Home › Forum › Ask A Member › 1957 Sea King 12HP won't run right

- This topic has 24 replies, 9 voices, and was last updated 5 years ago by

fleetwin.

-

AuthorPosts

-

April 11, 2019 at 3:11 pm #173106

I have a 1956 12 HP Sea King (very similar motor, remote tank). It ran skipping stumbling etc and was not sensitive to the carb needle settings. Although I had replaced the needle packings the motor needed additional packings on top of those already there. I think it was drawing air past the packings and running lean. Ran beautifully after that and was sensitive to the carb needle adjustments. Suggest you try adding some packings first. Good luck.

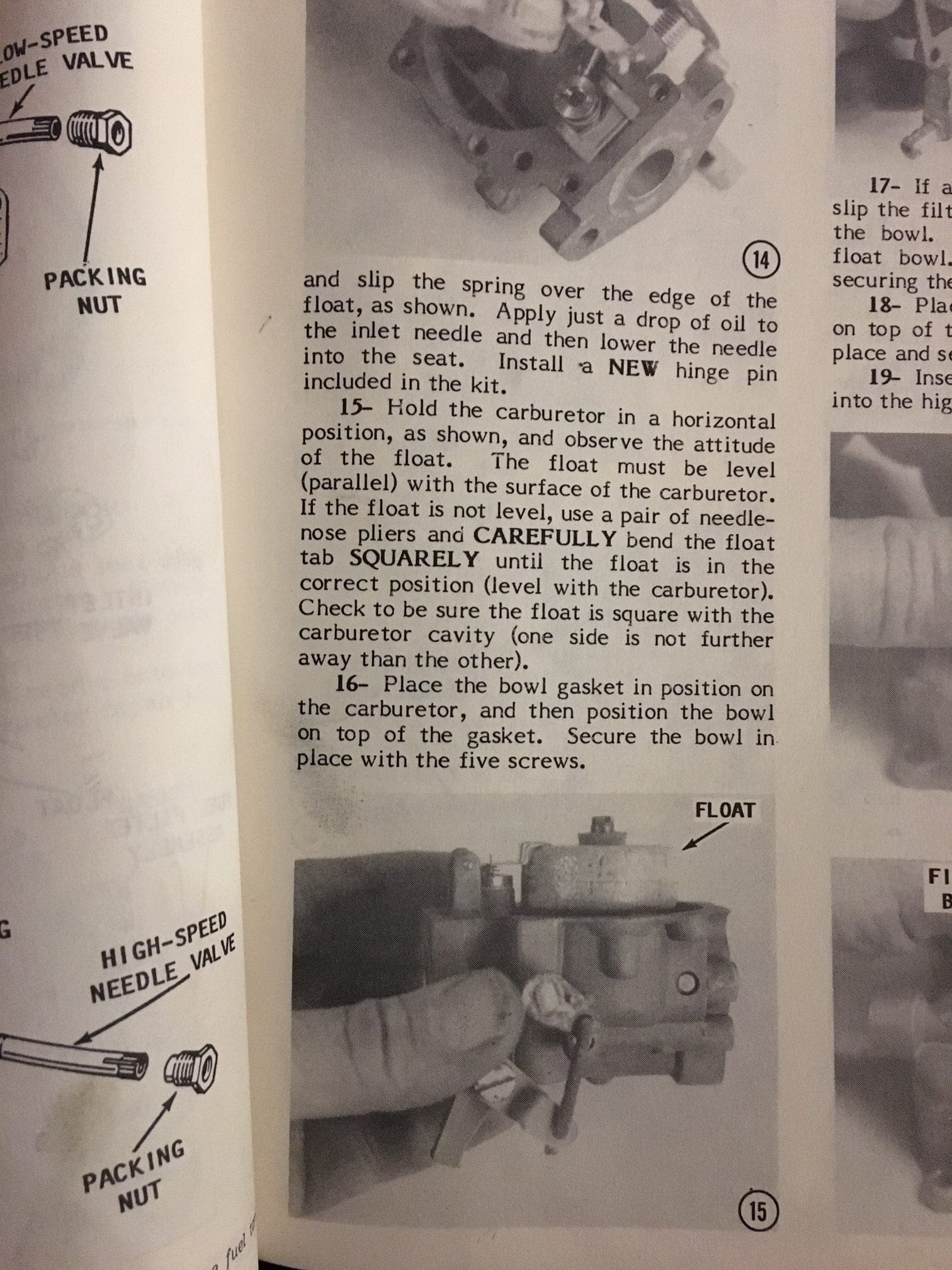

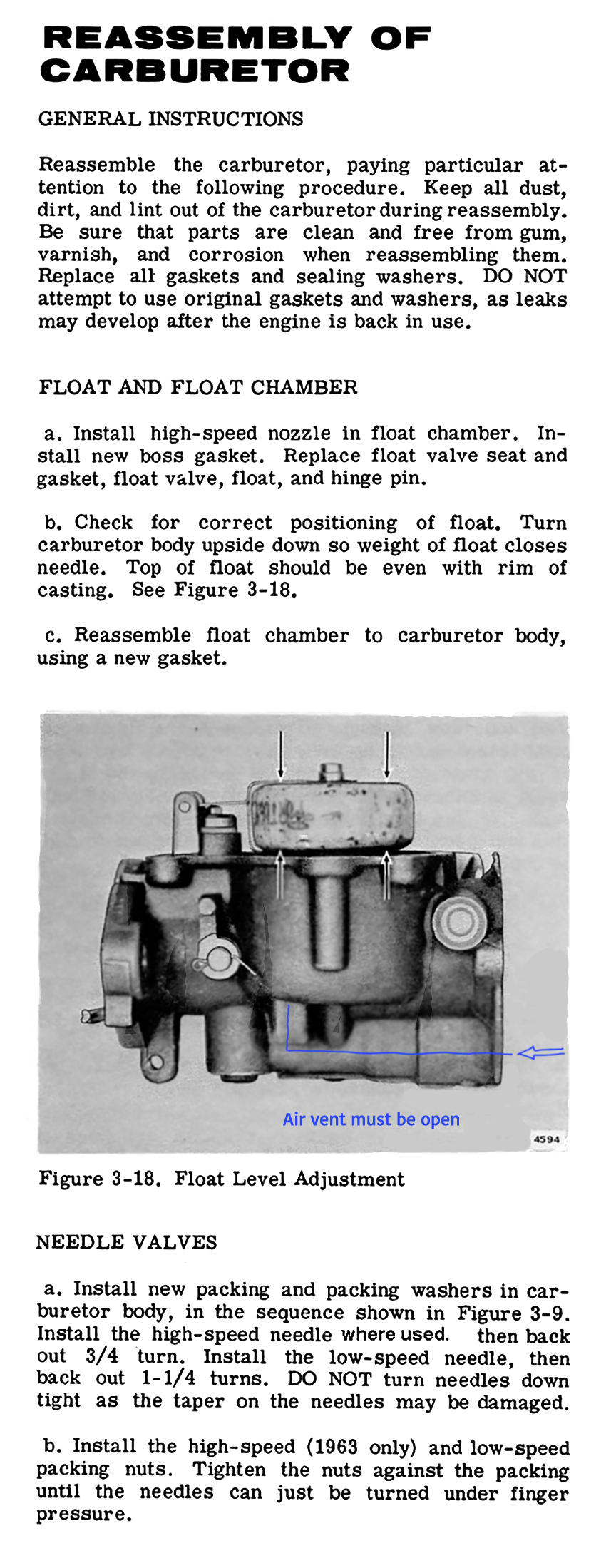

April 11, 2019 at 3:30 pm #173107I wouldn’t initially replace the float unless it is damaged. If it is cork you can reseal it. Generally speaking if you take the float bowl off and turn the carb upside down the float will rest in a fully closed position. This position dictates the height of the fuel in the float bowl. There should be a measurement you can find in a tune-up book that will indicate the distance between the float and the upper carb/bowl flange surface. To adjust the float height you carefully bend the needle valve tab with a pliers. Do not push down on the needle to bend. This is an adjustment that needs to be checked every time you clean a carb or replace a float. Brand new floats can be out of adjustment.

