Home › Forum › Ask A Member › 1959 Johnson RDSL 21B Info Needed

- This topic has 30 replies, 6 voices, and was last updated 4 years ago by

fleetwin.

-

AuthorPosts

-

March 20, 2021 at 6:57 am #234372

Tom

Thanks for the info… Ok, driveshaft won’t turn at all… What “corrosion holes” are you referring to? The next step when you get home is to remove the two big drain/fill screws (one underneath skeg in front, the other over top of the anti-ventilation plate) and see what comes out… If water comes out, this kind of confirms the worst. But, if nothing or very little comes out, this probably means the skeg is split open somewhere allowing the water to drain out after it thawed. Ideally, it would be nice to pressure test the gearcase before disassembly so you can see exactly where the leak(s) are before you pull it down, then concentrate on those areas once it is apart. I’m guessing parts are pretty badly rusted inside. The forward gear is usually more expensive that the reverse gear, sometimes this is because the pinion and forward gear are included in “a set”. Nonetheless, NOS repair parts for this project will probably include many more parts/pieces and be very expensive. Once you have pulled it apart and confirmed the gear housing itself is OK, might be best to look for a used gearcase assembly…This way you can pull the used one apart, and put its good parts in your original gear housing. You may luck out and find another white gearcase that will simply bolt up and go….DMarch 20, 2021 at 9:50 am #234377Forward and reverse gears are the same. The difference in price and part number is because the forward gear includes the bushing. But the bushings can be swapped between fwd and rev gears.

March 22, 2021 at 3:44 pm #234611OK, looks like you tacked the pictures of the disassembled gearcase onto your other thread. You mention the pinion is stuck, probably frozen in the bearing like you said…Can you pull the driveshaft out? If so, you could use a long drift punch through the upper seal, resting on the pinion shoulder, and tap it out, don’t think it will take too much effort. And yes, am assuming the two needle bearings in the housing will need to be replaced, along with the upper seal. Remove the gears/clutch dog off the driveshaft, clean everything up so condition can be determined…

Once again, am assuming there is not freeze crack in the gearcase skeg…Clean it up and have a close look before proceeding…March 22, 2021 at 5:16 pm #234612Hi, thanks for getting back to me. I have tried a drift on the shoulder of both the bushing under the water pump and the pinion gear/bearing without movement. Banging on them pretty hard too. Used ‘spot check’ dye on skeg and see no sign of any crack. I have looked the fwd., rev. Gear and dog over and they look pretty good. I am hoping I can find a place to get replacement parts as I don’t have a good feeling about getting the remaining bits and pieces out without terminal damage. I hopefully got some pics attached to this reply to show what’s happening. Thanks again. Tom

March 22, 2021 at 5:25 pm #234617I forgot to say yes the drive shaft came out pretty easy. I see lip seal score marks on the shaft either side of woodruff key slot for impeller. I do not see the chromed area for roller bearings that the red book says should be on this engine though.

