Home › Forum › Ask A Member › 1971 Evinrude 6hp model 6102G mechanical interference

- This topic has 9 replies, 6 voices, and was last updated 9 years, 10 months ago by

fleetwin.

-

AuthorPosts

-

January 27, 2016 at 9:33 pm #3499

I bought this recently did a comp test and gave it the quick once over before buying. When I get looking at it closer when I’m home ,the 4 bolt heads holding the lower unit on are snapped off,like somebody attempted to replace the water pump but didn’t get too far. Never tried to start it . I attempt to remove LU ,won’t budge .I want to spray some penentrant or apply acetone/power steering fluid around the bolts to break the corrosion that maybe holds LU stuck. I remove the motor cover, invert the motor and carefully and gently set the flywheel face down on level ground atop 2×4’s and soak the bolt remains with acetone mix so it will now soak in around bolts. Later I put it on the motor stand ,and now notice it is kinda stuck and the flywheel only turns a slight bit in either direction turning by hand ,like something is preventing the flywheel from moving.gearshift is in Neutral and prop turns freely.

Havn’t got to pull the flywheel yet ,waiting for warmer weather. Anybody have any idea what is causing the interference. If I had to guess,it sounds like the underside of the flywheel is hitting something and not allowing it to turn more than a degree or 2.Brilliant move on my part huh."Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonJanuary 27, 2016 at 9:49 pm #30893You might have an issue with the drive shaft rust fused with the base of the crankshaft. This can happen when the carbon seal and or o-ring are not replaced along with molly lube to protect the drive shaft and crank splines. The carbon seal, oring, and spring assembly help to form a seal to protect from water intrusion into the crankcase and also protect the drive shaft and lower crankshaft splines.

If you can not drop your lower unit this may be the issue. Please post some pictures of the motor and lower unit, it may shed some light on your problems.

January 27, 2016 at 9:51 pm #30896If the flywheel were hitting something, the mag plate would move. If the mag plate moves freely with the shift in forward, I would suspect a stuck piston, You can get crank movement if the pistons are close to top and bottom dead center, just from clearance in the bearings.

Good Luck . . . 😉

January 27, 2016 at 9:54 pm #30897

January 27, 2016 at 9:54 pm #30897Well I guess first you have to drained the gear lube or whatever might be in the gearcase if you haven’t done that? If it is full of water or goop the driveshaft might be seized in the upper or lower bearing housing? The propshaft would still turn freely in neutral. Of course the powerhead could be seized, rusty cylinders, etc. only letting it turn a partial amount, but neither would keep the gearcase from coming off. Unfortunately then we have to go to the splines of the driveshaft being stuck in the crankshaft, but that wouldn’t keep the driveshaft from turning. It would take a combination of two of these to cause your problem. Just trying to give you some of the options from my perspective. I am sure others will be along if I forgot the obvious. Hoping it is something easier/cheaper to fix. Those are great little motors. Plenty of parts available.

Dan in TN

January 27, 2016 at 10:13 pm #30899The motor turned over fine when I did the compression test before I bought it. That’s why I’m baffled. I think the jam is due to me turning the motor upside down and balancing the motor on the 2×4’s via the flywheel. I’ve worked on 2 other 1970"s 6 hp OMC motors and understand it might be the driveshaft spines stuck in the crankshaft. Now I’m goona brave the weather outside and check it out further. I’ll keep you posted.

"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonJanuary 28, 2016 at 12:17 am #30908Well, you inverted the engine, but you didn’t bang down on the gearcase or flywheel, correct?? If not, seems very unlikely that you caused damage that would jam it this way…

I’m thinking you may have a simpler problem. Right around your engine’s vintage, the design of the exhaust housing was changed slightly. OMC put a little "cup" up around the lower seal pieces to retain them up next to the powerhead when the gearcase is removed. There is a little slot that allows the driveshaft roll pin to slip down out of the cup when the gearcase is pulled down. BUT, the roll pin must be lined up perfectly with the slot in order for the gearcase to come down.

So, let me ask if you have gotten the gearcase to move down from the exhaust housing at all? If so, the driveshaft roll pin might be jamming on the exhaust housing cup causing the binding your are experiencing. And, because the broken bolts shanks are still jamming the gearcase in place, it is very hard to get the roll pin lined up properly so the gearcase can be removed.

Just to be safe, you may want to consider removing the powerhead, which is pretty simple on this engine, provided you can loosen the powerhead bolts. If the powerhead bolts are stuck, I guess it is best to leave the powerhead alone. I surely don’t want my suggestions to cause more problems for you. Have you tried heating the gearcase to loosen the salt around the broken screw shanks that are holding the gearcase in place? You will probably need a big boy torch for this operation, the little propane torch won’t be much help. Gently rocking the gearcase while an assistant heats the gearcase will help release it from the broken studs. Once the gearcase pops down a bit, don’t forget to disconnect the shift linkage! When the gearcase finally is released, you will notice that the roll pin has just been sheared off even with the driveshaft, no big deal.

