Home › Forum › Ask A Member › 1955 RDS-17 Johnson 25 hp-adjustment/shifting

- This topic has 15 replies, 6 voices, and was last updated 5 years, 1 month ago by

fleetwin.

-

AuthorPosts

-

May 7, 2020 at 6:27 pm #202415

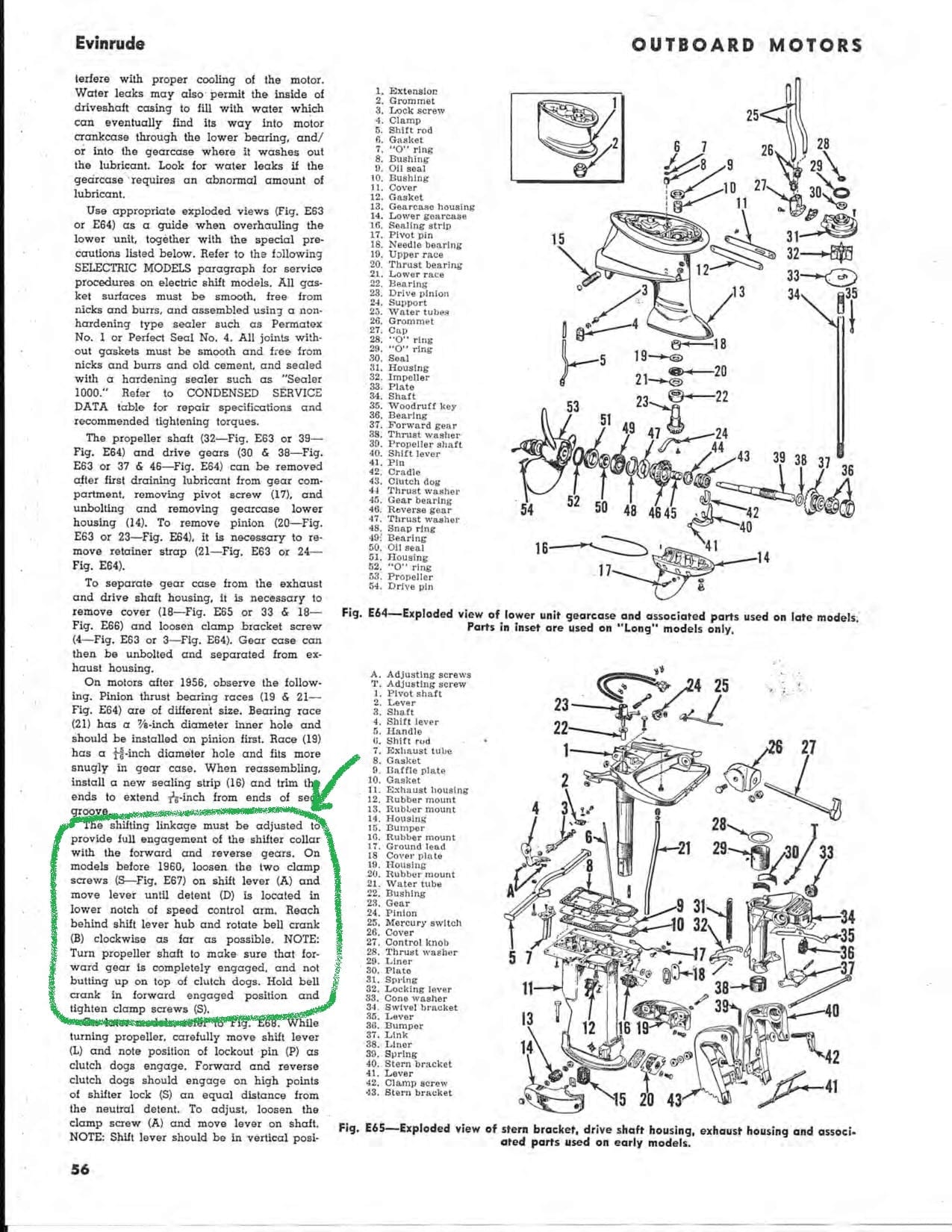

I followed the directions in the service data sheet.

Including the part about turning the prop.

