Home › Forum › Ask A Member › 1957 Sea King 12HP won't run right

- This topic has 24 replies, 9 voices, and was last updated 5 years ago by

fleetwin.

-

AuthorPosts

-

April 10, 2019 at 6:44 pm #173035

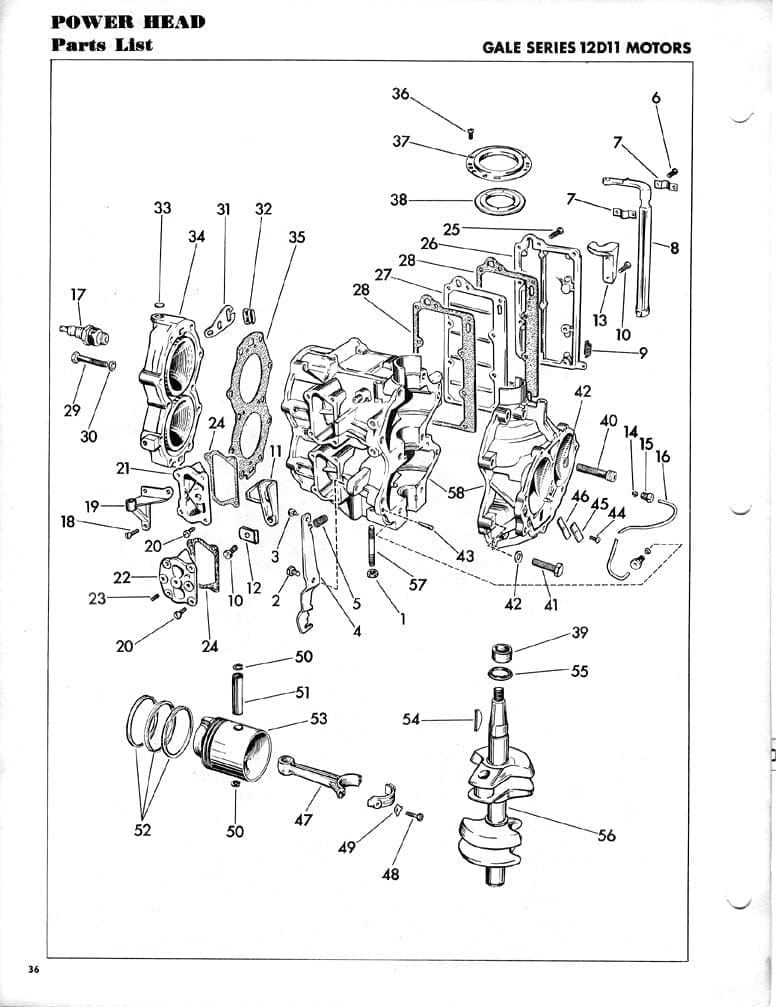

Got my Sea King put back together but it doesn’t run quite right. In order to get the motor to run well, the choke has to be closed between 1/2- 3/4. If I open the choke, it will sneeze and die. Seems to me there is a leak somewhere (maybe???). I tightened all the block bolts, head bolts, screws. Compression is 75 psi on both cylinders. I don’t have a parts manual for this motor so I don’t know if there is a seal leaking and if so, which one, and what the part number would be.

This would be a sweet motor if I can get it to run right. Any help on why this is happening would be appreciated.

Thank you

BillApril 10, 2019 at 8:17 pm #173042A crankcase leak might be a valid guess, but probably not it. I’d sooner say the slow speed circuit in the carburetor is blocked. Or the carb butterfly is opening way too soon. Or the main bearings are worn out–but you would have noticed that, right?

April 10, 2019 at 9:10 pm #173048Well, I went through the carb twice because I first thought it was a carb issue. One thing I forgot to mention was that I put about a half gallon of fuel in the tank and it sucked that down in about 15 min. I have the timing of the butterfly to open just as the the lever gets to the mark. There is no knocking so I am assuming the bearings are ok…or am I wrong. Could air be leaking past the bearings causing a lean condition that would require me to close the choke to draw more fuel? Hence going through more fuel than I think I should?

