Home › Forum › Ask A Member › ’57 Evinrude 7.5 fleetwin fuel mix

- This topic has 33 replies, 15 voices, and was last updated 5 years, 5 months ago by

oldemtr.

oldemtr.

-

AuthorPosts

-

February 7, 2020 at 8:14 am #194178

Hi – My first post here, as a guest.

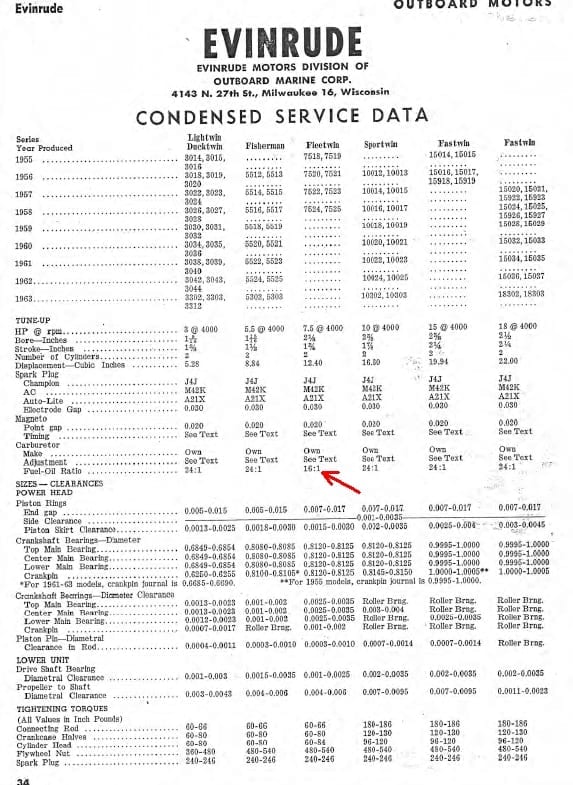

I’m presently working on the motor in the subject line – Going through the water pump, carburetor rebuild, and ignition tune up that’s usually / always needed to try to bring an old motor like this back into service. Also doing a fuel pump conversion, as it didn’t come with a tank. I think the motor is basically OK, but it’s been parked a very long timeMy question is about this particular motor, that I hadn’t realized when I bought it – Every small hp OMC motor of that era is listed in the factory literature as needing a 24:1 fuel mix, EXCEPT the 7.5, which is supposed to use 16:1.

This is not intended to be a general opinion type question about fuel mix, but about this specific engine, that OMC specifically calls for using the richer mix – Why ?Was there a design flaw in this one, that they tried to help with the richer mix ?

I do see, that instead of a top crankcase seal, the motor uses an oil slinger – Is that why? Anyone know ?

ThanksFebruary 7, 2020 at 10:07 am #194182At that time, the 3, 5.5, and 7.5 HP OMC motors all were recommended to use 16:1 mix. The 10 HP and up were recommended to use 24:1 mix.

The smaller motors were plain bearing. The larger motors had needle bearings on the crank.

Improvise-Adapt-Overcome

February 7, 2020 at 10:58 am #194187February 7, 2020 at 11:30 am #194193February 7, 2020 at 11:43 am #194196On my 53 Evinrude (15-1 mix) inside the cowl it stated to mix 1 qt of oil to 5 gallons of fuel. I carried a 5 GI can & exchanged & filled the remote tank. Always had the same mix & never carried a leaky half full oil bottle. Made it easy + had a filter on the GI can for clean fuel. Used a pair of nylons.

Never filled in the boat too. Fire scares me.-

This reply was modified 5 years, 5 months ago by

jeff-register.

February 7, 2020 at 2:14 pm #194207I generally refrain from getting into these fuel mix arguments, and continue to do so. However, if you look hard enough, you can prove anything you want to. For instance the ORIGINAL instructions were for 1 quart of oil to a 4 gallon tank of gas for the 5.5 and 7.5–that’s 16:1

I also have a 1960 Evinrude factory chart right in front of me with REVISED mixes of 24:1 for 3hp, 5.5hp, while 7.5 remained at 16:1.

If you really want to get in a fight I also have a 1973 factory chart right in front of me that states 24:1 for 3hp, 5.5hp and 7.5hp —AND is says you can use 50:1 in those motors ONLY if Evinrude/Johnson oil is used. Adding to the argument is the fact that E/J oil from that time is not the same oil as E/J oil of today.

Let the fight go on, and it will.

February 7, 2020 at 2:24 pm #194209No fight or argument here – I do understand and have read the many, many posts here on fuel mixes, in general, and I’m not looking for a recommendation on that.

I only wanted to know if anyone knew WHY the factory specified that particular motor for 16:1, when the others in that same list called for 24:1.

What was different about the 7.5.?February 7, 2020 at 2:25 pm #194210I always heard … read that modern oils are more efficient than the “old SAE30” grade oil mixed at…16/1 so I always mixed 1 liter of TCW-3 to 25 L of fuel on CD and AD’s

ho well….

Joining AOMCI has priviledges 🙂

February 7, 2020 at 3:10 pm #194218Just speculation, but the 7 1/2 was the highest hp motor that had plain bearings so I wonder if they were concerned about bearing load(?)

-

This reply was modified 5 years, 5 months ago by

Steve Martin.

February 7, 2020 at 3:55 pm #194220Plain bearing motors need QUANTITY of oil to maintain clearances without burning up from metal to metal contact. Remember, we are talking about 1950’s era manufacturing and mass production. It was hard to maintain a few thousandths tolerance in mass production back then, whereas nowadays a ten thousandth is possible with CNC machinery. People who say modern oils are better forget that those oils were made for modern motors, not 1950’s motors. Better, yes, but only in the ratio the manufacturer recommends. Run a good oil at 16:1 and your motor should be happy for another 60+ years.

If you have too many, AND not enough, you're a collector.

-

This reply was modified 5 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.