Home › Forum › Ask A Member › 1954 evinrude 7 1/2 hp question

- This topic has 12 replies, 9 voices, and was last updated 9 years, 1 month ago by

garry-in-michigan.

garry-in-michigan.

-

AuthorPosts

-

March 17, 2015 at 3:53 am #943

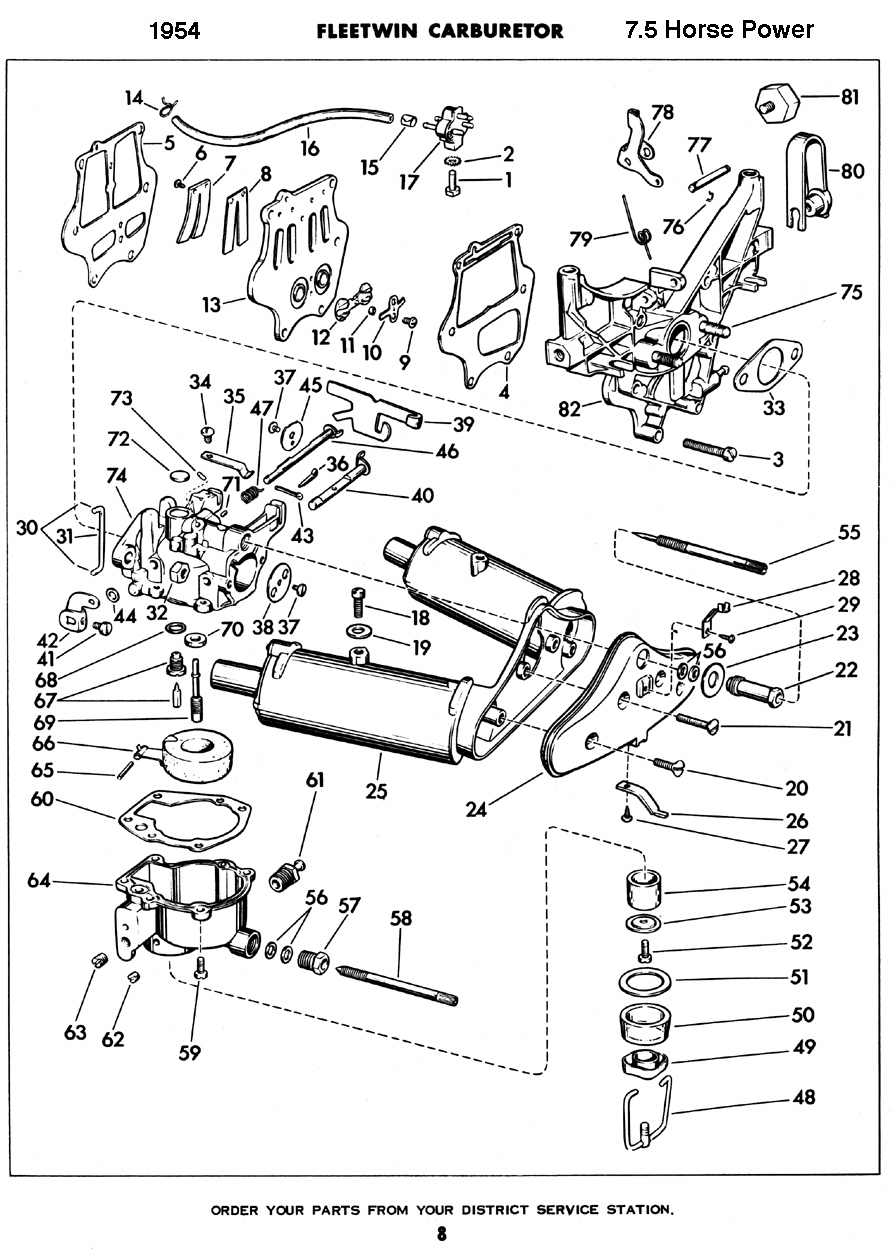

so this one is a bit older than my 7 1/2 hp Johnson from 1958. tried to disconnect the lower and it is hung up. dropped about an inch. is there a fastener I’m missing like on the early Johnson big twins?

