Home › Forum › Ask A Member › 1970 85 hp V4

- This topic has 65 replies, 8 voices, and was last updated 6 years, 10 months ago by

fleetwin.

-

AuthorPosts

-

May 29, 2017 at 7:52 pm #58592

An electric/air impact gun will usually remove the flywheel nut, eliminating the need to wrestle with the ring gear holder etc…The same impact gun can be used on the OMC puller nut to pop the flywheel off…There is no need to remove the flywheel to check spark and it is OK.

But, again, have you checked it for spark? There is no need to remove the flywheel if spark is OK. How far into this thing do you want to get involved? You mention wanting to end up with a Homelite for power. Like Frank has said, the electrical parts for this engine are very expensive, if you can find them, I don’t think you will find a replacement powerpack for under $200. So, I would recommend checking for spark before digging much further into this project. Again, you will need to use a jumper to the pack post on that terminal board while cranking because you don’t have a wiring harness. You can move forward to evaluating the gearcase if you find good spark.

Perhaps I have not read your posts thoroughly, I don’t mean to keep repeating myself. I just don’t want to see you dig farther into this thing than necessary, especially if it has spark and shifts OK.

Once you have confirmed spark and gearcase operation, you can search for a decent used control box/wiring harness. Again, you will want to check shift switch operation with an ohm meter. These control boxes are getting tougher to find in decent condition, but they are still out there.

PS- Yes, these engines will run backwards, which is why that goof anti reverse spring is there and must be functional…OK, just reread your posts. The ATF fluid may or may not work, but let’s give it another try. Are you sure the gearcase is full of fluid? The gearcase must be filled from the bottom plug until it flows for the top vent plug. In order to power up those solenoids, you must slide those rubber sleeves back on the shift lead connections coming up from the gearcase. This operation is tricky enough, try spraying a little WD40 into those sleeves before attempting to slide them back. Once the sleeves are out of the way, you can disconnect the two knife connections. There are two shift solenoid leads, one is green the other is blue. I can’t remember which lead is which, one is the neutral lead, the other is the reverse lead. When in neutral, only one lead is energized, both leads are engergized when in reverse. So, for now, let’s just energize both leads. I am assuming you will just jumper cables to crank the engine. So, the negative jumper cable should provide a good ground for the shift circuit. You will need to carefully run a jumper lead from the battery positive to both shift switch leads being careful not to let this connection hit the engine block/engine pan creating a direct short. Now you can connect your positive jumper cable lead to the starter positive. Then, while you are watching the prop shaft, have an assistant connect the positive jumper cable lead to the battery. You will probably see the prop shaft rotate clockwise for a few rotations until pressure is built up, then it will rotate counter clockwise in the reverse direction while cranking. Again, you will need a decent 12 volt battery that is fully charged, a little battery out of a riding mower/motorcycle won’t do. Once we confirm reverse works, I’m sure Frank will tell us which lead is the "neutral lead". Then, we can connect only that neutral shift lead to B+ while cranking to see if neutral works. Chances are pretty good that neutral will work if reverse works….Again, it is important to understand that both leads must be energized for reverse to work. If the gearcase fails these test, you can check the solenoids for continuity, we will research the resistance value of the solenoid, but I seem to remember a value of about 6-7 ohms. I would also drain the gearcase and refill with OMC premium blend before condemning the gearcase as well…

May 29, 2017 at 10:08 pm #58597The purpose of the electrohydrolic shift was to shift faster and with more force than mechanical while overcoming the electric shift failure to neutral. In the event of electrical failure it would default the forward and get you home. Like all outboard lower units, it needed lubrication that water did not provide. . . 😉

May 29, 2017 at 11:29 pm #58601

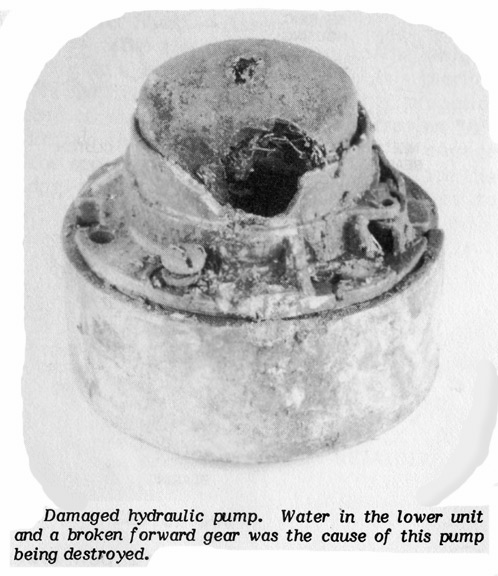

May 29, 2017 at 11:29 pm #58601Holy Moly, Garry. Where did you dredge that oil pump up? From the middle of Tampa Bay?

May 30, 2017 at 12:14 am #58607It was an example of "Don’t let this happen to you" in a service manual. An advertisement for OMC’s special oil . . . 😆

May 30, 2017 at 5:32 pm #58634

May 30, 2017 at 5:32 pm #58634OK, everybody seems to think I should focus more in ignition, so I’m checking that out. Coil found is 580740, German. Sec. resistance measures 3K. Primary resistance (blue lead to black lead) ohms out as close to a dead short (0.1 ohm). I couldn’t find any specs for this coil. Does this seem anywhere near right?

I’m a bit cautious about proceeding, now knowing if a shorted coil primary would mess up the "amplifier."

Thanks.

May 30, 2017 at 6:30 pm #58642Does this engine have spark or not? The resistance seems normal for the coil….

May 30, 2017 at 7:37 pm #58643quote fleetwin:Does this engine have spark or not? The resistance seems normal for the coil….It produces a nice 1/2" spark from the coil lead when the wire to the points is scratched. Point’s don’t appear to be making, by meter, and there is no spark from the coil while cranking. So I presume the points need attention. Need to pop flywheel next.

That "reverse cutoff spring," 313743, $39. Is it something I should expect to have to replace? Is it important? Does this motor have some special tendency to start backwards?

Interesting discovery: The red-painted battery terminal was on the negative cable, and the black one on the positive. So likely this setup has been connected with reverse polarity. So I expect various burn’t out diodes and suchlike. Interesting that the amplifier survived.

Time to check the shifting again…..

May 30, 2017 at 8:17 pm #58647So it shifts!

May 30, 2017 at 9:37 pm #58650Hoo-Rah! 😀

May 30, 2017 at 9:58 pm #58653I may be too late, but I had an Evinrude 40 hp with the push button hydro electric shift. I lost reverse the last year I owned it. I cleaned all the contacts from the box on the back of the motor and (if I recall correctly) it turned out to be the ground wire that went to the bolt on the cylinder head that fixed it. Wished I had found that sooner. It was a pretty decent motor, had it on a pontoon boat. One other time it got left out in a monsoon and would not turn over. That turned out to be the connections inside the shift lever box. They literally were green and furry. Cleaned all of those an it worked like a champ. I pretty much drained & refilled the lower unit every time I used it.

Good luck!

-

AuthorPosts

- You must be logged in to reply to this topic.