When I rotate the shift lever hub clock wise and secure-I get forward.

When I rotate the shift lever hub counter clock wise and secure-I get reverse.

When I put the shift lever hub in the middle I get reverse.

Your thoughts?May 7, 2020 at 7:29 pm #202427could be some looseness slop on the shift shaft. take a needle nose pliers and hold the coupling then move the shift handle back and forth look for movement. if so pull power head and tighten

May 7, 2020 at 8:06 pm #202434Service manual speaks of a perfect world. In the real world, wear happens and it is impossible to get it 100% right. Worst wear happens in the hole in the exhaust housing that the shift shaft passes through as suggested by dave. Grab hold of the shifter handle and see if you can rock it up and down. If you can, the lever inside the housing is also rocking up and down, reducing the up and down travel of the shift rod. I remember trying to put a bushing in the hole 60 years ago. I wasn’t as successful as I had hoped.

When you do the adjustment, favor full engagement of forward to protect the clutch dog. You may then have to go a tad “past” neutral to get it out of reverse, then go back to neutral position.

-

This reply was modified 5 years, 1 month ago by

frankr.

frankr.

May 8, 2020 at 10:49 am #202493Like Frank says, manual represents a perfect world…. I usually find that there isn’t enough “throw” in the lever/detent system to achieve full engagement in both gears, and be centered properly in neutral…I usually end up favoring forward gear a bit making sure the gearbox is in neutral when the shift lever is in the neutral detent…

So, you are saying that when shifted from reverse into neutral, the gearcase is still in reverse gear….OK, just favor forward gear a bit more, which works out for the best. Have you tried that, or are you trying to achieve what the manual prescribes.

All that being said, you should check for slop in the linkage, and make sure the shift rod connector is properly positioned and the screws are tight. I like Mumbles method of using red nail polish to highlight the beveled area of the shift rods to ensure they are properly positioned in the connector before tightening the screws…

It is important to mention that the linkage should not be “preloaded” in either gear. Doing this will cause premature wear in the cradle linkage and aluminum clutch dog fork…May 8, 2020 at 12:58 pm #202503Just so you guys know-

1.I do not have power head off

2.I replaced the #26 o-ring on the shift shaft when I did have the power head off.

Dave

I detached the brass connector that connects the upper and lower shift rod.

The brass connector is still on the upper shift rod.

I held the brass connector with a pair of needle nose pliers and moved the shift handle back and forth. In my opinion there is no much play at all.

Frank

I grabbed the shift handle and wiggled it up and down and right to left-there is about a quarter inch play in each direction.

Are you saying I may need a new exhaust housing because the hole in which the shift shaft rides in elongated?

Fleetwin

What I am saying is that I ether have forward and neutral or I have reverse and neutral.

I not sure what you mean by “preloaded”May 8, 2020 at 3:52 pm #202532Problem is, in the big picture of things, there are several places that wear and slop happens, the the result is the sum total of all the looseness. Yes my previous post suggested wear in the exhaust housing where the shift shaft passes through, and yes the “official” cure is a new exhaust housing. But that is such an extreme-case scenario that it is rarely done, people just living with it instead.

