Home › Forum › Ask A Member › 2hp Johnnyrude electrical problem

- This topic has 19 replies, 10 voices, and was last updated 9 years ago by

crosbyman.

-

AuthorPosts

-

March 29, 2015 at 4:50 pm #13001

coil primary wires backwards ?

if it is jumping (arc) that is the point of least resistance….you need to create an even shorter path to ground to stop zapping …recheck the grounding connection but in any event you have low insulation of resistance less than the spark gap on the plug.

plug gap set properly ?

Joining AOMCI has priviledges 🙂

March 29, 2015 at 10:20 pm #13023OK, I’m thinking what you are thinking, what seems to be an ignition problem is actually a fuel/sync problem. So, the engine isn’t misfiring, just dies right out when you decelerate, and you have to mess with the choke in order to get it to run at higher speeds in the tank.

Could it be that the throttle shaft is stiff/varnished/binding? In other words, the throttle shaft isn’t closing completely/quickly enough when you decelerate causing the engine to be lean and stall out when you decelerate. How about the throttle plate synchronization, is that correct? The engine will be lean off idle and while trying to accelerate if the throttle plate isn’t closing completely or is opening to soon. Are you sure you have got good fuel flow to the carb? Plugged up tank vent?

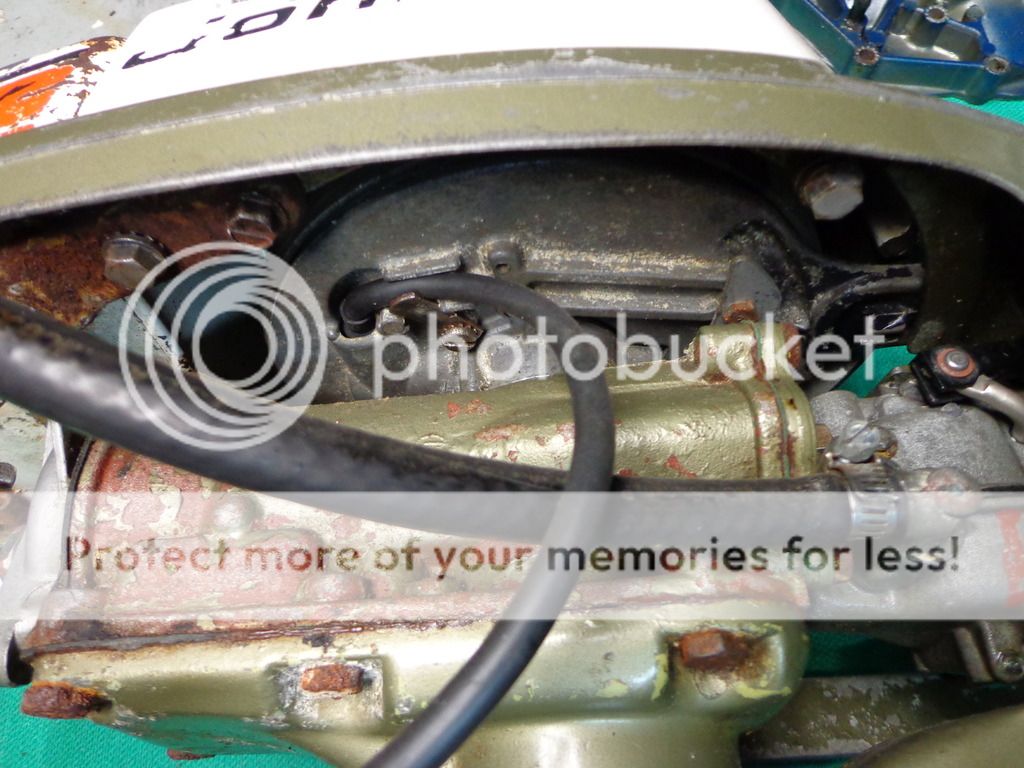

Nonetheless, did you get the arcing problem rectified? Sounds like you have replaced the ignition parts a few times over, how about the plug wire? Perhaps it is split/open/arcing when you decelerate.March 30, 2015 at 3:18 am #13036I’m not sure if this helps or not but I pulled out my two horse to see what happens to the ground wire while advancing the throttle.

At full throttle, it’s making contact at the top of the exhaust cover.