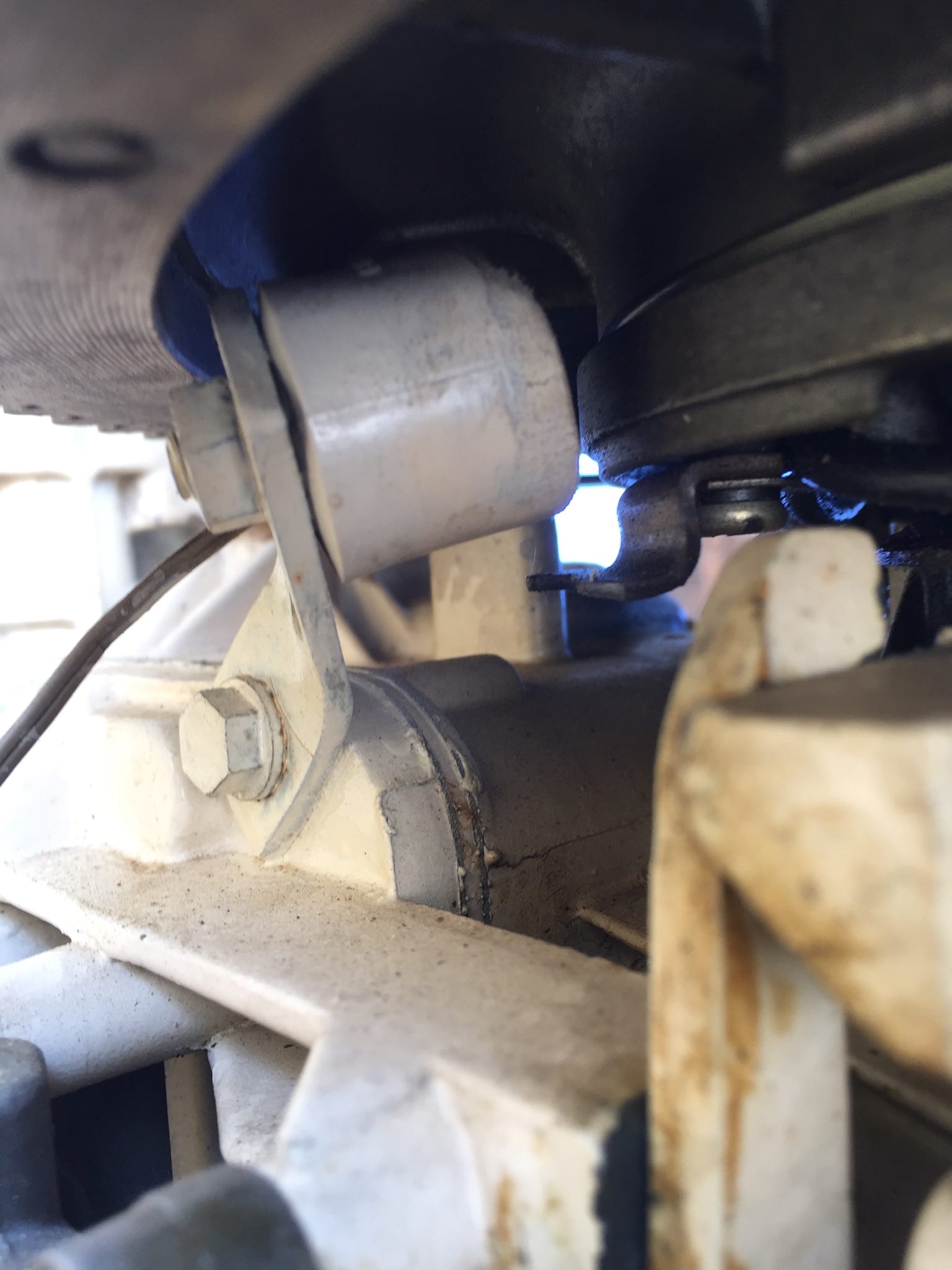

March 22, 2021 at 11:55 pm #234677Hi: we were away for a bit and I finally got to the yard today to look at that wiring thing. The wire is actually a pair of light gage conductors that go from a small short cylindrical thing mounted under the starter gear ring and slightly inside the outside edge of it, to the two pronged ‘plug’ that protrudes through the front of the pan and just behind the ‘handle’ where steering cable connector hooks on. The small cylindrical thing is flat on the end that mounts to its bracket and rounded on the opposite end. The whole thing is about one inch long, and maybe .85 “ in dia. Wires enter it through a ‘potted’ (I think) hole in the side at the flat end adjacent to the bracket. It is on the stbd. Side of the engine. Hope the pics show well. As good as I could get today. With no connection beyond this little cylinder, I am thinking it is not a kill switch connection but…. any guesses anyone? Oh, I downloaded the red book and can’t find a reference to this thing either.

-

This reply was modified 4 years ago by

Mumbles.

Mumbles.

March 23, 2021 at 2:58 am #234682Tachometer pickup ?

March 23, 2021 at 3:17 am #234683You may be right on the money! There is a non Johnson tach on the dash. I thought it could be a tach driver earlier but I was thinking a Hall effect pick up which wasn’t around in 1959 which is when I think the tach was put in. That means sort of aftermarket original equip. When I thought the Hall effect pick up wasn’t possible I threw that idea of a tach sensor out. I’ll bet you are right. The boat is upside down just now and it’s quite difficult to get under to trace the wiring. But I’ll bet that’s where it goes! Nice job. Just a simple coil shooting pulses to the tach? Even the right shape isn’t it. Thanks! I owe you a beer. Regards Tom

March 23, 2021 at 8:50 am #234688OK, sounds like you have ruled out any freeze cracks in the skeg, good news. I guess that pinion is pretty well stuck to the roller/needle bearing. I guess making up some sort of jig and using a big press to drive the pinion out would be the safest method. Perhaps the pinion bearing will press out with the pinion, which would be fine…I’m guessing you will need to replace all the bearings, but the forward/reverse gears are OK. The pinion may be toast due to pitted bearing surface. There should be a needle bearing underneath the upper seal, try to have a look again, or just remove the seal (which needs to be replaced anyway). Seal groove(s) on the driveshaft spell trouble, the driveshaft will probably have to be replaced….

March 24, 2021 at 12:15 pm #234832Total clean and inspection yesterday and last night spent my last dime on ordering the parts that I couldn’t find elsewhere buying from Marineengines.com. They are expensive! Scored shaft will be fixed with SPF Speedi Seal. One above the water pump and one below. Inquiries showed weld/grind not a good ides on that small;l a shaft dia. (5/8″) so the Speedi Seal will work but will have to replace it every time the impeller is changed in the future. I guess I should ask on the classified forum if anyone has a driveshaft in primo condition, maybe I will do that now as it will be awhile before parts arrive so I can reassemble the gear case anyway. Meanwhile, back to working on the boat itself. See Ya Tom

-

This reply was modified 4 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.