Home › Forum › Ask A Member › 1974 Evinrude 9.9 won’t idle at low RPMs, need help

- This topic has 56 replies, 14 voices, and was last updated 7 years, 11 months ago by

fleetwin.

-

AuthorPosts

-

April 25, 2016 at 4:00 pm #35472

I can’t comment on the booster gap but the cross referencing charts are only approximations. Most likely close enough. I don’t really know why the NGK work better then the Champions, on that motor, but I have seen it myself so I am a believer. I have heard of people using Champions with OK results as well. So what can I say.

One note on pulling that slow speed bearing. It is quite difficult to get at. Even difficult to see if one is even in there but most likely there is. We just don’t know its condition so I would change it. I have used a #8 deck screw to slowly bite into it and then pull it out. This is a dangerous approach because if that steel screw bites into the aluminum carburetor it can permanently damage the carb. I was given an idea from a poster previously, that I have not tried, but would suggest could significantly reduce the risk of damage. He suggested taking a barbed fish hook and bending it straight. He then inserted it lightly into the jet and used the barb to grab hold of that bearing. Sounds like a better approach, but I have not personally tried it.

April 25, 2016 at 4:11 pm #35476The low speed needle seal being referred to is #20 in the following parts breakdown:

http://www.marineengine.com/parts/johns … Carburetor

This piece surely does seal the air out of the low speed mixing pocket from sneaking by the threads on the needle. The price is ridiculous and I’m not even sure it comes with the carb kit. But, like Optsy says, it is trick to remove without damaging the carb, so be careful. Again, I just thought it would be easier to try another "known good" carb first to answer some questions. We can rip into your carb more if your engine idles OK using the know good carb….

April 25, 2016 at 4:22 pm #35477All the carb kits I have bought (BRP brand) have a slow speed bearing and a retainer for the slow speed jet. They also have a welch plug in them.

Definitely a good known carb will help you isolate where the problem actually lies.

I don’t want to send you in a million directions but if you are writing down these things, put the carb at the top of that list. Using a known good one would answer the question on it, once and for all.

The next thing I would be thinking about would be the point gaps. If you look closely that the throttle cam you will see that most of the slow idling happens when the carb roller is not even touching the throttle cam. This means that the carb throttle is completely closed. The question arises then, how is the motor still throttling down when the throttle butterfly is closed. It happens because the spark timing is being retarded (changed) as you move the throttle grip. As the spark timing happens later then top dead center the RPMs slow down.

So, with all that said, think about what would happen if instead of having the specified 0.020"gap on your points, your gap has decreased (which they do over time and use) to something like 0.005" or something like that. A point gap at 0.020" ensures your spark is properly timed at top dead center. If your point gap is reduced, the spark happens later, just like what happens with your timing advance when you reduce throttle. At higher RPMs this won’t matter too much (won’t stall but will give reduced top end performance) but at lower RPMs you might find that a spark that is timed to late, with an amount of gas that expects a better timing point, might just cause the motor to stall.

Anyway, I’ll cut to the chase. If the carburetor ends up being fine, I would check the point gaps. With this motor you really need to adjust them about every 3 years anyway, since they will narrow over time as the rub bar wears down.

April 25, 2016 at 4:22 pm #35478April 25, 2016 at 7:00 pm #35487April 25, 2016 at 7:33 pm #35489No, not the point gap. The points are under the flywheel,

