room for a wave washer to provide friction to make the throttle stay where you put it (motors without twist-grip throttle control). Wave washer was not used on such motors and the flat side was actually flat. Guess they didn’t figure on people actually paying attention to the drawing.

I guess myself and some others mistakenly thought that this was drawn upside down. I suspect that this reused mounting ring drawing from the 3 hp led to a lot of misunderstandings over the years wherever it was copied to the larger hp manuals. Thank you, Frank for pointing out this distinction.

1 user thanked author for this post.

August 1, 2024 at 11:52 am #289578steve, my problem is the roller going past the cam on the slow-stop side of the cam. Once the roller is past the cam the spring pulls the roller back toward the armature plate and gets caught on the cam. I need to stop the roller before it goes off the cam. I have had motors that had a screw on the throttle control gear which would stop the handle from turning at a certain point, but I don’t have that on this motor. maybe I could improvise something in this area.

August 1, 2024 at 6:12 pm #289581That would be one solution to try, if you got a throttle control gear from a later model that had the 1/4-20 screw. But not sure if you used that, would it also prevent you from idling low enough to shift?

I think I only ran across that once or twice but don’t really remember what I did.

In one case I may have actually filed down the leading edge of the cam a little to create a sharper angle that would pick up the roller easier.

1. Have you checked synchronization to see if the cam needs to be adjusted in a little?

2. Is the throttle control pinion #19 meshed properly with the throttle control gear #21?

August 4, 2024 at 10:45 am #289611For sure. This is a problem area, sure wish the stops on the armature link and vertical shift rod were more robust, but are prone to wear. Once this happens, the roller will come off the cam just as you describe. This is a very dangerous situation that will more or less “lock” the engine at WOT, YIPES! So, it is best to replace those worn parts if possible. I wish they had engineered this with a little more room for expected wear.

Did you resolve the vertical slop issue here? Was the threaded aluminum retainer installed upside down? Needless to say, the vertical slop issue must be addressed for the ignition system to work correctly.

-

AuthorPosts

- You must be logged in to reply to this topic.