Home › Forum › Ask A Member › 1964 Evinrude Speeditwin 28, @ cottage, no pwr

- This topic has 14 replies, 8 voices, and was last updated 1 year, 8 months ago by

fleetwin.

-

AuthorPosts

-

July 31, 2023 at 11:00 am #278685

Hello AOMCI,

Disclaimer: I am a new boater, boat owner and am aware that I am making mistakes 🤣. But I am learning!

My story is similar to ‘Kevin Johnson’s’ most recent thread.

The motor: 1964 Evinrude Speeditwin 28, Model 28-452MHistory: This motor (& boat) were gifted to me by a friend who acquired them along with a farm he purchased. The motor was hanging on a wall mount since the 70’s-80’s as a best guess. Once I got the motor home I built a stand and got to work.

- I removed the mouse house.

- Complete rebuild of the magneto, all components replaced.

- new plugs and wires, GOOD SPARK

- Tested compression: 125psi BOTH CYLINDERS

- Replaced cracked fuel lines : GOOD FUEL

- Replaced the impeller.

- Changed out the bottom end lubricant to spec.

- Filled a garbage can, it came to life and idled well.

l mounted the motor on the boat and lake tested it on the weekend of July 22-23. Good power. Got up on plane well. Made 19 knots WOT. All ready to go to the cottage on vacation. Got to the cottage, put the boat in & docked at the cottage no issues. Hooked up the rope to take the kids tubing (I know/I know) and headed out. First few runs were fine. I had 2 kids on the tube and the tube submerged almost stopping the boat (this happened quickly) and the motor surged as the back of the boat came out of the water. I throttled back and reset to get started again and didn’t have the same power. Recovered the kids and the tube/ropes and started back. As I added power the boat would accelerate to about 5 knots, the motor’s ‘pitch’ would change and I would start loosing speed. We managed to ‘limp’ home at 4-5 knots. It seems to shift into forward/reverse with no issues, no troubles around the dock.

Once back at the cottage I inspected the shear pin and it was fine. With the motor off I checked to see if the prop was moving freely when in gear and the answer was ‘no’. It would stop as I tried to rotate it by hand. I am assuming that I have stripped the splines on one or the other end of the drive shaft?? I won’t be able to pull the bottom end off till I get home, UGH!!If you have any thoughts/advice on how to tackle the diagnosis, I’m all ears. I’m very handy and not afraid of tearing this motor down.

Thanks for your time/consideration,

July 31, 2023 at 12:24 pm #278689OK, so the problems began when the tube almost stopped the boat.

First: I really don’t think there is anything wrong with the gearcase/lower unit, so please don’t take it off and rip it apart. With the engine in gear, you will only be able to rock the propeller back and forth just a bit, which is normal. The propeller should spin freely when in neutral though. You inspected the shear pin and it is OK.

Tell us more about the running symptoms now. You mention the engine has no power at WOT, does it idle properly? Does the engine rev up but not deliver any thrust at WOT, or does it not not even “wind up” when the throttle is pushed all the way up in gear?

It almost seems like the engine is running on only one cylinder, but idle performance would be affected as well if this was the case. I’m just thinking there might be some sort of connection between the boat being almost stopped in its tracks by the tube and the loss of WOT power. Perhaps the linkage got messed up when you were wrestling with the throttle during the event.

The throttle linkage on this engine is a little complicated, there are a few things there that could be causing issues. First, there is the “neutral lock out/limit” linkage that prevents you from over revving the engine in neutral. There is a vertical rod that runs up from the shift lever to underneath the mag plate. When in neutral, the vertical arm stops the mag plate from advancing fully, the vertical arm swings out of the way when in forward. So, if this linkage is messed up, it might be limiting timing advance at higher throttle settings, usually the throttle linkage won’t advance past this setting in neutral, but I suppose it might be possible to advance the throttle control/linkage past this point.

Next, there is a complicated little throttle linkage called the “economizer linkage”, this allows full WOT timing before the carburetor opens fully. There is a little brass barrel/screw on the left side of the engine mounted to a small diameter horizontal round rod which links the mag plate to the carburetor linkage at higher throttle settings. So, if the screw on that brass barrel has loosened up allowing the barrel to slide back, your carburetor won’t be opening up fully limiting WOT power.