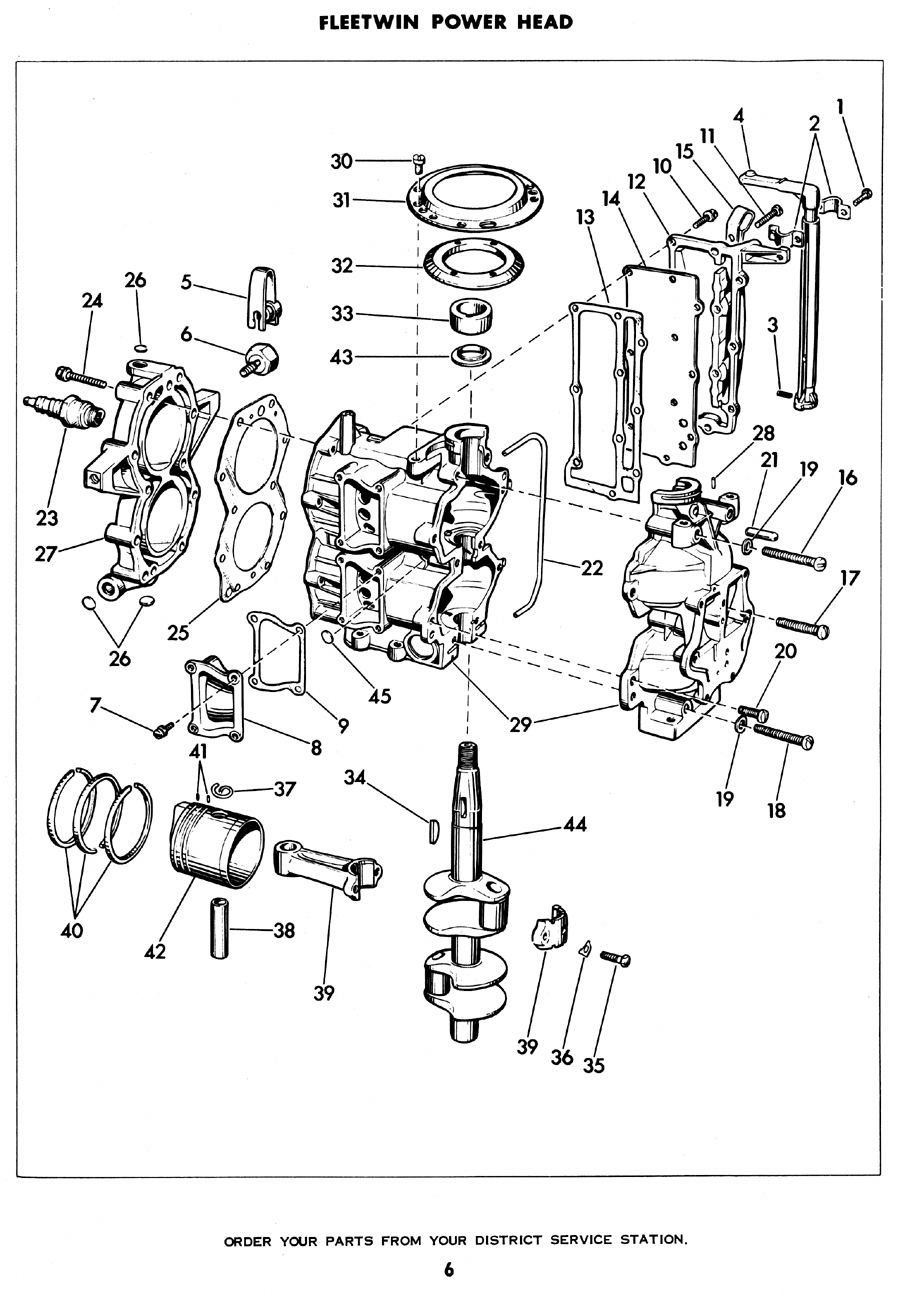

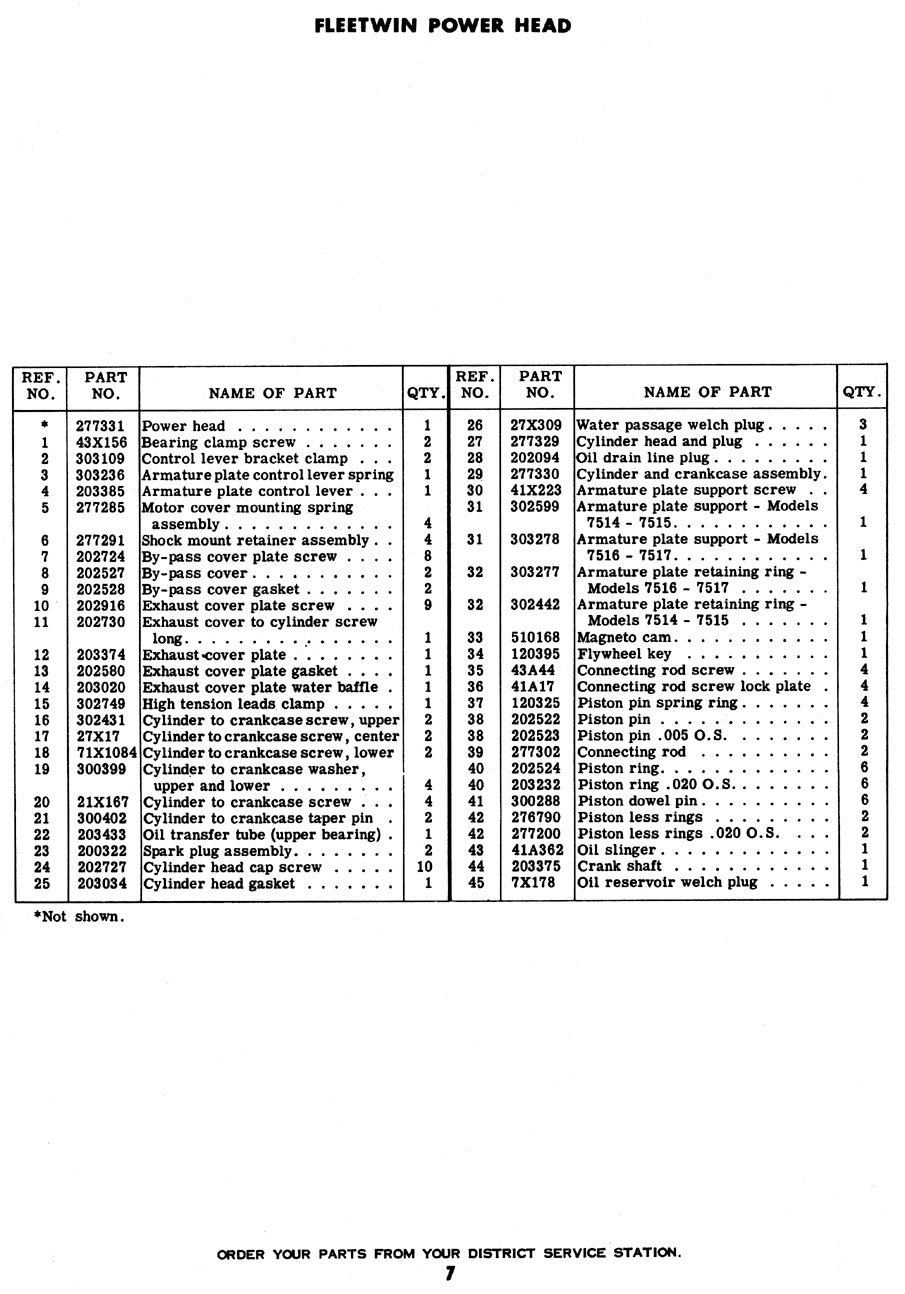

the motor is very hard to turn over. i assume this is due to the bad shock absorber in the tower. my 1958 model was hard to pull over also and wound up having a worn seal housing due to the shock absorber expanding and mashing it.

