Home › Forum › Ask A Member › 1963 Evinrude Sportwin Skeg Pin

- This topic has 4 replies, 3 voices, and was last updated 6 years, 2 months ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

February 21, 2018 at 2:35 am #9269

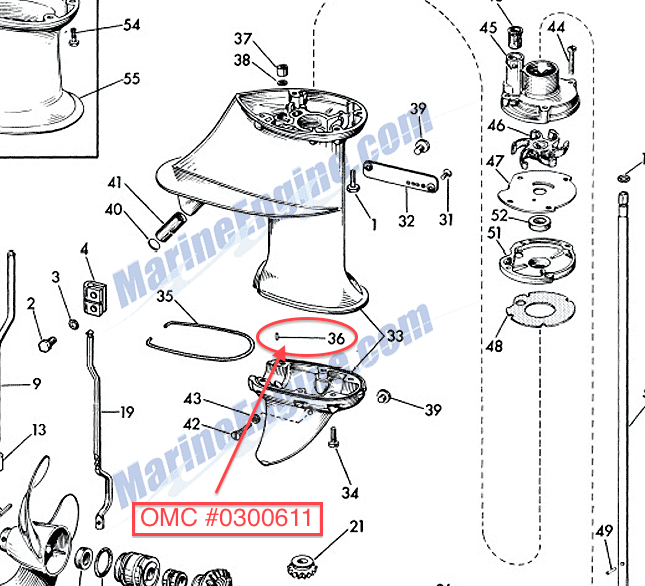

I’ve taken apart a lower unit on a 1963 Evinrude Sportwin (my first lower unit job) and there is a pin in the lower unit skeg that I’m trying to determine if it’s bad or not. It’s OMC part #0300611. It appears to be flush with the housing so I can’t see it doing much for holding any of the gear components in place.

Can anyone give me advice on what the purpose of this pin is, if this part looks good or not, and if not, how do I extract and replace it?

Any insights on what I should do here would be much appreciated.

Thanks.

February 21, 2018 at 3:15 am #71407Lew,

The last guy that was in there didn’t know what the pin was for. There is a corresponding hole in the bushing to keep it in the proper orientation on assembly. Best bet is to drill a new hole for a new pin in each piece, unless you can remove the pin and re-set it to the proper depth. Others have done this and will chime in.

February 21, 2018 at 3:50 am #71409The pin in your photo should be sticking up a small amount and it fits into a corresponding hole or slot in the front bushing to prevent it from rotating in the case. It can be carefully drilled out and replaced with a short length of drill bit, nail, or whatever. There is no real load on it so a piece of coat hanger would probably work to. If you can’t drill it out, another hole can be drilled in line with the original as long as the bushing has a slot for the pin. Epoxy will hold the new one in place.

When assembly time comes, make sure the new pin is properly aligned with the hole or slot in the bushing or the bushing will be damaged by the pin while tightening the screws down.

February 21, 2018 at 4:45 am #71411OK – that makes sense. I’ve added more photos to give a better notion of the parts I’m working with. Closer inspection on the front bushing shows it’s moved around a bit on that pin as there are multiple odd spaced dimples around it where the pin landed at various times – I’m guessing the pin sheared it off at some point. Drilling it out and getting a replacement that sits higher looks to be the answer. Thanks for the advice.

February 21, 2018 at 5:00 am #71412Yup, someones been in there before and never got the pin and groove aligned correctly before tightening the screws down. A common problem. I like to mark the bushing on the opposite side of the groove with a Sharpie so I know when it’s close. By lightly rotating the bushing while applying pressure, you’ll feel it snap into place.

-

AuthorPosts

- You must be logged in to reply to this topic.