Next, the is a vacuum switch located on the left hand side of the engine which keeps the engine from over revving when the throttle is cut back quickly by cutting out spark to one cylinder. The vacuum switch is connected to one crankcase to sense high vacuum which would occur if the engine is over revving with the throttle closed. When the switch closes at high vacuum, it grounds out one set of points killing spark to that cylinder. Once RPM comes down and vacuum decrease, the switch opens allowing that cylinder to spark again.

Finally, perhaps your control box/cables got messed up so the engine throttle linkage is not being advanced fully.

So, your best tool now is a good visual check of the linkages to make sure everything is working properly. In other words, shift the engine into forward gear (you may have to rotate the prop slightly to get the gear/dog lugs to align allowing full forward engagement). Now, have an assistant hold the engines throttle linkage in the WOT position. Is the carburetor opening fully? Is the mag plate moving to its WOT stop? You have already pulled the engine back off the boat? If not, I would simply use the remote control to set the engine to WOT in gear. Perhaps the cables/box is messed up preventing the engine linkage from advancing fully.

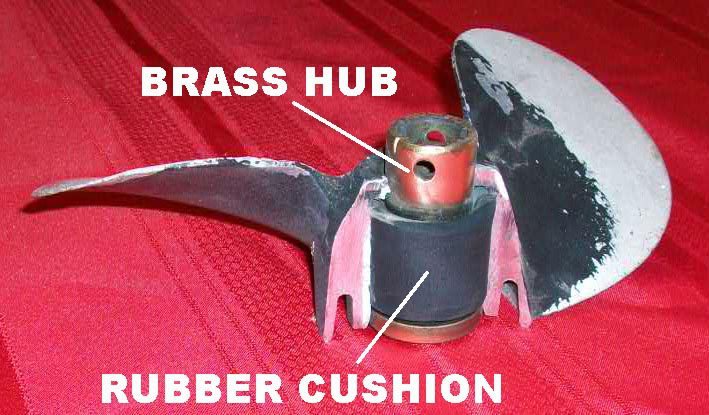

July 31, 2023 at 2:10 pm #278694Fleettwin knows his beans! So you can check all that stuff and also check your propeller it might be spun. Maybe you have a spare? Spun meaning the inside comes loose from the blades.

dale

1 user thanked author for this post.

July 31, 2023 at 6:31 pm #278696AOMCI Team,

Field test complete.

1st paragraph qstn’s:- engine in gear prop rocks back and forth.

- prop spins freely in neutral

- Prop is not spun

2nd paragraph:

- engine generates power just fine

- starts and idles no issues

- put into forward and and the engine spins up just fine, however there is a clicking sound as the rev’s go up and come down. Very little forward thrust

3rd paragraph:

- engine is running on both cylinders

- checked all linkages and everything appears fine

4th paragraph:

- all linkages are working to spec

- Vertical neutral lock out arm is working to spec

5th paragraph:

- economizer linkage is working to spec

- brass screw has not loosened

- min gear the engine can go to WOT

6th paragraph:

- The vacuum switch appears to be working to spec

7th paragraph:

- Control box/cables are operating/connected to spec

8th paragraph:

- the power head is working to spec

- it revs up and down

- I am very concerned with the clicking sound as the revs go up & down

- definitely very little thrust

I await your response 👍🏻

Thanks,

Quintin

July 31, 2023 at 6:31 pm #278697July 31, 2023 at 9:34 pm #278705I will pull the prop in the morning 👍🏻

August 1, 2023 at 9:36 am #278708To check for a spun hub, mark the hub and prop with a marker and run the engine to duplicate the problem. Then check the marks and see if they’re still aligned. If not: spun hub.

August 1, 2023 at 9:57 am #278709OK, so the engine revs up in gear under load, but little or no forward thrust?? Like Frank says, check the prop hub, or just try a different prop.

The “clicking” noise when revving or decelerating is normal for this engine.

August 1, 2023 at 10:37 am #278712Morning Trouble Team!!

Here is some more information:

- pulled the propane found these little balls of rubber

- there are these marks on the brass center

- I also dropped the washer from the prop into the lake 😩. Did a detailed underwater search and found all kinds of other stuff….but not the washer

I will mark the brass center and the prop and run the engine to see if the marks position changes. Can this prop be restored or is it done??

Thanks,

Q

August 1, 2023 at 10:40 am #278715seen some folks drill a small hole both sides of the prop body and drive a pin into the rubber hub to lock it in place … just use a shear pin instead of a solid drive pin.

temporary fix till you get a new prop.

but check for prop repair shops …if any for a new new rubber insert

Joining AOMCI has priviledges 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.