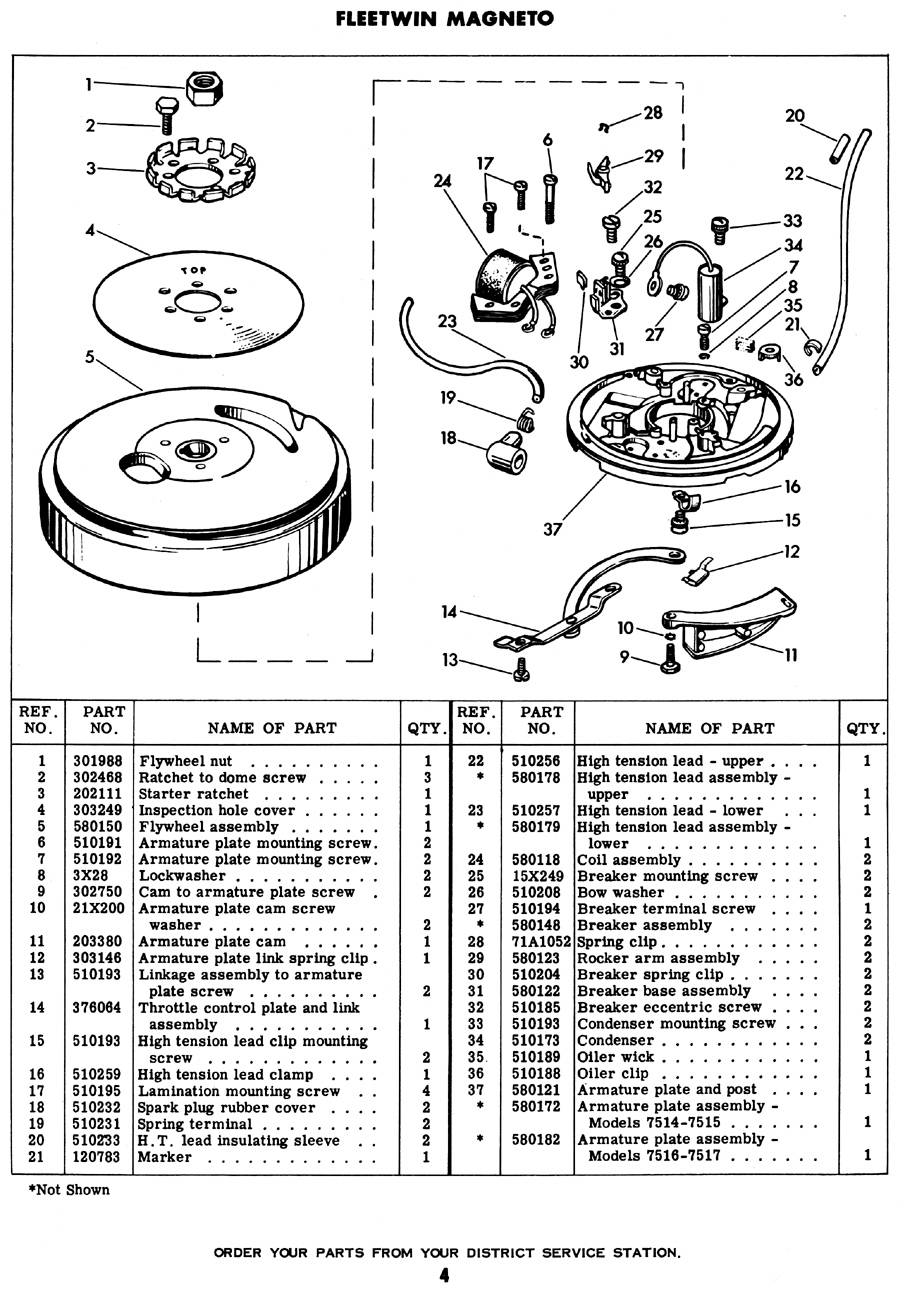

also the mag plate is very stiff. the throttle linkage (tiller, etc) moves very freely when disconnected from the mag plate lever so it must be the plate itself.

the one coil (dark green) test ok in the plate but I’m probably going to change both if I find the motor is worth pursuing. anybody know about these dark green ones?

this is another $25 motor but not as promising as the lightwin in my other thread. we’ll see if it can be brought around. there Is heavy mouse piss damage here and there and a couple missing carb knobs but you just never know. it may run like the wind again.

this is only my second 7 1/2 hp OMC motor. am I right in thinking that when they are hard to pull over that it’s due to the bad shock absorber? it’s so hard that I can’t even get a compression reading from it.

thanks for any help.

scottMarch 17, 2015 at 4:06 am #12148You have a lot of questions here.

