Home › Forum › Ask A Member › 1957 johnson 18hp fuel mixture

- This topic has 28 replies, 15 voices, and was last updated 2 years, 9 months ago by

billw.

-

AuthorPosts

-

July 18, 2022 at 3:41 pm #263146

maybe an air leak ..no fuel. are you getting any pressure in tank after 20 pulls?Also rig up a drill to turn it over. you can fiddle with the high setting while someone operates the drill.

1 user thanked author for this post.

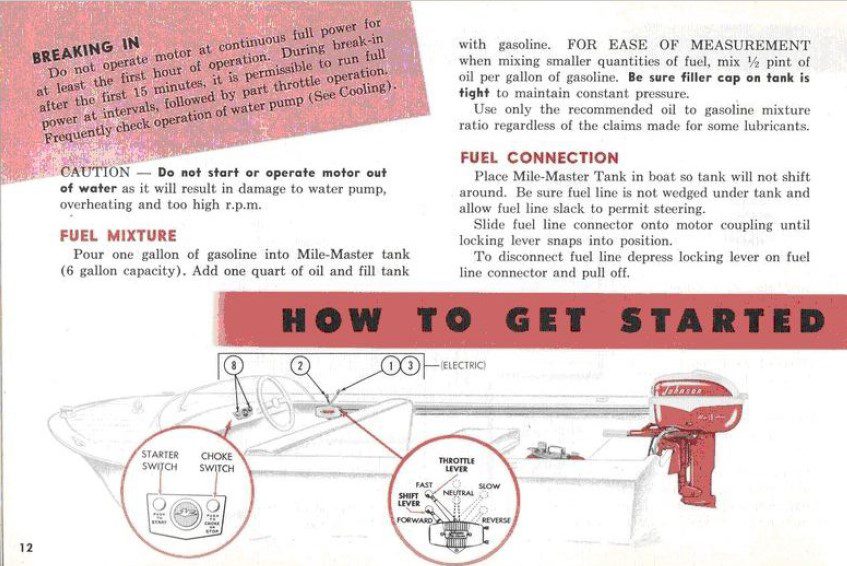

July 18, 2022 at 4:53 pm #263147The 1957 Johnson FD-11 Owners Manual states quite clearly one quart of oil to six gallons of gas (24:1) is the required fuel mixture for this motor. For ease of mixing smaller amounts of fuel, 1/2 pint of oil per gallon (16:1) is recommended as the oil also came in 1/2 pint containers, not 1/3 pint containers. The 16:1 mix is mandatory in the 3, 5 1/2, and 7 1/2 horse motors and nowhere is 32:1 or any other mix mentioned.

I’m sure OMC allowed some leeway with the 24:1 requirement due to inaccurate measuring by tipsy sailors but for peace of mind, I’d try and stick with the 24:1 mix.

July 18, 2022 at 4:58 pm #263151Hi Bob W — also happens to be my name. FWIW, friends and I in Michigan are all running 32:1 in all of our Johnsons and Evinrudes; 1956 Lark and Javelin 30hp, 1958 Lark 35hp, various smaller motors from 1956-58, Using TCW-3 spec oil. Less smoke and no lube-related problems in hundreds of hours at this ratio, and less oil in the lake too, of course.

I need help with a different issue. My 1958 7-1/2 Johnson, AD-12, has been hard to start for a couple of seasons, and began stalling when running at about shifting speed. It would stop suddenly, no signs of being rich or lean, no one-cylinder miss, just sudden death. And a rowboat ride home. I had rebuilt the carb (including a new float) when I got the motor a few years ago and it ran well until it started stranding me last year. Now it’s unusable.

I went through the carb again, everything looks as clean and beautiful as it did before. The sediment bowl and fuel bowl fill normally, inlet needle does not leak. But twenty pulls later, with choke on and throttle at start setting — she never popped once, and the plugs are completely dry. I took reed plate off, all looks good to me; but it’s as if fuel is not being drawn from bowl when cranking. But the motor runs fine, from idle to full throttle, when it does run. I’, looking through the carb again, hoping to find some clogged passage or something, but all looks great. Any ideas? I have started it with starting fluid a few times, after which it runs fine until it decides I need more rowing exercise. Argh.

Any advice appreciated,

Bob / Duralark

Hmmm. You mention it doesn’t seem to be dropping a cylinder, just stops. Perhaps it is dropping a cylinder, but you just can’t tell at that low RPM cuz it just stalls because it won’t run on one cylinder at that low throttle setting. When was the last time the ignition was serviced? Does it have relatively new/not original coils? It is easy to remove the flywheel inspection cover to have a quick look inside to see if the coils are cracked/failing. Try raising the throttle a bit more when starting cold, some of my 7.5s can be fussy this way also. I also discovered that the fuel in the tank/line gets fouled pretty quickly, so I always pump some fuel through the line/connector until I see clean fuel/oil mix before connecting the line to the engine.

The other thing I would recommend is draining/inspecting the gear lube. Water in the gear lube indicates trouble. This gearcase uses a shock absorber device in the driveshaft which likes to fail/expand, forcing the top of the driveshaft hard against the upper bushing/seal assembly. Sometimes this friction is enough to stop/slow the engine. Sometimes the upward movement of the driveshaft actually breaks the upper seal/housing casting allowing water to leak inside the gearcase. Raw water in the gear lube is usually a bad sign. And just because the gear lube is relatively clean, does not mean this condition can be ruled out. But, please don’t rip the gearcase apart on a “hunch” like this, unless there is raw water inside.

