Home › Forum › Ask A Member › 1956 Scott Atwater 7.5 hp Bail-a-matic impeller install

- This topic has 30 replies, 5 voices, and was last updated 4 years ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

January 20, 2021 at 5:14 pm #228314

Good job

January 20, 2021 at 7:57 pm #228325How did the Honda impeller feel going in, enough bend in the vanes? And did you have to pull the driveshaft out again to get the impeller on the pin?

-

This reply was modified 4 years ago by

Mumbles.

Mumbles.

January 20, 2021 at 10:01 pm #228332How did the Honda impeller feel going in, enough bend in the vanes? And did you have to pull the driveshaft out again to get the impeller on the pin?

-

This reply was modified 4 years ago by

Mumbles.

Mumbles.

This photo shows the tension on the impeller vanes better. Looks like enough to me,

but the proof will be in the pudding……. when I do the drill test in a bucket of water.

My 1/2″ drill is rather slow, so not sure how it will compare.

How many rpms does a Scott Atwater idle at???Once I had the impeller in the pvc sleeve, I just slide it straight down over the

key was I had sitting in the flat. I did nothing to the drive shaft.Prepare to be boarded!

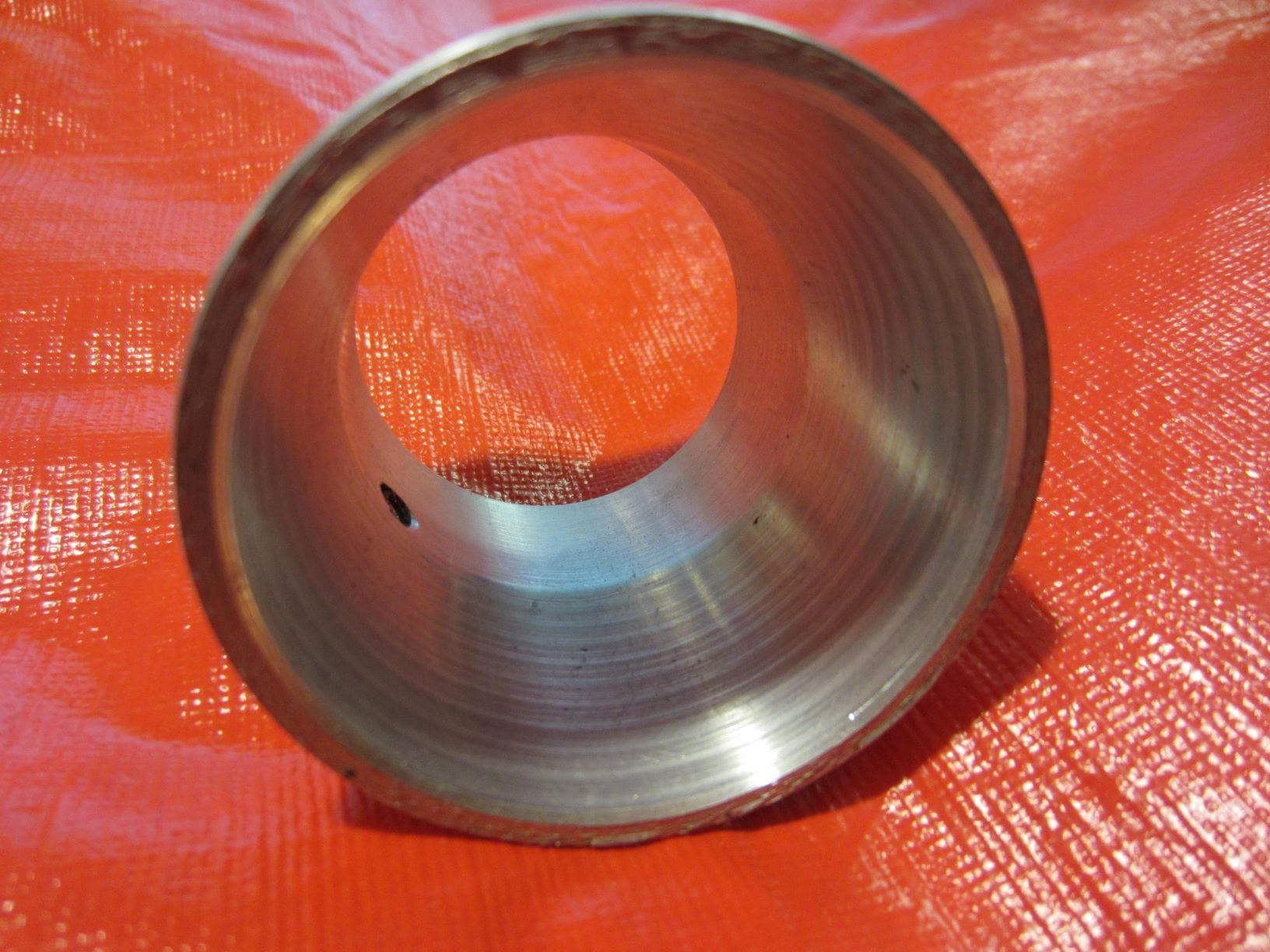

January 20, 2021 at 10:51 pm #228343Here is a picture of the tool I made up when I did my first Bail A Matic water pump impeller job

The bottom outside was machine to just slide into the pump housing 1.692

The bottom inside was machined to 1.627

The top was machined on a tapper from 1.952 down to 1.627

the impeller fits in the top and rotated down to the 1.627 diameter

the to tool is fitted into the pump housing and rotated until the key slot lines up with the pin , push the impeller down , hold it down and pull the tool up

That was about 25years ago and it has been sitting in my toolbox ever since-

This reply was modified 4 years ago by

Mumbles.

Mumbles.

January 21, 2021 at 9:34 am #228359Bruceter,

looks like I was on the right track with my little pvc sleeve.

I still have one more Bail-a-matic to tear into, so I may make something

similar. While my pvc piece worked, the ID was “too tight”.

Had trouble getting the impeller in, and it was a bugger to

slide it “out and off” of the impeller, after it was installed……. and that

was with using a little Vaseline.

Gotta wonder if there was a factory tool for impeller installations?

Thanks!Prepare to be boarded!

January 21, 2021 at 10:11 am #228362grease the pipe makes it easier.

January 21, 2021 at 11:39 am #228370January 21, 2021 at 11:53 am #228372I did the drill test…….. “Good News, Bad News”.

My 1/2″ drill, that fit on the 1/2″ driveshaft only put out