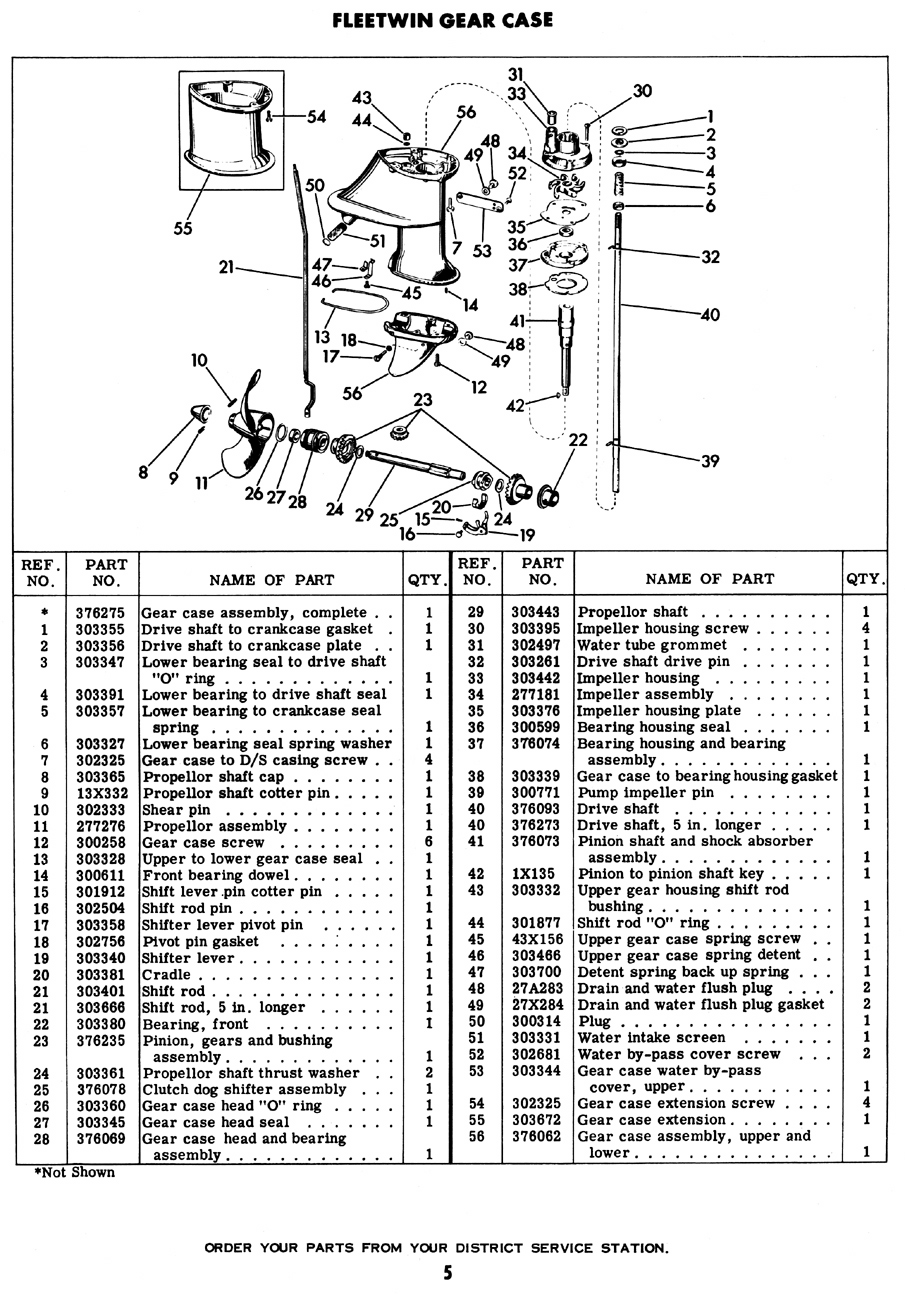

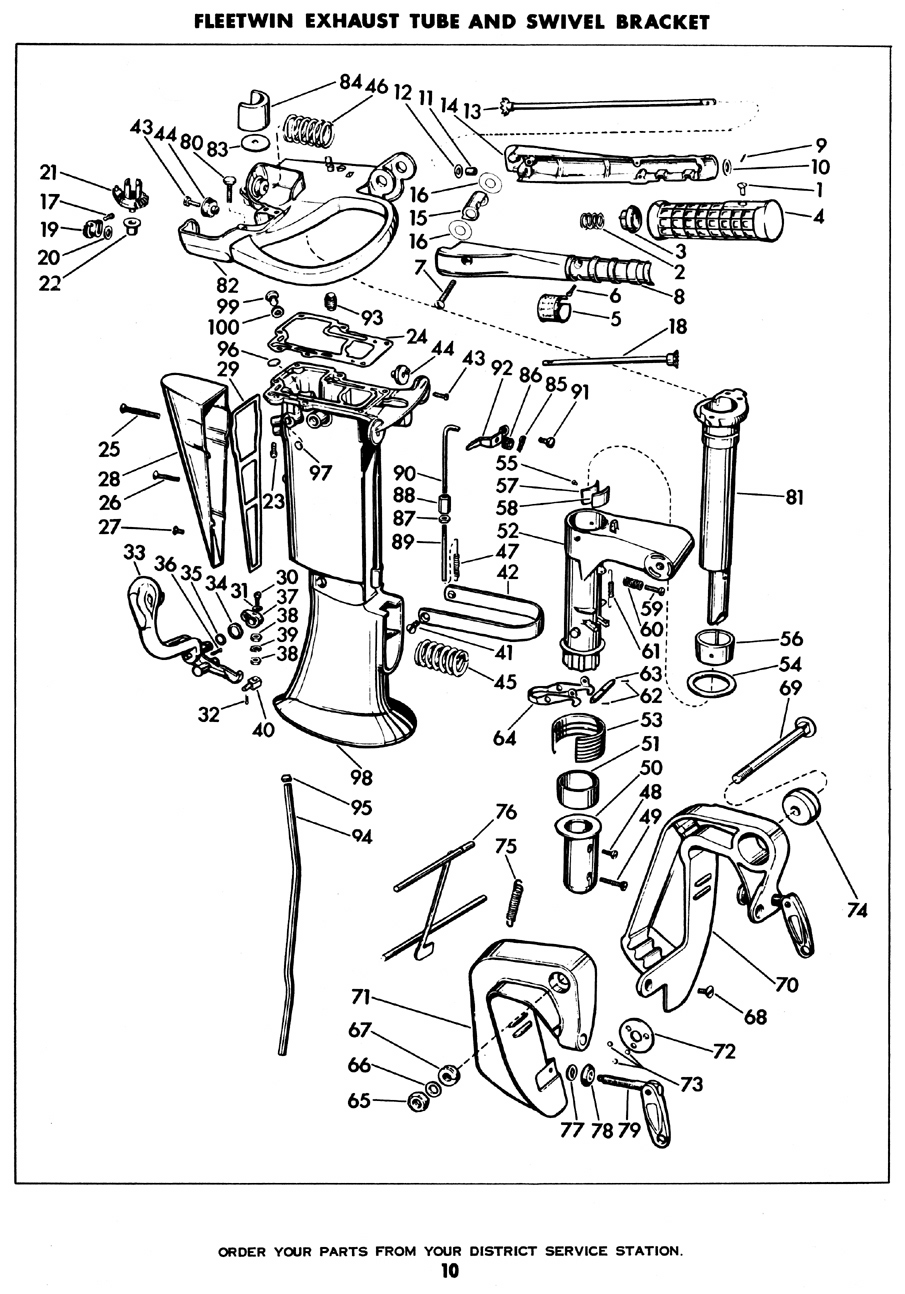

1. The gearcase can only be taken down by removing the powerhead. From there you unscrew a nut which is connected to the shift lever and that frees up the gearcase. Don’t try to force it out, you’ll break something up near the powerhead.