Needless to say, try to stick to the “basics”, like a compression test. Perhaps there is an internal engine problem, or the powerhead is just worn out. This engine absolutely requires a 16:1 fuel/oil mix because it uses “plain” crank pin bearings, not roller/needle bearings. Going light on the oil will wear the rods to the point when it might throw a rod through the side of the block. Perhaps there is some water in the fuel that is being sucked up filling the carb bowl. Perhaps the pressure tank system is not working properly and the engine is just running out of fuel. Just cuz there is fuel/oil mix visible in the glass bowl does not guarantee it is filling the carb bowl. Sometimes those stone type filters get plugged up and won’t pass fuel also, you could try running the engine with the filter removed.

Again, keep your diagnostic approach “simple”, 9 out of 10 problems are simple ones that get over looked in favor of more complex problems/diagnostics that just don’t exist.1 user thanked author for this post.

July 19, 2022 at 5:45 am #263202Going back to the oil for a minute, I think the thing is that in 1956, a Fastwin had plain bearings on the small end of the connecting rod, like the infamous tens; so you’d want 16:1 in 1956 and before. In 1957 and up, they had a roller bearing, thus you could use 24:1. I am just going on memory of taking a number of these apart; so correct me if I am wrong on that.

(For the 7.5, there is no question or debate: 16:1.)

Long live American manufacturing!

-

This reply was modified 2 years, 9 months ago by

billw.

July 19, 2022 at 11:20 am #263209Going back to the oil for a minute, I think the thing is that in 1956, a Fastwin had plain bearings on the small end of the connecting rod, like the infamous tens; so you’d want 16:1 in 1956 and before. In 1957 and up, they had a roller bearing, thus you could use 24:1. I am just going on memory of taking a number of these apart; so correct me if I am wrong on that.

(For the 7.5, there is no question or debate: 16:1.)

-

This reply was modified 2 years, 9 months ago by

billw.

Seems like the correct approach/advice for sure.

July 19, 2022 at 2:31 pm #263220Well, two subjects are mixed in this thread. On the fuel mix I have no comment; obviously there is contradictory guidance, including from OMC.

on the 7.5, it seems you are giving lots of attention to fuel, but what about ignition?

Have you changed the condensers? These are a bit of a problem because (1) ordinary ohmmeter testing isn’t reliable; they need to be tested under some voltage stress from a proper tester (2) condensers deteriorate in storage with age so NOS ones are not always good; and (3) the quality of new ignition parts has, in general, gotten worse.

Is it cooling properly? Changing water pump impellers is a project on these and might be neglected. Likewise thermostat should be checked for proper opening.

July 19, 2022 at 4:10 pm #263225Wow… MANY thanks to all who have responded re my no-start AD-12!

I hadn’t had the flywheel off this one before, but had looked thru the adjuster hole, and everything looked nice, for what that’s worth — green coils, shiny newer-looking condensers, etc and it ran well, so that was that. This time around, I decided to renew everything including the plug wires. The only visible problem was that the points had been installed without benefit of cam lube, so the rubbing blocks were almost completely worn away, retarding timing of course. All is new and proper now, but regardless of how good the ignition is, there is no air-fuel mixture getting through the reeds, and the plugs remain completely dry after 25 pulls with the choke closed. Pumping up the tank will fill the sediment bowl, and 4 or 5 more strokes will result in a firm tank plunger as the inlet valve closes. Removing the high speed jet will result in a few oz of fuel running out, verifying that carb bowl is filling, too.

All the gaskets in the intake tract are good, no evidence of any leakage there. Mention was made of possible air leaks at crankshaft seals, but a) I can’t see any such seals in the exploded parts diagrams and b) there’s no evidence of anything leaking OUT at either end of the crank, so I don’t know what to think. The compression is strong and even too.

There was a slight amount of corrosion/buildup on the reed plate so I smoothed it all off with some 400 sandpaper and will reassemble with new reeds in a few days and report back. Thank you all again!

Duralark

July 19, 2022 at 4:31 pm #263226If it truly is not pulling fuel/air in, there is a problem with crankcase sealing. Can be worn out bearings, worn out pistons / rings, missing or melted rubber valve that pressurizes the tank, etc. But you would have seen that with the reed plate off, right? What are your compression readings other than “strong”?

July 19, 2022 at 5:44 pm #263230make condensers from new capacitors with the correct voltage and micro farads

July 19, 2022 at 7:11 pm #263235Well, let’s attack one problem at a time. Try removing the plugs, squirting some fuel/oil mix in the plug holes, then starting cold. Perhaps the choke mechanism isn’t working properly. Like I said, try advancing the throttle past the “start” position also, but be prepared to lower the throttle quickly.

I really don’t think this is an issue with the upper/lower crankcase seals. There is not actual upper crankcase seal. The lower seal is often misassembled messed up on these engines but I really don’t think that will cause a hard starting issue.

Again, try to stick with the basics here, avoid “digging too deep” looking for more complex issues that don’t exist.

Do the compression test like Frank advises, you will probably only see around 70PSI, which is normal for these engines.

Did you drain/inspect the gear lube??

Have you done a cranking spark test? This ignition system should be able to jump a 1/4″ gap while cranking.-

This reply was modified 2 years, 9 months ago by

fleetwin. Reason: addition

-

This reply was modified 2 years, 9 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.