Home › Forum › Ask A Member › ’56 RDE-18 doesn’t want to start

- This topic has 19 replies, 8 voices, and was last updated 3 years, 9 months ago by

bobw.

bobw.

-

AuthorPosts

-

July 14, 2020 at 11:41 am #208584

Yes, it is perfectly normal for the starter pinion to stay engaged when cranking with no plugs installed. It is the kick of the engine or compression that bounces the pinion out of the flywheel…Be careful with the starter motor, it may be a 6 volt starter…Using 12 volts for quick cranks is OK, but extended cranking with a 12 volt battery will kill it.

What type of puller are you using? Is it the OMC puller? Those flywheels are tough to get off, using some other puller is bound to cause trouble and make removal more difficult. Yes, you will need to get that broken bolt removed before attempting to remove the flywheel again…

I don’t want you to pull that flywheel off just on a hunch, please confirm you have weak/no spark before getting in there again. Sometimes those inline neon spark testers are handy to check spark while cranking/running…

The flywheel must be properly torqued or you will shear the key which will kill the spark and make flywheel removal even more difficult..July 14, 2020 at 11:44 am #208585After you have checked out your ignition with a gap tester,using the starter but NOT starting the motor maybe this will help:

I had a 12 HP Sea King and later a RDE18 that did not want to start or run. They would fire then run terrible. Solution was that the carb needles needed more packing rings. Often it takes 3 rings per needle. Air was passing the needles and the motors were running lean. I would try one or two more packing rings to each needle and in tightening the packing nut assure that the lock nut is down against the packings. See how deep the packing nut is into the threads. Not too shallow, you do not want to strip the carb body threads.

WRT the starter it sounds like you need to oil the Bendix drive. I have found on four different RD18s that starter drive always retracts regardless of whether the motor starts. Fleetwin has way more experience and is far more knowledgeable so maybe I am wrong but that is what I have seen. Test it without starting the motor but with plugs in.

BTW if no one has mentioned it, do not start the motor without water to the pump. Running dry will destroy the pump impeller.

July 14, 2020 at 2:17 pm #208589The RD and Big Twin carbs don’t have a seal or gasket on the nozzle. It’s a machined fit.

Here’s a parts manual for you.

July 14, 2020 at 2:24 pm #208590I’ll try that again another way.

July 14, 2020 at 2:27 pm #208593The RD and Big Twin carbs don’t have a seal or gasket on the nozzle. It’s a machined fit.

Here’s a parts manual for you.

Well, that’s strange. I had a parts list when I did my RD restoration last year and saw in the carb diagram there was no seal or gasket on the nozzle. But when I took my carb apart, there was a gasket on the nozzle and it took a new gasket for the carb bowl and upper body to seal up together.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."July 14, 2020 at 2:31 pm #208596The RD and Big Twin carbs don’t have a seal or gasket on the nozzle. It’s a machined fit.

Here’s a parts manual for you.

To be more specific, the RD & Big Twin models with an adjustable high speed needle did not have, nor need a nozzle gasket because any leakage there is compensated for by adjusting the needle. On the other hand, later models with a fixed high speed jet do need the gasket because you can’t compensate for leakage. Summing up, it doesn’t really matter whether or not you put a gasket in the adjustable ones.

July 14, 2020 at 3:37 pm #208598I can see someone has been inside that carb before as there is a spring on the float valve needle. They probably added the seal onto the nozzle at the same time.

I’ve heard it doesn’t much matter about a seal here as these motors drink so much fuel that a bit of leakage in this area would be unnoticeable. Not like on a smaller motor.

July 14, 2020 at 4:19 pm #208600Mumbles – I’m sure you are right about how that seal ended up in my carb. I put in a new seal only because I found one in there. And you are certainly right about how thirsty these motors are – that seal won’t make any difference!

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."July 14, 2020 at 9:00 pm #208624The RD and Big Twin carbs don’t have a seal or gasket on the nozzle. It’s a machined fit.

Here’s a parts manual for you.

To be more specific, the RD & Big Twin models with an adjustable high speed needle did not have, nor need a nozzle gasket because any leakage there is compensated for by adjusting the needle. On the other hand, later models with a fixed high speed jet do need the gasket because you can’t compensate for leakage. Summing up, it doesn’t really matter whether or not you put a gasket in the adjustable ones.

