Home › Forum › Ask A Member › 1954 Evinrude 7516 questions

- This topic has 11 replies, 5 voices, and was last updated 8 years, 1 month ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

January 20, 2017 at 3:25 pm #6149

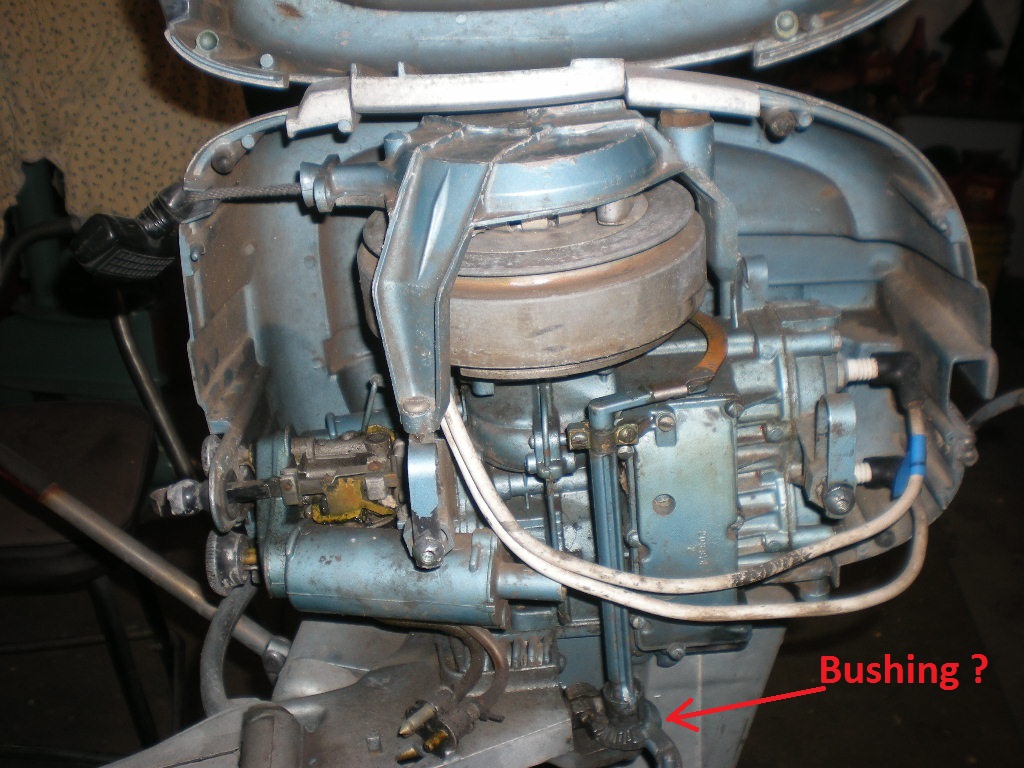

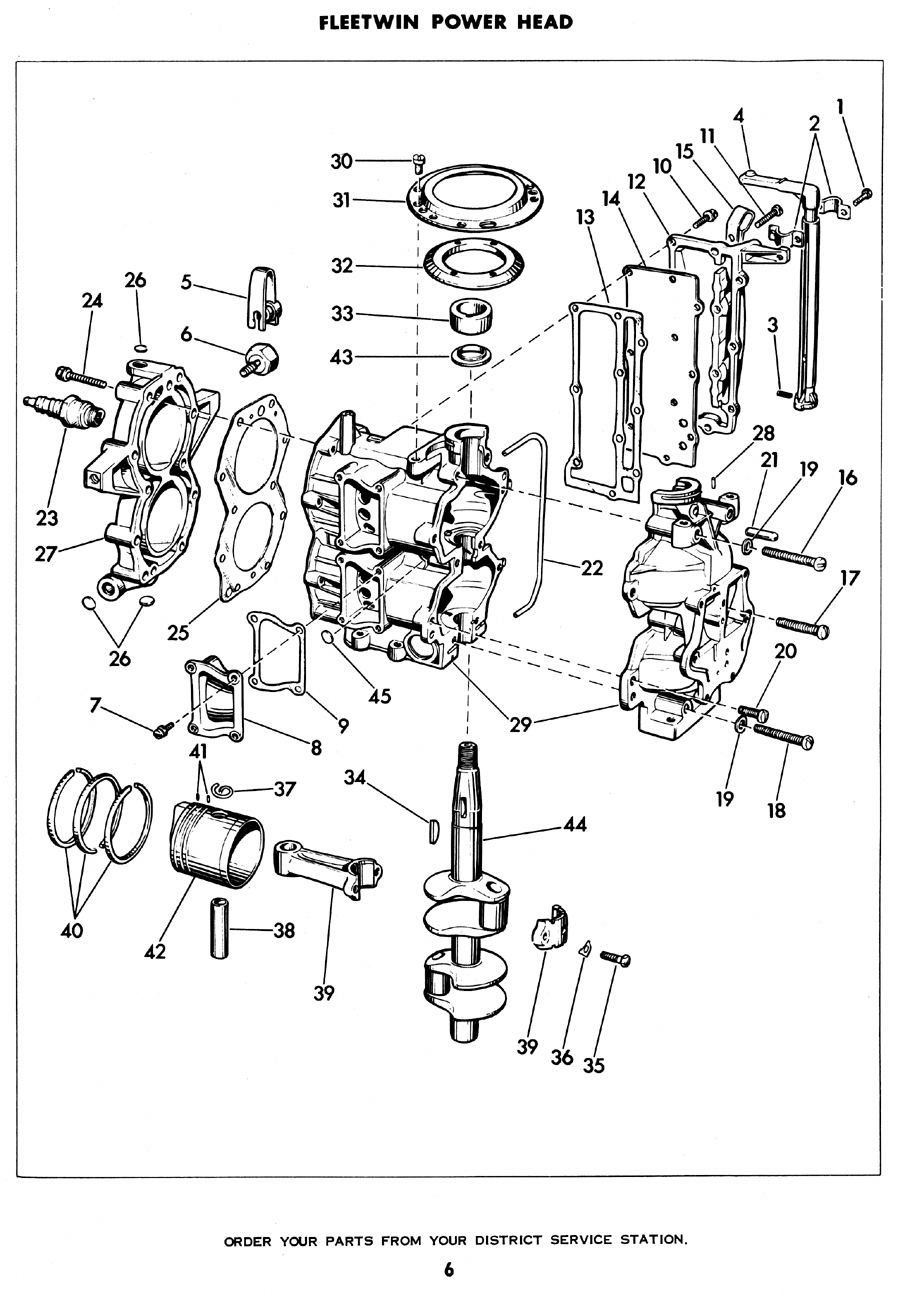

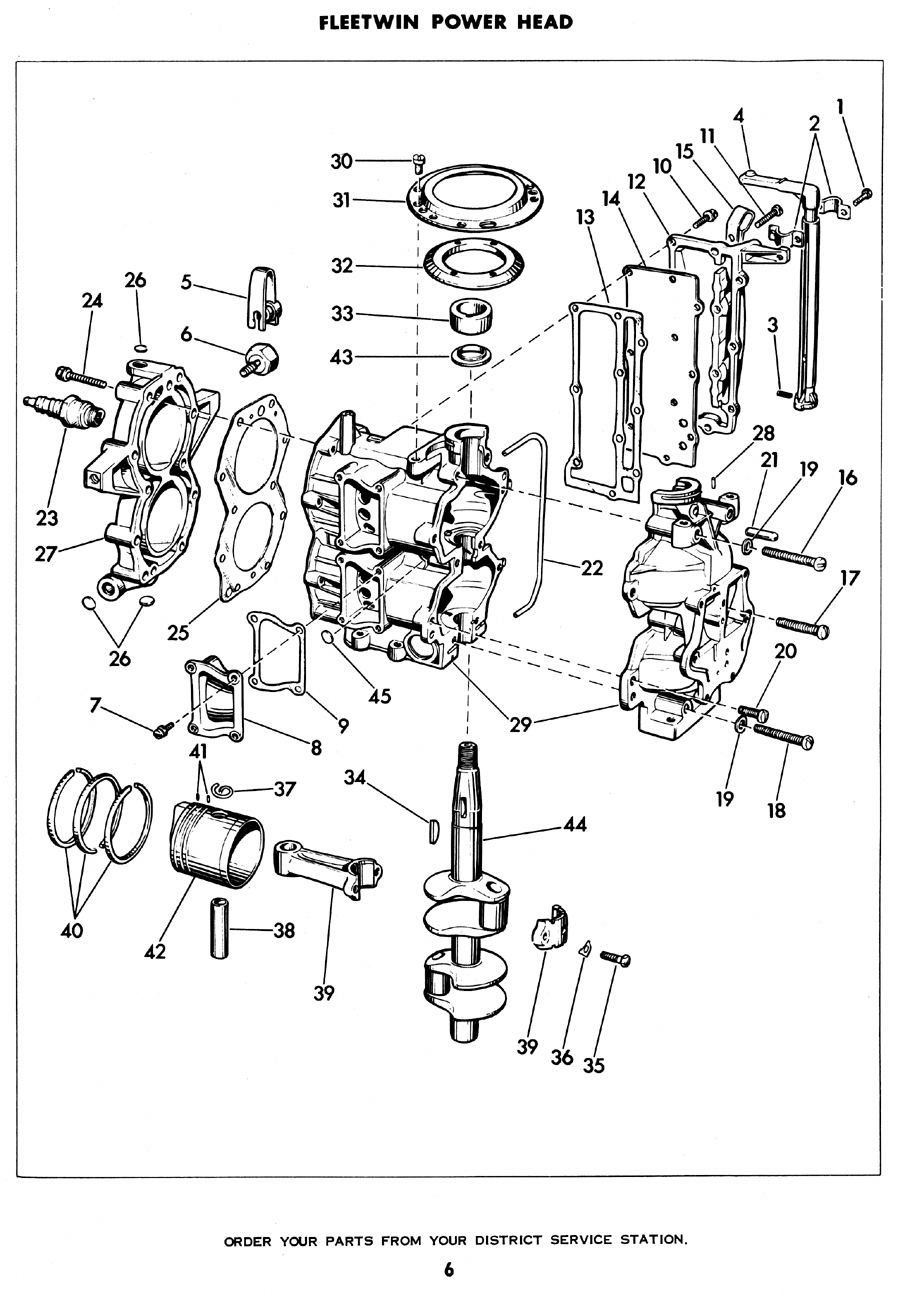

Just tore into this $40 Evinrude yesterday. Good news so far is that

the coils have been replaced at one time.

This one will be put back on the road / lake as cheap as possible.

May or May not paint it…… really ugly…. hard to even tell it was "blue"

at one time.The compression……. Top 75 psi, Bottom 81 psi.

I’m guessing it will run, but wish the numbers were a

little closer together. I inspected intake and exhaust

ports. No rings are stuck, and no obvious scoring

or "melt down" noted.