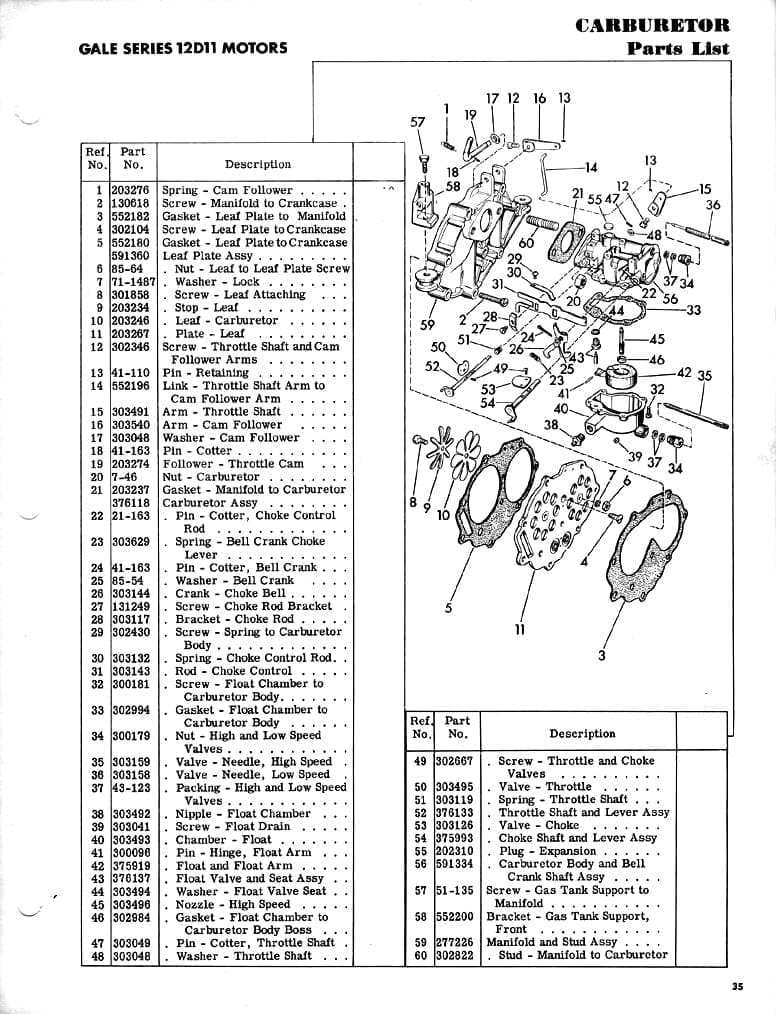

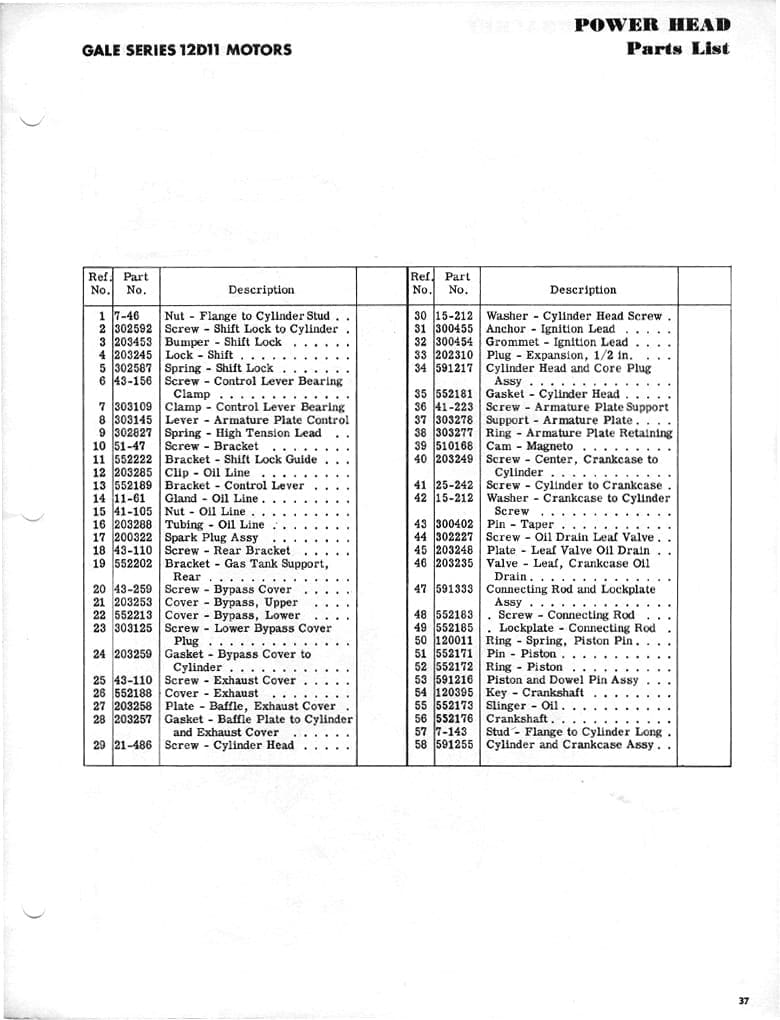

If that is the case, would you have part numbers for bearings/seals?

