Home › Forum › Ask A Member › 1967 Mercury Merc 60 6hp Sneezing and stalling

- This topic has 23 replies, 7 voices, and was last updated 7 years, 1 month ago by

silvab7232.

-

AuthorPosts

-

February 25, 2018 at 11:17 pm #9302

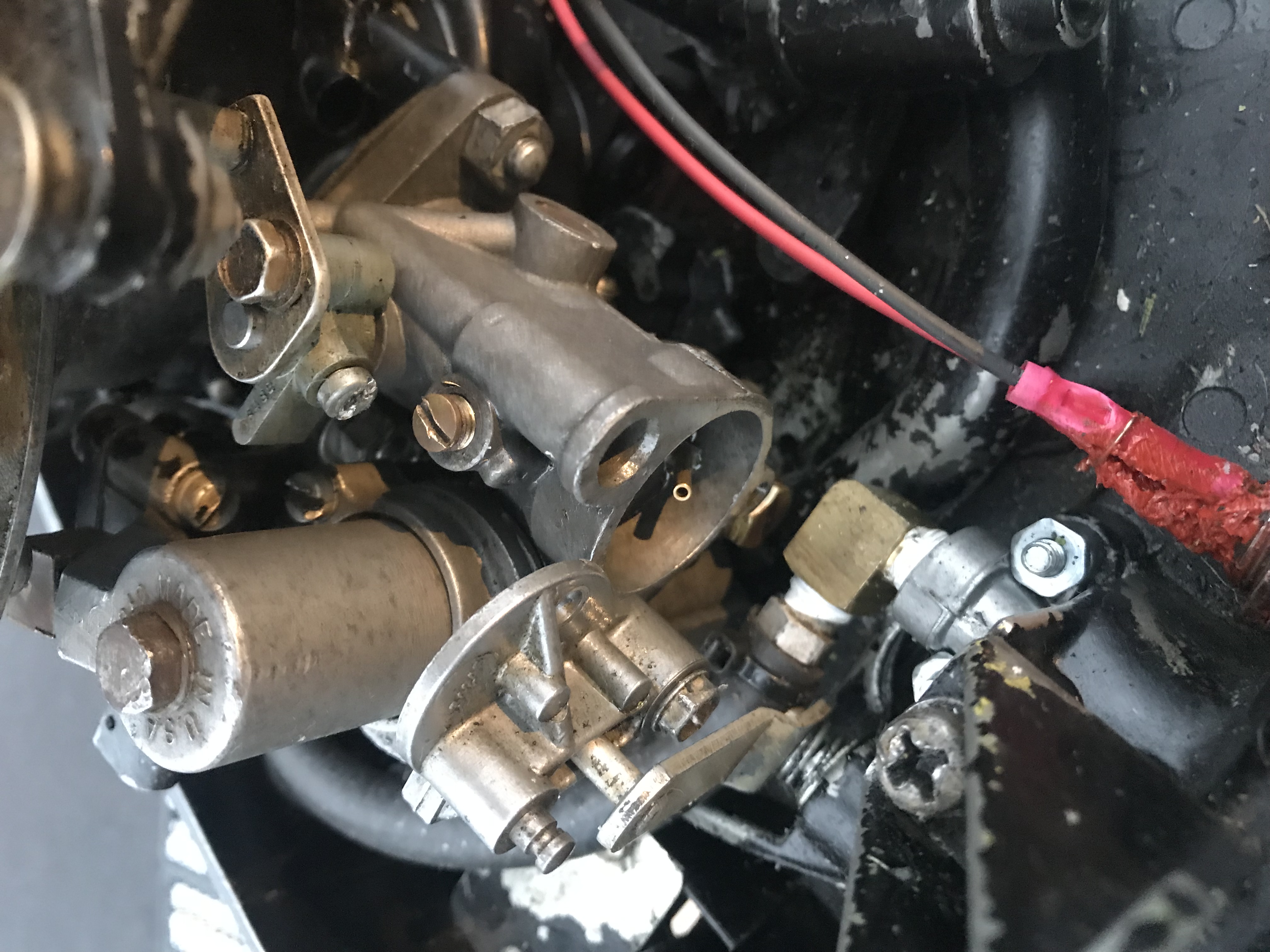

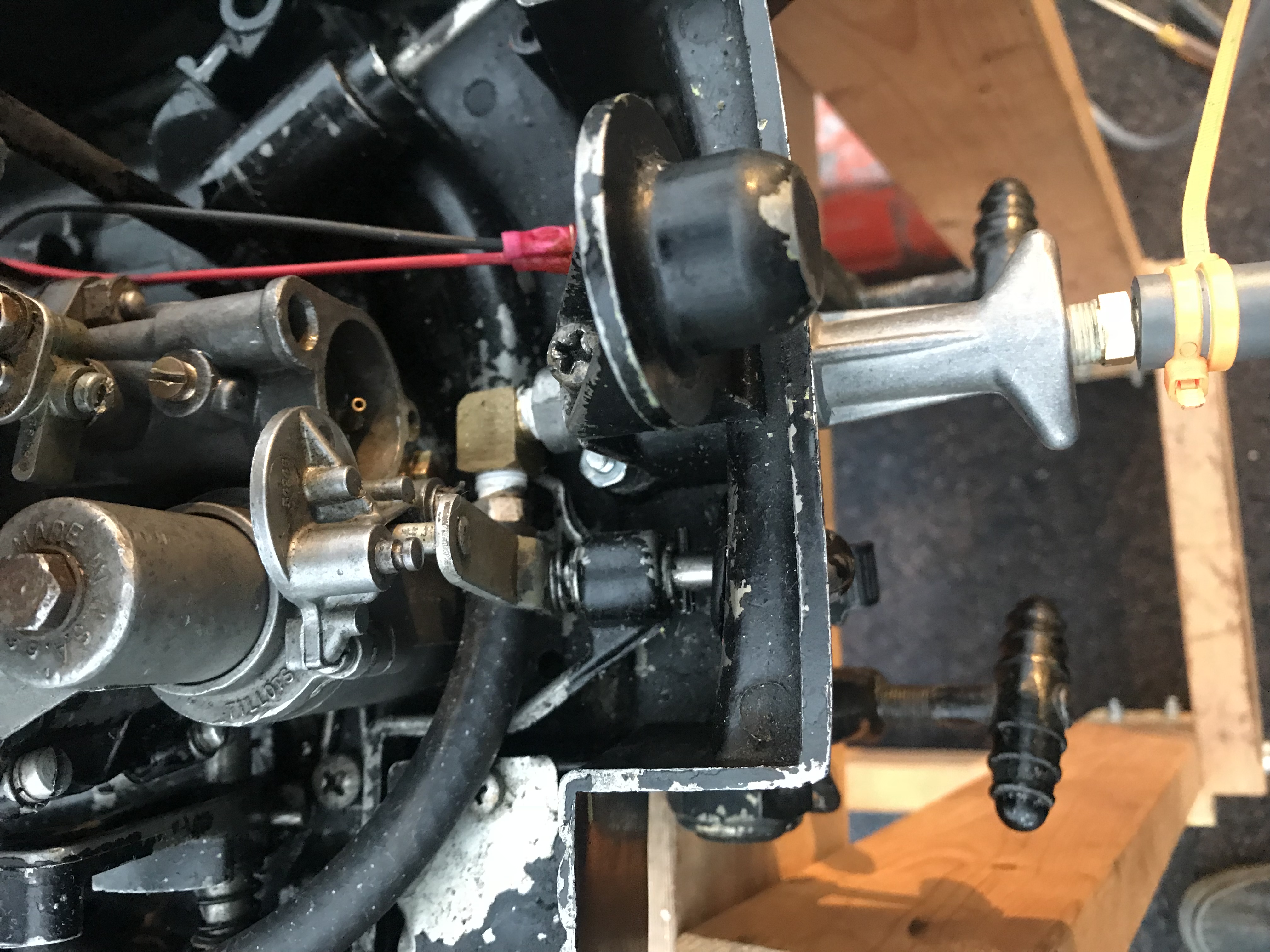

Hello again, I posted earlier about gear lube for this motor and I appreciate the replies and awnsers I’ve gotten. Now I “kinda” have the motor running in the test tank, but It keeps sneezing and stalling. Sometimes it will sneeze then stall, or it will just stall. Ive read that this may be to a lean air fuel mixture. I’ve messed with the carb and adjusted but no luck. I have a few pictures of the carb and the motor. Hopefully this might help you guys see what I have to help me out. Thanks! 😀