I don’t have a measurement for this carb float… maybe another member would know. Sometimes carb floats are designed to just be parallel with the carb bowl flange.

I’ve also heard about people installing floats upside down by mistake and having similar symptoms… goofy these things happen to the best of us!

If you’ve gone through the carb and everything is good, then look for cracks or poor fitting gaskets in the intake and block. A little light grease can seal cracks long enough to test. If the grease fixes your problem… you know where the issue is with an air leak.

If you have an air leak I wouldn’t expect that it would be at the crank unless it is worn out as mention previously. The old oil slinger style design on the crank top is generally looked as being reliable. I have heard that some other outboards rely on heavy oil mixes to provide a seal… theoretically if you were running a very light mix it could possibly occur on this type of motor as well.

A little information is a dangerous thing!

April 11, 2019 at 9:58 pm #173125I found some instruction in an old repair manual… The float just needs to sit parallel.

A little information is a dangerous thing!

April 11, 2019 at 10:00 pm #173126April 12, 2019 at 12:51 am #173150This is what I have . . .

April 12, 2019 at 9:52 am #173169

April 12, 2019 at 9:52 am #173169Couple things, you stated in your original post that you needed to keep the choke closed in order to keep the motor running. Did you check the screen in the fuel tank? Sure sounds like lack of fuel to the carb to me. Also remember if you coat the float with glue or whatever. It might not float the way it should. Coating makes the float heaver. I have one of these 12hp babys and it runs great. Little on the heavy side but aren’t we all!

dale

April 12, 2019 at 10:23 am #173174I have a 7.5HP Fleetwin that has similar issues. I was about 99% sure it was a carburetor issue but when I swapped carbs from a great running Fleetwin nothing changed. Mine runs “ok” above idle but seems incapable of drawing fuel through the idle circuit of the carb. Frustrating. Maybe your solution will be my solution.

One thing I could suggest you try: Have a close look at the needles. Are they the correct ones? I once had a 12HP like yours that ran terrible and when I swapped carbs things improved. Looking at the original carb I saw that someone had replaced the slow speed needle with an incorrect one. It screwed in but was not long enough and was of the wrong taper. Hard to tell without another carb to compare against as they have no part numbers.April 12, 2019 at 6:20 pm #173199OK…I took the carb back apart. It has packing in it but I put 1 extra (total 3) in each needle. I replaced the float ( just cuz I had a new one on the shelf) I don’t think the old one was bad so I’m going to save it. I also blew compressed air through all the holes. I made sure the vent hole was clear. I put it back together and ran the motor. I am attaching a video. Basically, it starts right up. It runs rough and as I turn the high speed needle in the motor starts to smooth out and pick up speed. Just as it smooths out nicely, it will buck and kick and dies out (approx 1 min in the video). It idles ok but the low speed needle is about 2 turns out

Maybe I just need to get it out on the lake and run it!! What do you think?

April 12, 2019 at 6:44 pm #173201you need a test prop to set the high speed in the tank. and you need a fan to get the exhaust away from the carb. do it on the boat run it rich then dial it toward lean till it runs to lean then set about 1/2 way in between . then you are about set. then set the idle the same way. hope this helps.

April 12, 2019 at 7:55 pm #173204If the float is set correct and looks ok I wouldn’t think that it is an issue. So are you still running it with 1/2 choke? I’ve had similar symptoms before of a failing ignition… but that wouldn’t explain the need for choke. If it isn’t a big deal i’d get some fresh gas and take it for a spin… as long as you have a way of getting back to the dock! lol… I’ve had good luck with seafoam gas additive to clean up carbs and combustion chambers.

A little information is a dangerous thing!

-

AuthorPosts

- You must be logged in to reply to this topic.