At half speed its hanging up on one of the hood or tank bolts

while at low speed it’s clear but almost touching the cover.

The plug wire is clear at all speeds

while the ohm reading is constant thru the full travel of the mag plate.

March 30, 2015 at 11:54 am #13041

March 30, 2015 at 11:54 am #13041That ground strap is improperly postioned on the exhaust cover, when properly positioned is doesn’t rub on the block like that. And the plug lead is actually supposed to be routed up and over the top of the head, kind of sandwiched between the top of the head and tank. I’m guessing this is to keep it secure and avoid snagging it on stuff while the engine is running being transported.

I realize that Mumbles is trying to make a great point about how much these items can flex/rub causing them to lose continuity or short to ground.March 30, 2015 at 12:18 pm #13043😳 Thanks for going to all the trouble Mumbles!

I have replaced the ground strap, and cleaned the bolt and the exhaust cover to ensure good continuity. It checks out fine now and the arcing has stopped.

I have re checked the mag to carb sync, and it is as it should be according to the service manual . It still wont co operate.

I also re checked the compression and it is only 100 psi, not 110 as I stated earlier. I know the info was on the old blue boards, but I will have to ask again here ….

What is acceptable compression on these little fellers ?

It’s kind of humbling that I can’t figure this out. This is probably the simplest motor to work on, so it should be easy right!

March 30, 2015 at 1:08 pm #13045Well, don’t be so hard on yourself. These little buggers can be like that. When they are right, they are great. But sometimes, when they are whooped/wore out, you can work on em forever with no success. Not that I’m saying yours is whooped, but that is just the way it goes with these things. I learned how to recognize the symptoms though. Kinda hard to start, no idle, low WOT power as well.

Does yours idle well? Is it idling well with the throttle plate completely closed and timing retarded to an appropriate idle position? If so, seems like there is hope.

I just want to review the symptoms as I have understood them. Won’t accelerate without feathering the choke. Stalls right out when the throttle is retarded, no missing, just stalls out. Correct?

Where are the needle valves set when the engine is running the best it can? How about intentionally richening up the mixture a bit to see if this helps overcome the mid range bog/stalling. You could also try purposely retarding throttle cam pick up which would help richening things up in the midrange as well. If this helps, then at least you will know what direction to head, or at least you can rule out ignition.

Everyone seems to report pretty high compression readings on these things, but I guess I have never taken the time to make notes. I would think that 100PSI would be a good reading though. Nonetheless, I have seen engines with good compression readings that have scuffed/scored cylinders.

And I have seen obviously badly worn engines run pretty well. But, this engine is less tolerant to poor internal conditions than others, I guess this is because it is only one cylinder. I have sometimes theorized that these engines can suffer from poor crankcase sealing if piston skirt fit is poor, this may not show up on compression tests. Would love to have time to really investigate one of these things fully someday.March 30, 2015 at 1:35 pm #13046Somewhere the ground path for the spark is interrupted. I would try a jumper wire from the mag plate to the ground of the spark plug, then the cylinder head itself. Kenn

Oops, I didn’t check page two. 😳

March 30, 2015 at 2:15 pm #13048Since it runs past that point and dies when you bring it back to it I would suggest you look at the high tension lead where it exits the coil and see if the lead is cracked or leaking secondary voltage to the plate.

You may be providing the path of least resistance (to ground) at that point with the spark advance arm.March 30, 2015 at 2:19 pm #13049Did you put back the nylon disk between the coil plate and motor? Item # 3, part # 315039. It could be worn out and grounding. They are only about .020 thick.

March 30, 2015 at 3:08 pm #13053imho any additionnal grounding caused by rubbing/ friction is no cause for arcing…. unless a worn out spark plug lead is grounded to a component of a lesser ground value than the frame to which the coil is attached.

At such a point the high voltage would continue its search to return to "home base" the coil itlsef…. by sparking across anything it needs to jump over to reach "0 ohm " ground .

Breaks on "non high voltage" wires can of course impede proper ignition (coil wire rubbing on the cam itself). The bonding strap from the plate to frame is there as an insurance Policy that a low (0) resistance path (back to the coil) is available to the high voltage pulse.

Joining AOMCI has priviledges 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.