Again, my recommendations are "assssuming" that you have the gearcase pulled down a little bit from the exhaust housing, and that the roll pin is jamming on the exhaust housing cup.January 28, 2016 at 12:43 am #30910quote fleetwin:Well, you inverted the engine, but you didn’t bang down on the gearcase or flywheel, correct?? If not, seems very unlikely that you caused damage that would jam it this way…

I’m thinking you may have a simpler problem. Right around your engine’s vintage, the design of the exhaust housing was changed slightly. OMC put a little "cup" up around the lower seal pieces to retain them up next to the powerhead when the gearcase is removed. There is a little slot that allows the driveshaft roll pin to slip down out of the cup when the gearcase is pulled down. BUT, the roll pin must be lined up perfectly with the slot in order for the gearcase to come down.

So, let me ask if you have gotten the gearcase to move down from the exhaust housing at all? If so, the driveshaft roll pin might be jamming on the exhaust housing cup causing the binding your are experiencing. And, because the broken bolts shanks are still jamming the gearcase in place, it is very hard to get the roll pin lined up properly so the gearcase can be removed.

Just to be safe, you may want to consider removing the powerhead, which is pretty simple on this engine, provided you can loosen the powerhead bolts. If the powerhead bolts are stuck, I guess it is best to leave the powerhead alone. I surely don’t want my suggestions to cause more problems for you. Have you tried heating the gearcase to loosen the salt around the broken screw shanks that are holding the gearcase in place? You will probably need a big boy torch for this operation, the little propane torch won’t be much help. Gently rocking the gearcase while an assistant heats the gearcase will help release it from the broken studs. Once the gearcase pops down a bit, don’t forget to disconnect the shift linkage! When the gearcase finally is released, you will notice that the roll pin has just been sheared off even with the driveshaft, no big deal.

Again, my recommendations are “assssuming” that you have the gearcase pulled down a little bit from the exhaust housing, and that the roll pin is jamming on the exhaust housing cup.I was thinking the same thing but was trying to verify my thoughts by going back and examining my notes on late 60’s and 70’s 6hp Evinrude/Johnson series. Thanks Don, for helping me along and saving me some time.

edit: Thanks Don for setting my miss information straight.

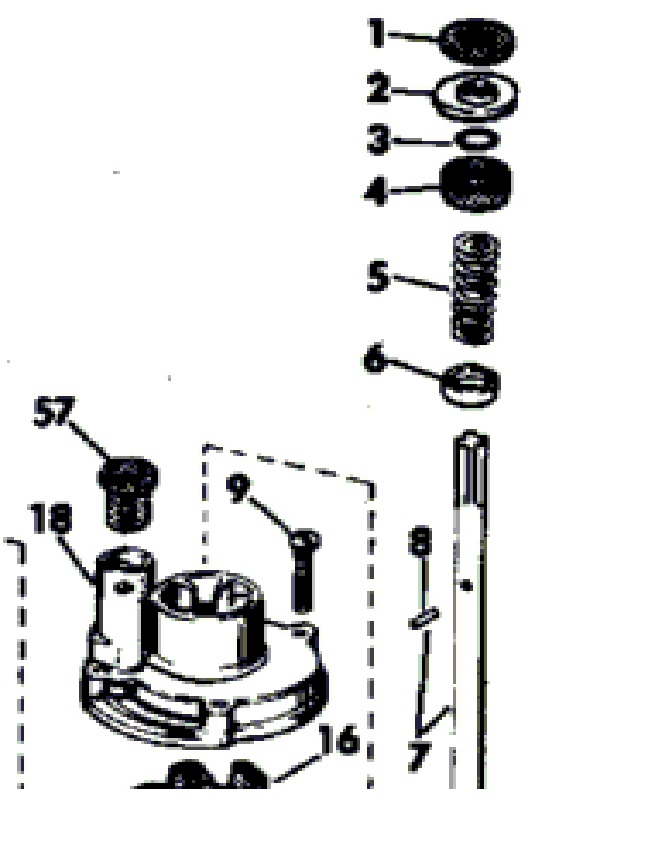

Part 8 in the diagram has to line up with a slit opening in exhaust housing to slide down.

January 28, 2016 at 12:54 am #30914Well, not quite…#6 is above #8. The slot is actually in the exhaust housing itself. So, #8 roll pin has to be lined up with the slot in the exhaust housing cup which is just below the roll pin.

Like I say, forcing the roll pin past the exhaust housing cup when it is not properly aligned will probably just shear the ends off the roll pin. No big deal. Again, I am hoping this is all that is wrong, and am assuming that the gearcase has been pulled down from the exhaust housing just a bit, so the roll pin is jamming on the exhaust housing cup when he tried to rotate the flywheel.

At this point, it is probably best to simply remove the powerhead, but I don’t want to introduce more problems by stuck powerhead screws breaking off.January 28, 2016 at 4:51 am #30921The pin and its slot.

January 28, 2016 at 2:13 pm #30937

January 28, 2016 at 2:13 pm #30937Thanks Mumbles, your picture is worth much more than my words!

-

AuthorPosts

- You must be logged in to reply to this topic.