2. Hard to turn over – spray some fogging oil or put some 2-stroke oil into the cylinders. It could be bone dry in there, or if the motor is really cold (like 10 degrees), you won’t be able to get that thing to turn over.

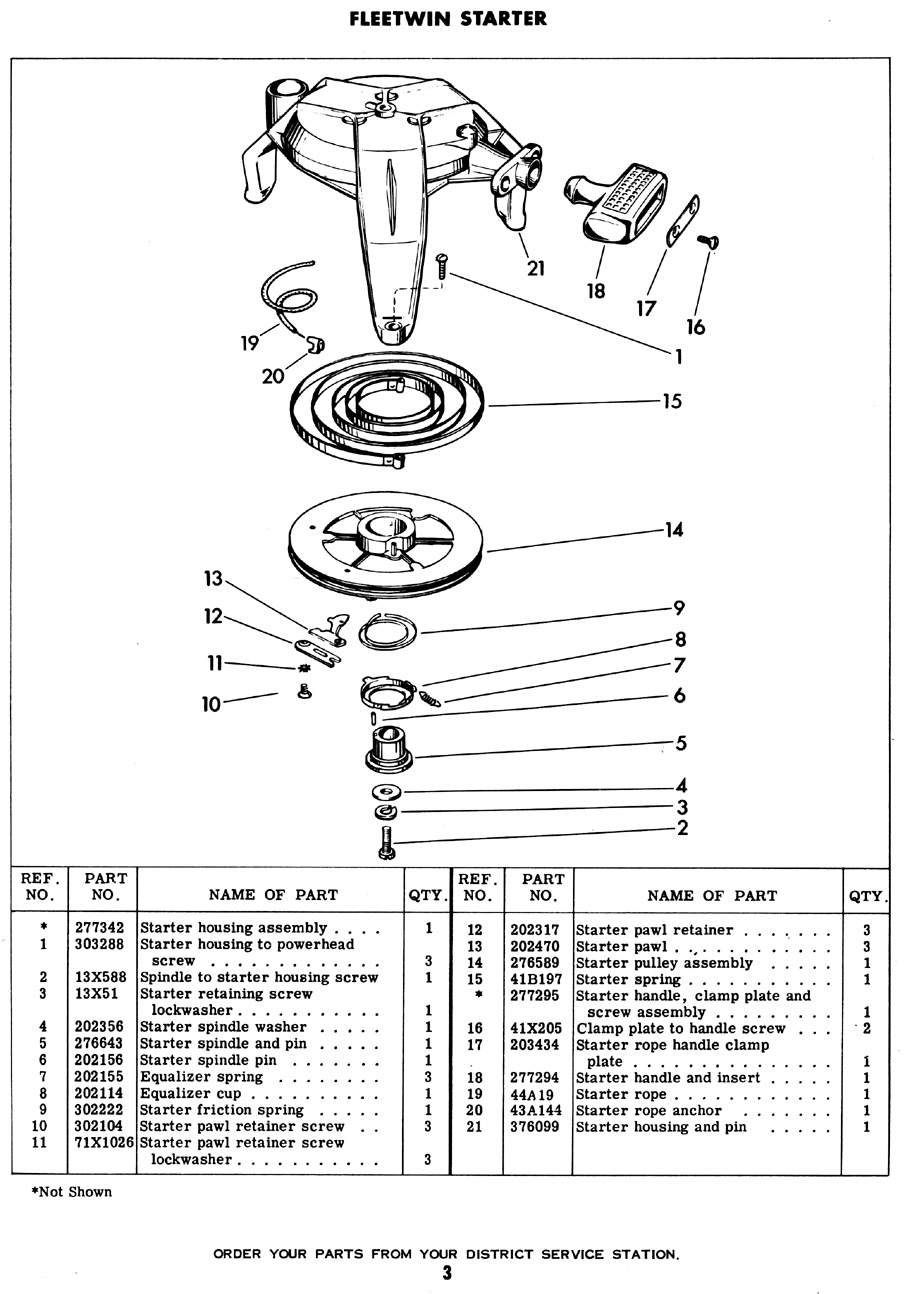

3. If the magneto is barely turning, remove the stator plate and clean any old grease off the armature plate. Relube the ring and it should move freely. Pretty common issue with an old motor (or even new ones too if left sitting and dried out).

4. Coils are coils. If you don’t get spark on one side it could be connections, dirty points (or dead points), condenser, or just a bad coil. Also could be a leaking wire (worn insulation) or faulty spark plug boot.

Anyone who knows me, knows that I hate the 5.5/7.5’s, not because they are bad motors, but because it’s a big hassle removing the powerhead to change an impeller or identify a cooling system issue. And as soon as you start disturbing things, then you get into 10 other headaches…broken wires, no-good gaskets, broken screws…the hell with that!!!! I sold 9 of them in the last 3 months and will never buy another again!