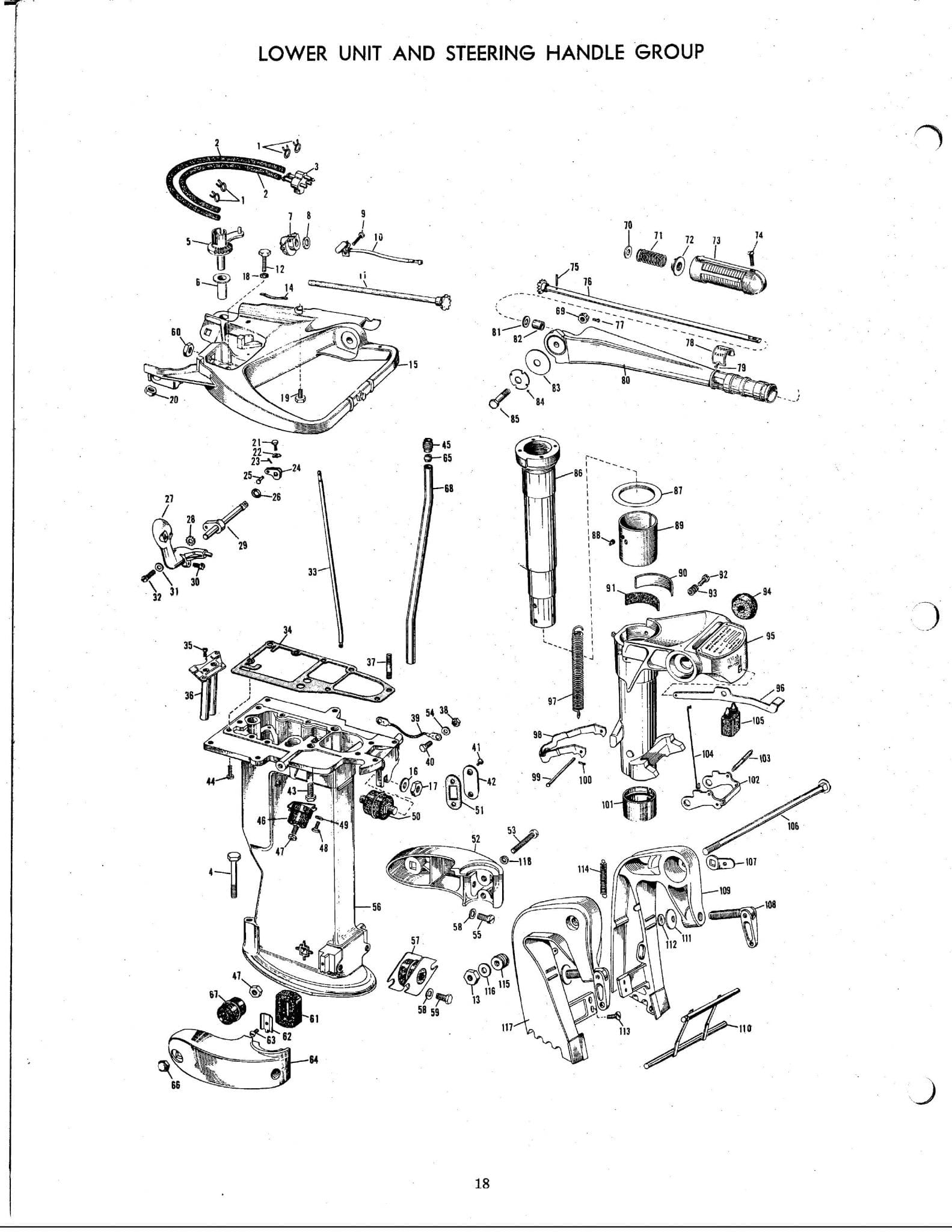

Let’s consider the sum total thing: Slop may occur in the following.

The shift shaft as mentioned

Loose lever #24 on the inner end of the shift shaft.

Loose screws in the shift rod connector

Worn cradle on the clutch dog (loose fit in the groove and/or loose fit between the fork and cradle)Don’t know if this is true or not, but the idea lurks in my brain that there are different lengths of the inner lever #24 and you could have the wrong one (??????)

Advice from here is try your best and if necessary “live with the very common problem”. Most of us have tried to “fix” it with poor results.

-

This reply was modified 5 years, 1 month ago by

frankr.

frankr.

