Home › Forum › Ask A Member › 1956 Johnson 30hp High Speed Tuning

- This topic has 17 replies, 8 voices, and was last updated 2 years, 9 months ago by

BRUCE REINHART.

-

AuthorPosts

-

July 12, 2022 at 11:36 am #262829

Ok – First I tried hard not to post this…but my trial and error approach simply is not working. This is a recently rebuilt 1956 Johnson Javelin 30HP that for the most part is running absolutely awesome – that in and of itself has been a journey but very rewarding.

The issue I am facing is that I cannot get the motor to run at full throttle and I have exhausted everything I can trying to use the High Speed knob to make adjustments. I use a phone app to track speed so will use that to explain the problem. If I set the throttle at 19/20mph I can pretty much go forever, but if I go full throttle which runs between 24-26mph, I can only go for 30 seconds before the motor starts dying. If I hit some wakes or choppy water that also seems to trigger this behavior. I would describe it like the motor is starving for gasoline and always have to pump the bulb to re-pressurize the gas line. If I go back to 7/8mph I can then come back and go full throttle for a brief period.

Admittedly I am new to this and every single stage has been a learning experience which has challenged me. I am definitely on the path to becoming Mechanic #1 for this motor!!! There just feels like there is another adjustment I need to focus on that I haven’t even tried and thought I would reach out to this awesome community. My last post yielded a perfect answer to my last problem… 🙂

Appreciate in advance your advice and counsel.

Rich

1 user thanked author for this post.

July 12, 2022 at 12:00 pm #262830“pump the bulb” strongly suggests you have converted it to a fuel pump system. I submit that therein lies your problem. The fuel pump, or installation, or a problem with the tank/hose. First try running it on a known good tank/hose to narrow it down.

July 12, 2022 at 12:17 pm #262831tell us more about your pump modification. (mikuni, B&S pump …etc…. ???) bypass cover mod or air nipple mod with channel block ??

what exactly this REBUILD consist of …….electrical, impeller carb job…..of the whole PH rework.

sounds like the engine is starving at higher rpms….

Joining AOMCI has priviledges 🙂

July 12, 2022 at 2:34 pm #262834I’d also look for a kink in the fuel lines, a classic as it restrains flow.

If you have a bulb on the tank fuel line, I gather that you moved away from the pressurized tank system in favour of either a vacuum or electric fuel pump, make sure each and every connection (vacuum, fuel and electrical) is tight.

Also run a pressure check on the fuel lines looking for pin holes and make sure all lines are of an appropriate size.

Regards

There are no old outboards, just machines so well built, they have outlasted their owners !

July 16, 2022 at 11:26 pm #263084OK – sorry for the long delay in replying – I was traveling and not with the boat :).

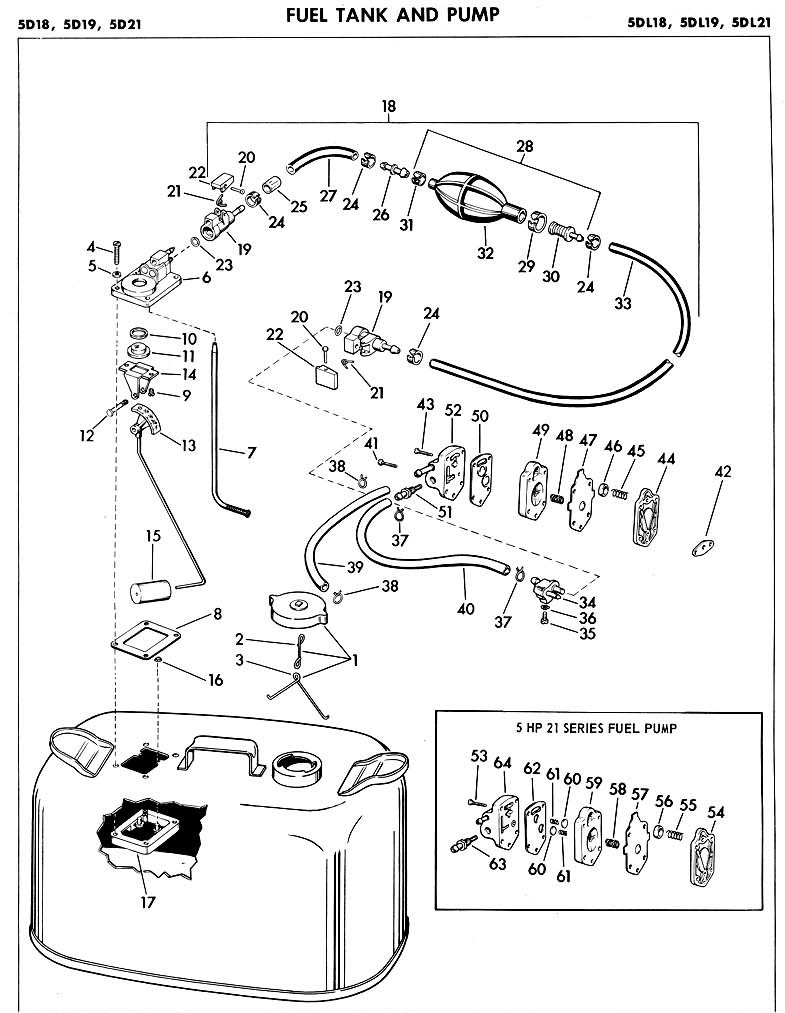

So to answer some of the questions – the motor was a complete overhaul – totally torn apart and put together piece by piece – using 2 additional motors for parts. I did not do it but it was as extensive as it gets. A fuel pump was added and I have added some pictures since I have no knowledge of what it is. I have 2 tanks but only 1 fuel line. I have switched tanks but am experiencing the exact same behavior.

From my check tracing the lines, everything looks very tight – the motor only has 15-20 hours of run time since the rebuild as well – so things look brand new.

Hopefully this gives a little more context. One theory of mine is a float adjustment – but not sure there is one..

Thanks again everyone!

Rich

July 17, 2022 at 9:48 am #263090I don’t recognize that pump so I would question is it adequate? How far away is the fuel tank? Looks like there may be some sharp bends in the fuel line first through the cowl pan and second behind that bracket possibly causing a restriction.

July 17, 2022 at 2:41 pm #263102The fuel line from the tank to the motor is 100″ long. Picture below…

July 18, 2022 at 9:36 am #263132I heard those pumps are good but no rebuilding kit is available

July 18, 2022 at 11:19 am #263134That pump is nearly as old as the motor itself. The diaphragm may be petrified hard from age. OR, there also was a bad version of the pump. The “good” ones had real check valves, the bad one used diaphragm “flapper” valves. Replacement parts are long ago NLA. Replace the pump with a Sierra 18-7351.

July 18, 2022 at 11:26 am #263135 -

AuthorPosts

- You must be logged in to reply to this topic.