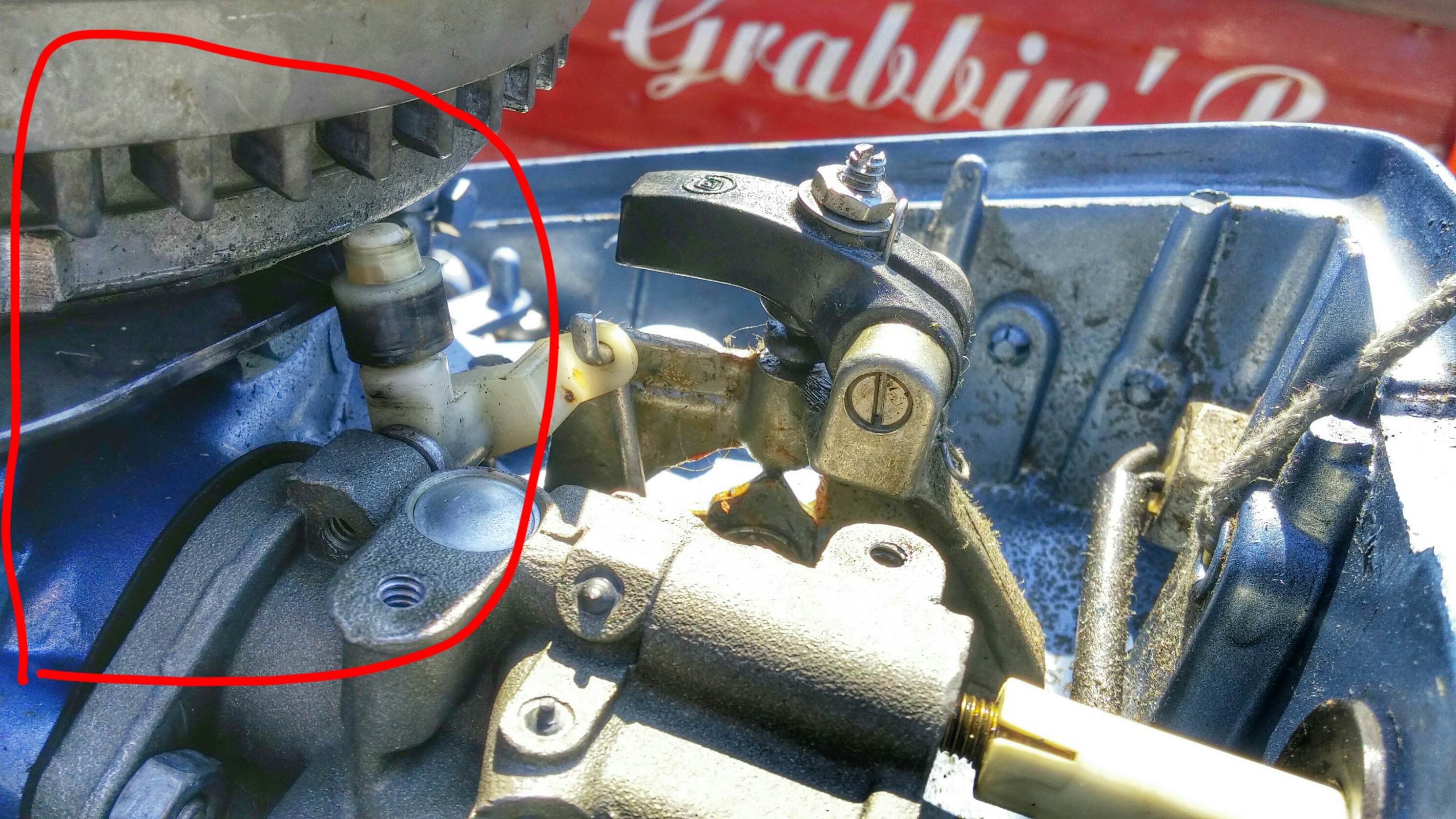

That metal bracket (throttle cam) is how you sync the carb. It will push on that roller as you turn the twist grip of the tiller arm. The first thing is to see if the indented arrow on that cam lines up in the center of the roller JUST as the cam starts to push on the roller (throttle butterfly starts to open). This is what they call the carburetor synchronization and it sync’s the carb to the spark timing of the motor.

In the quote you linked, I was referring to the fact that when the motor is running properly, as you reduce the throttle to idle the motor’s RPMs down, there will be a point where the throttle cam stops pushing on the roller. When that happens the carb’s throttle butterfly will be completely closed. As you reduce the throttle some more, the only thing that changes, to allow the RPMs to decrease anymore, since the gas from the carb is now constant, is the spark timing. Just so you know, on these motors the spark timing is changed as the plate under the flywheel is rotated. They call it the timing plate. As you throttle up, the spark timing is advanced a little ahead of top dead center to deal with the faster RPMs and as you throttle down, the spark timing it is retarded back again. This is because a plugs spark is not exactly instantaneous and therefore precisely WHEN it sparks, needs to be adjusted for the different RPMs of the motor to optimize its performance.

