Home › Forum › Ask A Member › 1966 6hp Chrysler coil

- This topic has 8 replies, 6 voices, and was last updated 8 years, 6 months ago by

Tubs.

Tubs.

-

AuthorPosts

-

May 25, 2017 at 10:33 pm #7123

I need some info, a friend brought me a model 6603 Chrysler 6hp outboard and asked me if I could help get it going again. I being of a soft heart and weak mind said I would try to get it going. The problem is that one of the coils is bad a WICO X14877 and it is riveted to the plate. Number 1 problem I can’t find a replacement and if I did how would I replace it being that it is attached by rivet’s and not screws. Any solutions ?

May 25, 2017 at 10:47 pm #58328I am sure someone that knows for sure will come along soon an give a definitive answer but maybe the coil will slide off the laminations. Usually there is a clip that will have to be straightened that holds it in place.

May 25, 2017 at 11:15 pm #58331More than likely, bullie is correct. The laminations probably cannot be switched side to side or motor to motor. Thus they don’t want you taking them off.

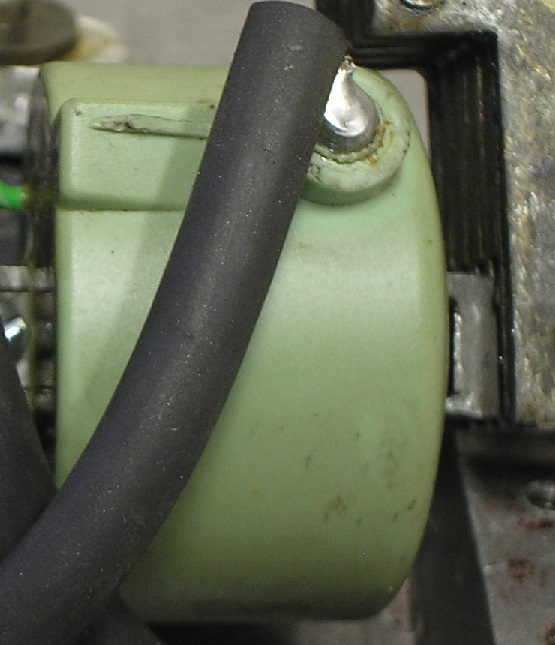

May 26, 2017 at 1:02 am #58332I have slid the coil off of the laminations the laminates look to be 7/16 of a inch square. I was wondering if a OMC coil would work if I slid it off its laminations and put it on the WICO laminates. Would it still work if the plug wire came off the top instead of the bottom of the coil like usual ? (upside down) ?

May 26, 2017 at 1:51 am #58334OMC coil inside dimension is .440" try to mike the Wico laminate to see if it will fit. Check to see if the Flywheel will hit the coil and or spark wire. I have not worked on a Chrysler outboard yet. Can you rotate the OMC coil a different direction downward ?

May 26, 2017 at 2:06 am #58337quote sbrown21:I have slid the coil off of the laminations the laminates look to be 7/16 of a inch square. I was wondering if a OMC coil would work if I slid it off its laminations and put it on the WICO laminates. Would it still work if the plug wire came off the top instead of the bottom of the coil like usual ? (upside down) ?Wont matter. I’ve even cut the sleeve off and soldered

the plug wire on when there isn’t room. I little dab of goober

on the solder is helpful in keeping the spark from arking.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

May 26, 2017 at 3:03 am #58342I’ve done this with success on Elgin and West Bend motors. If there is corrosion the old coil can be stubborn about coming off–possibly needing to be hacksawed. \ Otherwise it’s mainly a matter of getting the leads dressed so that nothing rubs or shorts. On one I ended up with one plug lead on the bottom and one on the top. Sort of inelegant but that seemed to be the best fit.

May 27, 2017 at 12:00 am #58418Thanks Tubs cut the sleeve off turned it upside down used the coil pin like a sparkplug connector through the side of the plug wire and put a zip tie around the coil to hold in place. I thought I messed up good ohm reading at the plug no spark , had to clean the points 3 times before I got fire. I put the condenser off of the OMC coil with it the old condenser was bad. I hope to start it up in a day or two hope everything works.

May 27, 2017 at 4:09 am #58438Sometimes more than just the contacts need cleaning.

Corrosion under the points where they mount to the

mag plate can cause the loss of spark. Same with the

condenser. Also the wire ends and the hardware where

they mount may need a cleaning. If a motor has been

sitting for a long time it worth while to remove the

points, take them apart, and clean everything to

insure a reliable spark.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.