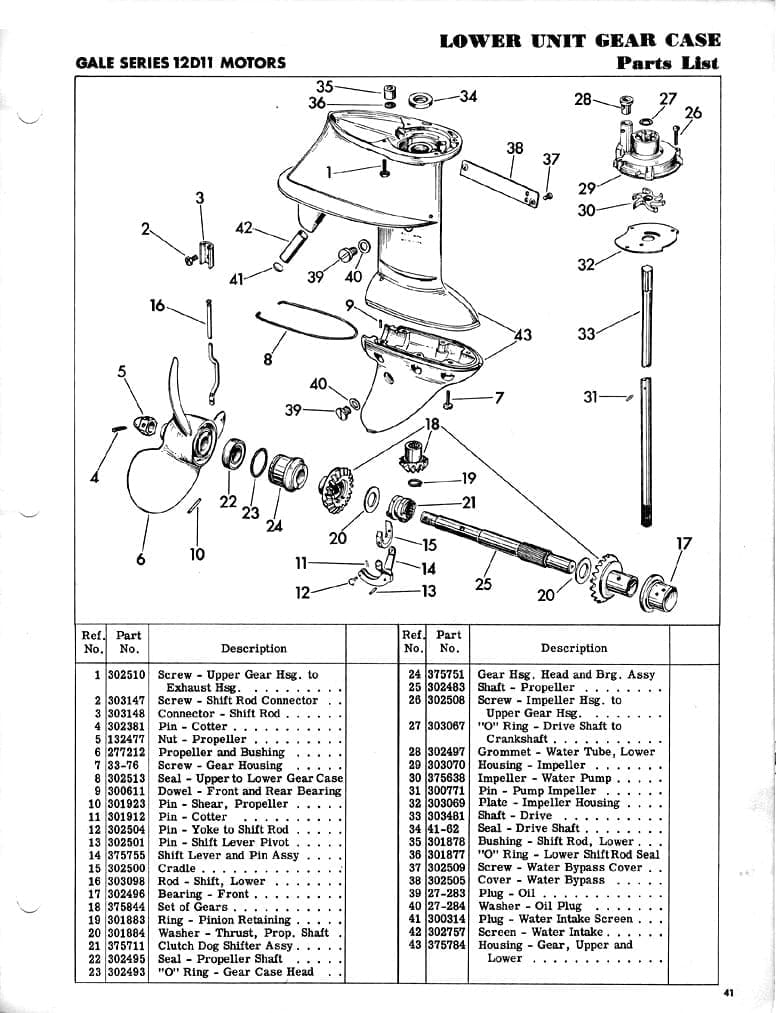

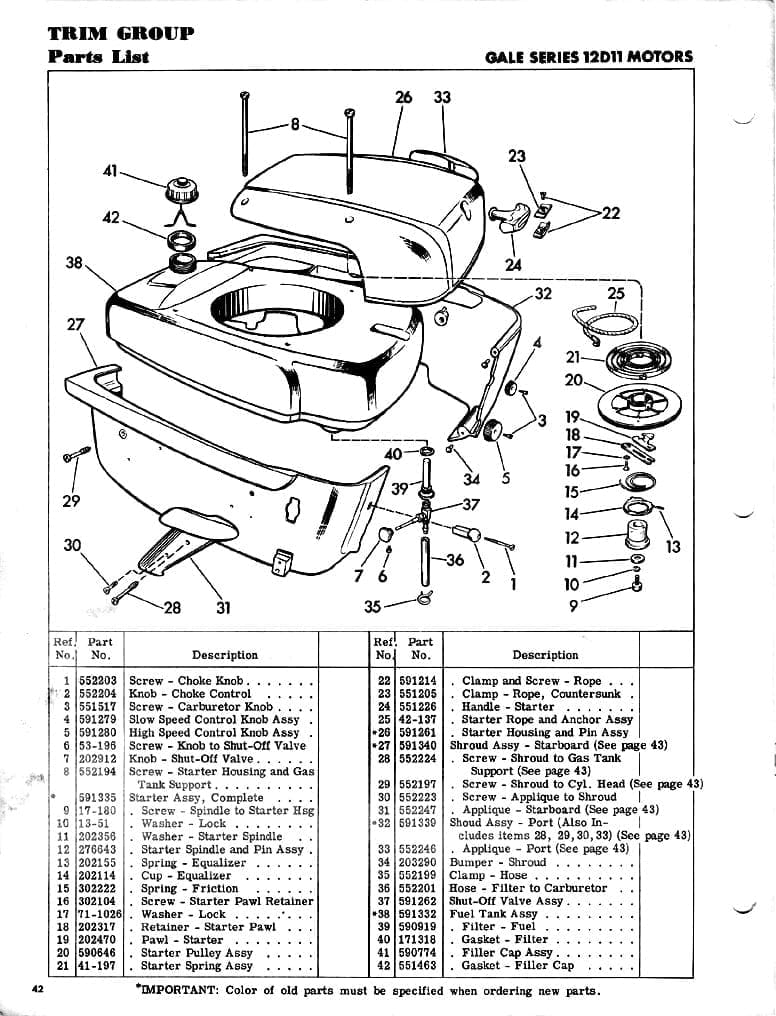

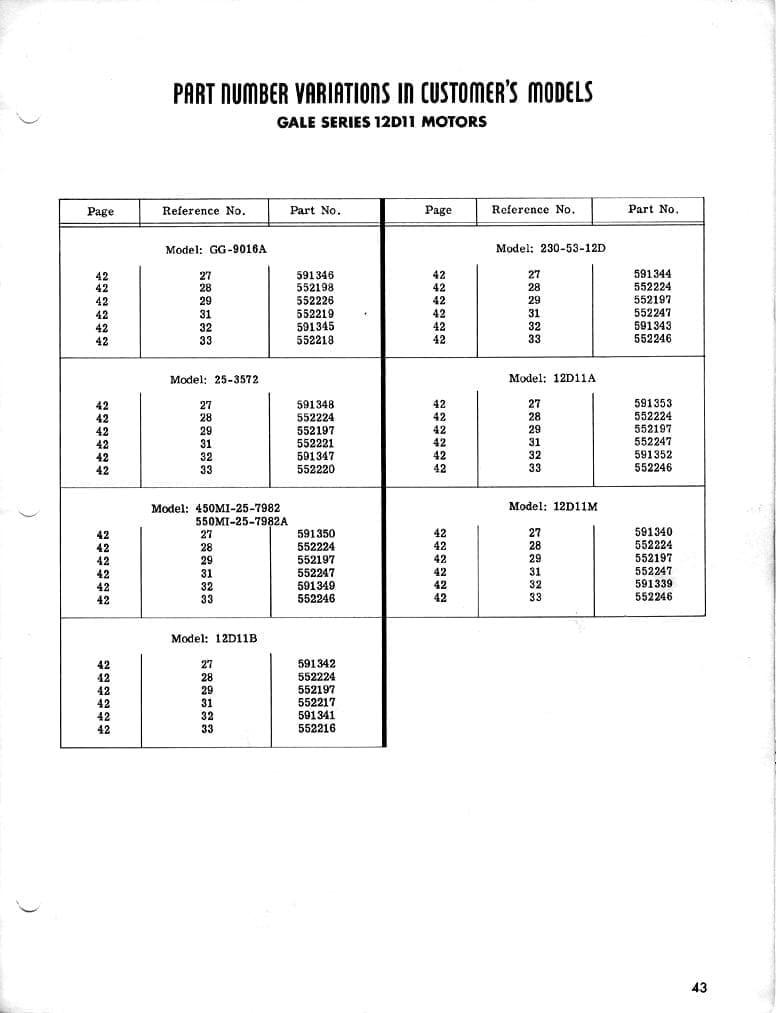

April 11, 2019 at 8:58 am #173067OK, first let me say that there were two 12hp motors for 1957, the “Standard” and “Deluxe”. Most obvious difference was the Standard has an integral gas tank, Deluxe has a remote gas tank. There are many other differences also. Give me a model number and I can post the parts list.

Back to the seals question, the Standard doesn’t even have any seals. It relies on the long cast-in bronze bushings to create enough seal–and does it quite well unless they are worn out. The Deluxe has a different exhaust housing, which necessitated adding a seal on the lower end of the crankshaft to keep water out of the crankcase (not to keep pressure in).

About that seal: As I said, it is to keep water out. The motor will run very well with a bad seal, which is a problem because water is getting in un-noticed, which will cause it to throw a rod. Worse, the 303804 seal was garbage and failed often. It is what trashed many a motor in the day.

Waiting for a model number.

April 11, 2019 at 10:06 am #173072Thank you Frank. GG9016A. Mine has the onboard fuel tank. By your explanation then, it would seem that a seal is not the cause of my problem. So, I guess I am back to my original question about what may be causing my problem. Thank you for copy of the manual. It will come in handy. Also, thank you for your advice.

April 11, 2019 at 11:33 am #173076Surprise, 9016A is a 1954-55 12D11 Deluxe. The Deluxe became the Standard in later years when the remote tank came into being and became the new Deluxe. Confused yet?

