Home › Forum › Ask A Member › 1973 9.5 Hp Evinrude

- This topic has 19 replies, 10 voices, and was last updated 4 years, 4 months ago by

outbdnut2.

-

AuthorPosts

-

December 1, 2020 at 11:04 am #224019

Hello,

I bring up a topic for the discussion of the amazing quality of the old coil (OEM). Where these OEM coils were made in 1970’s?

Just pick up a 1973 9.5 Hp Evinrude. It still has spark on both cylinders but I just want to check if the coils had been replaced or not and by the way to clean the points as well.

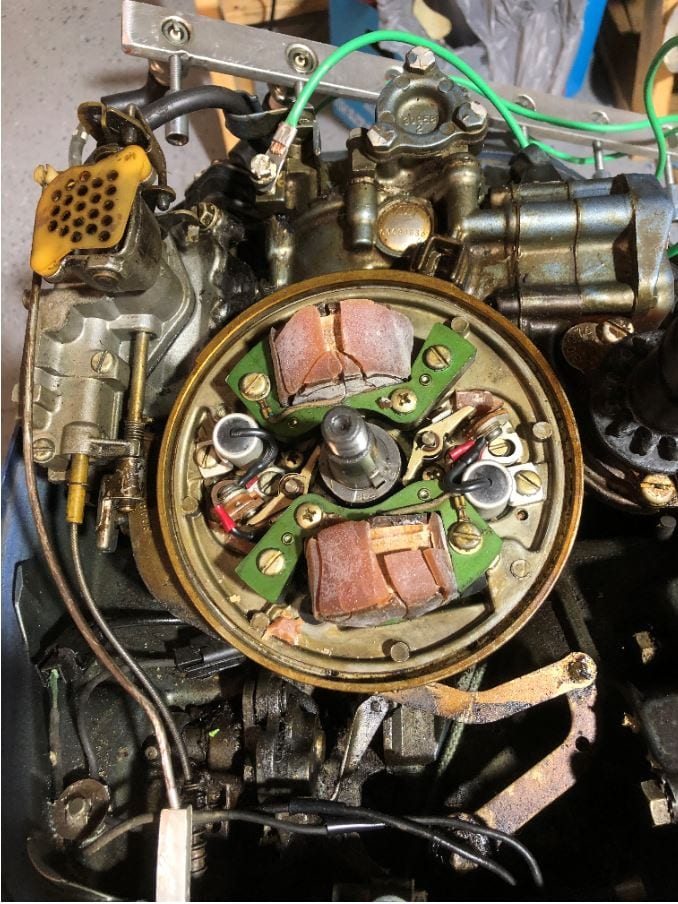

It was surprised me that the coils look like original in this condition and still works. The points look like have been changed. The rest looks original but it shows low compression (64/63 psi).

I will clean up the carb, replace the coils and put some gas in to see if it could run with this low compression.-

This topic was modified 4 years, 4 months ago by

Mumbles.

Mumbles.

December 1, 2020 at 11:43 am #224029While the points and condensers have been serviced, the coils look original. They might work for a while but will probably quit firing a few hundred meters from the dock. Don’t forget your oars!

Has this kicker been used in salt water as I see a green wire attached to it? It’s quite common to bond the motors when used in the chuck.

Before the insulation cracked and fell off, you could read the production date of the coil thru its translucent insulation. This one is marked Jan 30, 1969.

December 1, 2020 at 11:47 am #224032I will pull them out today and look for the date and letters say made in USA!

-

This reply was modified 4 years, 4 months ago by

Evinrude 25.

-

This reply was modified 4 years, 4 months ago by

Evinrude 25.

December 1, 2020 at 12:02 pm #224038

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

December 1, 2020 at 12:32 pm #224043I have fixed up half a dozen and all had weak compression compared to other motors mid 60,s PSI is ok by me and you will find leroy’s article highlighted that very same characteristic

do the electricals .. (coils) adjust the cam follower , adjust the carb, inspect -change impeller & gear oil and go for a good ride. my 9622a run perfectly at 65 psi

“A normal compression reading of 65# to 75# appears to be fine for this motor.”

http://www.leeroysramblings.com/OMC_9.5.htm

utube has good videos on carb clean up of the 9.5hp

if you can wait a bit chineese coils are ok and cheaper . I have had no issues with them

Joining AOMCI has priviledges 🙂

-

This reply was modified 4 years, 4 months ago by

crosbyman.

