Home › Forum › Ask A Member › 1974 Evinrude 9.9 won’t idle at low RPMs, need help

- This topic has 56 replies, 14 voices, and was last updated 8 years, 11 months ago by

fleetwin.

-

AuthorPosts

-

April 29, 2016 at 9:58 pm #35677

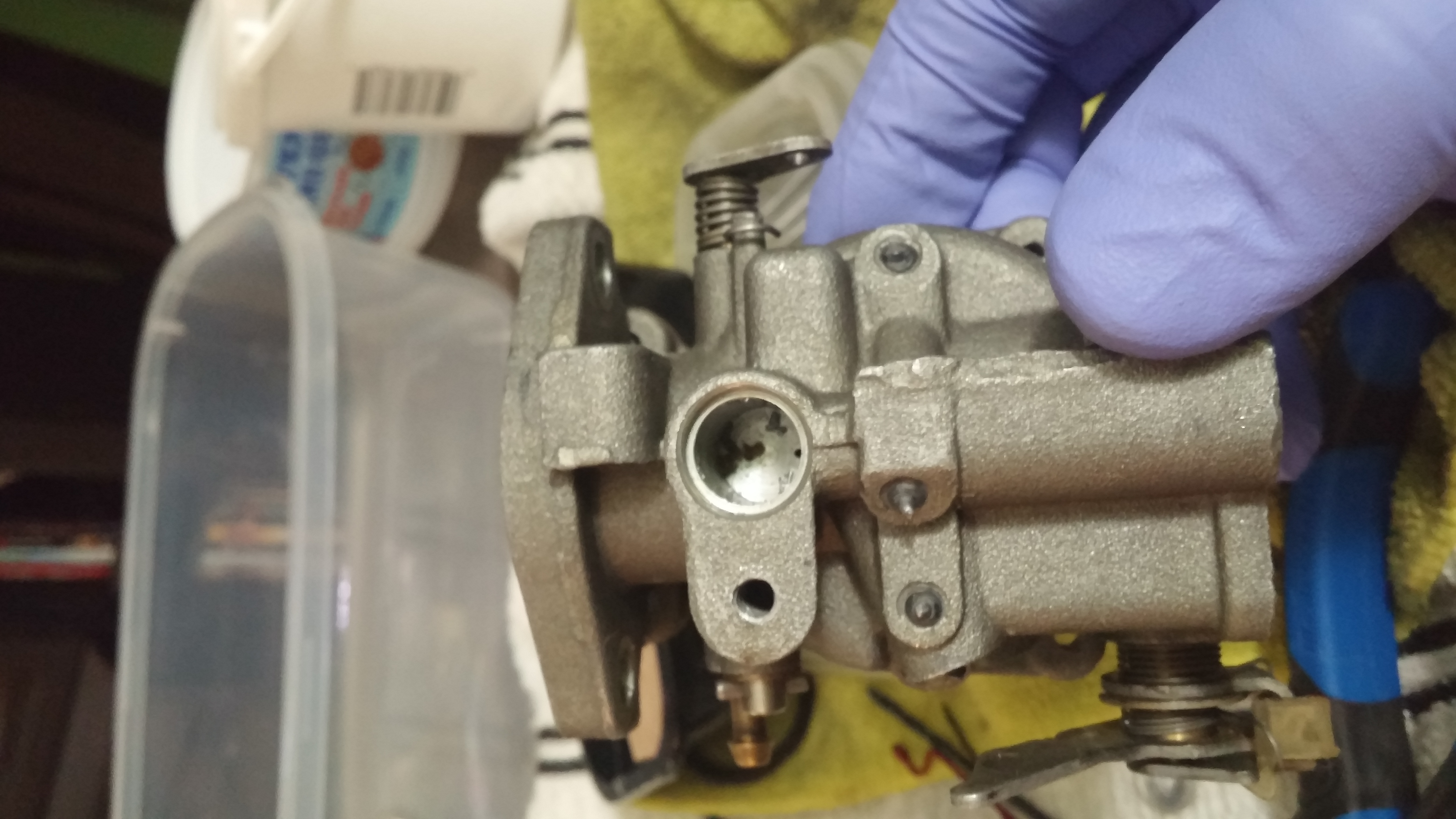

Brief update. The spark plugs turned out to be NGK BR7HS. I replaced them with NGK BR6HS, and it runs WAY smoother. Still the same problem though. Pulled the carb apart, found junk under the welch plug and a corroded needle (I attached pics. Currently I got the carb soaking in a pine sol bath, currently just shy of 48 hrs. I’m going to neutralize the acid, rinse thoroughly and use compressed air to dry, a toothbrush and small wires to make sure everything is clean.

A quick question about the needle valve retainer. I have tried a fish hook, a curved wire, I am unable to pull anything out. I tried to look down the hole, couldn’t see anything, but it is tough to look down there. I think that there isn’t one in there, but I can’t 100% say that. Does anyone have any easy tips for confirming if there is one down there? Or a different way to get it out? I don’t have access to dental tools.