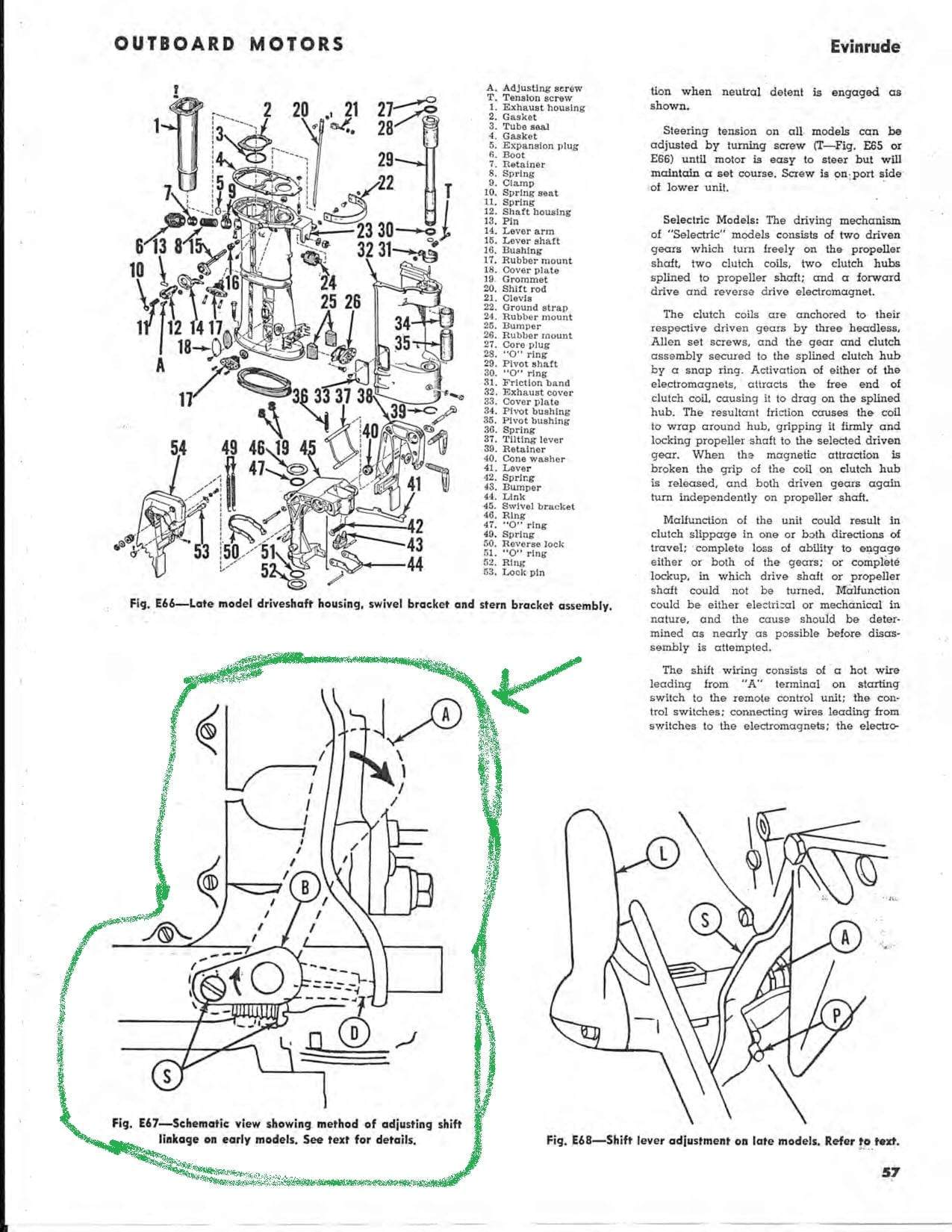

May 8, 2020 at 5:30 pm #202542Fear I am not understanding your issue.. You first mention having good engagement in both gears, but still being in reverse when shifted from reverse to neutral… This issue can be resolved by adjusting the fine adjustment on the shift handle as described in the manual…

Your latest post seems to indicate that the shift handle does not have enough “throw” to engage both gears. This issue can be caused by lost motion in the shift lever/bellcrank, loose/improperly installed shift rod connector, or internal gearcase problems…

I am probably misreading what you have written….DMay 11, 2020 at 12:47 pm #202783Well I tried adjusting again.

I ether get forward and neutral or reverse and neutral

The hole in the exhaust housing where # 29 (bracket and shift lever) goes through seems fairly tight.

I redid Daves test

I detached the brass connector that connects the upper and lower shift rod.

With brass connector off the upper shift rod.

I held the upper shift rod with a pair of needle nose pliers and moved the shift handle back and forth. There is quite a bit of play.