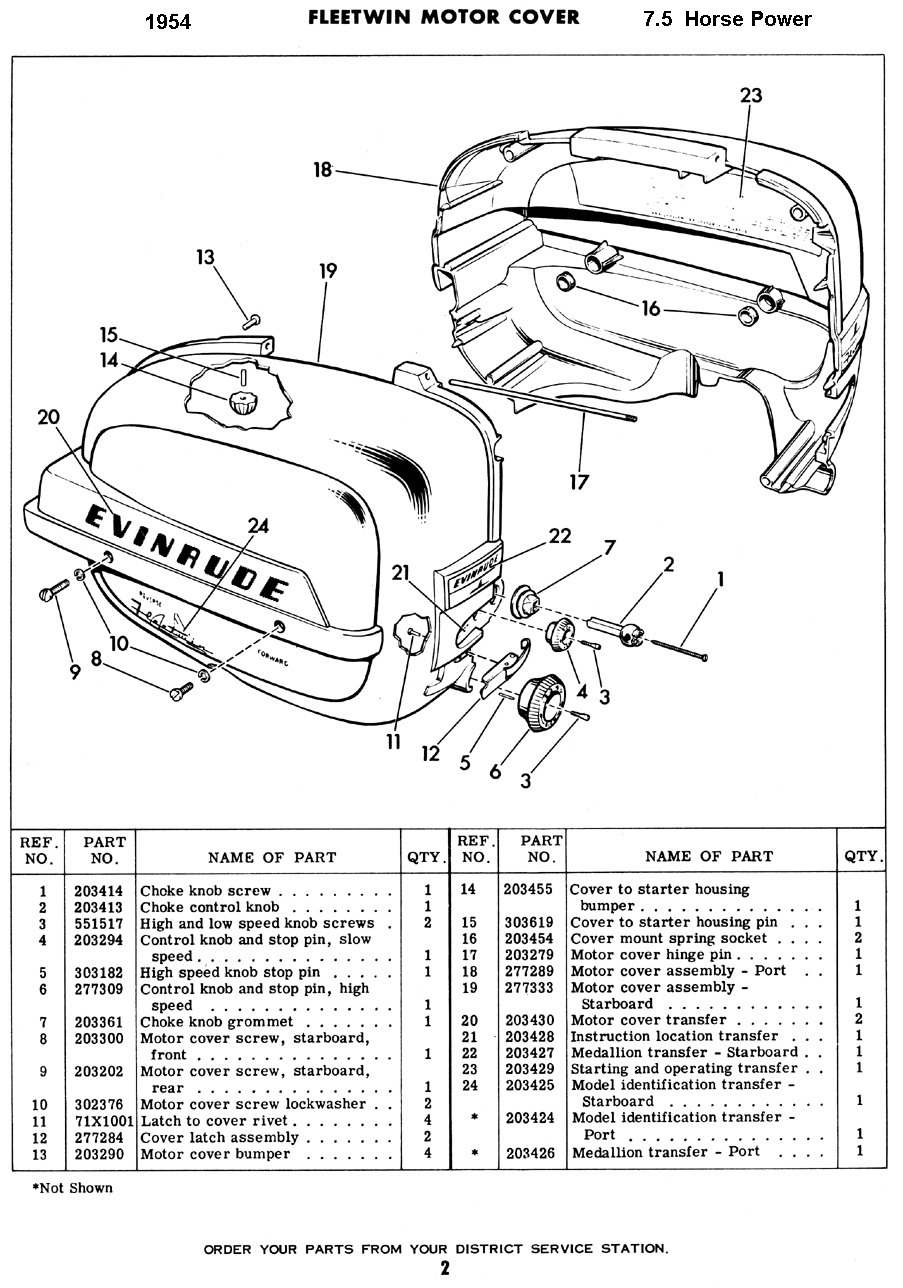

March 17, 2015 at 4:14 am #12149The starter on the 54 is different than the later 7.5’s. It. Is smaller, and doesn’t have the eliptical pulley that gives more leverage when the pistons are on the compression part of the stroke. My 54 Fleetwin is considerably harder to rope over than my later 7.5’s. Of course that doesn’t mean you don’t have something else going on too.

March 17, 2015 at 4:16 am #12151The starter on the 54 is different than the later 7.5’s. It. Is smaller, and doesn’t have the eliptical pulley that gives more leverage when the pistons are on the compression part of the stroke. My 54 Fleetwin is considerably harder to rope over than my later 7.5’s. Of course that doesn’t mean you don’t have something else going on too.

March 17, 2015 at 4:41 am #12153I hope that isn’t rust on those pistons…or it might just be a really bad glaze on the cylinders/pistons. Either way, I’d be hitting that with 2-stroke oil generously and hand-turning the flywheel SLOWLY before trying to do anything in terms of compression testing. They shouldn’t be that color. Looks like a badly shorted out coil that melted down too….