April 29, 2016 at 10:45 pm #35678The needle valve retainer is located is right inside the carb body threaded hole for the low speed adjustment needle and knob,located on the front control panel . Remove the knob ,unscrew the brass needle counterclockwise till it is free of the threads ,carefully remove straight out. Then look into the opening of the hole the needle came out of. The retainer should be flush or almost flush with the carb body exterior surface.

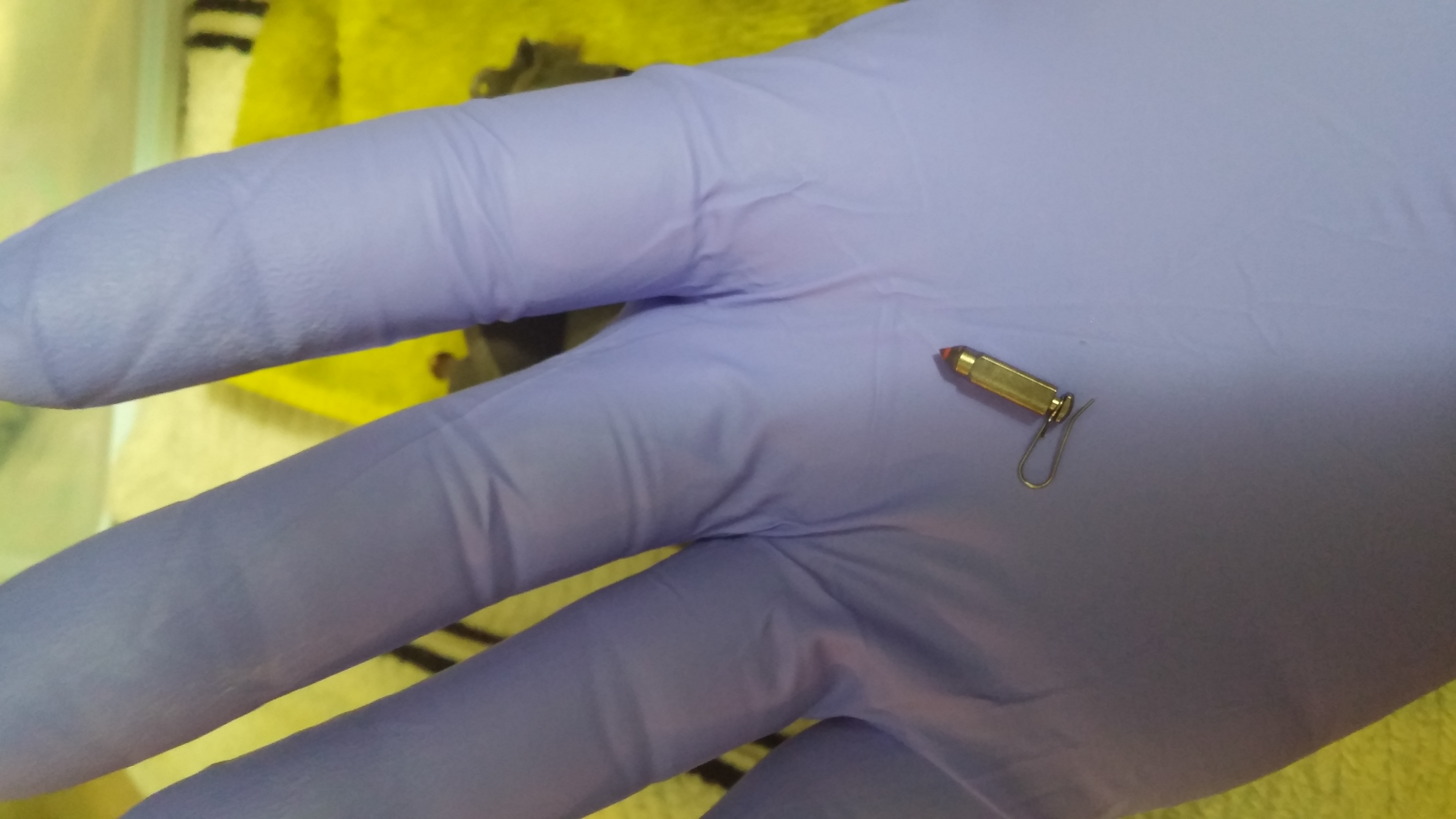

Your photo shows the float valve needle,which is a different set up."Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonApril 30, 2016 at 12:09 am #35682quote pugetsoundboater:The needle valve retainer is located is right inside the carb body threaded hole for the low speed adjustment needle and knob,located on the front control panel . Remove the knob ,unscrew the brass needle counterclockwise till it is free of the threads ,carefully remove straight out. Then look into the opening of the hole the needle came out of. The retainer should be flush or almost flush with the carb body exterior surface.