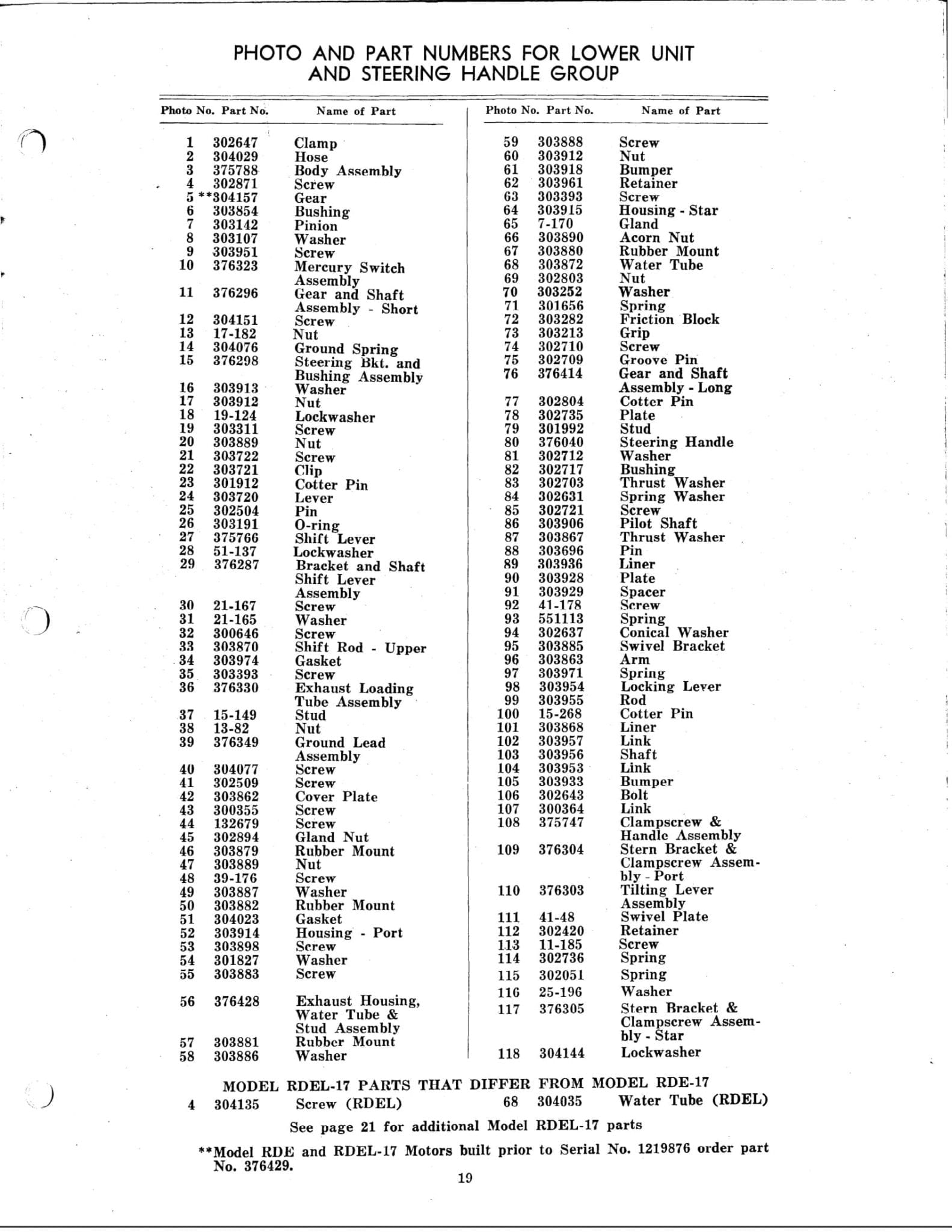

So at this point-I am thinking the problem is # 24 (lever)May 11, 2020 at 1:38 pm #202787most likely the screw on the top of the shaft. pull the power head you will see it right away. ### 21

May 11, 2020 at 1:38 pm #202788Frank

I would not know if I had wrong number 24 or not

Parts list for RDE shows as 303720

Parts list model S shows as 303720“Don’t know if this is true or not, but the idea lurks in my brain that there are different lengths of the inner lever #24 and you could have the wrong one (??????)”

-

This reply was modified 5 years, 1 month ago by

-

AuthorPosts

- You must be logged in to reply to this topic.