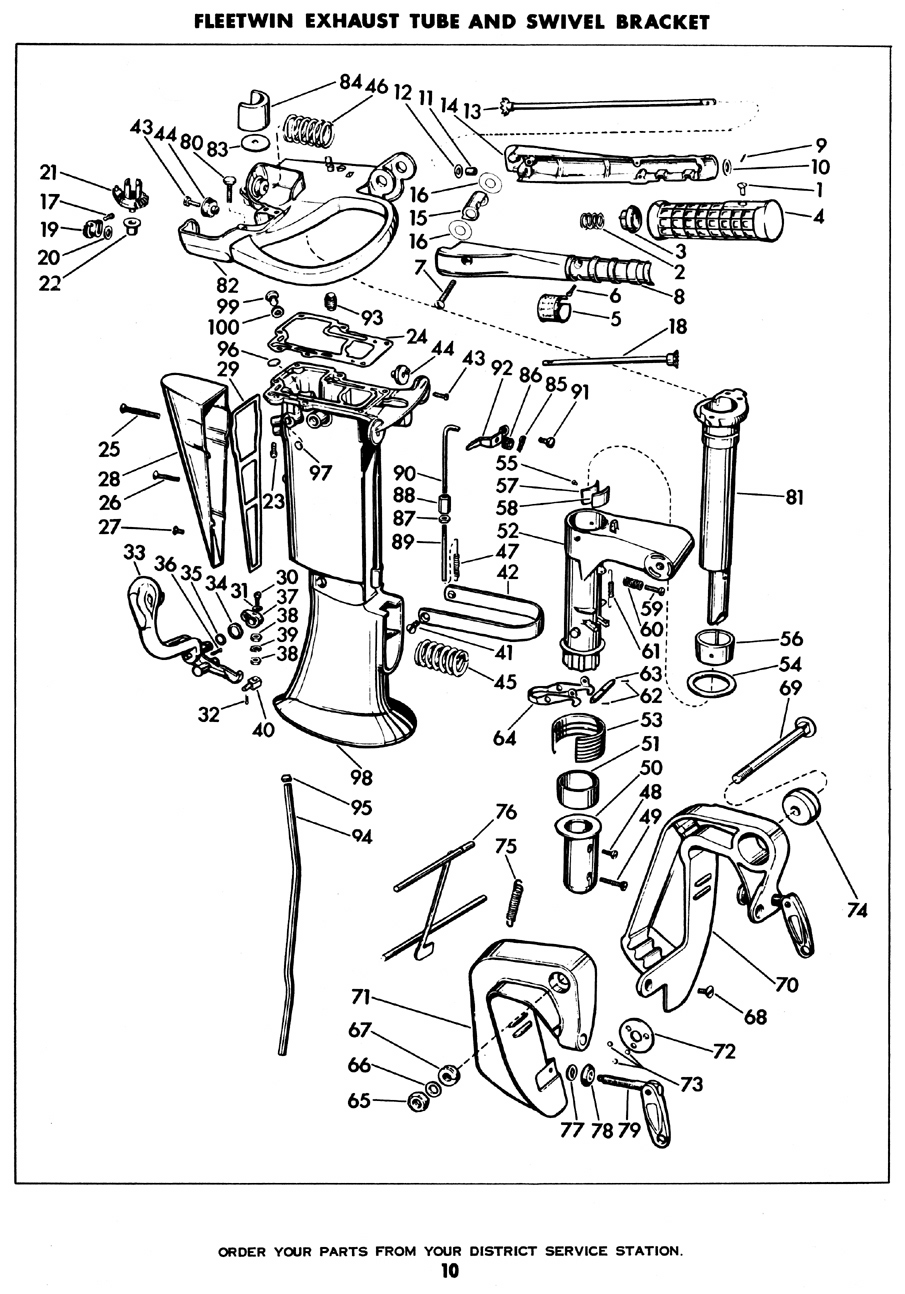

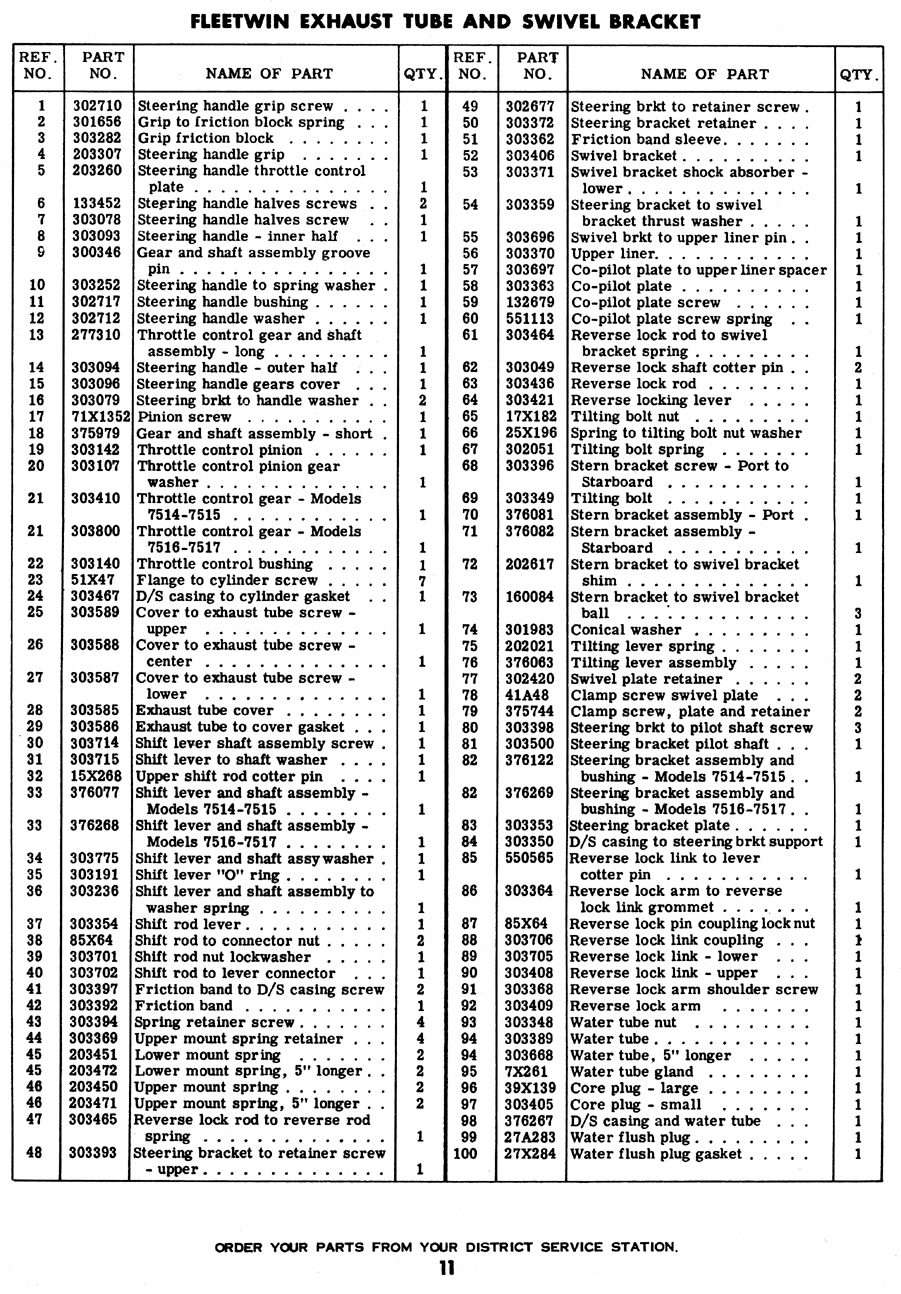

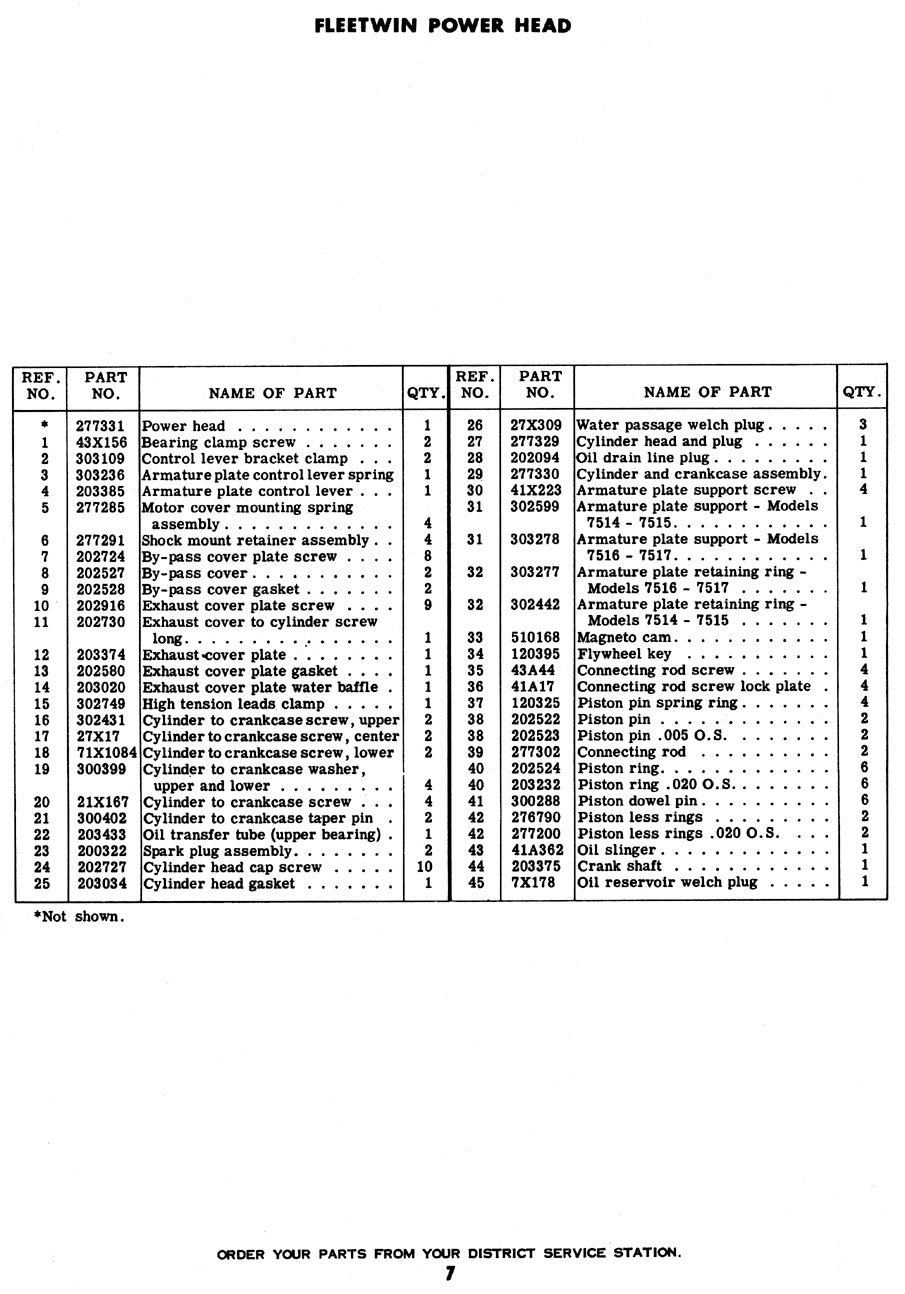

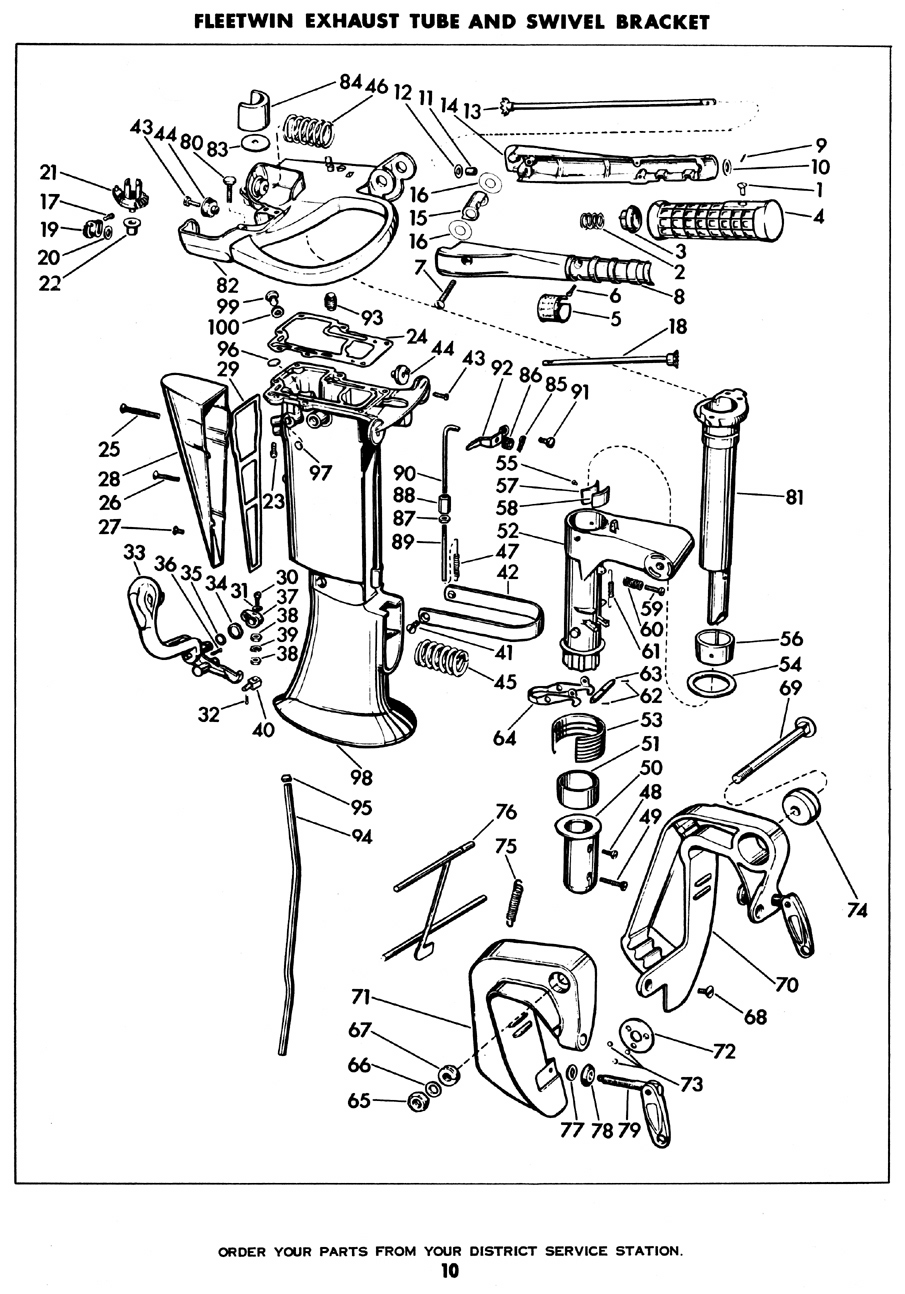

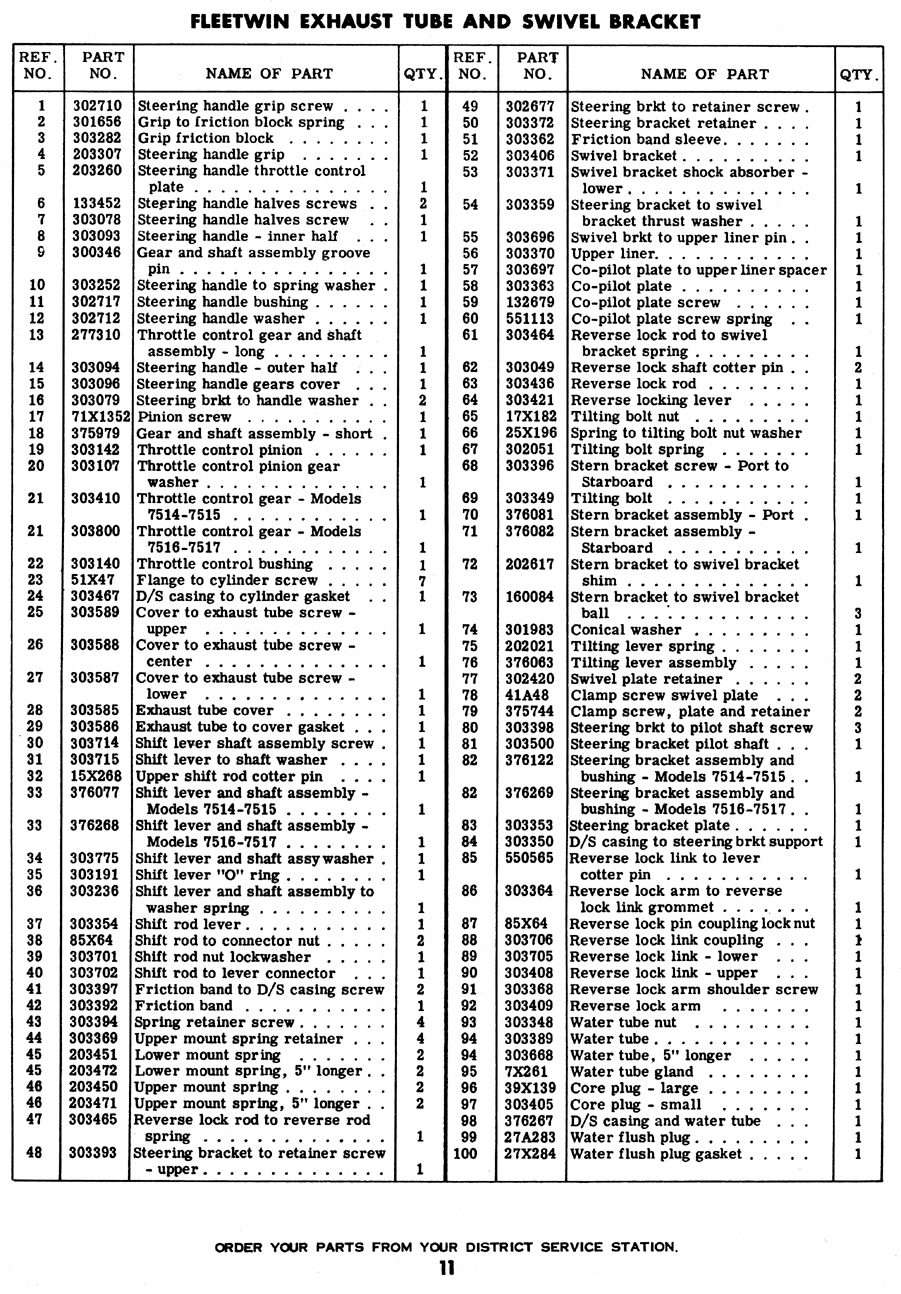

Q. Would you "hope for the best", or inspect further?The shift lever is pretty sloppy. I see no mention of a bushing in the

