Home › Forum › Ask A Member › 1969 Evinrude / 1971 Johnson 9.5 Runs Poor

- This topic has 21 replies, 6 voices, and was last updated 2 years, 6 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

June 2, 2023 at 12:06 pm #276693

Thanks, there’s a massive amount of info on the 9.5’s on Leroy’s page!

I put the motor on the workbench today to check out again.

I still could not find any “Sync” mark, but I see that Leroy could not either!

I pulled out the magneto from the parts motor, and found no marks on it either.

I was going to do the basics, so I pulled the plugs so I could observe spark

and then check compression. Now the engine does not turn over. It’s not

the powerhead, but it feels rather “spongy” when trying to turn the flywheel,

like the impeller is hung up.

I had put a new impeller in it, and it pumped water great, so I have no idea

what’s going on, but will tear back into it. :-()Prepare to be boarded!

June 2, 2023 at 6:05 pm #276705I had found a possible “sync” mark on the magneto before, but the

throttle pin never even came close to it.

After reading Leroy’s ramblings today, mentioned was a fast idle

adjustment on the side of the tiller handler….. hmmmmmmmm.I’m feeling pretty stupid now. The knob was cranked “way in”.

I reset it, and it looks like I’ll be able to use the mark now.I pulled the carb off, and came to the conclusion that I never

had this one apart…….. perhaps it was the parts motor carb

I was thinking of, or I dreamed it!

Anyway, it’s soaking in cleaner now.The impeller was holding up the motor from turning over.

It was pumping water great when I shut if off. As soon as

I dropped the L.U., the motor turned over fine.

I opened up the impeller housing, and seen no damage to

the impeller, but it was almost like was glued in the housing

at first. The width of the impeller appears to be “just right”.

Not sure what to think about that. Anyone have an impeller

stick in the housing before after sitting a few days?It has okay compression according to Leroy…… 68 & 69 psi.

The spark looks great, but I’ll probably order new condensers anyway.Regarding the fuel pump……. The 1971 parts motor had a square fuel pump,

part / casting number 312631.

Will have to research that and replace the pump, or find a repair kit, if available.Prepare to be boarded!

June 2, 2023 at 9:15 pm #276714OK, the issue I found many years ago concerned your first picture and the way those links are arranged/assembled. The one I was messing with was in the wrong order, so the sync was off. Wish I could remember the specifics better, but it was a few years ago. All I can say is to make sure the carb is closing all the way, look down the carb throat at the throttle butterfly, it should be completely closed when the cam isn’t touching that crazy pin/roller arm set up. If not, the engine will surely sneez/pop at low speeds like your does.

I have never seen an issue like you reported with that impeller. Are you using an OEM impeller or aftermarket.

And yeah, the 70PSI isn’t that bad for this low compression engine, try again after the engine has been running for awhile. Perhaps try a different compression gage.

June 3, 2023 at 5:46 pm #276732I believe I made some progress today with getting the motor running better,

