Home › Forum › Ask A Member › 1956 Johnson RDE-18E

- This topic has 30 replies, 9 voices, and was last updated 4 years, 1 month ago by

crosbyman.

-

AuthorPosts

-

September 17, 2020 at 1:54 am #216603

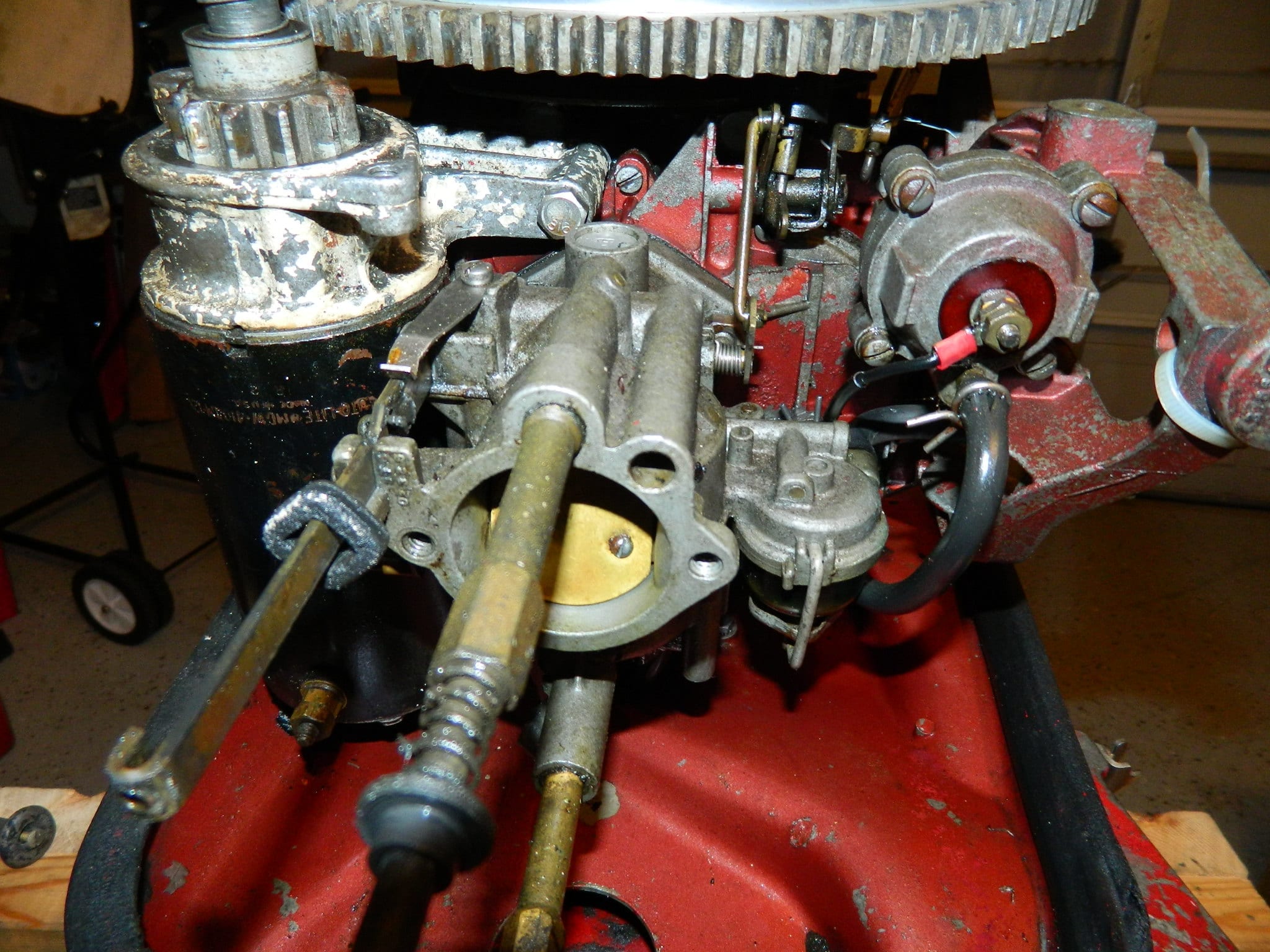

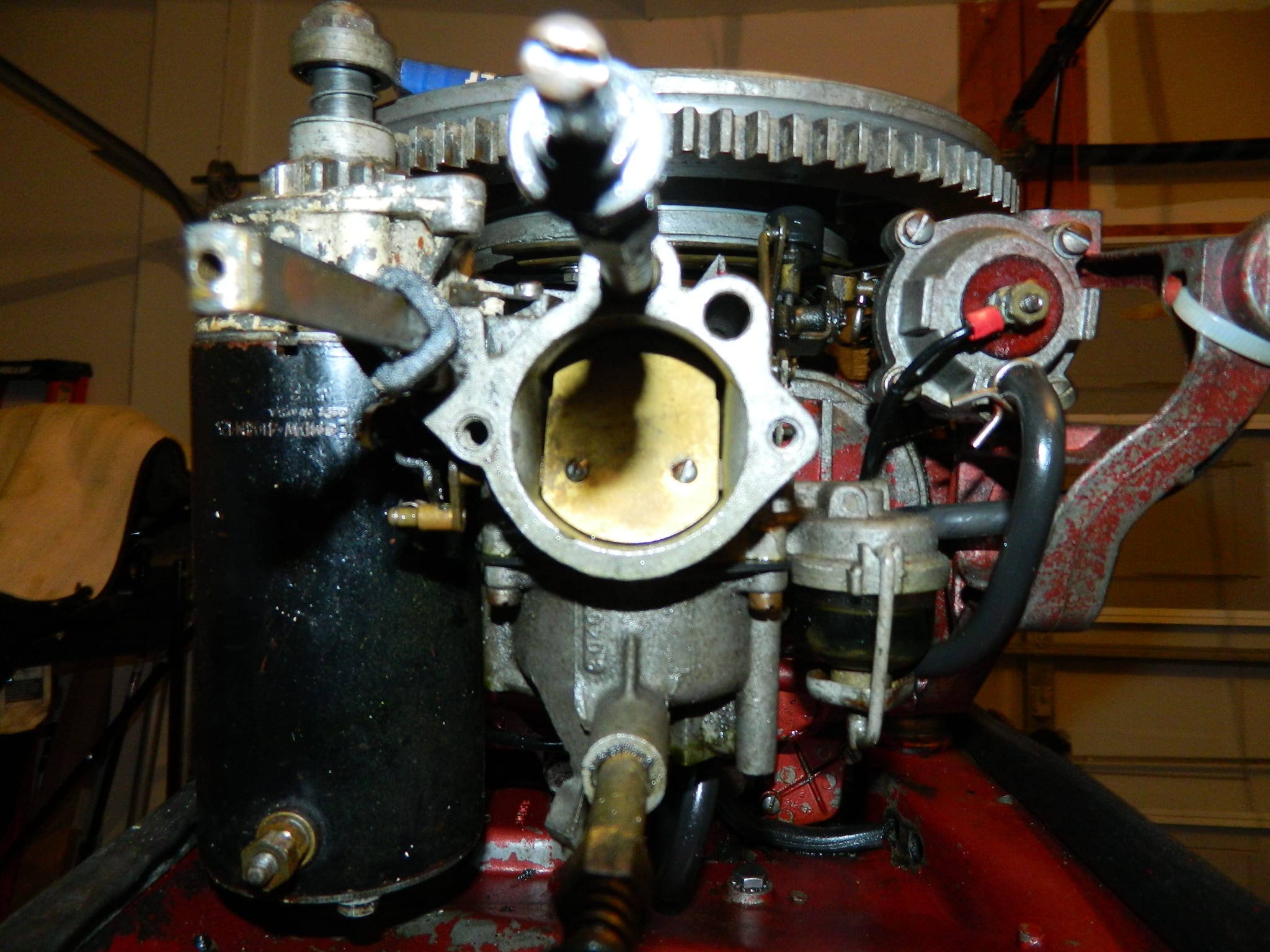

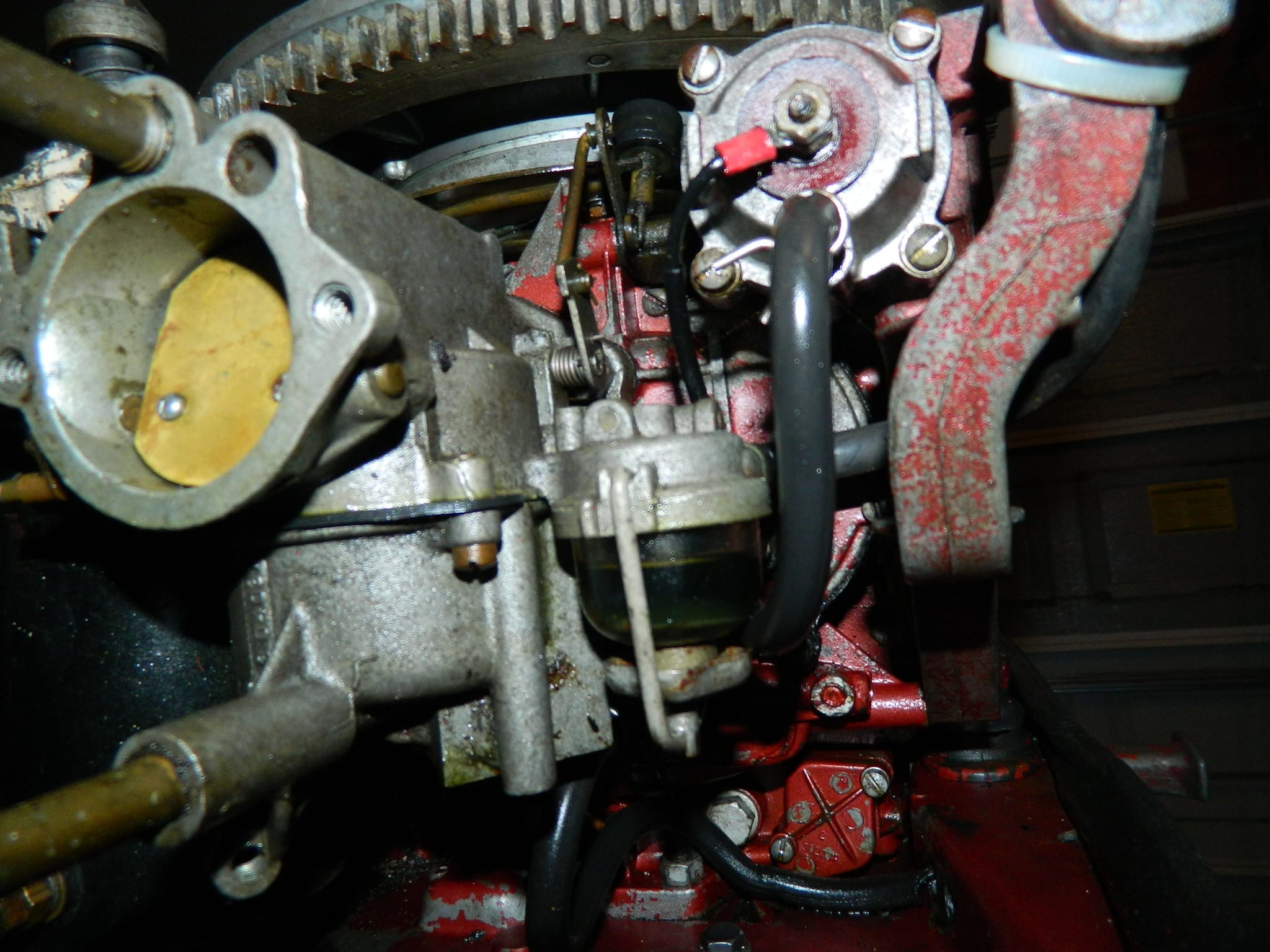

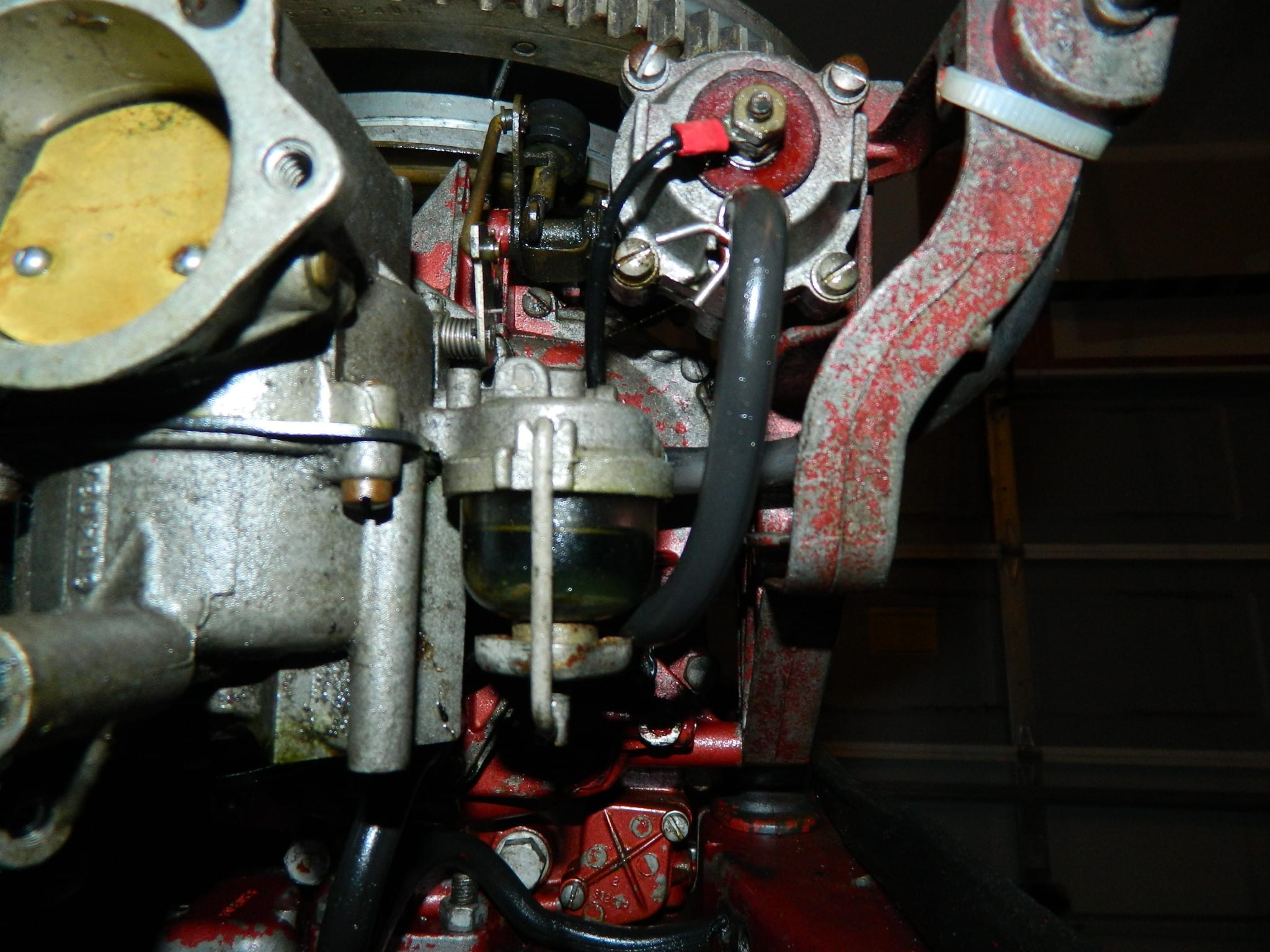

I just picked up a 56 Johnson 30 HP. I have 10 days to check the motor over and either keep or return it for a refund to the seller. I have not run the motor yet although the seller told me that he and his brother actually ran the motor recently and he said it ran fine. He told me the impeller and/or water pump will need to be replaced as it was not pumping water but he connected a water supply to the lower in order to run it for a short test. The original paint is still on the powerhead and internal metal and the condition of the paint gives no indication of overheating or anything like that. It actually looks pretty good. The outer surfaces were painted a different color red some time ago and the whole motor will need to be repainted at some point. It appears to be in good enough condition to make it a restoration project.

Repairs I know about

1. The motor does not have a pull starter attached under the cowling but it has electronic ignition and can be started that way. The seller started it using a battery and cable to jump the starter and he said it engaged with no problems. I still want to get the pull starter for it.2. The dual-fuel lines are attached, one at the glass filter bowl on the carb, the other in the powerhead but they have been detached from the connector which I have in hand.

3. The metal piece that fits on the left lower unit where the shift linkage connects is gone, needs to be replaced and the shift linkage has been disconnected.

4. The impeller/water pump needs to be replaced. This will mean the lower unit has to be disconnected from the upper to get to the pump area as well as the shift linkage.

5. I have not had the opportunity to go over the whole motor yet. I wanted to reach out to a few of you and see if any information, video instructions, repair/diagnosis material, or any other reference material would be suggested by anyone reading this post.