March 17, 2015 at 11:19 am #12163A few screws will release the Powerhead. Pay attention to the driveshaft nut, seal, o-ring seals and replace them (they are inexpensive) when you put it back together. Looks like you have a good project in the works.

Let us know how a good soak of the cylinders loosens up the works.March 17, 2015 at 11:24 am #12165Yeah, those pistons look kinda rusted…You will know what the deal is once the gearcase is off, you may want to drain the gear lube first to see if the gearcase is any good. This project may turn out to be more than you are interested in pursuing.

March 17, 2015 at 1:12 pm #12173Here’s a link that will explain how to disassemble that model.

http://www.duckworksmagazine.com/03/r/c … /index.htm

Good Luck with Your motor.

Steve A W

Member of the MOB chapter.

I live in Northwest IndianaMarch 17, 2015 at 4:56 pm #12182March 17, 2015 at 7:27 pm #12199

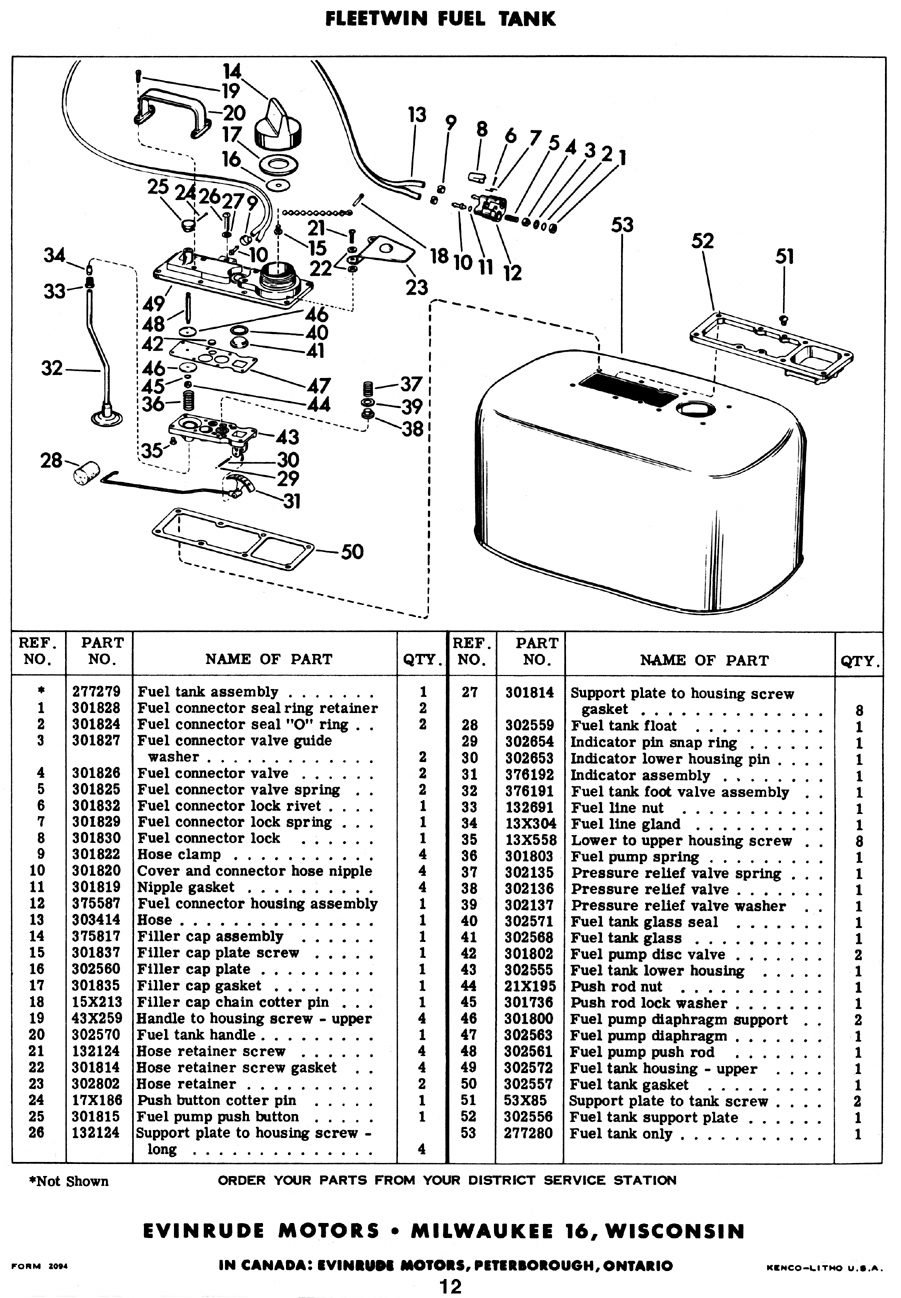

Hope this Helps –

-

AuthorPosts

- You must be logged in to reply to this topic.