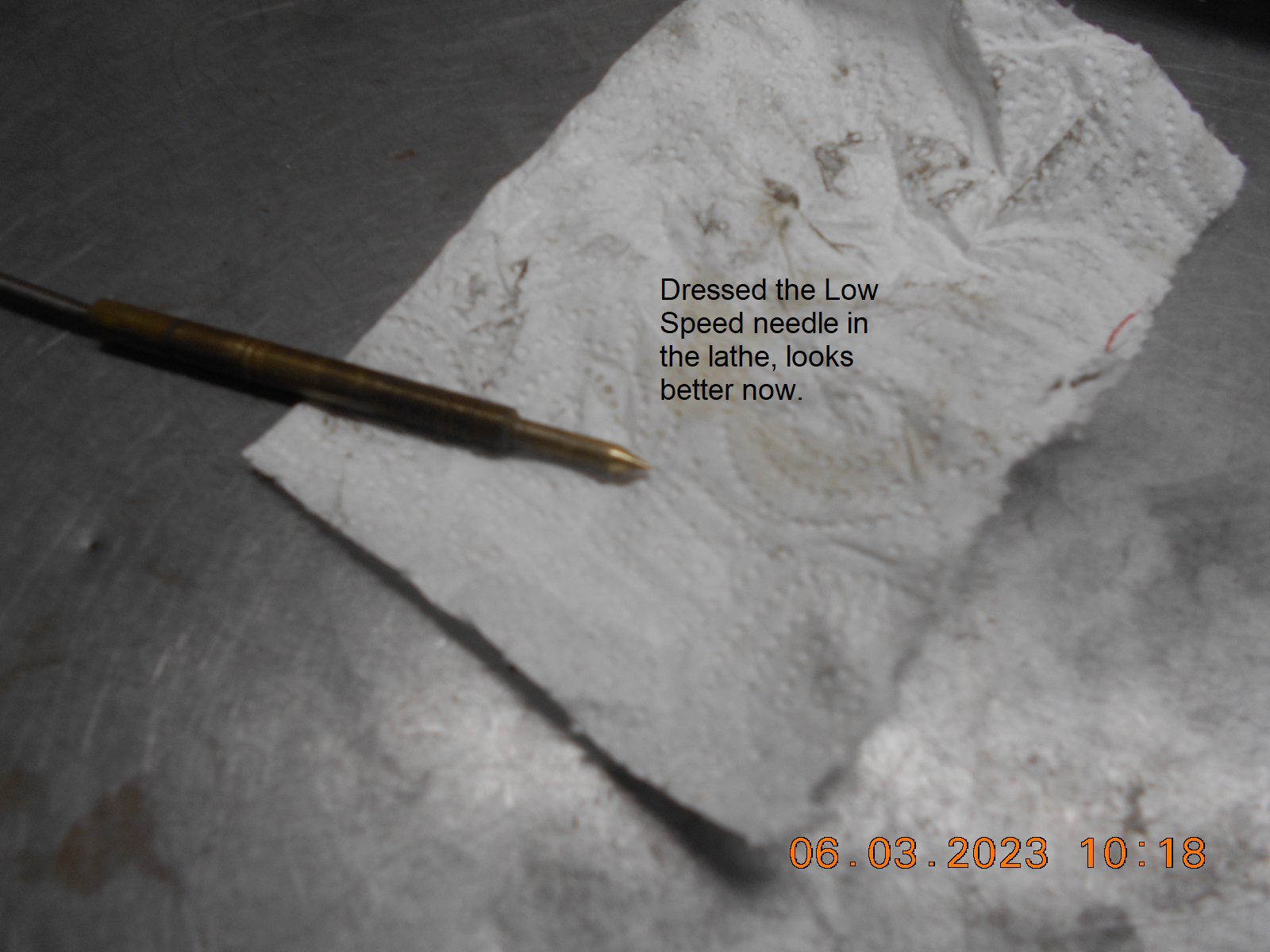

after figuring out the mag to carb sync issue.I went through the carb, and dressed the low speed needle in the lathe with

some 1200 grit sandpaper on a 6″ machinist rule. Looks much smoother now.Replaced the fuel line between the fuel pump and carb, as that was “toasty”.