500 rpms.

My 3/8″ inch drill does 2500 rpms.

The driveshaft has 12 splines. A 7/16″, 3/8″ drive, 12 pt.

socket fits on the splines perfect.

So that was the only good news…….I can’t get the pump to pump any water……… period.

I had the LU in 10 gallons of water, up to a point

well above the pump intake, and as high as if the

motor was on a boat.I poured water in the pump discharge to see if I could

“prime the pump”, to no avail. It did blow the prime water out

of the pump discharge when I spun the driveshaft, so

that gives me hope that the impeller is still keyed to the

shaft.I removed the intake screen, and with the LU in my

benchtop LU holder, I poured water in the pump discharge

and blew air in the bottom of the pump pick-up tube.

It blew water out, hence the pick-up tube is open.I’ll take the pump back apart, and if I see nothing obvious,

I’ll try to determine if the pickup tube could be sucking air

at the bottom of the pump housing.If that don’t work, I’ll stick in one of the old impellers that

was in it, and see what happens.Someone reported that a “liner” inside the pump cavity

was necessary to make the housing cavity ID smaller

for the Honda impeller to work. More people said

it’s “Not necessary.Hope I figure this out as I got another “Bailer” to revive!

Prepare to be boarded!

January 21, 2021 at 1:58 pm #228385That’s why I asked earlier if there was enough bend in the vanes. In your photo, it doesn’t look as if they are contacting the housing on the near side. When I was doing Giggle searches on this, I remember someone making a liner out of something and maybe someone using a Honda liner and modifying it to fit and others saying no liner needed. Hmmm…..

You’re so close but I know you’ll clear this hurdle in no time!

January 21, 2021 at 4:32 pm #228401No noticeable difference OD in the original and Honda impeller

Half of the vanes on the Honda impeller are always bent,

and the other’s appear to at least make contact.

Should they all be bent more when in the housing?

I’m making a impeller driver out of an old brass prop shaft

so I can play around with it easier, and it not having to

be mounting in the mid section.

I turned down the shaft where needed, and added a plastic

bushing on the bottom side for my driver shaft to fit

in snug.

I drilled three holes in the shaft and soldered in some 1/8″ brass rod.

Going back out now that it’s cooled off, and grind down the pins so

the impeller will slide over.

Maybe a waste of time, but better than falling asleep watching TV!

Prepare to be boarded!

-

This reply was modified 4 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.