parts list.

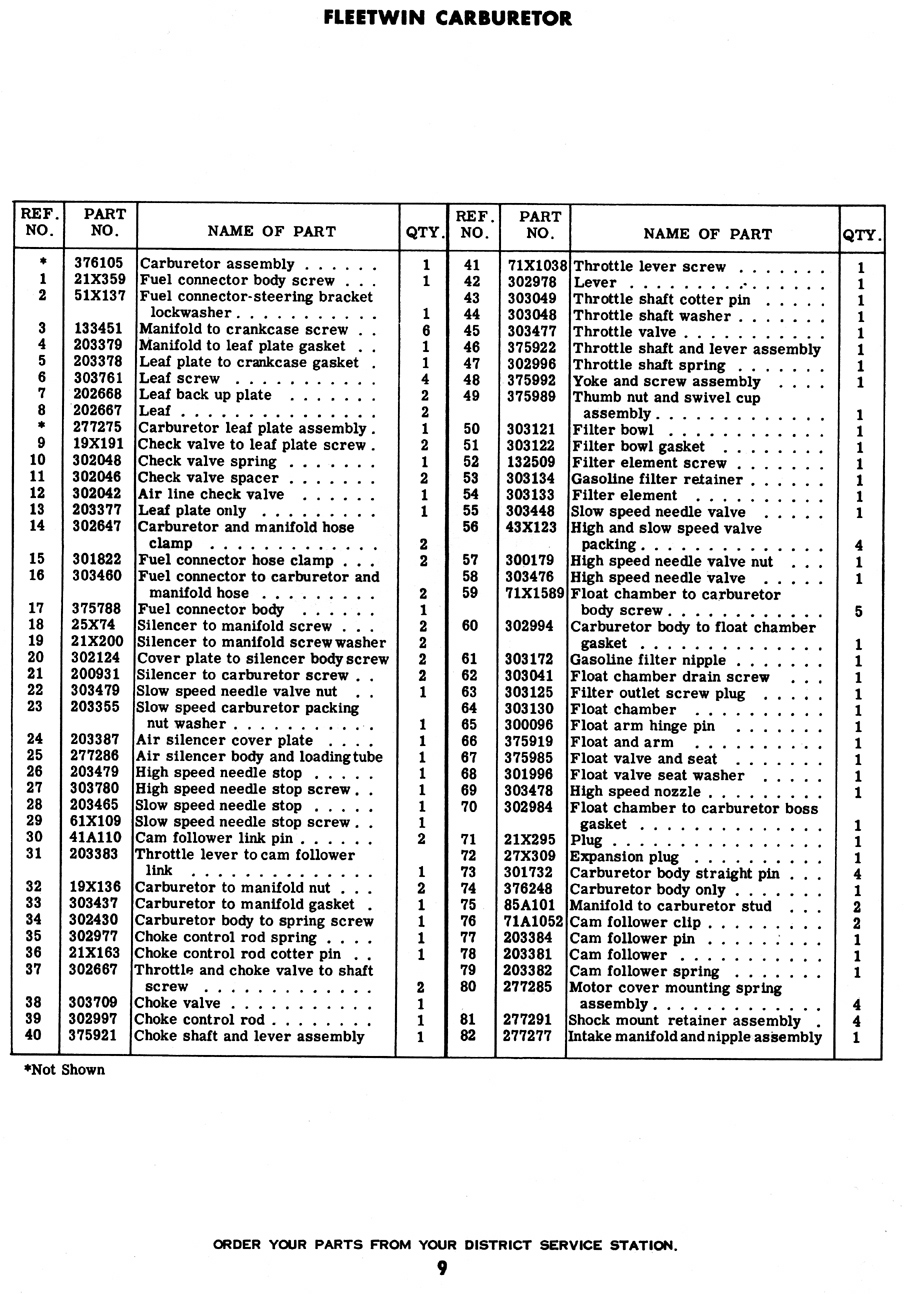

Q. What have you guys done to tighten up the shifter?The throttle control vertical rod "gear bushing" is very sloppy.

The parts list shows a nylon bushing (going for $30 retail).

It looks like too thin of a bushing to make on the lathe.