OK, but with the tight fit between the bowl nozzle tube and carb body, kinda seems like you couldn’t fit the conventional nozzle gasket in there on the adjustable needle carbs…

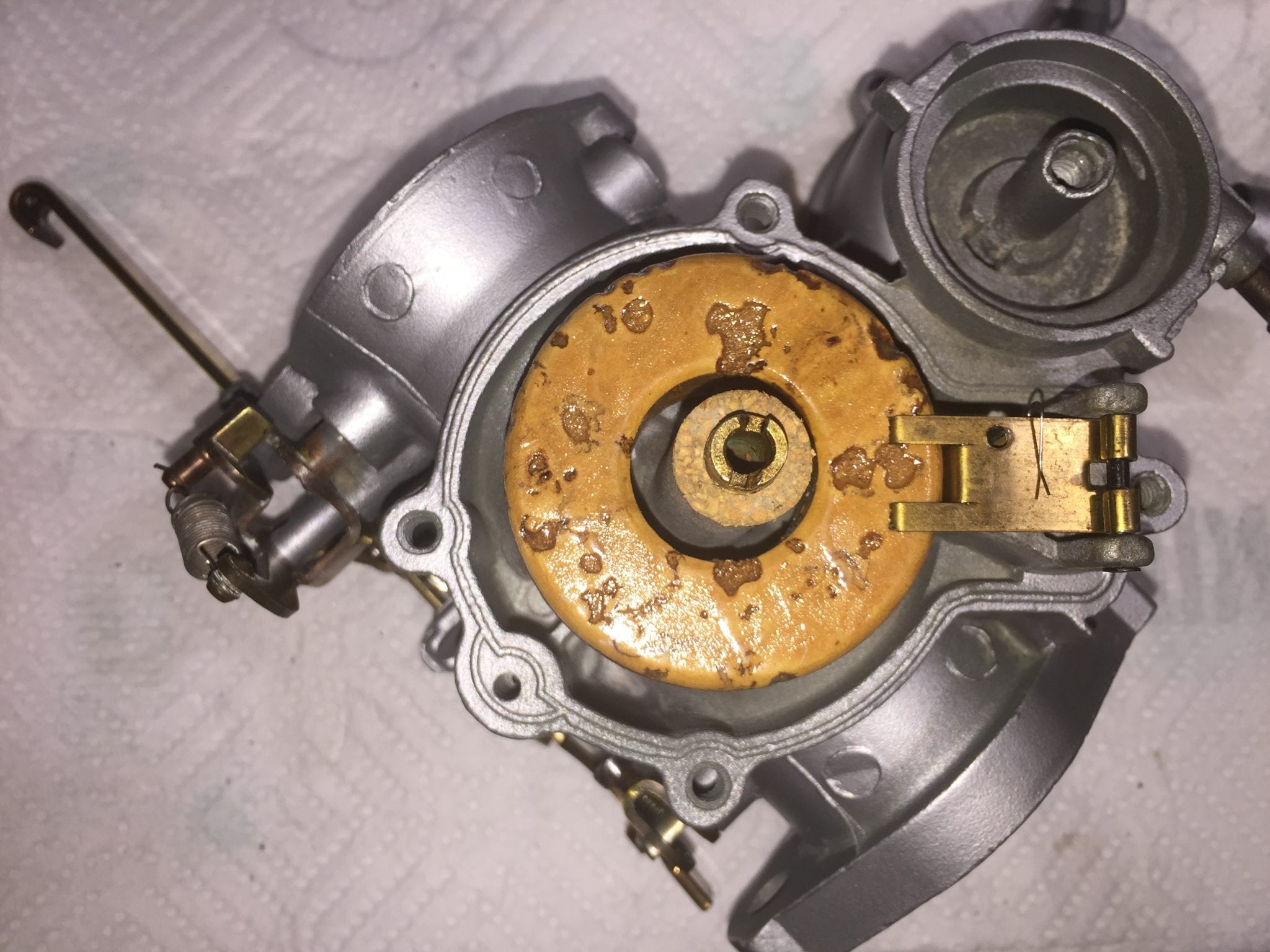

July 14, 2020 at 9:20 pm #208627The carb rebuild kit I got had a thin cork gasket included which is what I used on the nozzle. It was much thinner than the typical nozzle gasket. Now I know why. Here’s a pic of mine. I didn’t have any trouble reassembling the bowl and carb body with this gasket in place.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings." -

AuthorPosts

- You must be logged in to reply to this topic.