February 25, 2018 at 11:57 pm #71618Sounds like lean fuel mixture to me. Have you gone through the carburetor? A good cleaning is usually in order when bringing a motor back into service if it hasn’t seen regular use. Another place that is common for vacuum leaks can be by the fuel pump. Some of these had the pumps right on the carburetor, others had the pump bolted to the side of the block for the vacuum pulse. There can be a vacuum leak at these. Also, these pumps are not very strong. If you are running in a drum, and have the fuel tank on the floor, that 4′ of head that the fuel pump has to overcome is sometimes too much if the pump is not in perfect condition. Place the fuel tank at about the same level as the power head, or at least like it would be in a boat to see if that makes any difference.

These 60’s are wonderful little motors. She should idle like a Swiss watch.

Steve

February 26, 2018 at 12:07 am #71622a few things can do it.

the idle tube may be dirty the brass screw pic #2 center of top of carb . remove and clean

the idle adjustment mat be to lean . idle adjust screw recessed in the front of the carb. out is rich in is lean start at 1 1/2 turns out from lightly seated.

may be a vaccum leak check by a VERY light spray of starting fluid around any place you think it might be leaking

or as simple as breathing exhaust while running in the tank. use a fan to remove the exhaust when you run it.just for starters.

February 26, 2018 at 12:50 pm #71644All good points. I’ had one of those motors come through the shop that would lean sneeze.. I chased my tail on that one, till I finally found leaky crankcase halves. I would check that first before proceeding. I used some aerosol carb spray while idling the motor in the tank.

February 26, 2018 at 4:07 pm #71651Where would the valves be located on the crankcase? If they end up being leaky what would be a good fix for those?

February 26, 2018 at 4:45 pm #71652He was talking about the "Crankcase Halves", not valves. These cases are split at the crankshaft plane. The flat surfaces can warp, or for what ever reason can have air leakage at the sealing surface. The case is bolted together, and if you look at them, that mating surface is what Jerry was talking about. Carb cleaner, or any other spray that you spray along the seam will plug the leak momentarily and you should see a difference in how the motor runs.

Steve

February 26, 2018 at 5:11 pm #71654have you tried pump the fuel bulb when it start sneezing … check fuel connector for air leaks

Joining AOMCI has priviledges 🙂

February 26, 2018 at 7:07 pm #71660Still have the block tag? Or not?

February 26, 2018 at 11:30 pm #71671quote 20mercman:He was talking about the “Crankcase Halves”, not valves. These cases are split at the crankshaft plane. The flat surfaces can warp, or for what ever reason can have air leakage at the sealing surface. The case is bolted together, and if you look at them, that mating surface is what Jerry was talking about. Carb cleaner, or any other spray that you spray along the seam will plug the leak momentarily and you should see a difference in how the motor runs.Steve

Exactly.. the engine that I experienced this on was very hard to get started. Once running it actually ran fairly well considering. Here is a ”Hillbilly Fix” that I learned from another buddy of mine: Grab a can of color matched spray paint , (in this case Mercury Phantom Black) and after degreasing and cleaning the surface, paint the leaky seam. Let it dry and give it several coats. If your lucky, the paint may actually seal the leaky joint. I have had success with this on larger outboards that had some tiny leaks. I did it to a 115 Mercury back a few years ago, and it’s still running good. Of course the right thing to do is to take it apart and reseal it, but this can work in a pinch. I have actually heard of some porosity issues on OMC blocks back in the mid 90’s or so, that actually were fixed by painting the powerhead. Pretty wild Huh?

February 27, 2018 at 12:48 am #71672well before spraying it why not try to suck the air out of the crankcase somehow (vacum ??) .

. if you depressurize the innards… the paint should get sucked in the seam and close it up good

conversely .. before you spray paint it… if you pressurize the crankcase (both pistons closed half way if possible with exhaust ports closed) you could spray it with some soapy water to ""find" the bad seam

ho well… back to web surfing

Joining AOMCI has priviledges 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.