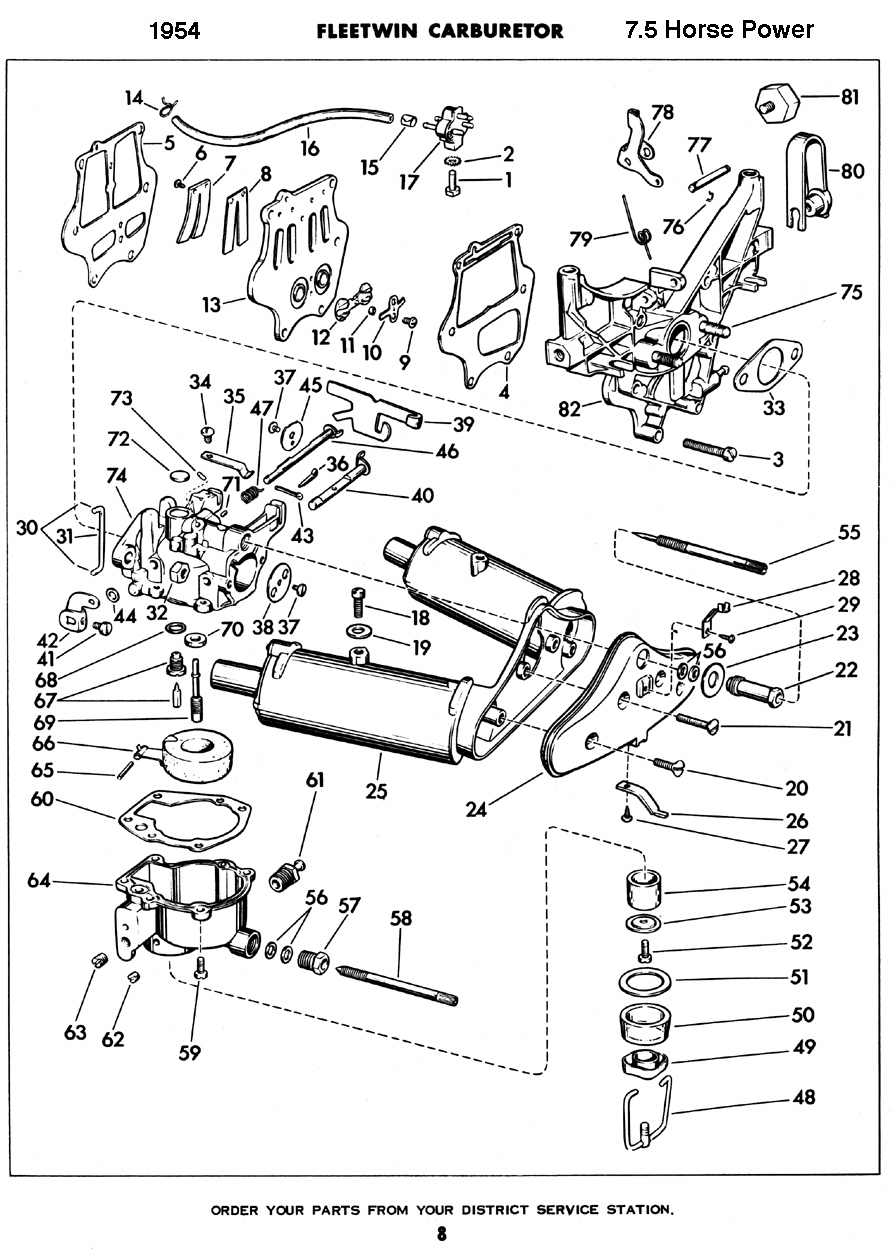

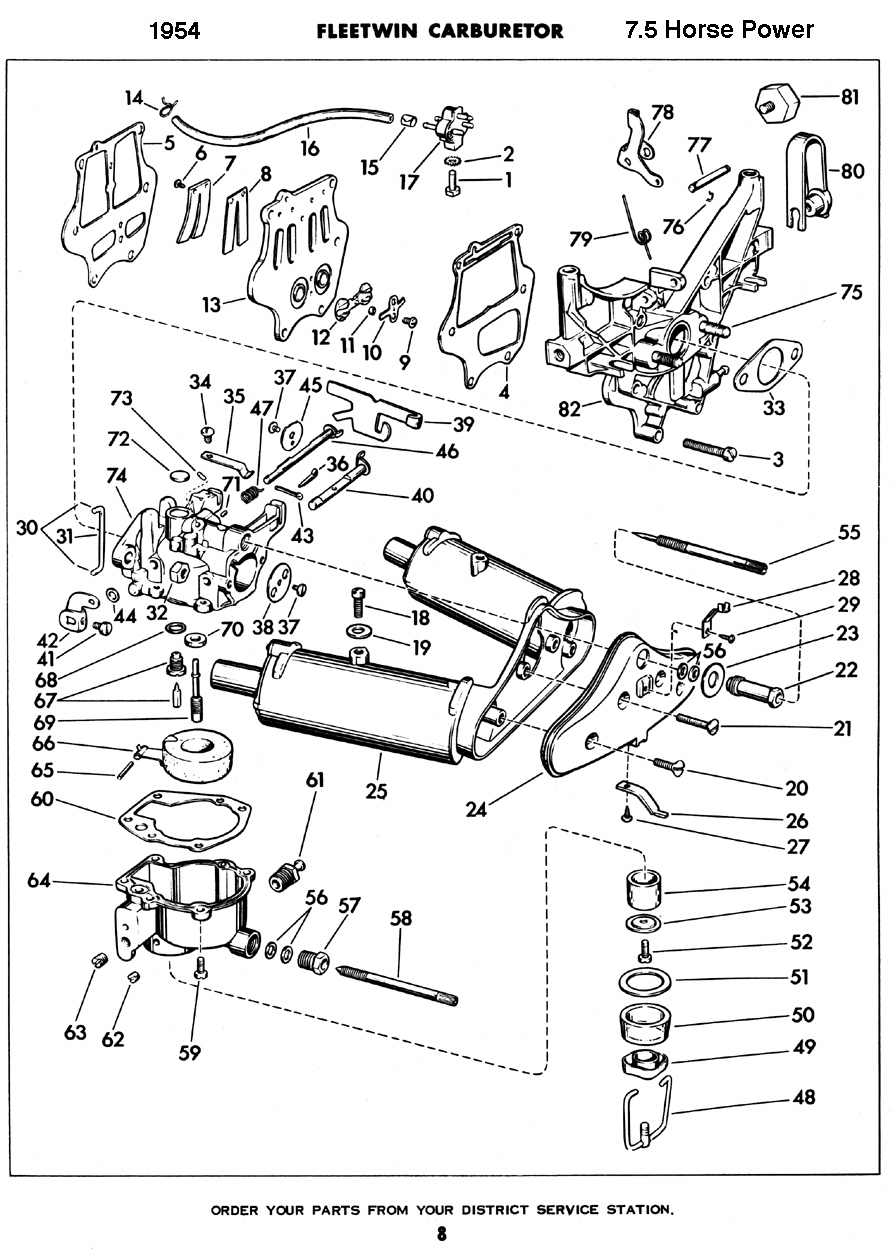

Q. What’s a good / cheap solution to fix this part?Q. What’s up with this funky looking exhaust chamber

(shown with cover off) ….. is it 1954 "tuned exhaust" ?Prepare to be boarded!

January 20, 2017 at 4:29 pm #513981. Me? I’d run it.

2. I suppose you could ream it out and install a bushing. Or let it flop.

3. $30 huh? I’d make one on my lathe. Or pick up a used one somewhere. But how about the stem on the gear? That could be worn too.

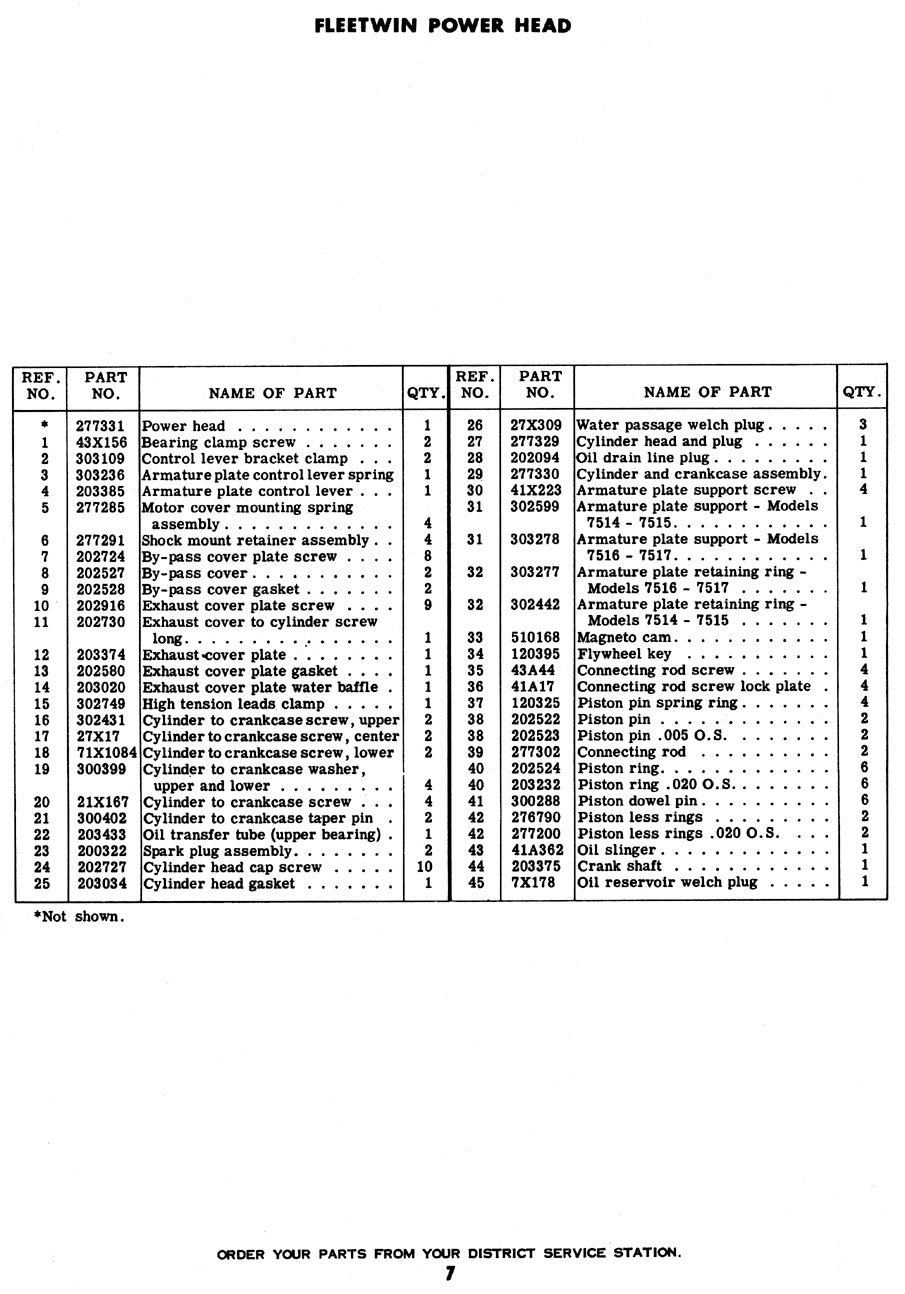

4. It’s a mufflerJanuary 20, 2017 at 5:16 pm #51402Your motor should run OK as the numbers are within 10% of each other and these fishing motors came with low compression ratios anyway. After running it a bit on the required 16:1 mix, they might even come up a bit.