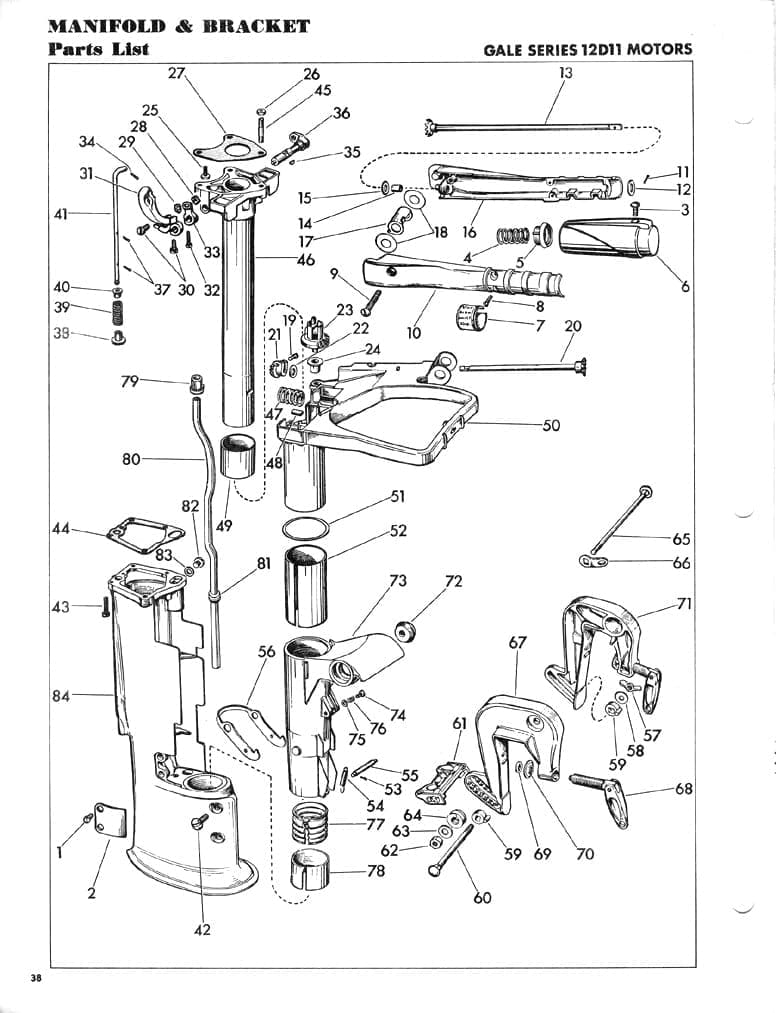

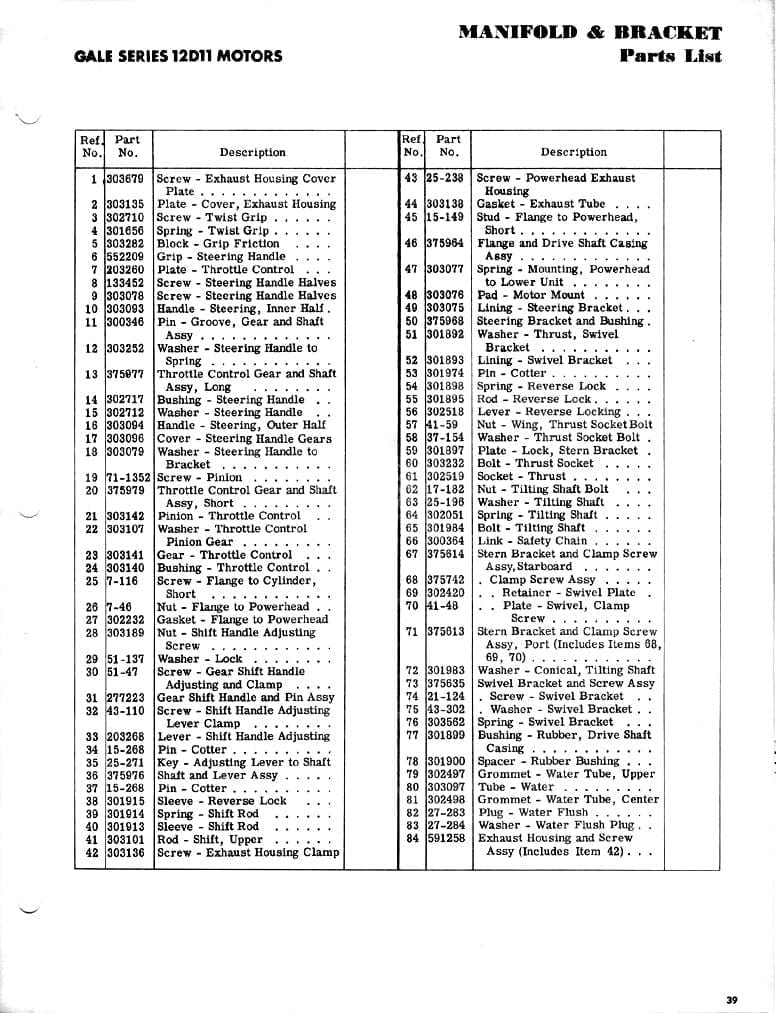

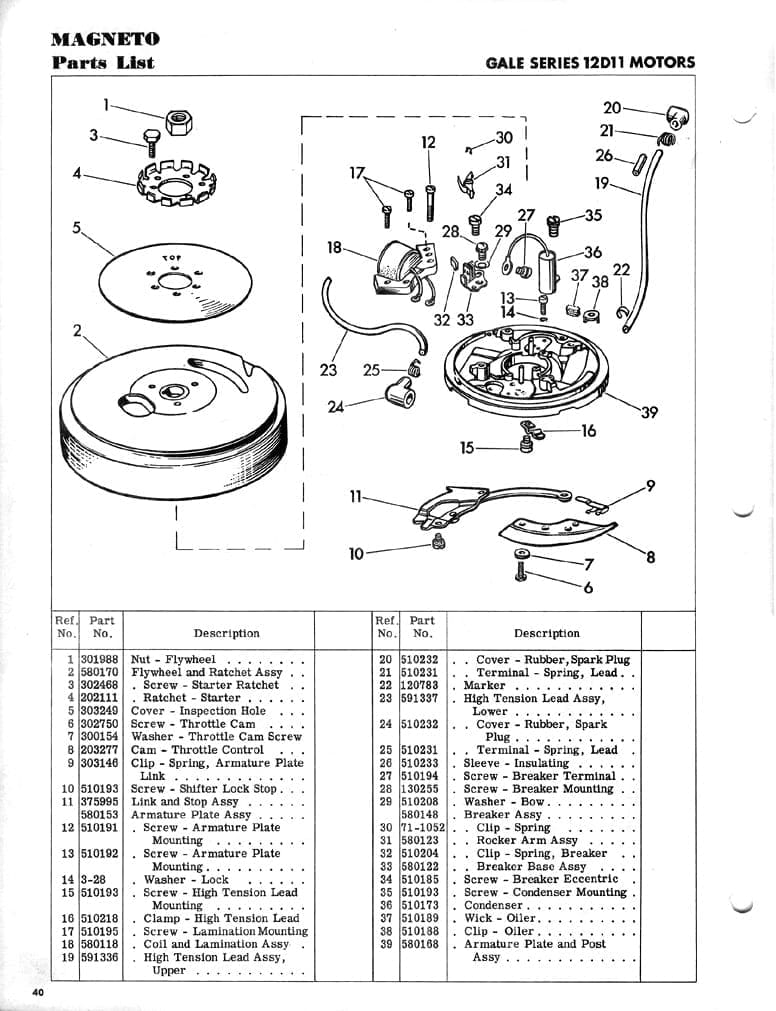

Anyhoo, here ya go—-

-

This reply was modified 5 years ago by

frankr.

frankr.

April 11, 2019 at 11:36 am #173081April 11, 2019 at 11:38 am #173087April 11, 2019 at 12:02 pm #173094Hi! I’d agree without pulling everything apart it sounds like a carb issue. definitely check for blockages in the low-speed passages. I’ve had similar issues with miss-adjusted floats. If the float isn’t performing correctly sometimes the bowl won’t fill up enough to allow the weak low speed suction to work properly. operating a half choke will increase the suction to pull fuel. I’d also check to make sure your needle packing… a complete go-thru of the carb before you start chasing other possibilities.

A little information is a dangerous thing!

April 11, 2019 at 1:47 pm #173096Thank you Frank.

I will go back through the carb. I replaced the packing, but I did not replaced the float. I’m not sure I understand why the low speed needle may be clogged as it does not matter what speed, the motor is at (either high or low), the condition still occurs.

-

This reply was modified 5 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.