My question has to do with any reference material in the way of videos that show this particular model being repaired or restored. I do have a CD that has the factory reference material for Johnson from 1922 up to and including 1964 so I believe I have the technical material. It is always best to see someone who is experienced actually showing the work done so you can actually see it being done.

If anyone has any suggestions as far as this particular year/model is concerned, please respond with any relevant material that you think would be helpful.

Also, if anyone has any parts that might be useful here, let me know and maybe we can work something out.

As always, thanks in advance for helping a newbie like myself to make it just a little further up the creek. I appreciate the accumulated knowledge and experience and I will put into play what you guys pass on to me.

Thanks.

-

This topic was modified 4 years, 2 months ago by

Harmattan1.

-

This topic was modified 4 years, 2 months ago by

Harmattan1.

September 17, 2020 at 2:03 am #216609Some more pics I have attached

-

This reply was modified 4 years, 2 months ago by

Harmattan1.

-

This reply was modified 4 years, 2 months ago by

Harmattan1.

1 user thanked author for this post.

September 17, 2020 at 8:18 am #216628If compression is good, and the price is right, go for it. I have a RDE-17

and it’s a nice running motor.Prepare to be boarded!

September 17, 2020 at 8:45 am #216630They are great old motors and as Buccaneer says if the compression is good (110+on both cylinders) most everything else can be addressed. Pull the gearcase drainplug and see if there is water in there. If you see water, it will need seals replaced. Will most likely need coils, possibly points and condensers and a carb rebuild. And of course an impeller. This could easily cost $150 for parts. Did it come with the fuel tank? I personally wouldn’t pay more than about $100-150 for the motor and less if no fuel tank is included.

-

This reply was modified 4 years, 2 months ago by

lindy46.

lindy46.

September 17, 2020 at 8:48 am #216631Needs a lot of work. Price would have to be mighty right (low enough that you can afford to junk it if necessary).

September 17, 2020 at 9:08 am #21663450 bucks, tops

September 17, 2020 at 11:54 am #216661And in case you don’t know that starter in 1956 would have been 6 volt.

That one needs a lot of TLCSeptember 17, 2020 at 11:56 am #216662It has a newer starter on it, 12V. Also wrong starter bracket with no hood mount.

September 17, 2020 at 1:05 pm #216664Harmattan: I hate to judge a book by its cover, but I agree with Frank. How much did you pay for this engine? The price needs to be low enough so you won’t mind writing this project off if it needs too much work. And, like Frank says, you will need to find the proper starter bracket, because the engine cover will rattle without the cover mount that is supposed to be on the correct starter bracket. Like Lindy and Buccaneer said, check compression and crack open the lower gearcase fluid fill plug, do not remove the phillips head screw in that are or the internal shift linkage components will fall out of place. Milky or raw water in the gear lube spells trouble.

I am trying not to judge this ugly duckling unfairly, it could be in good mechanical condition. Generally speaking, an old engine like this will require the following to be a “reliable daily runner”:

Ignition overhaul (you will need the special OMC puller and a ring gear holder to remove and reinstall the flywheel)

Fuel system overhaul including carb cleaning/rebuild/new fuel lines….Do you have the two line fuel/pressure tank for this engine? If so, is it clean inside? The tank is worthless if rusted or fouled from old fuel inside

New waterpump The seller already admitted the engine doesn’t pump water, there could be many causes for this. Some simple, perhaps he just didn’t have the water level high enough over the gearcase. Perhaps the impeller is work/broken. Or, perhaps there is some other cooling system issue. Again, the gearcase will have to be torn down if watery or milky gear lube is present. Resealing one of these gearcases is not as easy as many would proclaim. Yes, most could probably get it apart, attempt to reseal, and reassemble…. But, few can do it properly. You will need to pressure test the gearcase to pinpoint any leakage areas and check to see it is properly resealed after replacing seals/orings, etc.

So, only you can decide if you are up to all these tasks. It sounds as if you haven’t had much experience working on OMC outboards. Reviewing the proper OMC service manual first is always a great place to start. There are some videos out there, but most are posted by self proclaimed experts that have little OMC experience and have no business advising others. There are a few videos posted by members here that are more reliable though.

Let us know what you decide to do….D-

This reply was modified 4 years, 1 month ago by

fleetwin.

September 17, 2020 at 1:12 pm #216667OK, just spent 15 minutes posting a reply, then tried to correct it, and poof, it’s gone….

-

This topic was modified 4 years, 2 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.