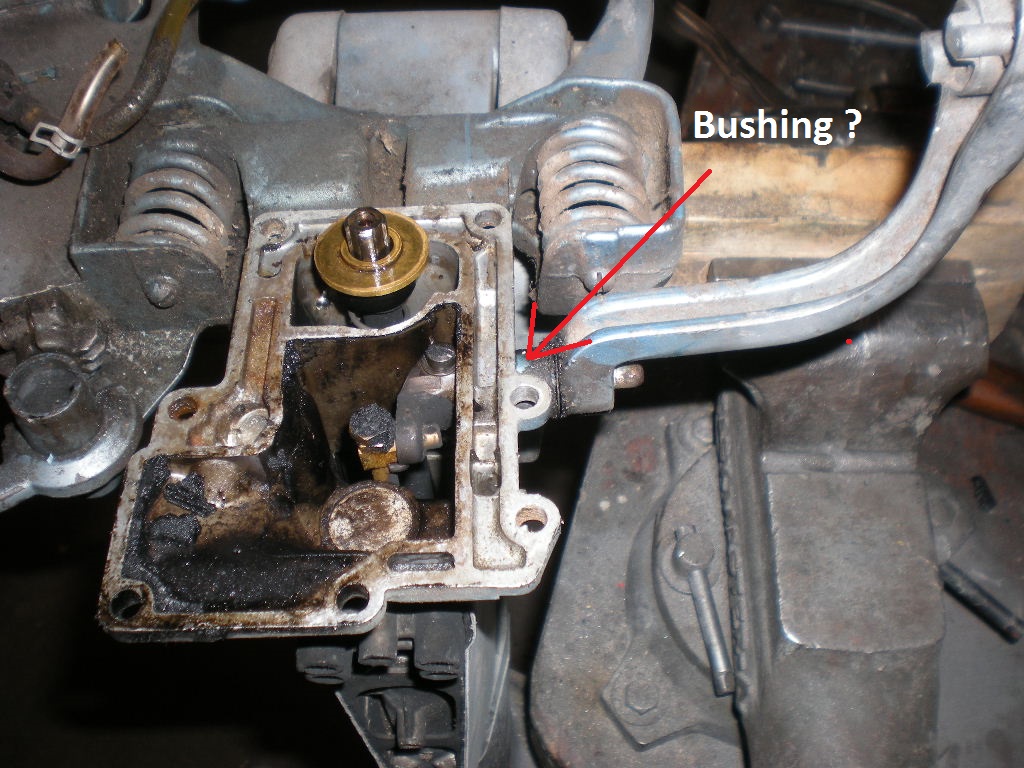

I ran a full story on fixing those sloppy and dripping shifters on the old boards but basically I just drill it out and glue in a brass bushing made out of tubing from the hobby store. In these photos I’m using epoxy but it seems super glue works just as good to.

January 20, 2017 at 5:39 pm #51404I’m with Frank, I think it will run fine without further powerhead disassembly. Recheck compression after you get it to run a bit. Perhaps you can just try to start it the way it is if there is spark, then recheck compression. Looks like you have already had/have the powerhead off, so am hoping you replaced the water pump impeller and checked/changed the gear lube. Hoping you serviced the lower seal components on top of the driveshaft as well.

Those shift handle bushings do get sloppy, there are no replacement NOS bushings available. I would run it the way it is, be sure to replace the shift lever oring, and don’t got to concerned if you see water dripping from the shift handle, this is not big deal and has no effect on reliability. I know Mumbles has engineered some sort of bushing replacement for this issue, so you can always contact him if you decide to replace the bushing.

The plastic bushing in the vertical throttle gear is no big deal either, I’m sure you can find a replacement for less than the OEM price. But, like Franks says, the gear stem might be worn also. Shouldn’t be hard to find a used one of these either.

So, I guess I would probably try to just get the engine running doing the minimal amount of work first to ensure all the internals are OK, if possible, before going crazy on the detail stuff.

Looks like Mumbles has already posted a nice how to on replacing that shift handle bushing!January 20, 2017 at 6:02 pm #51407Thanks for the helpful replies! The copper tubing

repair looks "do-able".

I haven’t tore into the LU yet. I’m seeing a lot of

similarities in this 1954 7.5 fleetwin as to the 1960

5.5 hp Fisherman I went thru in the past, and do

remember replacing the shift rod o-ring in that, etc.,

but couldn’t remember if it had the sloppy shift lever

and throttle bushings to deal with.

Back to the garage!

Thanks!Prepare to be boarded!

January 20, 2017 at 9:22 pm #51418The shift rod in the gear case has notches that a spring engages to hold it in gear. The nylon bushings lasted longer in testing than brass. they were also cheaper. In actual practice the brass withstood heat better, but needed to be lubricated more often. The transom bracket thumb screws also work better/longer when coated with grease. . . 😉

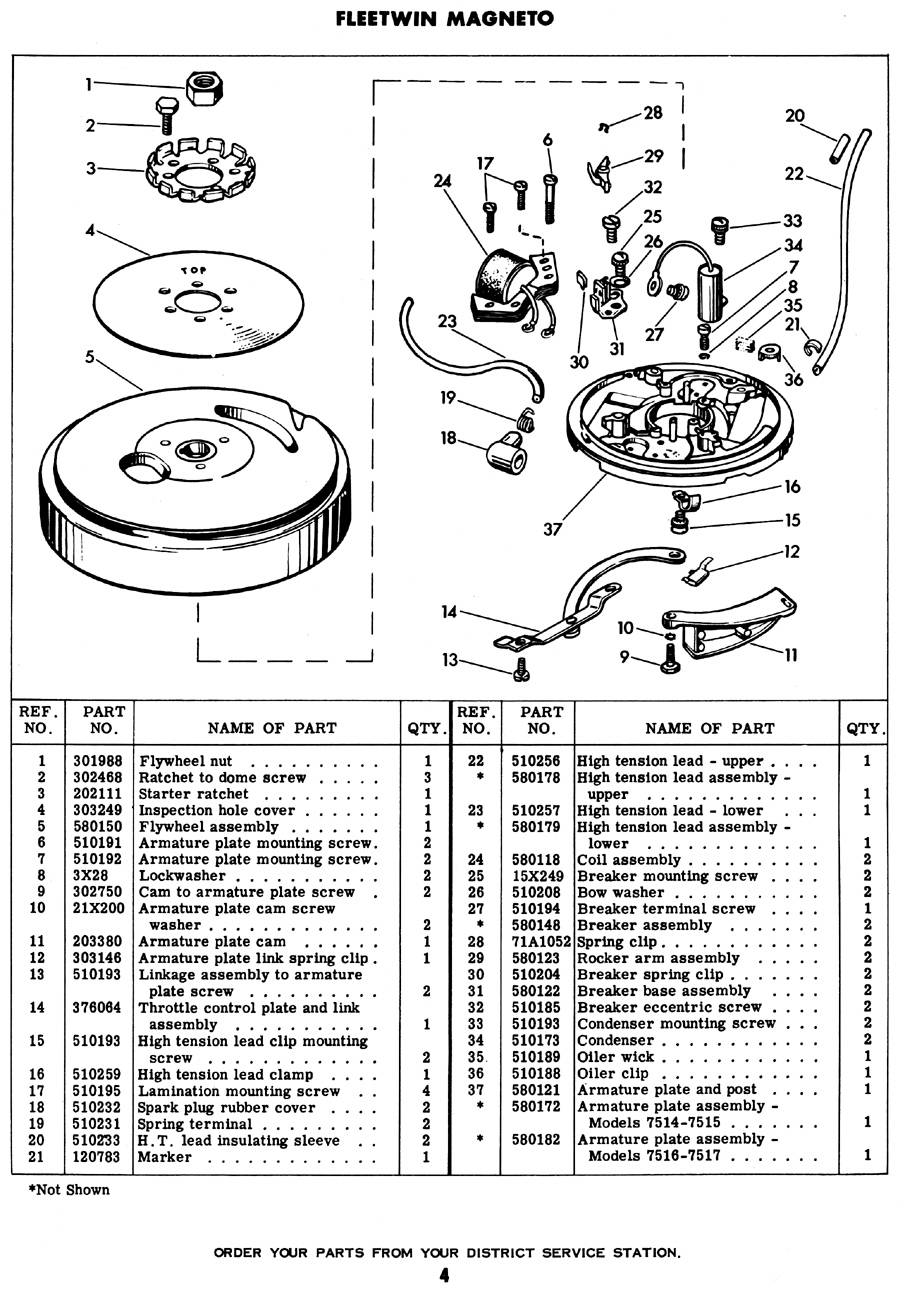

January 20, 2017 at 9:23 pm #51419

January 20, 2017 at 9:23 pm #51419The shift rod in the gear case has notches that a spring engages to hold it in gear. The nylon bushings lasted longer in testing than brass. They were also cheaper. In actual practice the brass withstood heat better, but needed to be lubricated more often. The transom bracket thumb screws also work better/longer when coated with grease. . . 😉