December 1, 2020 at 10:17 pm #224078Nice paint job on your 9.5. Does it original OMC painting color? I like to get my painted the same as your after I get it in good running condition.

December 1, 2020 at 10:52 pm #224079colors original … not repainted……..except for a dash of blue spray on the L.U. . guy sold it to me $50 cdn seized….took a week or two to get it to turn over with marvel oil pb blaster peg and a hammer . my only issue to this day is it is a hard starter but it runs great all day after a sqwirt of carb cleaner. trolls all day fine. it is just stubburn electrical new, carb cleaned, cam follower adjusted … no deal

it even had the original break in instructions on the white sticker

Joining AOMCI has priviledges 🙂

-

This reply was modified 4 years, 4 months ago by

crosbyman.

December 2, 2020 at 9:42 am #224088Those little 9.5hp outboards do run well if they do not have exhaust leak issues. These motors can not be compared to the 1950’s to 1963 10hp motors or the 1974 and later 9.9hp motors. These motors were made from 1964 to 1973. They were an attempt at marketing a low profile fishing motor for the average fisherman. Cast in all directions without any interference from the motor was advertised….lol

These are not high compression motors. Not uncommon to find compression numbers from 60 to 80. Low 50’s is not that uncommon either. The starter is a low impact starter that allows for easy starting. Because it is a low impact starter, you don’t spend the motor over high enough to get higher compression numbers. Take a simple starter rope and wrap it around the flywheels own rope sheave. Pull hard about 4 to 5 times and you will notice you will have higher compression number usually between 60 to 80. Again for compression check do not use the low impact starter setup. Please use the rope starter method. Do not use the drill to spend the power head to check compression. Gives false higher compression assessment values. Using the rope start method gives you an assessment of a non starting motor’s compression values and compare it to known values as stated above.

These motor will typically get 8 to 12 mph on a loaded 14 ft aluminum boat. They run real smooth (if they do not have exhaust leak issues) and can low troll all day long.

An exhaust leak issue can be identified by removing the motor hood. With an exhaust leaking issue the motor will run sluggish and rough with the hood on. It is being smoothed with its own exhaust fumes. By removing the hood while running on the boat, the performance will significantly improve. It is now getting fresh air for combustion.

Since it normally sits low on the boat, it will also sit low in/on the test barrel. It tends to run poorly in the barrel, because it inhaling its own fumes. Placing a fan near by (safely), you can blow the exhaust fumes away. It is much preferred to run, test, and set the low idle speed needle on the boat.

There are four areas of exhaust leaks. Parts diagram for the exhaust housing.

1.) torn or missing shift rod rubber boot (part number 78)

2.) torn or deformed exhaust housing seal (part number 87)

3.) exhaust hose is cracked or torn (part number 43)Under gear case parts diagram

4.) Impeller housing seal (motor part number 6)

If you have the extended shaft model then the Exhaust housing to impeller spacer seal (part number 61)

The 4 listed item help prevent exhaust fumes from entering the power head chambers from the exhaust housing below. Leaking from one of the those 4 exhaust items can cause exhaust fumes to enter the power head chambers. Thus causing the motor to inhale its own fumes with the hood on.

http://www.marineengine.com/parts/evinrude-johnson-parts-diagrams/EVINRUDE/40171.gif

http://www.marineengine.com/parts/evinrude-johnson-parts-diagrams/EVINRUDE/40174.gif

December 2, 2020 at 10:10 am #224089WIth some rubber seal parts hard to find and engine take down apparently a real pain has anyone ever tried stuffing the low portion (leg) with ex: fiberglass wool or similar stuff ( fireproofing foam) to keep the fumes out the engine compartment. ???

I even saw one with a lobotomy !! ..2″ circrle cut out on top of the cowl near the carb !!!! to bring in fresh air

Joining AOMCI has priviledges 🙂

-

This reply was modified 4 years, 4 months ago by

crosbyman.

December 3, 2020 at 12:19 am #224157I have saw many with holes cut in the hood.

-

This topic was modified 4 years, 4 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.