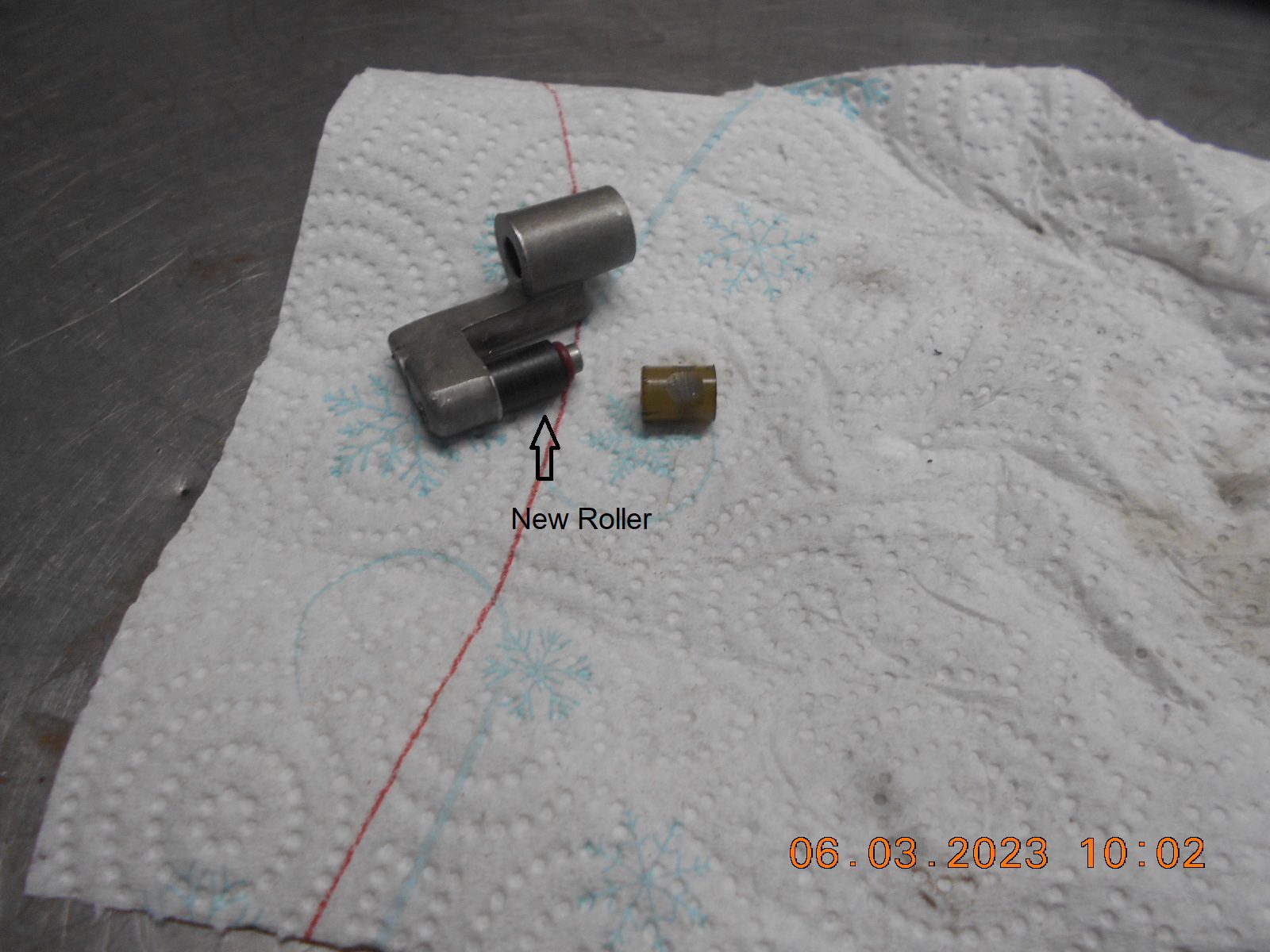

Made a new roller for the mag to throttle shaft mechanism out of Derlin, as

the original nylon? one was quite grooved. The other nylon guide pin

is grooved as well, but that would be a little more involved to make one.I rechecked the timing sync between cylinders, and that was still “spot on”.

The impeller and housing was cleaned up with alcohol, then I polished up

the inside of the housing with aluminum polish and a little wire wheel in the

Dremel. The impeller plate was previously installed with some Permatex

Aviation sealer under it, and perhaps a wee bit made it into the housing.

I lightly lube the impeller housing with Vaseline and reinstalled it and

the lower unit. It seems to spin over a little “stiff”, but starts okay, and

pumps water fine. I guess I’ll know more after it sits a while before I

know if the impeller “sticks” in the housing again.

I looked back in my Ebay purchases, and while the impeller doesn’t say “aftermarket”

or China, it was only $8.00, so pretty sure it’s not OMC!It’s still running on the fuel pump that came with the motor, so no clue how old

it is. I took apart the little square pump from the parts motor, and am thinking

about making a diaphragm. May post separately about that mission.The motor started on three pulls today and runs much better, but it

needs to be ran on the boat again, and with the correct and fresh gas

mixture. Pretty sure it’s 16:1 in the tank, and half from last year!VIDEO

Prepare to be boarded!

June 3, 2023 at 10:26 pm #276751OK, well I would get rid of that impeller in favor of the OEM impeller. You don’t want the engine to get ruined due to overheating, or have that impeller break and plug up your cooling system.

Why is it that you want to rebuild that fuel pump? I wouldn’t mess with it if it is working OK. Some of those pumps are rebuildable, but it depends on its vintage. Again I would not mess with it if it is working OK. These pumps usually explode into tiny pieces when disassembled, making it real tough to get em back together properly. 16:1 is a pretty heavy mix for this engine, which might explain why it smokes so much and seems rich at high speeds.

Nice work engineering a new cam roller!

June 4, 2023 at 9:14 am #276755Fleetwin, I didn’t touch the “working” fuel pump that’s running the motor.

The little square pump is from my parts motor, and I wanted to rebuild just to have “handy” for when

I need it. I got the pump apart without loosing any springs, but that’s not to say

I’ll ever get it back together again, lol.On my agenda today is to mix up some 50:1 gas……. something I never have

a use for around here with my mostly pre-1960 collection.Prepare to be boarded!

June 5, 2023 at 12:46 pm #276768I’d stick with 24:1. AARGH. I replied to a oil-mix issue!

June 5, 2023 at 4:14 pm #276769I should just go with 100:0 and be done with this motor, lol.

Like most of my motors, then get ran a time or two, and

back on the rack forever and a day.

I still haven’t tried the motor on the boat since I got it running

better in the barrel……. hopefully I get the urge soon.Prepare to be boarded!

June 6, 2023 at 10:05 am #276785I’d stick with 24:1. AARGH. I replied to a oil-mix issue!

Absolutely, can’t go wrong with 24:1

June 6, 2023 at 10:09 am #276786Fleetwin, I didn’t touch the “working” fuel pump that’s running the motor.

The little square pump is from my parts motor, and I wanted to rebuild just to have “handy” for when

I need it. I got the pump apart without loosing any springs, but that’s not to say

I’ll ever get it back together again, lol.On my agenda today is to mix up some 50:1 gas……. something I never have

a use for around here with my mostly pre-1960 collection.OK, sounds good. Just make sure its “up arrow” corresponds properly to the mounting position on your engine. Once installed on the engine, you could also try blowing back through the pump from the carb line back through to the fuel supply port on the cap. You should not be able to blow backwards, something is wrong if you can. Again, don’t try this test unless the pump is either installed on the engine, or you have secured the two empty screw holes in the pump with screws and nuts. Those plastic caps are notorious for cracking as well, so don’t be fooled into a negative test result just due to a cracked filter cover/cap.

OK, let me try to correct myself a bit. I guess the air should not even be able to blow back into the cover cavity if the pump is “OK”. So, I guess the pump test would be negative/fail even with the cracked cover because air should have not be able to enter that cavity when blowing backwards. Nonetheless, those darn cap/covers crack easily.

Please be sure to replace that cheesy impeller though.

-

AuthorPosts

- You must be logged in to reply to this topic.