January 20, 2017 at 10:31 pm #51423

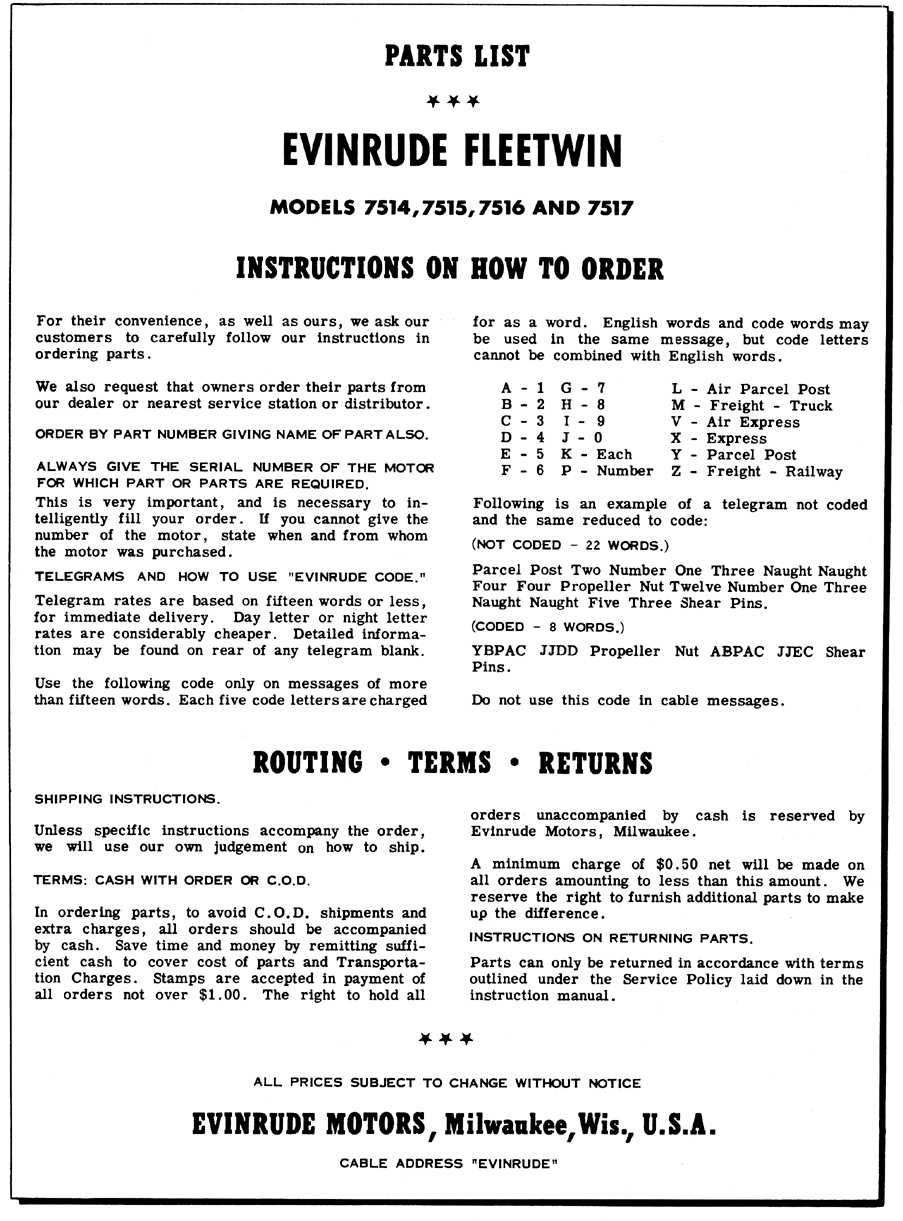

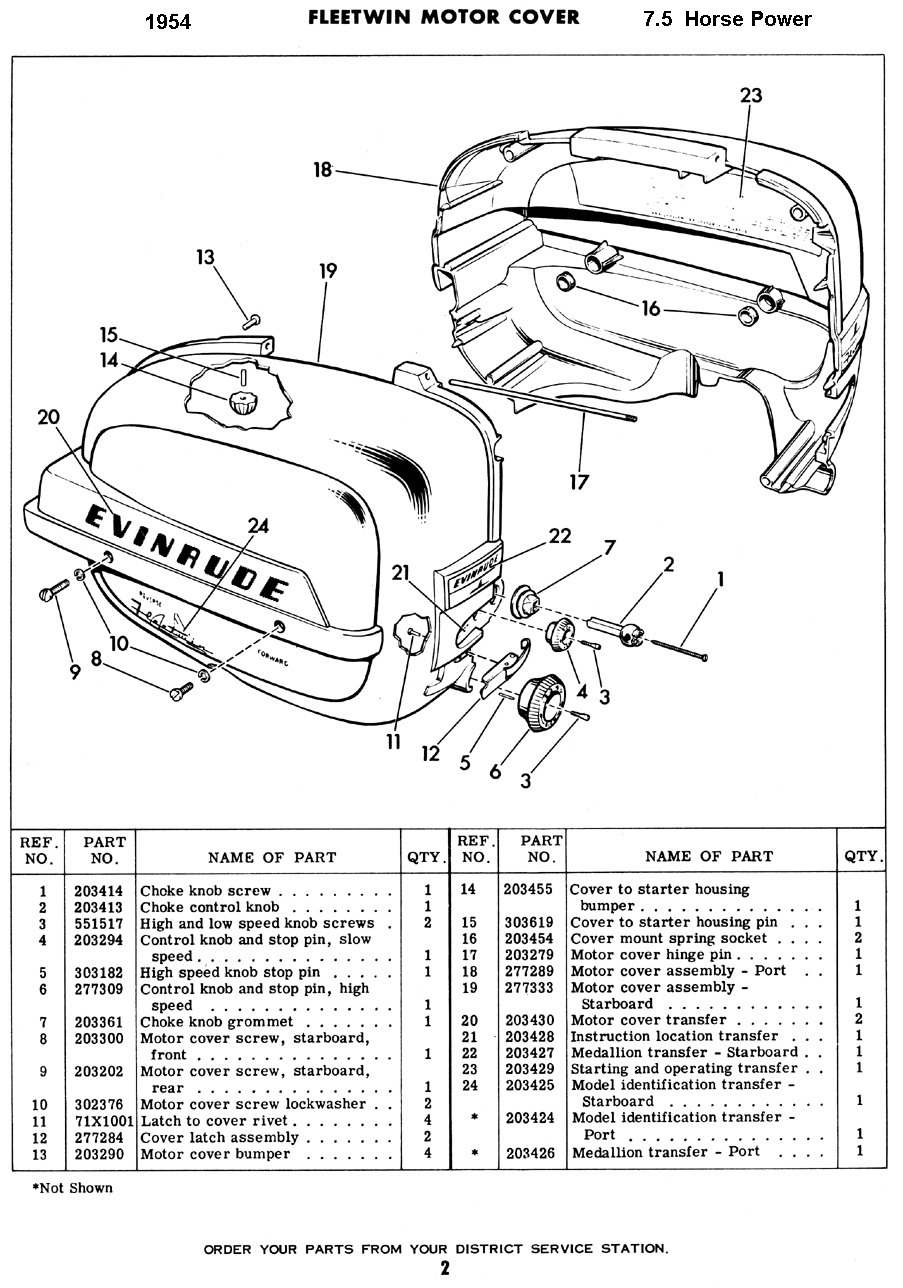

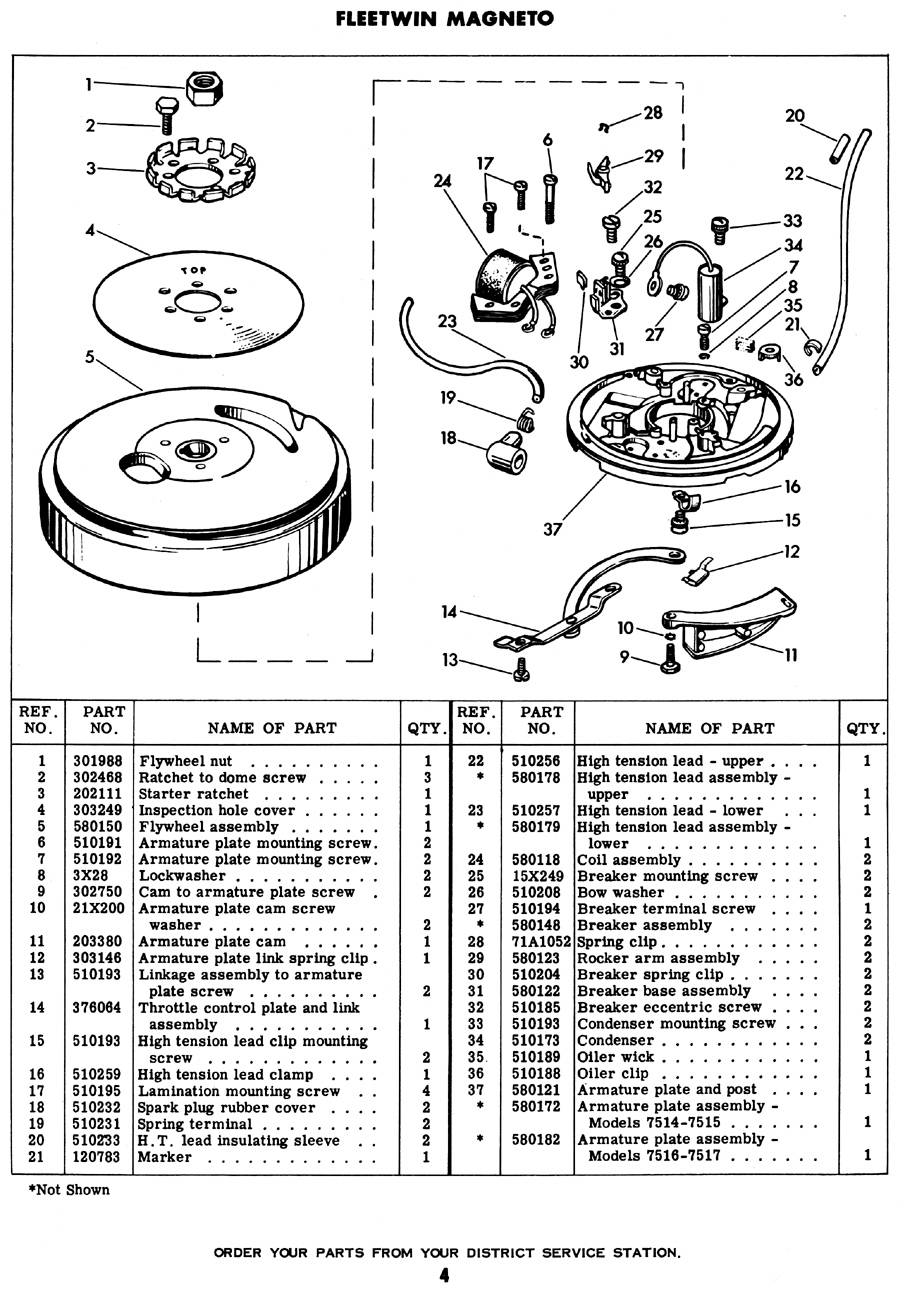

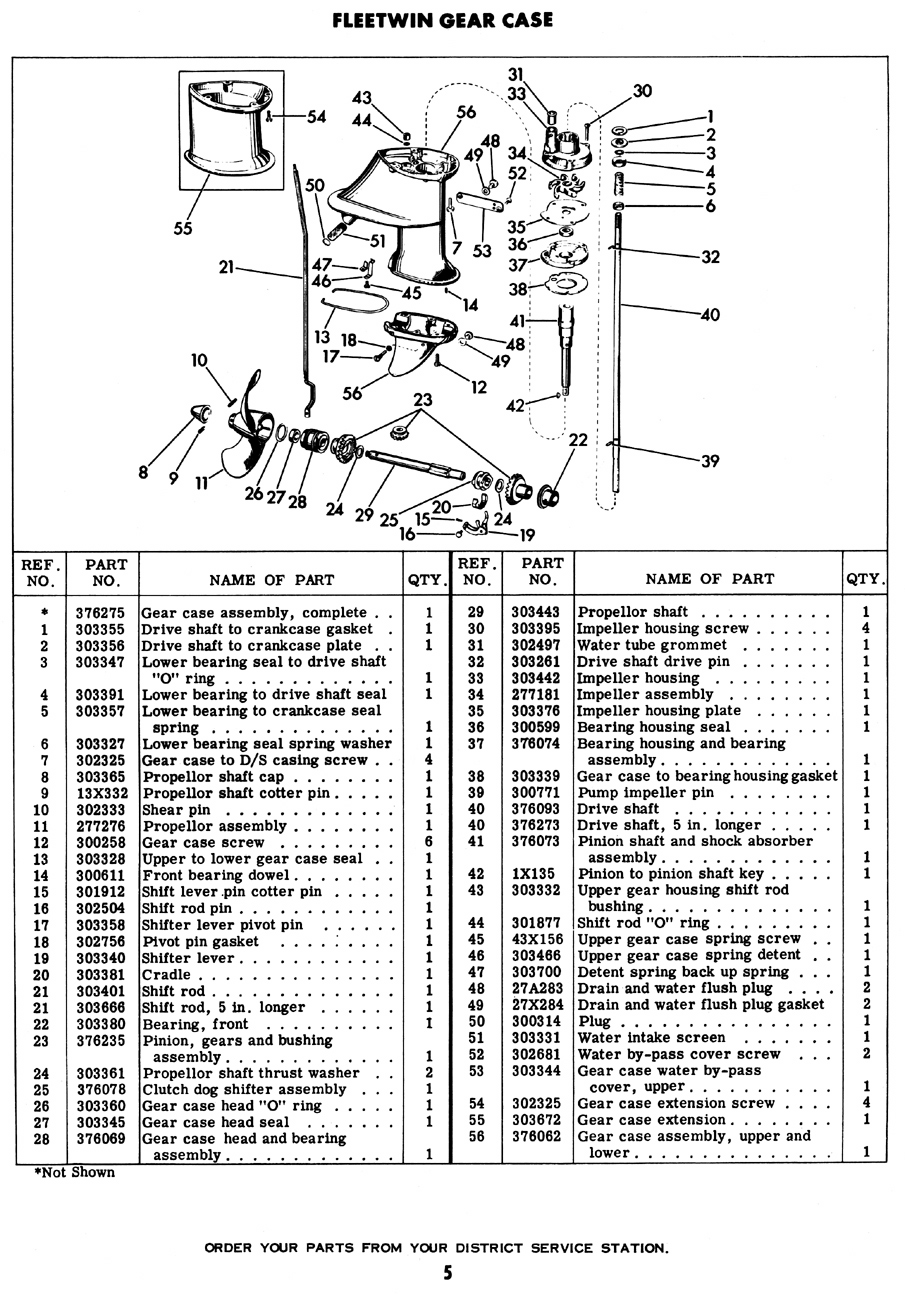

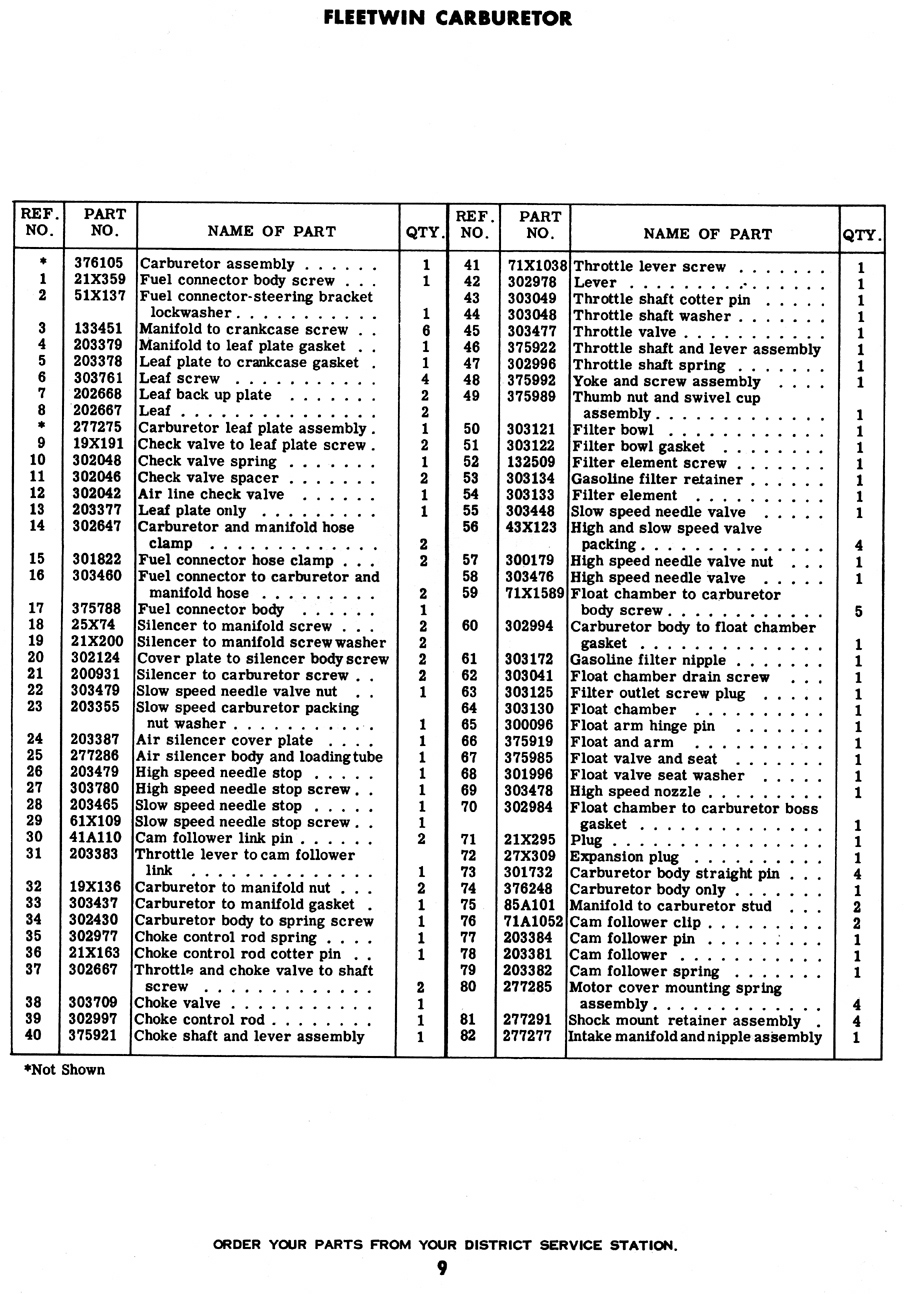

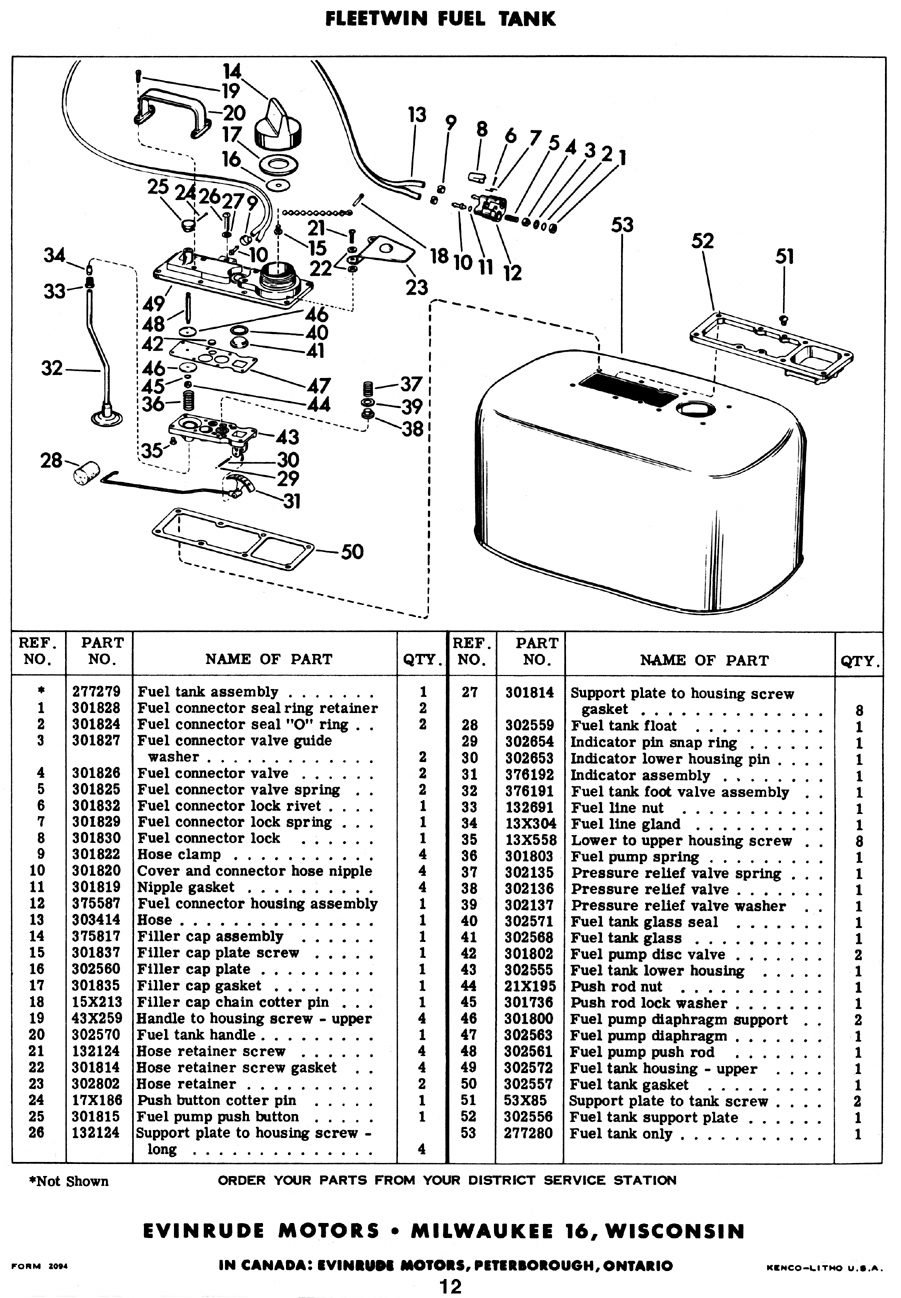

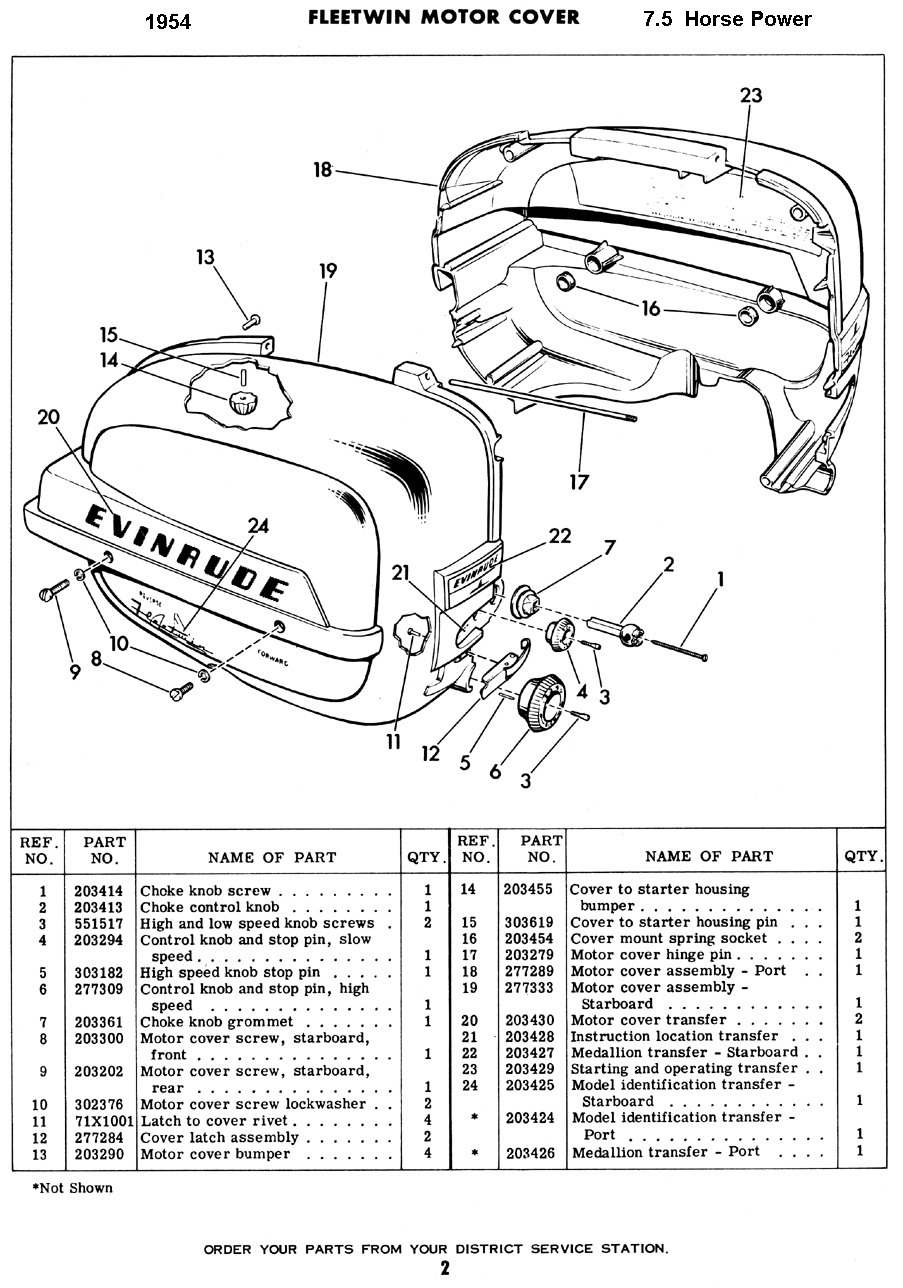

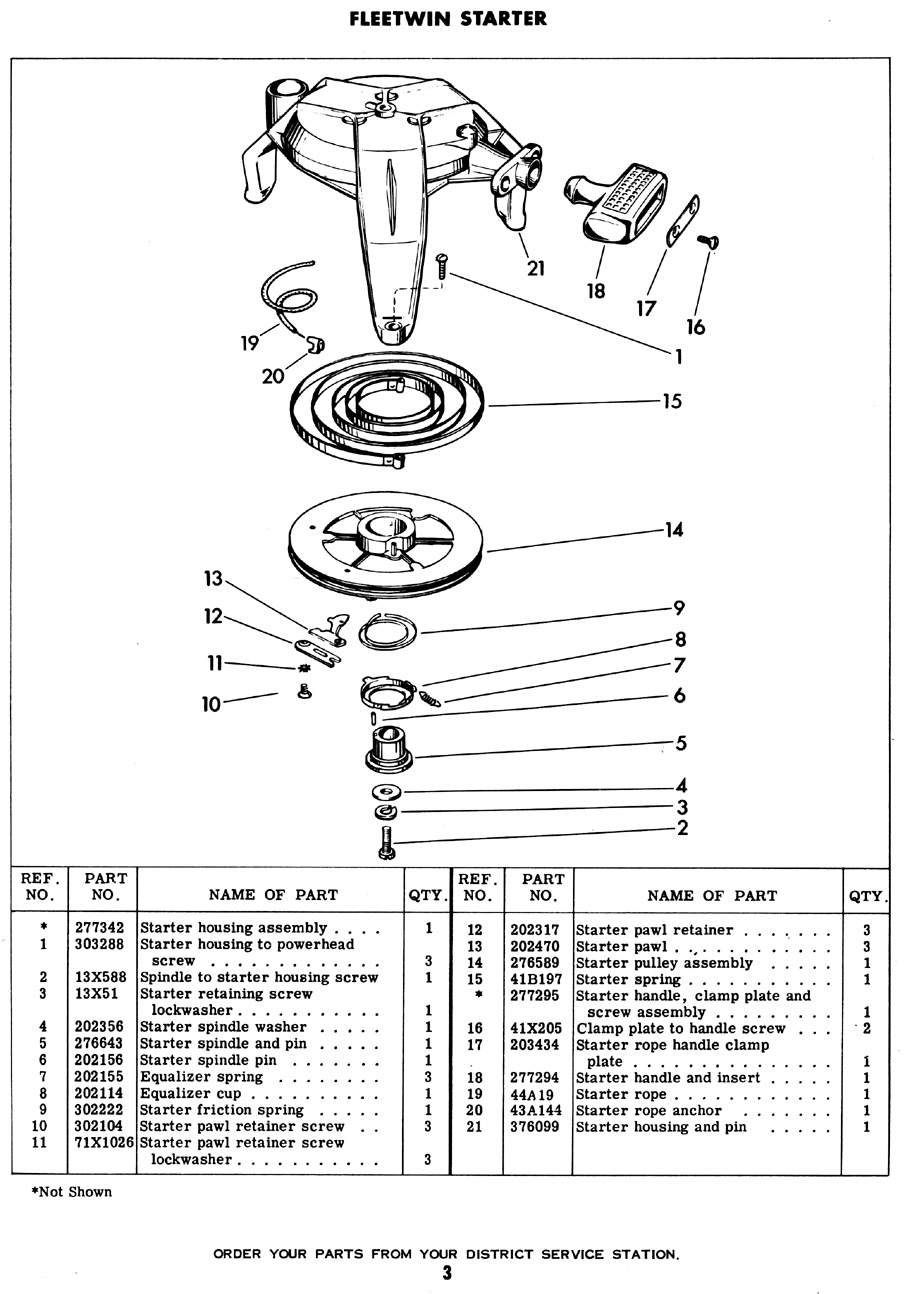

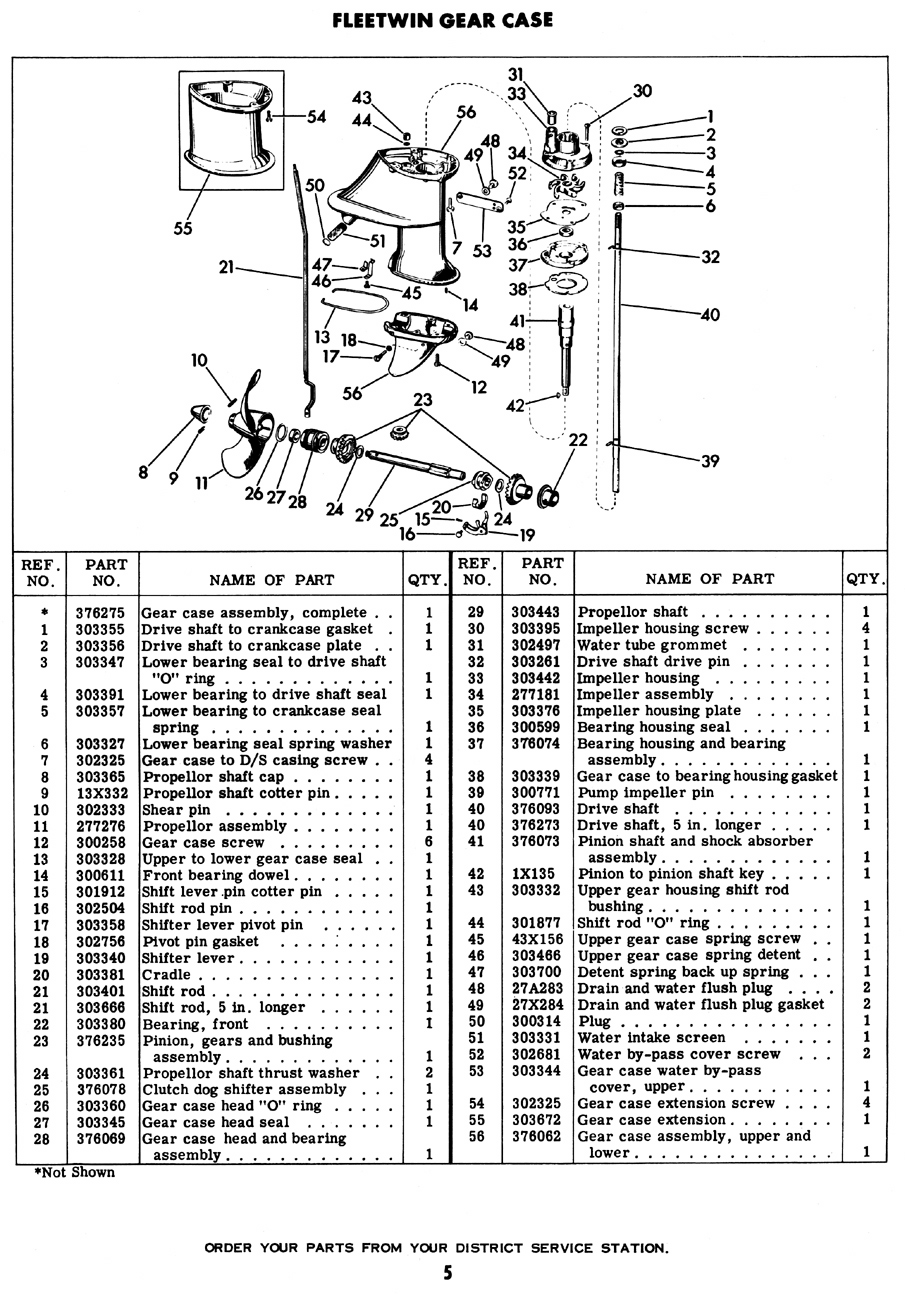

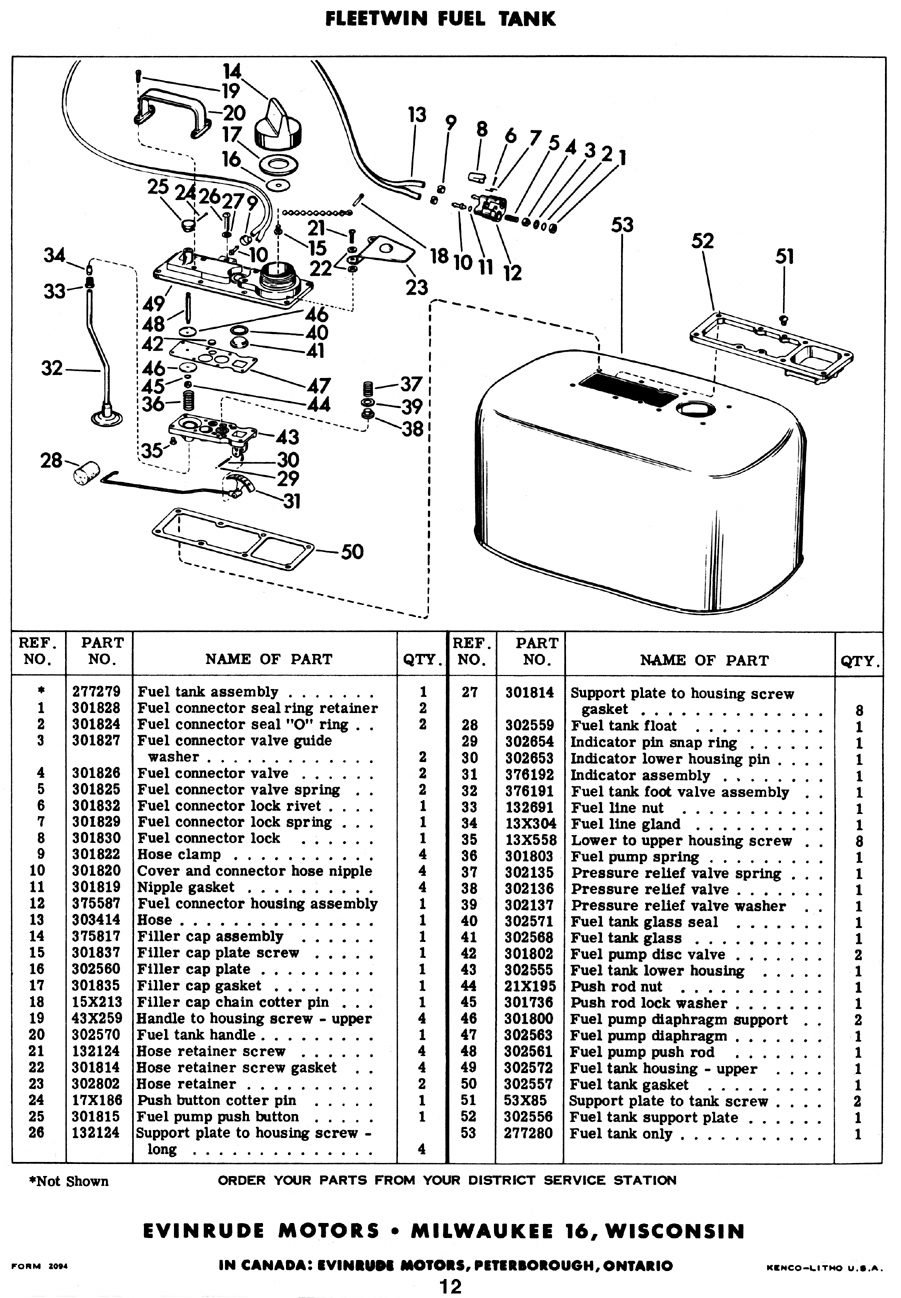

January 20, 2017 at 10:31 pm #51423Gary, thanks for posting the parts diagrams!

I pulled the lower unit off this afternoon.

I had the bolts removed, and LU "flopping"

around loose, but it didn’t want to separate much.

After looking at the diagrams, I finally decided the

water pump discharge tube was held tight in the

water pump grommet. The Evinrude manual forgot

to mention that this might be a problem after 60

years! Will open up the gear box tomorrow and

see what I have to work with.Prepare to be boarded!

January 21, 2017 at 12:04 am #51426

You DID disconnect the shift rod under the powerhead, didn’t you? ? ? . . . 😕

January 21, 2017 at 2:20 am #51439

January 21, 2017 at 2:20 am #51439Gary, Yes! It was just the water pump discharge tube stuck in the grommet

on the water pump. The tube goes in the rubber grommet / bushing

quite a ways and it was dry as a bone……. squeaked on the way out.

One I had it far enough apart I was able to spray some WD-40 around

the bushing to lubricate it a little, and it finally came apart.Prepare to be boarded!

-

AuthorPosts

- You must be logged in to reply to this topic.