That change of spark timing is also going on at the very low RPMs required for idle. If the timing is also changed due to improper point gaps (another spark timing mechanism) then it can cause problems when trying to idle the motor.

April 25, 2016 at 8:16 pm #35492Wicked. Thanks for clarifying! I will spend more time with the carb first for sure. I definitely appreciate the advice. If the fix is as simple as pulling that welch plug and I don’t need to try any of this other stuff, I learned a ton from this thread. Really helped my understanding.

April 29, 2016 at 12:40 am #35644I am glad I cam across this thread and am glad I found this antique outboard engine forum. Thanks to all who are responsible. I own several antique outboards and have done so for the past 30 years I am in no way an expert but not a beginner either. I wan’t to post what I have encountered on these particular 9.9hp’s. I have seen a lot of things in this thread I want to check out next winter on my 9.9hp’s which are located in Key West. I don’t know if any of this will help but thought I would share my experience with these engines.

I own 3 of these 9.9hp engines . My runners are a 1991 and one is a 1976 with a 1987 being for parts all 3 enginnes were given to me last winter in Key West while I was wintering/camping on a Navy Base. I repaired 2 of them for a 11 foot boston whaler I purchased and wanted 2 runners one for a back up and one for normal my regular runner. I am pretty good at fine tuning carbs on vintage outboards but always learning. My 1991 is technically a 15hp but the only difference I can find is the carb on it mainly the high speed jet and possibly the throat size. The power head piston size and strokes look the same on all 3 engines regardless of the years they were built.

The 1976 has points and the 1991 has a cdi. The carbs are also different on the 2 out of the 3 engines. The 1976 and 1987 has essentially the same carb the 1991 has a different style carb with a needle valve retainer I don’t see a needle seat bearing on that carb like I do the 1976 carb

http://www.marineengine.com/parts/johns … Carburetor

To cut through the chase I had one heck of a time getting them to idle as they should. I fined tuned the carbs the best I could, rebuilt the fuel pumps, new plug wires and caps, new wires also and new fuel lines and cleaned the carbs.

What I found strange about the carbs is one the 1991 I had to pull the choke out 1/4 inch and it would idle done like normal and keep on idling. On the 1976 I had to pull the choke out 1/2 inch and it also would idle down and idle as it should. I mainly ran the 1991 15hp when out on the boat and after it ran for like 1 hour just above idle speed I could then push in the choke that 1/4 inch and it would idle normally also. I never ran the 1976 that long I used it for my back up motor. I guess what I find strange about it is the ignitions are different, carbs different, fuel pumps the same but the both had the same type of issue. I pulled the carbs down a couple of times but once I got them running correct I just have learned to live with it. I do want to tear the carbs down again now I have found this thread to see if I can get that quirk out of them. I forgot to mention I was running new NGK plugs in one and Champions in the other so not sure if it’s a plug issue wouldn’t think so they always look clean after I run them for a while on the water at just above idle speed.

I do have a like a 1968 Johnson 9.5hp I totally rebuilt even added the elctronic modules to it and got rid of the points. I also re-did a buddies 1965 Johnson 9.5hp that was his grandfathers never had this type of issue with those carbs.

Sorry to be so long winded.

Take Care,

JoeApril 29, 2016 at 12:53 am #35645I did forget to mention I put new needle valve retainers in both running engines the 1991 and 1976 9.9hp. Sorry I left that out.

April 29, 2016 at 1:01 am #35646A couple years ago, I worked on one of these 9.9s for a neighbor and I could not get it to idle and troll decent no matter what I did. The neighbor had put the correct new Champion Spark Plugs in it. Just on a whim, because I ran out of things to try, I put in new NGK spark plugs I had laying around and the motor ran perfect! I couldn’t believe the difference – I had previously also tried another set of new Champions. I also tried Champions that were running perfect in a 1989 15 HP, which is a similar motor and that didn’t work either. I mentioned my experience at the Ask a Member board here and several guys verified that NGK plugs, for some strange reason nobody seemed to know, work much better in those 9.9s than other brands. At $2 to $3 per plug most places, it’s worth a try if you haven’t already. I noticed a couple earlier posts suggesting this.

Dave -

AuthorPosts

- You must be logged in to reply to this topic.