Your photo shows the float valve needle,which is a different set up.There’s an orangey (possibly from corrosion) gasket here (in the pic). Is that what you are talking about? If so, the replacement in the carb kit doesn’t have that notch coming out of it on the top left (its just circular). Will that still work?

April 30, 2016 at 12:24 am #35686I double checked, in my carb kit there is no replacemenr for what I circled in that last photo

April 30, 2016 at 1:05 am #35689That thing that is circled is the low speed needle valve seal. Not all kits have this. The nylon bearing thingy, which not all kits have, goes over the pointy end of the low speed needle valve. Because there is a long distance from where the threads end to the tapered end the bearing guide keeps the tapered part centered in the low speed needle seat. Without this the pointy end would or might orbit around the inside of the needle seat instead of staying centered while adjusting. This would or could cause large swings in mixture with a slight adjustment rotation.

Buy the oem kit, it has everything one needs, including that needle seal.

April 30, 2016 at 1:26 pm #35703That welch plug area does look a little dirty. Definitely needs to be cleaned. I have never used pine sol so I can’t say how it might work on a carb. If you can get a can of carb cleaner, give it a good spray and blow out with compressed air, multiple times. Your part naming may be a little confused. Deep inside that jet orifice is a slow speed needle bearing. It is plastic and looks like a very small funnel. At the other end, to seal the needle and provide threads for turning, is the needle retainer. You need both and both need to be in good condition. I have rarely been able to see the needle bearings that were in my carbs, but I always had one in there. I can’t really help with it’s removal except the ideas I gave earlier and you have already tried the fish hook. Any small sharp wire where you can manually bend the end into a hook would probably work. It is also possible that some previous owner removed one and forgot to put a new one back in.

All that being said, every BRP kit I ever bought had both in there, including a new inlet valve that you said looked corroded, if I recall. You could post a picture of what they have in there that might work for the retainer seal, but it was usually red, plastic and had a little notch to make sure it did not turn as you turned the needle and would fit into the slot of the carb perfectly. It needs to be there or your carb will just suck air instead of fuel during idle. It seals the needle.

April 30, 2016 at 3:20 pm #35707What brand of carb kit did you buy, so we will know who dosn’t supply the needle valve seals. I always buy BRP parts.

While replacing a water pump early on in outboard repair , I saw a water pump inpeller that I was replacing, the rubber was not bonded anymore to the metal octagonal shaped hub,and remember Leeroy’s Ramblings photos of a Sierra impeller octagonal hub,now identified as a Sierra brand,I decided then and there I would always get factory parts. A lot of good info and photos on his site ,a whole section for the 9.9/15."Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonMay 1, 2016 at 3:11 am #35747quote outbdnut2:A couple years ago, I worked on one of these 9.9s for a neighbor and I could not get it to idle and troll decent no matter what I did. The neighbor had put the correct new Champion Spark Plugs in it. Just on a whim, because I ran out of things to try, I put in new NGK spark plugs I had laying around and the motor ran perfect! I couldn’t believe the difference – I had previously also tried another set of new Champions. I also tried Champions that were running perfect in a 1989 15 HP, which is a similar motor and that didn’t work either. I mentioned my experience at the Ask a Member board here and several guys verified that NGK plugs, for some strange reason nobody seemed to know, work much better in those 9.9s than other brands. At $2 to $3 per plug most places, it’s worth a try if you haven’t already. I noticed a couple earlier posts suggesting this.

DaveI’ve got the ngks in my ’76 omc15 and by looking the center electrode and insulator are slightly smaller in diameter than the champs. Could be illusion but now I’ve got to check it.

May 1, 2016 at 2:21 pm #35769Again, the part you have circled in your photo is not the seal we are referring to. The piece you have circled is a plastic friction nut that keeps the needle valve from vibrating closed/open after you set it.

That needle pocket is definitely full of crud. So, you did not get the plastic friction nut in the carb kit, that is OK, is does not need to be replaced. Did you get the little clear plastic needle seal? Have you found the original one, is it in place? I know, pretty tough to see down inside there. You don’t want to have two seals jammed inside there.May 1, 2016 at 8:51 pm #35795Well guys, we have an operational motor! After a 72 hour pinesol soak, quick dip in a neutralizer, thorough rinse, brushing scrubbing and dry with compressed air (and new, hotter spark plugs earlier in the week) the motor now sounds like a completely different engine.

Thanks a ton to all who helped. The simple things did the trick.

If anyone has a minute to check out one more motor, my brother in law just picked up a 1981 Evinrude 15hp. Runs well, dies down at idle, not as bad as mine did tho. We believe a thorough carb clean will do the trick, but in case there is anything we aren’t picking up on, we figured this would be the forum that would point us in the right direction. Just in case there’s any other suggestions/tips/tricks.

-

AuthorPosts

- You must be logged in to reply to this topic.